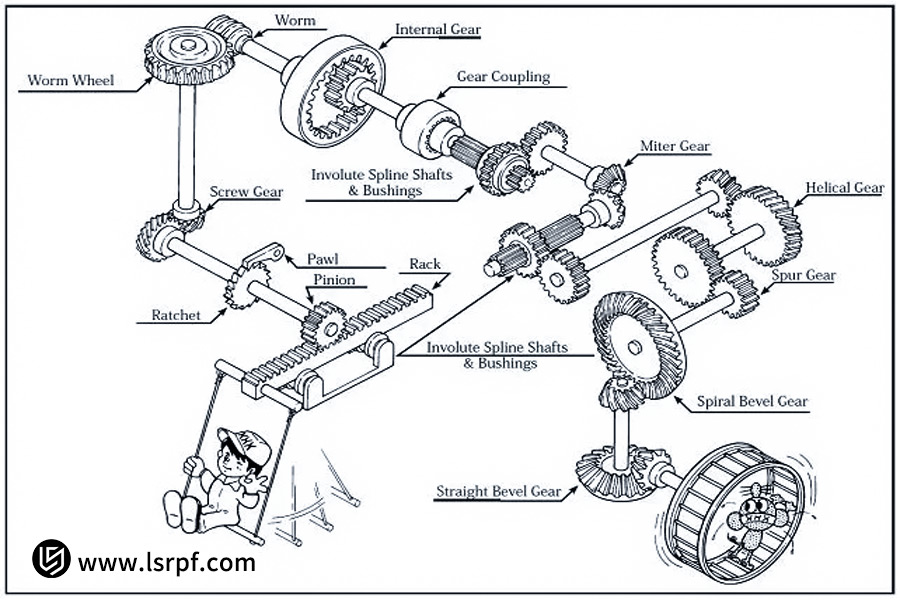

At the heart of the mechanical world, gears are the fragile rhythms that convey power and movement. Choosing a gear type is more than new one for old part; it is a thoughtful choice that affects the performance, life, and noise performance of the overall system. A wrong choice can lead to inefficiency, excessive wear and tear, and even system catastrophe.

Spur gears, helical gears, bevel gears, worm gears, all have specific performance features and uses. A clear understanding of the differences among them is necessary for selecting the right one for your project to transition from drawing board to successful execution.

When precision transmission expertise is needed in the industry, you can contact LS Precision. Not only do we provide complete series of excellent gear products, but we also fully employ our wealth of technical resources to provide professional selection consulting and personalized solutions, so each project is well provided with the most powerful and reliable "heart" to ensure precise and perfect power transmission. In order to save your valuable time, below is a brief summary of the key conclusions.

Quick Reference: Choose Your Tap At A Glance

| Gear Type | Chief Features | Advantages | Disadvantages | Typical Applications |

| Spur gears | They are parallel shaft tooth shape and straight tooth line. | Low cost of manufacture, easy to design, high efficiency (~98%), no axial loading. | But noisy, for parallel shafts only, and susceptible to incorrect installation. | For low-speed, low-load drives: clocks, toys, conveyors, printers. |

| Helical gears | Use teeth at an angle (helix angle) to the shaft. | They have smooth action, lower noise, high load, and will be applicable for non-parallel or parallel shafts. | They create axial thrust, have relatively lower efficiency (~97%), and are more expensive to manufacture. | Usage in high-speed, heavy-load applications: car transmissions, heavy machinery, and elevators. |

| Bevel gears | Have tooth surface that is tapered and are used to transmit motion from an intersecting shaft to another. | They transmit power change of direction (usually 90°). | They are hard to design and produce and generate large axial and radial forces. | Use best in situations where transmission direction change is required: machine tools, marine propeller, and differentials for cars. |

| Worm gears | Consist of a worm and worm wheel with skewed axes (typically 90°). | Smoothness, single-stage high ratio, self-locking, and lower shock loads are offered. | Low efficiency (~50%-90%, depending upon the lead angle), high temperature, and expensive manufacturing. | High ratio of reduction and self-locking uses such as elevators, conveyors, rotary tables, and valve control. |

Choosing the proper gear is a careful process of compromise in performance, efficiency, and cost:

- Spur gears are economical and easy in low-complexity transmissions;

- Helical gears are stable and cost-effective, the commercial workhorse;

- Bevel gears excel in reversing power rotation;

- Worm gears provide high ratios of reduction and safety of self-locking.

