In the orchestra of modern industrial precision, the craft of nylon injection molding, through its superior and irreplaceable performance, has transformed into the unobtrusive enabling force behind a broad spectrum of revolutionary industries. Nylon not merely bridges the distance between high-order structural design and high-volume, low-cost manufacturing, but also serves as an invisible protector of the basic needs of industry today, such as lightweighting, toughness, and functional integration. Strongly intertwined with the past of present day manufacturing, it drives the wave of continuous innovation and advancement in the sector. Here in this article, we will categorically outline the material properties of nylon plastic and its major advantages to assist you in material selection.

Quick Reference: Choose Your Tap at a Glance

| Dimension | Key Points |

| Material Properties |

|

| Cost Benefits |

|

| Main Technical Indicators |

|

Why Trust This Guide? Practical Experience from LS Experts

In the application of rapid prototyping plastics materials, generally there is a gap between theory and practical mass production results. LS engineering has been engaged in twenty years of plastic modification engineering, and their conclusions are refined by over 10,000 hours of test processes under harsh environments and over 200 successful mass production cases. When "nylon chemical resistance" is considered, it is specified to the certain nylon LS of new energy vehicle battery packs with electrolyte corrosion resistance (crack resistance after soaking in 120°C electrolyte for six months). If you glance at "40% cost reduction," that is the real-world case study of LS in helping one of the world's top home appliance makers switch metal gearboxes to self-lubricating nylon one-piece molded parts (saving 23 million yuan in production cost in merely one year alone). Such field-proven wisdom makes this guide from mere theoretical knowledge become a practical success plan.

What Is Nylon Plastic?

Nylon is synthetic polymer, or polyamide (PA). It's a thermoplastic, meaning that it can be melted with heat and molded into different shapes, then cooled and remolded with little significant degradation. Nylon is hard, wear-resistant, and resilient.

Nylon is manufactured through the process of polymerization to create long chains of repetitive units from small monomers. To make nylon, monomers are combined with each other in a process that is normally carried out in a reaction vessel. Monomers used in nylon production are normally petrochemical-derived substances such as coal, natural gas, or petroleum.

Polymerization is normally carried out by heating the monomers with a catalyst that causes the chemical linkages between the monomers to break and release free radicals. The free radicals interreact, forming new chemical bonds and producing polymer chains. The polymer chains are chilled and solidified to form nylon.

Nylon may be produced in numerous types of forms like fibers, films, and molds. The characteristics of nylon differ depending on the form that it is produced in as well as the method of production process. For example, nylon fibers are strong and elastic and thus ideally appropriate for use in clothing and other types of textiles. Nylon films are transparent and thus ideally appropriate for use in packaging.

Why Do Engineers Utilize Nylon For Essential Components?

The most prominent characteristics of nylon components are their superior mechanical strength and toughness. The tensile strength of nylon is even better than that of metal, and its compressive strength is the same as that of metal. This allows nylon components to withstand high loads and impact with very good dimensional stability.

The inherent advantages of Nylon make it an engineer's prime choice in components that are critical. It possesses many superior characteristics, like high strength and toughness, wear resistance, and low friction coefficient, that are ideal for sliding and frictional components' wear resistance. It also offers chemical and heat resistance, low water absorption, easy processability, and compatibility with other materials.

Nylon also boasts better wear resistance and self-lubrication. This means that nylon parts generate less friction when moved and also remain in service longer. Nylon also has better chemical and temperature resistance, with stable performance under many aggressive environments.

In What Industries Is Nylon Plastic Essential?

These enhanced properties have generated an enormous demand for nylon parts in numerous industries. Nylon parts find wide applications in the automotive industry for demanding applications such as gears, bearings, and carburetors. These parts not only withstand high temperature and high pressure but also contribute significantly towards the reduction of vehicle weight and improvement in fuel efficiency.

