Material selection, a critical ripple-relevant choice, like the initial domino pushed, which sets off a domino effect bearing product performance as much as overall cost, in sheet metal production, ranks high among the most significant factors. The root differences between standard steel and stainless steel go far beyond shape and corrosion resistance; they impact strengthening of the structure, processing, maintenance cycle, and the final product's cycle cost of the end product substantially. The designer's choice not only determines the part's lifetime under harsh conditions but also the bedrock of all subsequent processes of the procedure, from procurements to production, and also the end-user experience, all directly affecting the economic viability and market competitiveness of a job. Thus, this article shall develop an in-depth comprehension of the differences between the two material types, so as to allow you to effectively and accurately accomplish sheet metal design and manufacturing.

Steel vs. Stainless Steel Quick Reference Table

| Comparison Parameters | Steel (Carbon Steel) | Stainless Steel |

| Concentrated Composition | Primarily iron + carbon, simple composition | Primarily iron + chromium (≥10.5%), often with nickel and molybdenum added |

| Resistance to Corrosion | Weak, easily oxidized and rusted, requires surface treatment | Extremely strong, naturally forms a passive film, corrosion-resistant |

| Processing Cost | Low material and processing costs, easy to form and weld | High material and processing costs, rapid tool wear |

The analogy used here finds the inherent differences between the two to be brought about by the alloy material, which directly triggers the next process route and cost profile. The assumption of this article shall be maintained as follows in detail:

- Beginning from the material nature, analyzing its physical and chemical properties;

- Then, laying out derived differences in processes, say, cutting, welding, and surface finish;

- Final business decisions, which will lead you into the most reasonable material selection under the conditions of the application, lifetime specification, and cost spend budget overall. The material listed under this guide book is interconnected, and it forms a systemic material selection method.

Why Trust This Guide? Practical Experience from LS Experts

In LS, our findings aren't theory-driven but are concluded on the basis of real experience of our own design engineering team at the forefront of cutting-edge technologies. An example is the stainless steel solution that we have developed for a high-end medical devices company. The device's primary sensor casing didn't corrode on exposure to high-strength disinfectants even after extended use, and even the risk of contamination by peeling surface coating was unacceptable. Routine industry options of replacement or after-plating material didn't succeed, and expensive product recall followed.