No matter what your project demands—high loads, high speeds, space limitations, or quiet requirements—LS Precision may be your one-stop source of assistance from experienced selection consulting to quality gear manufacturing to help your design come perfectly to life.

Why Trust This Guide? Practical Experience From LS Experts

This is learned through the tens of thousands of high-precision transmissions that LS Precision has conducted throughout its existence. We are not just a manufacturer of gears; we are your solutions partner. With proficiency in providing critical components for high-end markets such as automotive, industrial automation, and aerospace, LS Precision gains an intimate knowledge of gear performance demands in different work conditions and utilizes that knowledge in every aspect.

LS Precision Manufacturing advice is not theoretical. For instance, we previously helped a robot designer overcome high-speed helical gear noise and heat generation problems. With material optimization and precision shaping, they had prolonged their product life by 300%. This vetted, tried-and-true know-how which LS Precision provides is founded on state-of-the-art theory combined with more than 300 real-world applications.

Why Is Choosing The Right Gear Type Crucial For Your Project?

In mechanical system gear design, the choice of gear type is not a technical one but rather one that breaks or makes the project. A small, insubstantial error in gear choice can set in motion a chain reaction of chain reactions:

1. The significance of proper gear choice:

An extreme loss of transmission efficiency results in wastage of energy, resulting in non-uniform vibration and noise, significantly decreased equipment life, and even total failure of the complete transmission system. The cause of such troubles is usually the inability of the engineer in selecting the most suitable type of gear depending upon true application speed, torque, spatial relation, and operating conditions.

2. LS Precision has a guide on gear material selection:

This guide is prepared to be your go-to choice reference, freeing you from these errors. More reliable even, LS Precision not only provides you with professional choice suggestions but also tailors best-performance equipment solutions to provide a competitive advantage for your project from day one.

With the technical expertise and experience of expertise at its disposal, LS Precision is committed to providing holistic solutions for every project, from the selection to manufacture, through the application of its seasoned technical experience.

What Are The Most Common Gear Types? What Are Their Respective Advantages And Disadvantages?

In mechanical transmission, few basic types of gears are the center point of every application. Understanding their strengths and weaknesses individually where they can be used is the start of making the correct technical decision. Each type of gear has its strengths and its weaknesses; the trick is finding the appropriate one for your requirements. Let us explore the four basic types of gears:

Spur Gears

- Advantages: Minimum production cost, lowest, uncomplicated design, highest transmission efficiency (as high as 98%), and absence of axial force during power transmission between parallel shafts.

- Disadvantages: Increased vibration and noise in running, increased meshing shock, used for parallel shaft transmission alone, and minimum flexibility towards any defects in installation.

Helical Gears

- Advantages: Easy meshing, significantly less vibration and noise compared to spur gears, and more load-carrying capacity since the teeth engage progressively.

- Disadvantages: The taper tooth profile produces thrust forces, which have to be taken care of by appropriate bearings. More complicated and costly to fabricate, efficiency of transmission is marginally lower than the spur gear (around 97%) and there is some sliding friction involved.

Bevel Gears

- Advantages: Employed primarily for the transmission of power and motion systems between intersecting axes (frequently 90 degrees) and for the reversal of the direction of transmission.

- Disadvantages: More complex design, construction, installation, and alignment, generates heavy axial and radial loads, and requires high support from bearings and housing.

Worm Gears

- Advantages: High single-stage ratio of transmission, quiet and smooth working, self-locking if the worm lead angle is small (the worm will drive the worm wheel but not vice versa), and compactness.