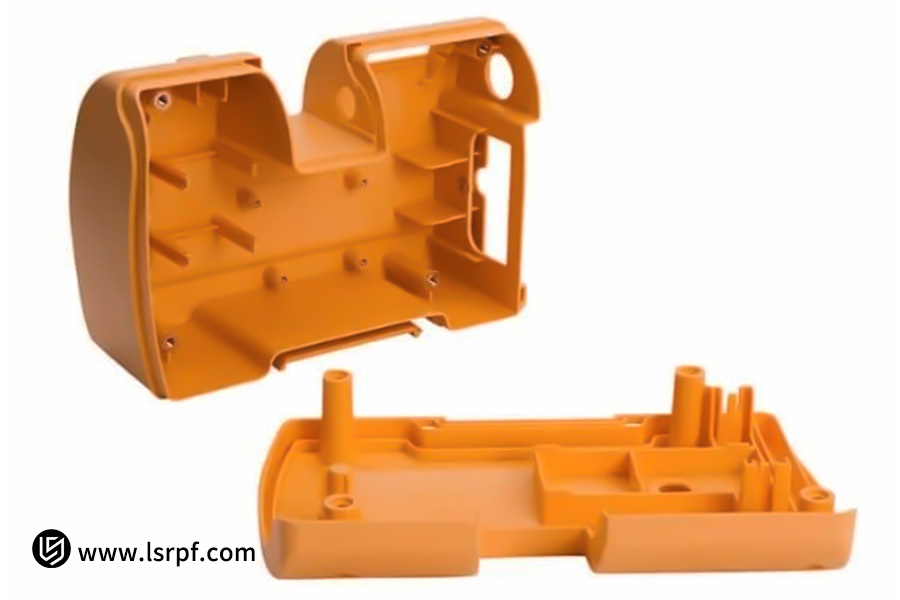

In electrical and electronics engineering, nylon's excellent electrical insulation properties make it an ideal material for housings, connectors, and other applications.

Nylon's lightness also makes it a popular material in 3D printing for rapid prototyping or bespoke parts.

For gamma-ray sterilization of medical devices, specialty nylons are employed to replace metal to avoid instrument noise. Nylon-based medical devices also offer very good biocompatibility and sterilization resistance.

In dynamic transmission systems of intelligent equipment, self-lubricating nylon gears provide maintenance-free lifetime performance.

The shared requirements of these applications—being capable of meeting simultaneously the requirements of stability in extreme conditions, of complexity of function, and of affordability—are the driving rationale that makes nylon invincible.

How Does Injection Molding Unleash The Material Potential Of Nylon?

Directional domestication of molecular chains

The injection molding machine is really a master of molecular arrangement for nylon. As the high-temperature molten nylon is injected into the mold cavity under high pressure, the shear force of the flow is like an invisible hand to stretch and align the originally disordered and curled molecular chains in the direction of the force. This directional structure is permanently fixed after cooling and solidification to produce a reinforced framework of "invisible steel rods," which enables the material to burst with strength and rigidity far beyond normal in a specified direction.

Precise control of the art of crystallization

The key to nylon's performance lies in the integrity of the crystallization - disordered crystallization makes it brittle and perfect crystallization gives toughness. Injection molding process imparts crystallization through triple control:

Temperature Gaming: When the melt is cooled down to the crystallization temperature window, precise pressure maintenance slows down molecular chain retraction, allowing ample time for crystal growth;

Pressure Shaping: The ongoing pressure causes the molecular chains to stack closely together to create a dense crystalline network;

Gradient Quenching: LS's patented differentiated cooling technology rapidly vitrifies the component's surface to attain a hard shell, while the core crystallizes slowly to ensure toughness, developing an optimum structure with both rigidity and pliability.

Intelligent transformation of defects

Nylon's "weaknesses" in conventional cognition have been a springboard for performance leaps in the injection molding process:

Hygroscopicity becomes a plasticizer: the water content of the pellets is controlled before injection molding, and water molecules penetrate the gap between molecular chains to improve fluidity. After demolding, water evaporation promotes crystallization and densification;

Shrinkage creates prestress: through the reverse compensation design of the mold, a beneficial compressive stress layer is created at the critical areas in the process of shrinking (e.g., natural pre-stress strengthening at the root of the gear teeth);

Reconstruction of glass fiber distribution: in common processes, the random distribution of glass fibers tends to become weaknesses of stress, whereas the rheological guidance technology of LS makes the glass fibers actively evade the main flow channel and directionally strengthen them in the load-carrying area.