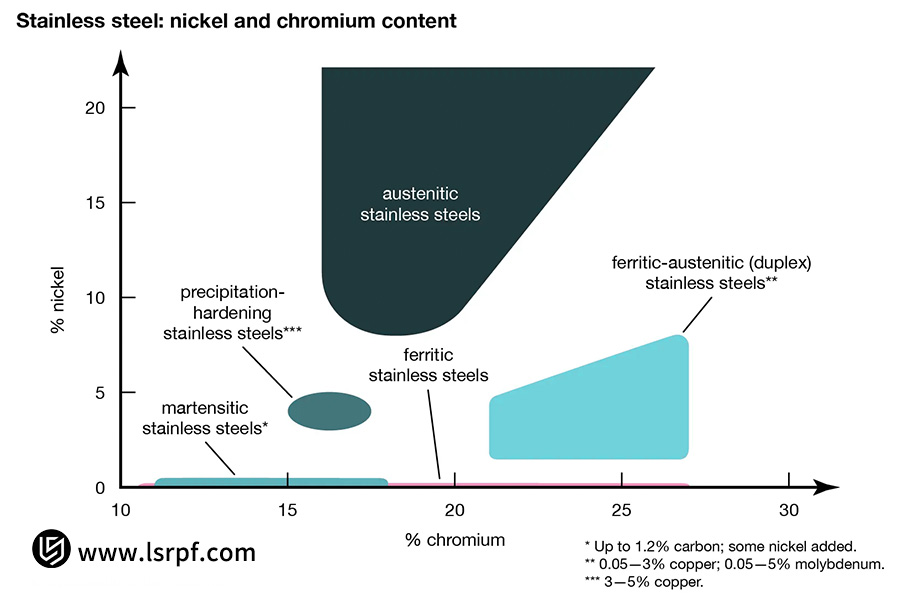

This daunting task prompted LS's technology innovations in material selection and precision manufacturing. We only recommended and utilized ultra-low-carbon austenitic stainless steel, Grade 316L, whose chemical resistance is greatly enhanced by the presence of its molybdenum content. We also made the technical stride from ordinary welding and passivation processes to twice ensure an integrated defense of the passivation film from a possible weak link. The end product not only survived clear extreme acceleration corrosion testing standing tall but also earned market confidence by achieving a zero-failure rate, an industry first and a new standard of safety. LS utilizes its own extensive stainless steel expertise and technology innovations to change customer challenges into its own source of competitiveness.

What Are The Main Differences Between The Chemical Composition Of Steel And Stainless Steel?

The main differences between stainless steel and steel are due to prudent composition designing of the alloy composition, having direct implications on performance and scope of use. Though both are the derivative of iron (Fe), the presence of the other constituents as well as proportionality leads them in opposite directions.