- Disadvantages: Low efficiency of transmission (typically between 50% and 90% depending on the lead angle), high generation of heat by sliding friction, expensive to manufacture, and need for proper lubrication and cooling.

| Gear Type | Core Advantages | Major Disadvantages | Typical Applications |

| Spur Gears | Low cost, efficient, simple structure. | Noisy, impact-stressing, only parallel shafting. | Low-speed, light-load applications: printers, conveyors, toys. |

| Helical Gears | Smooth running, low noise, high loading. | Generates axial forces, slightly higher cost. | High-speed, heavy-load applications: automobile transmissions, industrial reduction gears. |

| Bevel Gears | Two-way transmission of rotation (intersecting axes). | Hard to make, complex loads. | Differentials, marine propulsion, machine tools. |

| Worm Gears | Low noise, compact, self-locking, and high transmission ratio. | Inefficient, generates a lot of heat, costly. | Elevators, conveyor belts, rotary tables. |

Your efficiency, quiet operation, load-carrying capacity, steering, or self-locking needs will immediately determine the optimal solution.

LS Precision is a professional R&D engineer as well as maker of various gears. Not only can we professionally advise selection for you, but also custom-manufacture high-performance precision gear products for you to ensure foolproof design.

How Do I Choose A Gear For My Specific Application?

There are just so many gears available. How do you choose the right one for your project? The trick is to translate your specific application requirements into simple technical specifications. The following decision tree will help you quickly decide on the right gear for your application and achieve efficient and reliable performance of your transmission system.To pick your ideal gear, simply follow the steps above:

Step 1: Define the axis layout

- Parallel axes: Use spur or helical gears.

- Intersecting axes (usually 90°): Use bevel gears.

- Staggered axes (usually 90°): Use worm gears, a very common application.

Step 2: Determine performance priorities

- Seeking maximum efficiency and cost, with noise not a high concern? → Spur gears are the lowest in cost.

- Must work smoothly, make little noise, and handle high loads, with some absorption of axial forces? → Helical gears are your answer.

- Must reverse the direction of power transmission primarily? → Bevel gears are your default option.

- Must have a very high reduction ratio, be self-locking, or very quiet operation? → Worm gear sets have special advantages.

Step 3: Consider space and operating conditions

- Is space severely constrained? Helical gear and worm gear offer compact designs.

- Harsh environments or limited lubrication? Some special materials or coatings may be required, which means custom gear processing.

When off-the-shelf products don't exactly fit your particular application requirements, that is where special expertise comes in. You may need to engage the services of a gear processing expert to perform custom gear processing. For example, specific tooth profile modifications can optimize noise performance, or unique materials and heat treatments may be applied to facilitate high-stress operating conditions.

Gearing selection is an orderly process of decision-making that begins with shaft layout and weighs performance trade-offs delicately. There is no one size to fit all conditions.

As a seasoned gear processing firm, LS Precision does not simply provide commodity items but excels at solving your most difficult application issues through precise custom gear processing services.

Besides Type, What Other Key Specifications Should Be Considered When Customizing Gears?

Determining the appropriate gear type is only the beginning of accurate transmission. For gears to function in their best capacity within real conditions, a series of deeper technical specifications are necessary. These factors as a whole determine a gear's durability, resilience, noise quotient, and thus cost, and play a pivotal role in getting an exact fit. When producing custom equipment, specify the following main specifications clearly to your supplier:

1.Module and number of teeth:

Influence directly the size of the gear and load-carrying capacity of each tooth. Big module means big teeth and big load-carrying capacity but fewer teeth with the same center distance.

2. Pressure angle:

The pressure angle is typically 20° and affects the gear tooth profile, contact strength, and evenness. Special usage may require a non-standard pressure angle.

3. Material selection:

Different applications require different materials:

- Carbon steel and alloy steel: These are the most commonly used materials, being strong and having excellent wear resistance. Their performance can be enhanced further by heat treatment.

- Stainless steel: Suitable for applications where corrosion resistance is desired, i.e., in medical, food, and chemical industries.

- Brass/bronze: Used extensively in worm gears, they achieve better friction reduction and anti-seizing properties.

- Engineering plastics (e.g., POM and nylon): Suitable for light load, low noise, self-lubrication, or corrosion protection applications.

4. Heat treatment:

For steel gears, there are different heat treatment processes such as carburizing, quenching, and nitriding, which can significantly increase tooth surface wear resistance, fatigue life, and surface hardness, making them extremely critical to endure shock loads and heavy loads.

