Gear machining services can prove troublesome for the engineer and the purchasing professional in terms of noise generation, early failures, the shorter-than-expected lifespan of the gears, and the overall efficiency of the system. This happens due to the lack of efficiency in the supplier in terms of tooth profile accuracy, heat treatment methods, and the overall quality control process.

The underlying reason is that many processors lack in-depth knowledge about gear meshing, do not have professional measuring equipment, and have poor end-to-end quality control processes. They only have "similar shapes" rather than providing "true performance." This article exposes how LS Manufacturing bridges this gap through expert design assistance, superior processes, full inspection capabilities, and rigorous quality management.

Gear Machining Services Overview

| Aspect | Key Content |

| Pain Points | Common problems: excessive noise, early breakdown, low efficiency, short life-span. Underlying cause: inadequacies in precision, heat treatment, and quality coming from the suppliers. |

| Core Problem | Reason: There’s a lack of in-depth knowledge in gear theoretical concepts, advanced measurement tools, and complete quality processes of gears, causing form over function. |

| Key Solutions | 1. Expert Design Support; 2. Advanced Precision Machining; 3. Overall Inspection (for example, Gear Measuring Center); 4. Strict Quality Management System |

| Anticipated Outcome | To achieve not only qualified, but rather high-performance and long-life custom gear solutions. |

To get superior gear machining services, there is a need to go beyond simple fabrication. It requires a partner who is knowledgeable and competent in gear dynamics, as well as a partner who is capable and thorough in quality from design through to delivery. It is with this approach that gears can ensure optimal performance, reliability, and durability, which is essential for the success of the application.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Concerning the gear machining services industry, we remain practitioners and not theorists. We have been involved in the manufacturing of important gear components for the automotive sector, whose performance requires the use of precise gear components, and we strictly adhere to a strict quality standard set by our ISO9001 quality management system.

Our dedication and commitment extend to the challenging demands required in the automation industry as well. Tailored gear sets from our firm put the efficiency of our production line as our top concern. Our dedication to delivering to the challenging demands required by ISO 13485 for Medical Devices has actually provided us with the same level of concern for all our projects in terms of high quality control with respect to gear sets that last.

Starting right from the design recommendations to the final machining stages, 'turnkey solutions' can be offered to the clients. The recommendations and guidance given in the publication are 'frontline experiences,' which have been developed through the company’s success of supplying more than 50,000 precision parts. Every problem whatsoever, whether it is related to gear tooth profiling for improved damping or choosing the best means of heat treatment, has added to our expertise in know-how. The knowledge and expertise that you are about to acquire will assure you that these will be useful know-how.