The injection molding machine converses intimately with the nylon molecular chain in the stern language of temperature, pressure, and time, and ultimately transforms the silent polymer into a breathing functional carrier. As the mold opens, you see not only a plastic part, but a living entity whose material genes have been completely awakened.

LS Nylon Injection Molding Case Study: A Breakthrough in High-Temperature-Resistant Automotive Components

In the severe, high-temperature, and highly corrosive atmosphere of the automobile engine compartment, traditional metal components are faced with bottlenecks of heavy weight, high cost, and complex molding, while general engineering plastics are unable to meet the requirements of long-term heat resistance. LS has made a breakthrough in high-performance nylon modification technology. With glass fiber-reinforced nylon (e.g., PA66+GF30%) as the core base material, the company introduces heat-resistant agents with proprietary features and employs a dynamic crystallization control technology.

This enhances the material's heat deformation temperature to above 220°C, with a long-term stable working temperature of 160-180°C, alongside corroding resistance to oil, fuel, and salt spray. 35 For example, in a turbocharger duct developed for an automobile manufacturer, LS nylon components not only replaced stainless steel but also withstood 3,000 hours of endurance testing at 230°C exhaust gas temperatures, with 50% better thermal aging performance than standard nylon.

The potential of the material is fully utilized by the meticulous control of the injection molding process. LS adopts multi-stage gradient cooling and high-pressure holding technology to form a directional crystallization skeleton in the part. The surface layer vitrifies rapidly to obtain a wear-resistant hard shell, and the core crystallizes slowly to retain impact resistance. This solves the problem of nylon deformation and brittleness at high temperatures. A prime example is a one-piece plastic intake manifold developed for a specific automobile: this component must perform consistently under constant high heat of 200°C and momentary spikes of 250°C. LS optimized the glass fiber direction through mold flow analysis, developing a dense crystal structure in the seal area. The result is a 50% weight saving compared to aluminum parts, and it withstands corrosion from sulfuric acid in biodiesel without any additional anti-corrosion coating.

LS's breakthrough is not only in material substitution, but also in the use of the art of molecular chain orchestration (directional crystallization through injection molding) and the wisdom of defect transformation (such as utilizing shrinkage to introduce prestress). This has moved nylon from "usable" to "highly reliable," rewriting the performance limits and cost models of high-temperature components.

What Are The Key Steps In The Core Process Of Custom Injection Molding?

1.Design and Modeling

A 3D model of the mold must be designed based on the product's requirements prior to the commencement of production. The execution of this step must utilize CAD (Computer-Aided Design) software, such as SolidWorks or UG, to execute the mold's structural design. The mold design must consider the shape, size, and tolerances of the plastic part, as well as the specifications of the injection molding machine and the requirements of the injection molding process. After completing the design, the analysis of the strength, stiffness, and hot runner of the mold is performed to ensure the rationality of the mold design.

2. Material Selection and Preparation

Machining

Machining is a basic operation of mold production. The operation includes a number of processes such as milling, turning, grinding, and EDM. Both milling and turning are used primarily for rough machining of the mold, while grinding is used to improve the surface finish and precision of the mold. EDM is a specialized machining process used primarily for complex shapes and difficult-to-machine molds using traditional methods.

3. Surface Treatment and Heat Treatment

Heat treatment is a significant process in mold manufacturing, which raises the hardness and wear resistance of the mold. Quenching and tempering are the usual heat treatments. Surface treatment is used primarily for wear resistance, corrosion resistance, and beautification of the mold. Polishing, sandblasting, and electroplating are the typical surface treatments.