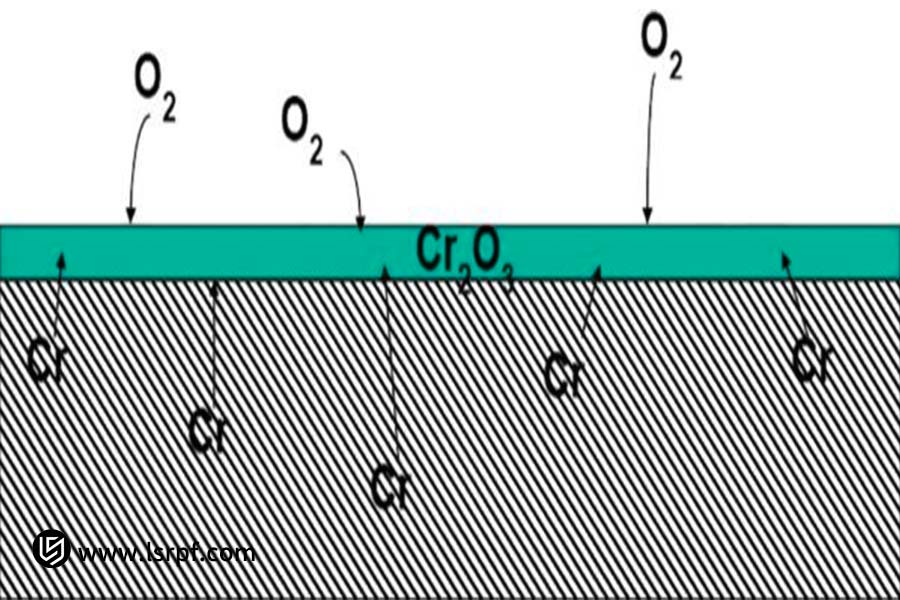

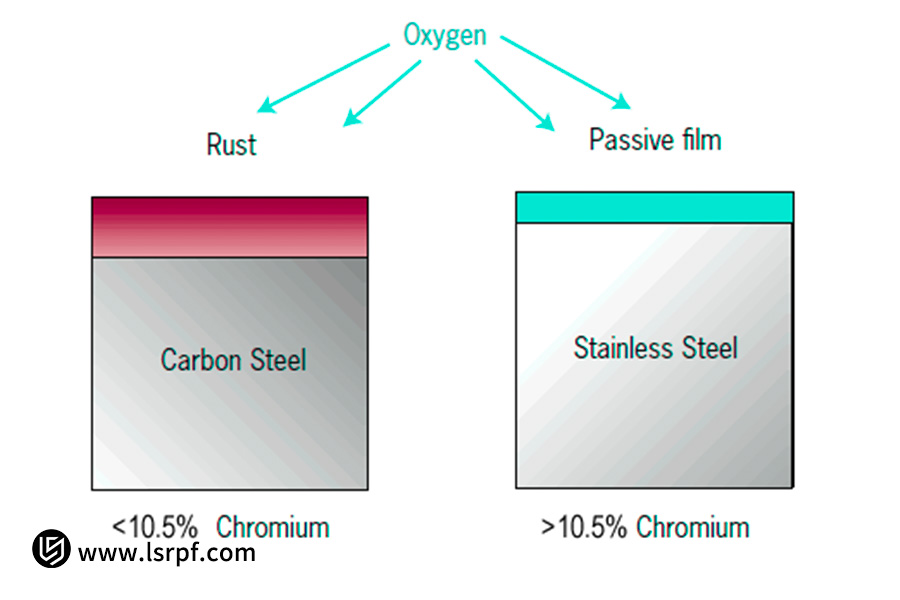

Second and most importantly, the simplest characteristic is the existence or lack of chromium (Cr). Common steel, or carbon steel, predominantly consists of carbon (C). Carbon clings firmly to the molecule of the iron, greatly raising its tenacity and hardness, but by the cost of ductility. Most of all, carbon steel unites and reacts easily in the atmosphere by the moisture and the oxygen, initiating corrosion and rusting. The key to the "stainlessness" of stainless steel is its required minimum of 10.5% chromium material content. Chromium clings firmly to the oxygen, developing an immensely thin, self-healing, chromium-rich oxide protection coat over the steel surface. Such an unrecognizable coat essentially isolates the substrate from the corrosives, thus granting stainless steel great protection from corrosion.

Second, constituents other than chromium split the stainless steel family further into highly specialized categories. For example, the presence of nickel (Ni) enhances ductility, toughness, and weldability, creating the widespread austenitic stainless steels such as the 304. The presence of molybdenum (Mo) will enhance greatly the pitting corrosion resistance to hostile environments such as the chlorides, creating the more corrosion-resistant grade 316.

Carbon steel is an "iron-carbon" binary alloy, famous for its hardness but predisposed to corrosion. Stainless steel, by contrast, is a sophisticated "iron-carbon-chromium" alloy, which adds the key constituent chromium and may also augment this by adding nickel, molybdenum, and the like alloying constituents. Such a small variation in the constitution lies behind the enormous differences of the resultant corrosion resistance, mechanical characteristics, and hence cost between the two.

Why Is Stainless Steel More Corrosion-resistant? What Role Does Chromium Play?

Its excellent corrosion resistance does not result from its incapacity to corrode but from some "superpower"—passivity. The characteristic property is a consequence of its predominant alloying element only: chromium. One may say, therefore, that if chromium were not present, the stainless steel would not gain its "stainless" reputation.

The star material here is chromium. If the percentage of chromium in stainless steel exists or goes higher than the critical value of 10.5%, some kind of miraculous transformation takes place. When atmospheric oxygen exists, the chromium immediately reacts atop its surface and forms an incredibly thin (with a thickness of just a few nanometers) but tremendously compact and stable oxide protective film. Such a thin sheet goes by the "passivation" or "passive" film name.

Such a film has a critical role. As an invisible, powerful shield, such a film completely covers the steel matrix from water, atmosphere, and any corrodent chemicals (e.g., chloride ions and acids), literally halting the ongoing corrosion and oxidation. Better still, this film self renews itself. In the unforeseen circumstances the movie gets partially destroyed by machining, abrasion, or surface damage, if there is a pre-existing suficient supply of oxygen within the atmosphere, the chromium re-reacts and renews the passivation film, re-taking its protective role.

To improve this corrosion resistance even more, and in the tougher conditions such as marine or chemical exposures, additional alloying items are incorporated into the chromium. For instance, the inclusion of molybdenum adds greatly to the resistance of the passive film to chloride pitting, and this is the main reason why 316 stainless steel has better corrosion resistance than the 304.

In a word, the corrosion resistance of stainless steel lies not in its inertness but in its active, dynamic protective film. The key driving force behind the manufacture and preservation of this "eternal armor" is chromium. By forming an aggressive, self-replenishing passive film, chromium converts ordinary steel into an ideal material impervious to the abuses of environment and of time.