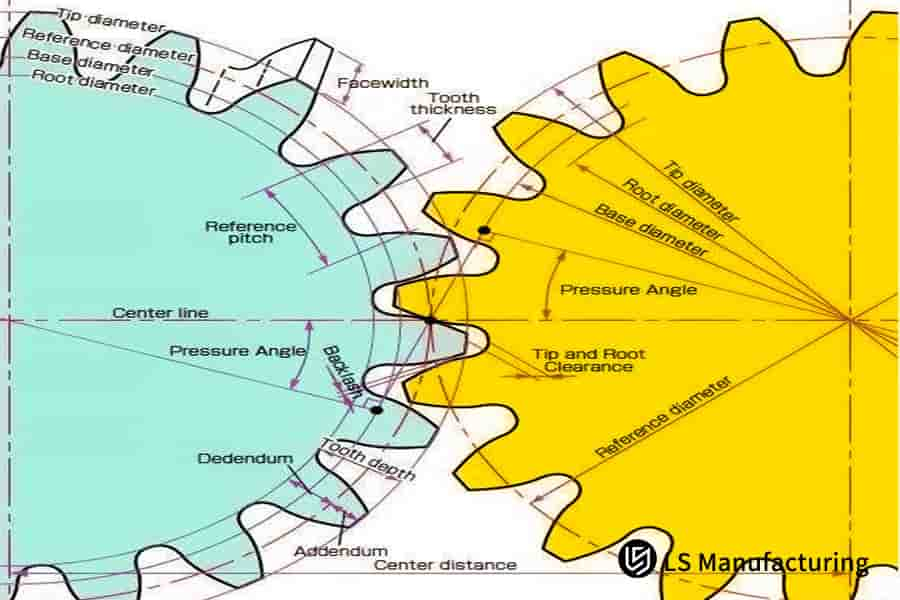

Figure 1: Gear transmission schematic and technical data by LS Manufacturing

What Are The Core Elements That A Professional Gear Machining Service Must Possess?

When sourcing a reliable supplier, understanding the essential pillars of high-quality gear machining is critical. It's the difference between a part that merely fits and one that performs reliably for years. This guide outlines the key elements that define professional gear machining services, ensuring you have a clear benchmark for evaluation, as exemplified by LS Manufacturing's professional capabilities.

- Expert Design and Simulation Analysis Capability: The key to success is in the gear design. The start of a real professional gear machining partnership is in the expert simulation analysis for loading distribution, points of contact, and noise distribution before ever cutting the first tooth on the gear. For the kind of design capabilities offered by LS Manufacturing, the only true measure for the best is in their optimized designs for strength and integrity over accuracy.

- Appropriate Manufacturing Processes and Expertise: In gear production, a non-one-size-fits-all approach is needed. A good supplier would be the one who has knowledge of a variety of techniques, such as hobbing/shaping for the production of the first teeth and grinding for the production of teeth on the hardened gear. Selecting the optimal process for the material and application is a core element of delivering high-quality gear machining that meets precise tolerance and surface finish requirements.

- Specialized Heat Treatment and Surface Finishing Knowledge: The mechanical properties of a gear are defined by its metallurgy. The skills required include experience in controlled carburizing processes, induction hardening, and other specialty coatings. The fact that the professional capabilities in this area of LS Manufacturing makes their core toughness and surface hardness optimal, which affects their wear life and fatigue life directly.

- Comprehensive Precision Inspection: Verification goes hand in hand with creation. high-end machines like gear metering centers are the necessity in the process of inspection of tooth profiles, leads, & pitches. Its precision marks the difference between a novice gear machinist and a professional gear machining service, as it ascertains that everything is as per the design made by the software.

- Robust, Systematized Quality Control: Consistency is for systems, not luck. Such Quality Management System Certifications (for example, ISO 9001) give us traceability and continuous improvement for all and any processes. This systemic approach is what transforms isolated quality checks into a reliable promise of high-quality gear machining for every order, every time.

In conclusion, professional gear machining services can be considered as the perfect culmination of design foresight, versatility, material sciences, and manufacturing discipline, and working with an organization such as LS Manufacturing, who has the best features of all these, can be the quickest method to ensure that overall reliability in the final product improves through reliable gear machined by them.

Which Machining Processes Are Suitable For Common Gear Types (Such As Helical Gears And Bevel Gears)?

It is always crucial to understand the connection that exists between the different gear types and machining processes. It may happen that using the type of gear you prefer may not give you the optimal method of machining, and this is based on the type and design of the gear you intend to create. LS Manufacturing is able to provide custom gear machining solutions through the selection of the optimal method of machining depending on the type of gear you intend to create.

| Gear Type | Important Features and Applications | Important Machining Operations (Approximate Accuracy) |

| Spur Gear | Full teeth; parallel shafts. Used primarily for low-speed applications like gear boxes and machines. | hobbing, shaping, milling |

| Helical Gear | Angled teeth; smoothers and quieter operation than spur gears. Transmission in automobiles and power transmission in industry. | Hobbing, shaping, and grinding are some processes used in helical and bevel gear machining. |

| Bevel Gear | Cone shaped, used for changing the turning motion in intersecting shafts. Gears like these, and cone clutches, are the most important ones that exist in differentials or power tools. | Helical and bevel gear machining generally requires special milling/grinding operations by bevel gear generators. |

| Worm Gear | Rotary or screw gear. Element: A wheel. Function: Employed for high percentage reduction and for locking. Find greatest application in lifts and conveyors. | Worm grinding of Worm and/or Hobbing of Wheel. Not commonly supplied as a pair. |