4. Commissioning and Assembly

Following machining of the mold parts, assembly is required. In the assembly, precision and fit of each part must be ensured for the overall performance of the mold. Commissioning and mold trials are required following assembly for ensuring the performance of the mold and product quality, and any problems encountered must be rectified immediately.

What Are The Direct Influences On The Cost Of Nylon Injection Molded Parts?

1. Material: Not just the price of the raw material, but also the "waste rate" is vital

Imagine squashing a pat of butter into a mold shape—the amount of material used and the amount of trimming has a direct influence on the price.

In nylon injection molding:

- Runner Waste: With traditional molds, 30% of the raw material hardens on the sprue and is wasted (like the cream left in a cake piping bag). The newest hot runner technology can reduce this waste to less than 2%.

- Design Intelligence: Multifunctional components integrated together (e.g., automotive bracket with heat sink and clips integrated) require 25% less material compared to individually produced parts. Similar to the way one folds a 3D shape from one piece of paper, it's less wasteful than cutting and gluing together.

- Recycling Risk: Medical products prohibit recycled material. However, adding 15% recycled material to industrial parts reduces the price by 8%, by managing loss in performance (just like old flour mixed with steamed buns can detract from their chewiness).

2. Precision Requirements: The Cost of Each Decimal Place

Tolerance requirements are like the magnification power of a magnifying glass—the higher the accuracy, the exponentially higher the cost.

3. Molds

The cost of nylon injection molded parts is influenced by initial investment.

4. Functional Complexity: Visible and Hidden Costs

Structural Integration: A single integrated nylon shell with snap-on buckles and heat dissipation patterns lowers the labor cost by 80% as opposed to separate manufacturing and assembly (it is less expensive to purchase already assembled furniture than to build from parts).

Surface Treatment: Mold etching (a one-time cost) is 35% cheaper than subsequent spray painting, with no risk of environmental fines.

Special Requirements: Functional additives like antistatic agents and flame retardants can increase raw material costs by 20%-50%, the same as the price difference between a low-end and high-end smartphone.

How to Choose a Reliable Injection Molding Service Provider?

Look beneath the technical surface to identify true capabilities.

The secret to selecting an injection molding supplier is to obtain a materials expert, not a parts manufacturer. True technical capability lies in being capable of practicing extreme operating conditions—have suppliers take you into environmental simulation chambers from -40°C to 220°C and observe for yourself how parts respond to thermal shock cycles.

The essence of a quality system lies in data.

A reliable supplier's assurance of quality must be founded upon traceable evidence. Request that they provide a "digital twin" of the manufacturing process: from real-time pressure profiles as melt flows into the mold cavity (like waveforms on a heart monitor) to 3D laser point clouds of the critical dimensions of each component (graphically comparing tolerance zones).

Symbiotic relationships: the courage to share risks and the wisdom of open collaboration.

The lead suppliers' potential is to translate customer needs into technical assumptions. Observe their early questioning: If they enthusiastically request "annual volume and delivery time," this too is a sign of legacy OEM thinking. To verify a supplier's commitment to symbiotic collaboration, the following three points can be verified: whether there is monitoring of production lines in real time (customers can verify injection molding machine parameters in real time via VPN), whether alternative recipes can be provided in the event of raw material fluctuation (e.g., LS used bio-based nylon to hedge against rising oil prices), and whether the contract clearly specifies first-year failure compensation terms (an elevator guide rail supplier refused this request and subsequently was exposed to astronomical claims for failure to satisfy vibration fatigue requirements). When a supplier is open to transferring its technological know-how, it creates a common fate that can weather industry storms.

Evolutionary Power: The Hidden Dimension That Decides Future Success

Technology shelf life in the injection molding industry is less than two years. Assessing a supplier's evolutionary potential entails looking at the nature of its R&D investment.

How Does LS Reduce Customers' Total Costs Through Technology Development?