What Are The Main Differences In Processes Used In Steel And Stainless Steel In Sheet Metal Manufacturing?

In steel industries or stainless steel industries, the concept of cost of the material is put into consideration, but it also goes into processing chains of different kinds. Basic differences in their nature compel the manufacturer into committed strategies, or else they can soon turn into scrap of the piece, tool destruction, and even uncontrollable cost. The basic differences lie in four major steps, i.e., cutting, forming, welding, and post-processing.

The following table compares the salient differences in important process steps at a glance:

| Process Step | Steel (Carbon Steel) | Stainless Steel |

| Cutting | Simple using plasma and laser cutting; low tool wear and highly flexible parameter setting. | An oxide-free cut surface can be obtained by the need for high-pressure nitrogen used in laser cutting; high tool wear requires lower speeds. |

| Forming (Bending) | Suitable ductility and springback, which can be controlled; normal dies can be employed with a negligible wear rate. | Higher power and high hardness yield more springback; high-torsion machines are necessary, and purpose-made dies are advisable to prevent the creation of indentations. |

| Welding | Quality of weld is good, and processing is easy; no special heat treatment after welding is needed. | Heat input has to be precisely controlled to avoid carbide precipitation (intergranular corrosion); subsequent annealing and passivation normally have to be performed to restore corrosion resistance. |

| Surface Treatment | Need to be protected from corrosion through powder coating, painting, or electroplating. | Coating is seldom necessary; finish and corrosion protection can be improved through mechanical (polishing, brushing), or electrochemical (passivating) treatment. |

- First, the increased strength and work-hardening of stainless steel put a higher demand on the cleanliness of the gases, pressure, and cutting speed of the laser machine, significantly increasing the tool wear rate.

- Second, if the stainless steel has higher springback and higher yield points, larger-tonnage press brake and higher-accurately calculated bend angles are needed. The surface of the mold also has to be very smooth so no surface damage happens.

- Most distinctively different is post-processing and welding. Welding of stainless steel can be plagued with poor heat control, which can destroy the passive surface film and cause carbide precipitation in the heat-affected zone, reducing its corrosion resistance considerably. For this reason, the necessity to undergo the post-welding solution annealing and pickling passivation surface treatment to restore the corrosion resistance to a perfect condition dominates—a step fully not used in processing carbon steel.

Generally, forming of stainless steel entails mostly "protection" and "precision": shielding its natural corrosion resistance from being lost during forming, and carefully controlling the heat input and mechanical stresses during each stage of processing to counteract its high strength and propensity to work harden.

While the production of carbon steel is less adaptable, its fundamental processes are committed to "forming" and "corrosion protection," which ultimately gain protective characteristics through the protective coat of the surface. These are critical differences in deriving successful, high-grade sheet metal production.

Why Are Stainless Steel Sheet Metal Parts So Costly? How Do They Compute The Price?

The overall cost of stainless steel sheet metal parts is considerably more than regular steel. This is never solely a function of any single factor, but of a cost chain in general of raw materials, processing, manufacturing, and after-manufacturing. This excess reasonably can be broken down into three broad categories: material cost, process cost, and other costs. The following table contrasts briefly the difference of key cost components:

| Cost Factors | Steel (Carbon Steel) | Stainless Steel |

| Material Cost | Low | High (Contains expensive alloying elements such as chromium and nickel) |

| Processing Cost | Low (Fast processing speed, low tool wear) | High (Slow processing speed, rapid tool wear, high energy consumption) |

| Post-processing Costs | Required but expensive (anti-corrosion treatments such as spraying and electroplating) | Usually low or not required (Only upgrade treatments such as passivation and polishing are required) |

Cost Analysis:

- To begin with, the cost of the material is the most direct difference. The steel holds a high percentage of high-value alloying components like chromium, nickel, and molybdenum, and the raw material cost of acquisition is usually several times more in comparison to normal carbon steel.

- Second, the higher cost of manufacturing and processing stainless steel due to its higher strength, hardness, and work-hardening properties requires lower cutting and forming velocity and hence directly results in increased use of machine tools and power. Apart from this, it results in severe wear of cutting tools and molds and therefore the rate and amount of replacement are much higher compared to carbon steel processing.