In short, for the design to move from being designed to a functional gear, there has to be standardization in terms of geometry and process design. Every gear has to use its own process path, whether it will have the quiet power transmission of the helical gear or the right-angle drive of the bevel gear. To have a functional custom gear machining solutions, it's important to work with an expert like LS Manufacturing in order to make the right decisions within the process of creating the gear that will turn out to be useful in its intended purpose.

Why Are Heat Treatment And Surface Treatment So Important For Gear Durability?

Along with precision in geometry, the final reliability of the gear also depends on properties as far as the material is concerned. Only the most reliable gear heat treatment process and surface finish will enable the resulting accurately cut workpiece made out of metal to transform into a reliable and top-notch mechanical drive capable of surviving stressful conditions even after millions of cycles. All this forms the core service related to the high-strength gear machining services.

Core Hardening for Wear Resistance

Considering this criterion, the processes of Carburizing and Induction Hardening are being considered. The employment of both processes helps to achieve a strong core capable of withstanding an impact load and a hard, wear-resistant surface layer which can attain 58-62HRC on the teeth of a gear, and that too is quite beneficial as far as strength is concerned. Even when it comes to obtaining a contract related to gear machining services, it is quite beneficial.

Enhancing Fatigue Strength

Surface processing methods, such as shot peening, result in a beneficial compressive residual stress near the root and flank of the teeth. Its effect on fatigue strength in particular for the bending load is tremendous and usually neglected as a must-processing step during the manufacturing of gears for highly loaded application fields, such as wind turbines and heavy industry machinery.

Optimizing Performance with Specialized Coatings

Further surface treatment to improve durability can include phosphating or specialized coatings. These processes reduce friction, enhance corrosion resistance, and improve lubricant retention. This would decrease the temperature during operation and micropitting in order to facilitate smooth and long-lasting functioning of parts after taking high-strength gear machining services.

Precision-Controlled Process Parameters

Manufacturing process parameters determine the effectiveness of gear heat treatment process. Operational parameters for conventional processing of alloy steel include temperature, carbon potential, and quenching. These can also be applied in those conditions where the specified depth of the hard surface lies between 0.5-1.2mm and the surface hardness corresponding to that would lie between 58-62HRC.

In other words, actual durability cannot be reached by mere shaping alone. Instead, it is the fitting combination of the gear heat treatment process that enhances its strength with a subsequent focused surface treatment to improve durability that actually unleashes the real strength of the gear. That is a multi-faceted approach that represents what constitutes actual high-strength gear machining services such that the machined item actually can function as the durable drive for success in your operation.

Figure 2: Professional custom gear machining service examples by LS Manufacturing

How Can We Ensure That Each Gear Meets Design Specifications Through Precise Testing?

The precision of the gears depends on their precision performance capability. Where the precision can be determined: At LS Manufacturing, the precision for precision depends upon the gear precision inspection accuracy. This can only be achieved at the end of our LS Manufacturing quality control process. Precision for precision can only be achieved by utilizing the gear measurement center. These factors shall be addressed below as the criteria for precision for the performance capability of our gears:

| Inspection Focus | Key Parameters Measured | Method & Technology |

| Tooth Profile Accuracy | Involute deviation, profile form error. | Gear measurement center scan probe. |

| Tooth Alignment (Lead) | Helix angle, lead deviation, error of the flank line. | Automated scanning of the flank on the tooth axis. |

| Indexing & Runout | Single pitch error, cumulative error of pitches, radial runout. | High precision indexing of rotary table, circular scanning. |

In summary, quality has an information source that is an aid in determining the meaning of quality. There is an inspection report that is useful in developing something out of the process. There is an assurance that provides you the true ingredient of conformance. Finally, the complex process that comprises first article inspection and AQL inspection is the backbone of our LS Manufacturing quality control. Our commitment, and this we assure you, is that not only will we deliver an item, but it will comprise specific elements of functionality, backed up by statistics to validate our gear precision inspection process.