5. Precision grade:

The precision grade, according to AGMA or ISO specifications, defines the gear's meshing error, noise, and vibration levels. Smoother operation but a higher cost implies greater precision, so it should be chosen in terms of actual performance demands.

LS Precision, possessing strong technical expertise and high-end manufacturing capabilities, is in the position to provide you with comprehensive professional consultation and manufacturing service, from material recommendation and heat treatment service to precision control, so that every gear you get perfectly matches your application.

Every machined gear component is a result of a combination of some technical parameters. Success in custom gear production relies on precise control of each detail.

How Did LS Precision Overcome A Complex Custom Gear Machining Challenge?

In precision manufacturing, the true value does not lie in the production of a part but in providing the ultimate solution to the customer's unique and difficult application problems. The ensuing case study, involving an operational relationship with a medical customer, graphically demonstrates how LS Precision turns this philosophy into a reality.

1. The client's challenge:

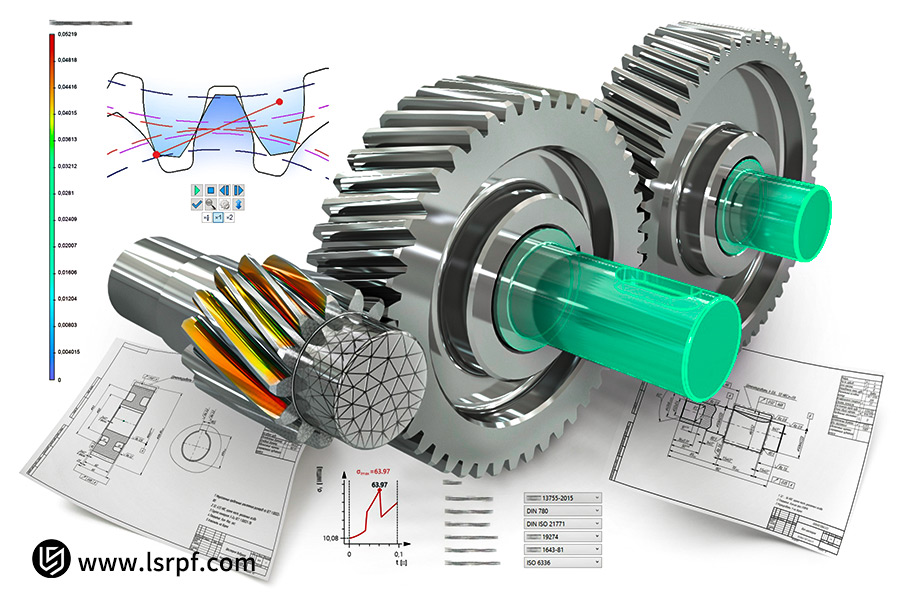

LS Precision's client, a sophisticated automated surgical equipment designer and manufacturer, required a critical core gear component for its precision transmission system: a small helical gear. The requirements of this section were extremely stringent:

- It must have extremely high dimensional accuracy in order to ensure absolute transmission reliability;

- It must be essentially silent in order to avoid disturbing the surgical environment;

- As it would be installed inside a directly sterile field, the material for the gear must possess superior corrosion resistance and a very cleanable surface.

- The project needed to handle small batch sizes and tight delivery cycles.

2. LS Precision's customized solution:

Faced with this complex specification, LS's engineering team approached it not as a standard order but as a joint development project. We were deeply involved and provided a comprehensive custom gear machining solution:

- Material Science Application: We applied and utilized martensitic stainless steel that meets medical requirements. It possesses high strength, excellent corrosion resistance, and biocompatibility.

- Ultra-precision Machining: Through utilizing a five-axis precision gear grinder from Germany, we achieved a very high accuracy of tooth profile to within ±0.005mm for smooth and precise transmission.

- Special Post-Processing: To meet the requirements of "absolute quietness" and "sterility," we subjected each gear to a special mirror polishing and deburring procedure. This not only reduced operating noise dramatically but also created a smooth, seamless surface that is bacteria-resistant and easy to disinfect.