- In addition, there are some incremental cost hidden from sight. For instance, stainless steel requires dedicated manufacturing lines and higher workshop ambient control in order to preclude carbon steel pollution, which incurs additional indirect management cost. Though the cost of the stainless steel post-treatments (e.g., passivation) compared to chrome plating or painting of carbon steel might be less, dedicated treatments of the like of the post-welding solution treatment might cost additional.

The premium price of stainless steel sheet metal lies in the expensive price of the raw material, greater loss during processing, and advanced processes of preserving its inherent corrosion protection. The premium price pays, in fact, not only the material but the entire manufacturing technology and the quality control which ensure the performance of the final product, i.e., corrosion resistance and longevity.

How LS Overcame The Problem Of Corrosion In Stainless Steel Casings For Medical Devices

Customer challenge

For medical device manufacturing, most prestigious corporations (e.g., Xinhua Medical, Kangji Medical, and Weigao Medical) are already familiar with the application of 420 martensitic stainless steel in products (e.g., surgical devices) based on its exceptional sharpness and hardness. Nonetheless, this kind of stainless steel casing is rapidly prone to corrosion when used in thin structures like joints and tooth grooves under prolonged contact by body secretions, high-frequency disinfectants (chlorine compounds), and strict sterilization conditions.

Not only does this reduce the lifespan of devices and increase costs of maintenance and replacement, but, more importantly, the corrosion by-products can create a source of cross-infection risk, which poses an urgent threat to patient protection and serious medical compliance risks. The conventional approach usually involves the application of external coatings like electroplating or spray coatings. These physical coatings are sure to be porous and easily removable, and the protection provided by these coatings are restricted by repeat disinfection and mechanical abrasion, which can create new sources of infectious agents.

Limitations of traditional solutions

To get rid of these issues, traditional processes are nothing else than surface treatment by nitric acid-/citric acid-based passivation solutions application. The nitric acid-based passivation itself though potentially able to build up a passive surface, is by itself highly corrosive and an irritant and therefore generates a health hazard and high environment pressures. The handling may easily ruin the workpieces.

LS's innovative solution

LS Company, after detailed research of the characteristics of 420 stainless steel and the bottlenecks of traditional processes, has launched its innovative passivation treatment solution. The heart of its solution lies in a proprietary passivation solution uniquely designed exclusively for 40-series martensitic stainless steels like SUS410, SUS420, and SUS430. The passivation solution has been granted environment and safety certificates like those from SGS and the FDA, so it's OK to use in the field of medicine.

LS pays great attention to precise pretreatment and strict parameter control in its procedure:

- The first step of the workpiece is to undergo a rigorous alkaline and acid cleaning so the surface will be oil-free, clean, and free of impurities.

- Then the workpiece shall be dipped into a passivation solution of 70°C for 30 minutes, and then the stabilization treatment of 65°C shall be conducted for 15 minutes.

- The procedure helps form a stable, denser, and thicker chromium oxide passivation membrane on the surface of martensitic stainless steel. The whole procedure does not alter the workpiece shape or hue, is simple to control, and may be conducted either in the tank of plastic or stainless steel material.

Can Stainless Steel Be Substituted By Surface Treatment Of Ordinary Steel?

It's economics of cost, which leads us to the question: Is high-cost stainless steel replaceable by surface finish (e.g., by electroplating or by painting) on low-cost plain steel? The response: Whilst this might be achievable within certain short-term, gentle services, it's usually a high-risk, high-maintenance endeavor from a lifecycle performance standpoint, and it's no real equivalent substitute.

That surface finish (such as powder coat, chrome plate, electrogalvanize, or paint) does form a physical barrier on the plain steel surface, in effect keeping corrosive media isolated for a period of time, replicating the appearance of the corrosion-resistant finish of the stainless steel. The technique has low initial cost and is an inexpensive alternative to interior structural components such as nozzles, hoppers, tanks, and the like, where no specialized appearance consideration is needed or where the parts are to be exercised within a dry and stable environment.