Industrial Automation: Custom Machining Of High-Precision Helical Gears For Robot Joints

This is LS Manufacturing success case: Industrial automation equipment machining: "This is a reflection of our commitment to answering fundamental engineering questions. To put it into perspective, one of the world's largest robot manufacturers was seeking innovation to provide customized precision of helical gear within the design of a next-generation joint module unable to provide optimal noise and life characteristics.

Customer Challenge

The customer faced a problem because of the following reasons while using the helical gears provided by his previous supplier: High operating speed, which tends to be a characteristic of the customer, resulted in increased operating noise from the use of helical gears provided by his previous supplier. The helical gears provided exhibited tendencies of pit failure even prior to testing.

LS Manufacturing Solution

We provided an engineering service. The service started with high-tech software concerning optimization of tooth profile and micro-geometry errors. The next service provided by us was gear grinding concerning manufacturing with ISO accuracy grade 6. The above services were backed by an accurate heat treatment service concerning carburizing with an emphasis on high hardness. This service provided a tough core, and in addition, it had a hard surface with HRC 58-62.

Results and Value

Plugging The result was nothing short of revolutionary. The result gave a result of 15 dB and an astonishing 300% improvement in fatigue life for the new gear pair that had been designed. This high-precision helical gear customization provided the client's product with a clear advantage in quiet operation and reliability, establishing LS Manufacturing as their trusted strategic supplier for critical transmission components.

In summary, this LS Manufacturing success case: industrial automation gear machining showcases how targeted engineering and precision execution in custom gear machining directly translate into tangible product superiority. We partner with clients to overcome specific performance barriers, delivering components that enhance their competitive edge in demanding applications.

Have you considered any set of tools in particular as a method to solve for the problems introduced by noise and robustness? Click to get free DFM review help.

What Are The Key Factors That Influence The Price Of Gear Machining Services?

In fact, for deriving the gear machining service quotes, there has to be some understanding about the process for costing. Costing, by any means, doesn't occur randomly, and it relies on the demands that can be specified according to your projects. In reality, the custom gear cost analysis can be considered as an effective method for cost planning, by which you can attain the correct output for your demands.

- Design Complexity and Precision Grade: This is the simple reason for the cost in terms of the complexity design and precision grade for the corresponding gear. The cost for the design of the spur gear would result in an amount lower than the cost for the design of the double helical and crown gears. This is the first step in any detailed custom gear cost analysis.

- Material Selection and Thermal Processing: To a certain extent, not only does the requirement state that the material used for gear processing the gear processing device must be of a certain type, for example, alloy and stainless steel, and so on, but further, the most critical aspect of the entire process is that the gear heat treatment process that are related to carburization, induction, and nitridation processes, and so on. If the final product to be delivered has to be of a standard type, the assumption related to gear machining service quotes also holds relevance.

- Order Volume and Secondary Operations: Production economics are heavily influenced by batch size. Prototype or low-volume orders incur higher unit costs due to setup and programming. Higher volumes allow for cost amortization. Furthermore, additional surface treatment to improve durability (like shot peening or coating) and specific packaging or documentation requirements will also be included in a comprehensive proposal when you get gear machining prices.

- Inspection and Quality Assurance Stringency: This becomes relevant in connection with the cost of our process of inspection within the facility. In addition to the cost of our process of inspecting trace materials at the gear measurement center trace of 100%, all these factors have been taken into account in what we do.