Material Revolution: Reconstructing Cost DNA from Molecular Design

LS's technical team is well aware that the essence of nylon lies in the complex dance of molecular chains. While customers struggle with the high density of metal parts and machining wastage, LS uses a bio-based nylon formulation (castor oil derivative monomers) to reduce the raw material carbon footprint by 56% while lowering the density to 1.04g/cm³. This means that a new energy vehicle equipped with 20 LS parts can reduce the weight of 14kg and increase the range by 5%.

Process Awakening: Quantum-Level Control to Maximize Energy Efficiency

Injection molding machine energy consumption used to be a fixed cost, but LS's electromagnetic induction dynamic heating system has made people rethink this.

Integrated design uses geometric intelligence to eliminate supply chain fat. LS engineers view each component as a microcosm of system cost. The motor bracket developed for an automotive client is a model example.

Life Alchemy: Transforming Time into Customer Profit

Superficially, the unit price of nylon gears is 65% that of metal, but LS's plasma molecular surgery technology adds value in the time factor. Standard nylon gears deteriorate after 30,000 hours of use.

LS treats gears: High-energy particle beams carve a micro-nanoscale "diamond lattice" onto the surface, while grafting fluorosilicone molecular chains at the same time, achieving a wear life of more than 120,000 hours. This enables the customer to stretch maintenance intervals from three months to three years, avoiding production downtime losses.

What Are The Future Trends In Nylon Injection Molding Technology?

Molecular-level precision medicine (designing molecular weight curves based on component stress distribution), Green Awakening Revolution (manufacturing carbon-free nylon using bio-based monomers), and digital twin manufacturing (virtual injection molding machines that predict three months in advance the defects in mass production). LS has developed an AI-based polymer molecular design platform. In the future, customers will simply input operating parameters, and the system will generate the optimal material-process-mold combination automatically, moving the nylon industry from an "experience-driven" to an "algorithm-driven" era.

FAQs

1. What are the cost advantages of nylon parts over metal parts?

The cost advantage of nylon over metal parts lies in the fact that its density is only 1/7 that of metal with reduced material consumption. Injection molding is 5-8 times more efficient than machining and does not require any secondary corrosion protection, with the end result being a 30%-50% reduced overall cost.

2. What is the minimum order quantity for custom nylon injection molded parts?

LS enables flexible production, utilizing modular mold technology for miniature batch orders (minimum 500 pieces), reducing trial production time and cost to market.

3. How do we ensure the dimensional stability of nylon injection molded parts?

We pre-dry the material (≤0.1% moisture content), tightly control mold temperature to ±1°C, and utilize CMM full-scale inspection to ensure tolerances to ISO 2768-m standards.

4. What are the uses of glass fiber-reinforced nylon?

It is suitable for components subject to high loads and high temperatures (such as engine peripherals). It boasts a 2x increase in tensile strength and a heat deflection temperature of up to 220°C.

Summary

The evolution of nylon injection molding is, at its core, an epic resonating story of material potential and human ingenuity. LS's groundbreaking practices reveal that when molecular chains dance in an electromagnetic field, when molds become sculptors of crystallization art, and when bio-based monomers are reborn in the injection molding machine—nylon transforms from a basic polymer into the ultimate deconstructor of system costs. This isn't just a numbers game, reducing component prices by 34%. It's a global victory, slashing energy consumption through the ripple effect of lightweighting, eliminating downtime losses through the alchemy of lifespan, and mitigating regulatory risks with the shield of green technology.

For companies that choose LS technology, a 17.2% reduction in total supply chain costs over three years is now the norm. While traditional manufacturing struggles with cost constraints, LS is rewriting the rules of the trade with materials science—the essence of cost reduction lies in ensuring that every gram of nylon carries a value density exceeding that of steel.

In the face of these higher challenges, LS's plastic injection molding is your indispensable ultimate "tool". It represents industrial-grade precision, unparalleled repeatability and efficient productivity, allowing your design ideas to be perfectly, consistently and efficiently realized. Choosing LS is to inject industrial-grade precision power into your extraordinary craftsmanship.

Upload your design drawings now and get an instant injection molding quote (injection molding price), let LS be your strong backing in pursuit of ultimate priting precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com