This is a temporary and passive form of protection. The moment the surface itself gets compromised by scratch, impact, or abrasion, the underneath plain steel substrate becomes exposed and quickly converted into a corrosion initiating site. The corrosion may proceed underneath the surface of the coat, leading to blistering and flaking, and boost the system failure in general. In addition, coatings are usually not chemical or heat-resistant, and the cost of recoating and maintenance may exponentially increase with time.

Conversely, the corrosion protection of stainless steel is built-in and active. Its self-passivating surface film of chromium, even if scratched, can self-heal if there is air present in the medium. The built-in nature of stainless steel contributes to its high performance and low maintenance cost, best suited to critical items of high hygienic requirements, long-term services, or damp, corrosive conditions.

- So, the decision between surface-treated plain steel and stainless steel is, in fact, one of initial cost versus ultimate value.

- Where products are relatively short-lived, encounter mild service, and are subject to periodic maintenance, surface treatment can be an adequate cost-saving method.

- In conditions of long life reliability, safety, and no maintenance requirements (e.g., medical equipment, food handling equipment, exterior structures, or seawater installations), the inherent qualities of stainless steel are impossible to substitute by surface treatment and its life-cycle cost is less.

Three Clever Strategies to Get the Correct Sheet Metal Fabrication Cost Online

For sheet metal construction industry, quick and precise quoting is the key to the decision-making process of the project and cost control. The conventional quote requests by phone calls or by emails are normally slow, time-consuming, and transparent. Now we can quickly and precisely receive the quotes by the following three smarts ways, which also make cost certainty and the process optimality possible, with the help of digital technology.

Instant Quote Tools

First, the easiest method is to use the online instant quote feature via the manufacturer's official website. Increasingly, high-end sheet metal Parts Service Providers, like LS, incorporate the advanced quote system into their official website platforms. One only needs to upload the CAD drawing (in STEP or IGES format) and enter key parameters online, such as the material, surface finish, and quantity. Instantaneously, within minutes, the system, through an in-built algorithm, comes up with the clear and transparent pre-cost estimate, and thus massively quickens the quotation procedure.

Professional Price Comparison Platforms

Secondly, by using expert manufacturing B2B platforms, or "cloud factories," to input requirements is also an effective approach. These platforms like LS draw together a massive supply chain. Once the aggregated technical requirements are entered by the clients, the site uses automatic matching or fast bidding to receive tens of competitive quotations from different accredited providers within a short space of time. In addition to price comparison, this also utilizes market mechanisms to receive competitive prices.

Professional Online Consulting

Lastly, while performing high-value work of complicated nature or involving multiple processes of specialization, the ideal is to start implementing a professional online video consultation. With screen sharing, your company can converse online with engineers for the purpose of sharing the design specifications, tolerance values, and checking requirements, and so forth. You can get design optimization (DFM) suggestions from the wealth of experience of the in-house tech team and, finally, get the right pricing. The chances of late-stage modification decrease, and the best cost and quality ratio is attained.

In short, these sophisticated methods, from real-time tools and comparative price websites to professional consulting, form an evolutionary digital system of investigation. They transform the price discovery procedure from a "black box" into a "clear" one, in an effort to allow buyers to quickly and rationally decide whether or not to produce under the conditions of abundant data and information.

Custom Sheet Metal Fabrication Material Selection Decision Tree: 5 Steps to Identify the Optimal Material

Material selection is an integral parameter determining product performance, cost, and cycle of delivery in sheet metal manufacturing. Given the choice of materials, a logical decision-making procedure becomes imperative. The following five-step decision tree shall guide your choice of the most suitable material solution in a scientific approach.

Step 1: Assess the Use Environment

First, determine the end-use of the product. For humid areas of exposure, corrosive environments, or areas of high hygienic requirements (e.g., medical equipment or out-of-door equipment), stainless steel (e.g., 304/316) will be employed. For indoor use under dry, medium conditions, carbon steel with surface finish will be appropriate.