In short, an exact gear machining service quotes requires a comprehensive perspective on the project in order to provide an exact quotation. When design, material, accuracy, and quality factors are taken into account in the initial phases of investment planning, that paves the way for an exact custom gear cost analysis. Of course, you can contact us to get gear machining prices in your specifications and thus give you an investment proposal.

Figure 3: Product lineup of industrial gears and machined samples by LS Manufacturing

How To Choose A Reliable Gear Machining Supplier?

The choosing of the right partnership for the production of the final product has immense importance, as it decides the possibility of success in each and every undertaking. When choosing a gear machining supplier, a number of factors, there are a number of considerations taken into account, apart from the cost factor. Each successful business will be the most important factor for a reliable gear machining manufacturer.

Evaluate Technical Expertise and Engineering Support

Being a supplier, an important technical skill was essentially required for a supplier. Key requirements were proposed and this is the requirement that factored them in as eligible candidates for DFM basing on the shapes and materials required from the supplier. A solution and not a price was needed and this is the assessment conducted for LS Manufacturing supplier evaluation.

Audit Manufacturing and Quality Assurance Capabilities

While performing an audit of the suppliers, the fact related to equipment infrastructure ability and requirements must be kept in mind. The most critical point is that it needs to be a quality supplier and the related services related to the manufacture of cut, grind and finish machines must be quite sophisticated, and then there is equipment requiring a reliable gear machining manufacturer.

Review Relevant Case Studies and Industry Experience

Try to find out their experience in cases like yours. It can be based on the level of applications or requirements of their cases, for instance, an example project that has previously been taken up in an industrial automation project. This historical performance is a vital component in choosing a gear machining supplier.

Assess Communication and Project Management Standards

There are those suppliers who will have the capability to provide the best services provided that the standards of communication and project management meet the required standards. It is important to ensure that the response to matters pertaining to communication, as well as matters pertaining to project management, have been taken care of appropriately. The supplier will be responsible for ensuring that the business is well-run in matters related to proper communication, project management, as well as offering a free quote for gear machining.

Therefore, the whole exercise that comes with the evaluation will ensure that time spent on the project, the investment that goes into the project, as well as the performance level attained, is factored in. You are advised to make use of the various points which have been highlighted above to assess the LS Manufacturing supplier evaluation. However, once you manage to get gear machining prices, one is advised not to undervalue the aspect of experience and collaboration.

Figure 4: Gear specifications and dimensional drawing by LS Manufacturing

What Is The Basic Process For Custom Gear Manufacturing In Collaboration With LS Manufacturing?

A good process for the project, therefore, will be a necessity for the success of the project. The gear customization collaboration process, which has been adopted by our team, also takes place in an orderly fashion that will ensure smoothness. This little process explanation of how to start a gear machining project may add emphasis on this.

- Initial Consultation and Specification Review: At LS Manufacturing inquiry process, we initiate our gear machining process. We analyze your 2D/3D diagrams, specifications, and applications that you have provided for us. First consultation is basically the inception of a great start for the overall process that pertains to gear machining.

- Technical & Commercial Proposal: The analysis will be done based on the inputs that shall be given by you to us. The same shall be absolutely free, and this shall be followed by a cost structure that shall be formed in terms of our providing you the total proposal, which shall include the total roadmap for you regarding the processing solution, which shall include the custom gear machining services you require.

- Confirmation of Order and Production: When the proposal has been approved, the step will entail processing the order for the commencement of production of the proposed design. Some of the processes that may be involved include developing machining programs and developing tools. Following this, the project schedule will be developed to engage in the gear customization collaboration process.

- First Article Production and Validation: Now, at this stage, we have manufactured the first article; this is correctly received by the test process that we undertake using the gear-measuring machine. We shall provide you the test result outcomes for your validation.