3. Core value of results and creation:

The gear parts that LS Precision supplied completely met all of the client's stringent requirements and performance standards, allowing their next-generation healthcare device to successfully pass testing and enter the market in a matter of weeks. Not only did we meet the client's immediate needs but also earned us a long-term trust and partnership through our unmatched dependability.

This case demonstrates LS Precision is so much more than a stand-alone parts supplier. We are your trusted technical partner, committed to bringing your most demanding design concepts into reality as high-performance, working products by tapping into our deep process knowledge and leading-edge manufacturing capabilities.

How Easy Is It To Get A Gear Machining Quote And Custom Service Online?

You might think getting a professional quote and custom gear machining service would take back-and-forth emails and extended waiting times. But at LS Precision, we make it easy and more streamlined than ever before with our straightforward and clear-cut online gear machining service process. You can easily get your project started by simply following these four simple steps:

1. Order online:

Visit the Service Center of LS Precision's official website and place your customized gear machining order in one click by simply uploading your gear design (e.g., format DWG/DXF/STEP) or inputting important parameters (such as type, module, tooth number, material, accuracy grade, and estimated quantity).

2. Swift review and recommendation by our expert team:

Your request will be handed over directly to our expert technical team. Our engineers will review your design within the shortest possible time window (usually 1-2 business days) and provide professional technical optimization recommendations (such as material choice or process choice) to ensure the best and reliable solution.

3. Receive a clear quote and delivery schedule:

You will receive a detailed, competitive quotation for gear processing based on the proposal. This quote explicitly mentions the structure of costs, production order, and exact delivery schedule with no extra charge.

4. Quick production and order confirmation:

From the time you approve the quote and proposal, your order will be immediately on production. Through the use of our latest digital management system, we manage production effectively and update the production schedule regularly to provide top-quality gear products within timely delivery.

It has never been easier to relish professional online gear processing services. LS Precision promises to erase the hindrances of complex processes so that you relish superior technical support, open gear processing prices, and assured production guarantees without leaving the confines of your door.

What Are The Main Factors Affecting Gear Processing Prices?

Understanding the cost factors that comprise gear processing will make you plan and budget your projects more effectively. LS Precision adheres to the strict policy of open pricing. The ultimate cost of a gear is due to a blend of technical specifications. Keeping it honest with you in terms of these cost factors is the first step towards building long-term trust. The following are five basic cost factors that comprise gear processing:

1. Gearing type and process complexity:

This is the simplest factor. Generally speaking, simple spur gears are cheapest to produce. Helical and bevel gears are more costly due to their higher complexity of processing. Worm gear sets, due to their unique tooth form and the matching and adjustments required, are usually the most expensive type of gear.

2. Material cost:

The choice of material directly affects the raw material cost. Material costs vary extensively from normal carbon steel to high-expense alloy steel, stainless steel, bronze, or certain engineering plastics. Your application environment (e.g., demands of strength, wear resistance, and corrosion resistance) is the initial consideration in material selection.

3. Precision requirements:

Precision is a significant driver of cost. The more accurate the required level of precision for dimensions such as tooth form, tooth profile, and radial runout (e.g., ISO Grade 5 versus ISO Grade 9), the exponentially greater the processing time, inspection time, and scrap potential, which translates into higher manufacturing costs.

4. Heat treatment and other post-processing:

In order to improve gear hardness, wear resistance, and life, carburizing, quenching, and nitriding heat treatments, together with post-finishing operations such as shot peening and polishing, are typically required. These additional processes increase the cost of gear processing but pay for themselves to ensure performance.

5. Order quantity:

Bulk production effectively minimizes up-front costs such as mold setup, programming and debugging, and tooling adjustment. Therefore, bulk orders tend to have better unit prices.

The final cost of processing gears is a trade-off between technical specifications and quantity to buy. There is no standard price; it is a matter of working out your specific needs.

LS Precision's strenghth lies in our deep experience and efficient production management. We can provide you with the lowest-cost solution through process optimization and batch production, without compromising on your all requirements of gear type, material, and accuracy.

Why Is LS Precision Manufacturing Your Trusted Gear Processing Partner?