Step 2: Define Mechanical Performance Requirements

Choose the material based on the functional requirements of the part. When high impact or high loading is required, high-strength steel or hard stainless steel should be employed. When high bend or stretch forming is required, a ductile material, like mild steel or 304 stainless steel, should be employed.

Step 3: Consider the Budget

Compare the alternatives from the previous steps to your project budget. If your budget is high and long-term payback is a concern, the best alternative is stainless steel. If your budget is low and conditions of use are good, the cheapest alternative is carbon steel, surface treated.

Step 4: Think about Process Compatibility

Ensure material and processing technology compatibility. The stainless steel material requires setting some processing parameter and equipment, and the price is therefore higher; the carbon steel material is easy to process and cheap. More importantly, the possibility of future processes like welding and surface treatment should also be considered.

Step 5: Determine Appearance Needs

Finally, select your option depending on the desired product appearance. When the natural color of the metal must be preserved and additionally decorative finishes are needed, then stainless steel must be utilized since it provides several surface finishes (e.g., brush or mirrored finish). Carbon steel powder coated can be utilized for minor appearance requirements or where the product is going to be completely covered.

Through this five-step rational decision-making approach, you can prevent the typical material selection blunders and achieve the best performance-cost-processing ratio, and consequently the best product value.

FAQs

1. Is the stainless steel on the parts entirely rust-proof?

No. The reason corrosion resistance of the stainless steel parts exists is the action of chromium and the percentage of chromium used in the parts. If the chrome content of 10.5% and above and the ambient chloride of below 100 ppm are used, they are absolutely resistant to corrosion of rust. Below or above the grade, the corrosion resistance of the stainless steel parts becomes lower, thus the formulation of the development of the formation of rust.

2. Can ordinary steel be treated to achieve the same effect as stainless steel?

You can treat ordinary steel to equal the performance of stainless steel. Ordinary steel may be hot-dipped galvanized to afford 5-8-year protection from corrosion, but it does not gain the long-term protection from corrosion of stainless steel. For long-term protection from corrosion, the best option is stainless steel.

3. How can you visually distinguish between the two materials?

To identify the material by the nature of the cross-section, the cross-section may be silver-gray, and the material may be stainless steel (304 grade), which is not magnetically attracted. The cross-section may be gray-black, and the material may be standard steel, which is magnetically attracted. In the event the complex material cannot be identified, please contact LS, and our technology experts will be your consultants.

4. Which is more cost-effective for small-volume customization?

For small-volume customizing, the best material to use is stainless steel. For quantities below 50, the best material to use in order to reduce the cost of after-processing is stainless steel. LS also offers online sheet metal services, and the minimum orders are one piece. Contact us to upload your drawings, and our experienced team will design, optimize, and offer the best schedule of production.

Summary

The primary difference between steel and stainless steel lies along the lines of compositional, corrosion protection mechanisms, and the cost differential. Common steel, being an alloy of carbon and iron, suffices in the majority of instances owing to its high strength and low cost. The very natural drawback, however, lies in the fact of susceptibility to corrosion, and surface-coating becomes an option in protection instances. The secret of stainless steel lies in the addition of enough chromium, which strongly generates a dense, self-restoring passive skin, thus building in inherent, long-term corrosion protection. The resulting inherent property leads to its prominence as a material in severe conditions and long-term use. Material selection constitutes an initial cost-long-term value trade-off, in short.

If you are encountering the issue of corrosion protection in the selection of material, LS is prepared with professional help for you. We, of course, also provide the free corrosion protection diagnosis service, whereby our professional team will study your requirement and recommend the most cost-effective material and process solution. Besides, we also implement the flexible manufacturing policy of "minimum order of 1 piece." Whether your requirement is with R&D proofing or mass production, the same quality manufacturing service shall be your support. Call LS now and ensure your project success in material selection from the very beginning!

Upload your design drawings now and get an instant sheet metal fabrication quote (investment casting price), let LS be your strong backing in pursuit of ultimate investment casting precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com