- Batch Production and Quality Monitoring: We would then proceed with the entire process of production upon getting your approval. During this process, we shall also implement the process of statistical control. During this stage, we shall treat the matter of deliveries similar to what was promised to you when you first showed interest in that specific item at LS Manufacturing inquiry process.

- Final Delivery and Support: Completed batches undergo final quality audits before careful packaging and on-time shipment. Our support continues after delivery, as we are available to assist with any technical questions, ensuring a complete and satisfying conclusion to the gear customization collaboration process.

Our method of answering the question of how to start a gear machining project through our six-step process is a safe and reliable method. Whether it be your very first question and its response within the context of the LS Manufacturing inquiry process, or any further possibility of after-sales services, it is our response to every single step that is required in the context of custom gear machining services to your business.

FAQs

1. What precision grade of gears are you machining?

About the gear grinding issue, we can ensure that the accuracy of class 4-6 gears about gear grinding meets the National Standard's requirement, GB/T10095.1-2008. About the gear transmission issue, there has been an introduction of the gear measurement center. The size measuring of this kind of gear has been done.

2. Does it support both small-batch prototyping and high-volume production? What is the minimum order quantity (MOQ)?

Without any limitations in orders, from the prototype manufacturing to mass production of tens of thousands, processing orders for different kinds of products will never confine you. Be it developing or mass producing, we always have the best available solution ahead of you at an economical cost, considering the situation.

3. Is the price fixed, and are there any other costs?

How much it would cost us in the near future depends on what the technology will finally require when it is applied to the process involving processing, heating, testing, and packing. If, however, there are those who need to swear off when it comes to design.

4. Can you elaborate on your strategy to achieve optimum gear design along with protection of IP?

The costing that would be applied in our business would depend upon the technological demands that are in place currently and all resultant costs that are involved with regard to the processing charge, heat treatment charge, test charge, as well as the packaging charge. However, in cases where there are designs as well as processes that need to be followed, yet changes are necessitated, this particular industry can be taken care of.

5. Define the production cycle in your production process. Could this not be able to be reduced?

This time for the turn around would, in general, require around 15 to 25 working days, depending on the levels of complexities. There may also be an opportunity for doing the urgent job, and hence an express turn around cycle would also be required since the production order would move depending on the levels of urgency.

6. Are there different types of paper that have quality certificates?

Further, where the shipment relates to quality reports in respect of raw material, quality reports in respect of heat treatment process, overall full-size inspection including tooth profiles, and error curve reports in respect of cases related to tooth direction errors, an overall documentation pack of quality forms part of the shipment. Thus, the evaluation in respect of the overall quality developed at the different levels in the process is possible.

7. My applications experience is quite unusual; can I dare ask for an information resources suggestion?

This includes material selection on the basis of process and processing of materials, especially those of heat treatment, based on the conditions of processes such as loading spectra, velocity, temperature, and others; apart from process conditions of heat treatment. The options may also be made available to you by our experts.

8. What if problems are found during assembly after receiving the gears?

It will be ensured, if the issue is perceived to have been caused due to us, that within 12 hours of the detection of this issue, including priority rework/re-manufacture, return, and negotiations for the issue resolution and for agreeing over the concerned liabilities, that this will never create any sort of hindrance for the execution of your projects.

Summary

Nevertheless, in the business of gear manufacturing, it would be appropriate to identify an appropriate gear required for gear machineries in case of successful integration of gear transmission in your product. It is exactly where, in fact, an understanding and knowledge of gear manufacturing and an appropriate role in maximizing efficiency, right from its inception, has allowed the company, LS Manufacturing, to be the best partners to gear manufacturers of high-quality equipment products.

The overall benefits in gear transmission efficiency systems will be acquired by you in your project. CLICK “Get My Free Gear Machining Quote and Technical Solution” now and let us know your project in order to revert back to you within 24 hours with gear analysis and gear price.

Get a personalized quote now and unlock the manufacturing potential of your products. Click to contact us!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.