When you are choosing a gear supplier, you need more than just a manufacturer; you need a long-term business partner who will hear your voice, solve your problems, and develop together with you. LS Precision Manufacturing, with its overall strength and commitment, is your better half. The advantages of LS Precision are in:

1.Sophisticated facilities and technical assistance:

LS Precision have access to world-class CNC gear machining centers, precision gear grinders, and testing equipment to ensure that every product meets micron-level precision specifications, meeting your custom gear processing requirements from the standard to highly advanced.

2. Senior engineering staff:

LS Precision's staff not only has extensive knowledge in gear theory but also has decades of hands-on experience. They can offer detailed technical advice and process optimization guidance, transforming problems into trusted solutions.

3. Serious quality control system:

LS Precision are ISO 9001 certified and conduct rigorous quality monitoring and inspection, from raw material warehousing to final product shipment, to ensure that every product delivered to you has stable performance and best quality.

4. Flexible production and service model:

Whether you are carrying out prototype development for the R&D phase or bulk orders at mass production, we offer flexible and efficient production support to help you advance your project fast.

5. Customer-centric service:

Your success is our focus and we provide prompt communication, transparent project management, and comprehensive after-sales service, ensuring peace of mind and peace of mind throughout every stage of your association.

Choosing LS Precision Manufacturing is choosing a gear processing partner you can trust regarding technology, quality, and service. We are committed to providing the most reliable guarantee of the success of your project with the most advanced manufacturing capabilities, high quality standards, and customer-centric service, transforming your products into the best in class.

FAQs

1. Can you process non-metallic gears such as POM or nylon?

Yes. We have expertise in machining non-metallic gears and have experience working with many of the engineering plastics, such as POM (polyoxymethylene), nylon (PA), and polycarbonate (PC). Gears made from these materials exhibit very desirable characteristics such as light weight, self-lubricity, corrosion resistance, and quiet running, for which they are especially well suited for application in food and pharmaceutical usage, precision instruments, and where quiet running is essential. We can recommend to you the optimum material for your specific use.

2. Do I need to provide a 3D model of the gear before I can get a quote?

Providing a 3D model (in STEP/IGS format) or detailed 2D drawings is the best way for us to be in a position to quote you a correct price estimate for gear machining and process planning. This enables us to interpret your technical specifications, tolerance levels, and material selection so that any miscommunication may be avoided and we are able to quote our best price. If you have a preliminary concept only, we recommend direct consultation with our engineers to design the solution.

3. Do you accept small-batch or prototype orders?

LS Precision most warmly welcome and whole-heartedly believe in prototyping and small batch orders. We have extremely high requirement of flexibility in product development stage, and our online gear machining process is exactly capable of such orders. You can test your design and obtain good-quality prototypes without investing the initial investment of large quantity. We believe in being your trusted partner from idea to mass production.

4. What is your typical lead time?

Lead time will depend on the level of complexity of the nature of gear, processes needed (e.g., heat treatment), and size of order. For uncomplicated designs, prototype designs typically take 5-15 working days. For large orders, we plan to produce in advance in order to provide you with more forceful lead times without compromising on ensuring you are informed of firm time commitments prior to your taking an order, so that the progress of your project is maintainable.

Summary

The right choice of gear is an essential requirement for proper, stable, and efficient operation of mechanical equipment. The book handles the subject step by step to establish principles and selection criteria for gears, from simple spur and helical gears to complex bevel and worm gears, to provide a clear technical road map.

LS Precision, your company of choice for excellence, not only provides this expertise but can also turn theory into reality. Precision machining, materials science, or custom manufacturing – we are committed to providing you with complete precision gear solutions.

Ready To Learn The Perfect Gear Solution For Your Project?

Don't let gear selection complexity keep you from achieving your goals. LS Precision is your go-to source, with experienced technical assistance, accurate high-quality gears, competitive gear processing rates, efficient and dependable service, and much more.

Act today and send your drawing to get a quick quote by clicking the link below, or contact gear specialists at LS Precision directly to speak with us at no charge. Let us custom design the perfect solution for your application and make your project a success!

Upload your design drawings now and get an instant gear machining quote ( gear machining price), let LS be your strong backing in pursuit of ultimate gear machining precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com