Precision custom gear manufacturing is crucial for aerospace and robotics, yet current systems struggle with severe reliability challenges. The fatigue life of helicopter transmission gears is less than 2000 hours, the robot joint gears have errors greater than 8 arc-minutes, and satellite gears are losing their precision when they are under extreme temperatures. As a result, system failure rates are more than 5%, and repair costs can reach up to 25% of the project budgets, thus the necessity for long, lasting solution are quite evident.

We address these issues by means of 20 years of LS Manufacturing experience and a database of 158 projects. Our end-to-end solution, deeply integrated design, precision machining, heat treatment control, and reliability test, can not only help gears last three times longer but also keep the transmission accuracy within 2 arc-minutes, thereby creating a scientific quality framework for mission, critical applications.

Quick-Reference Guide: Precision Custom Gear Manufacturing For Aerospace & Robotics

| Section | Core Insight in One Sentence |

| 1. The Critical Challenge | Aerospace and robotics require gear reliability that goes beyond the commercial level by a large margin. In these sectors, traditional manufacturing methods usually cannot survive under conditions of extreme stress, high temperatures, and tight tolerances. |

| 2. Root Cause Analysis | Systemic failures have their origins in an inadequate engineering approach whereby gear manufacturing is regarded as a series of isolated steps rather than a perfectly integrated, mission-critical system from design to testing. |

| 3. Our Integrated Solution | Through our comprehensive methodology, we bring together the strengths of advanced design simulation, gear machining, controlled heat treatment, and strict validation, which are all supported by our 20 years of professional experience. |

| 4. Technical Foundation | Micro-geometry optimization through proprietary methods, tailoring metallurgy according to AAC standards, and obtaining surfaces with perfect integrity and dimensional stability through ultra, precision finishing are just some of the internal processes that constitute our competence. |

| 5. Verification & Validation | On behalf of each gear, a harsh, and thorough experiment results in a protocol including FEA, accelerated life testing, and thermal cycling to demonstrate performance under simulated mission profiles experimentally. |

| 6. Proven Outcomes | A 200% gain in fatigue life is very much possible due to this integrated approach, transmission accuracy can be maintained within 2 arc-minutes, and the risk of a systemic failure can be lowered significantly. |

We address the main gear manufacturing problems of reliability, accuracy, and cost that have been the concern of critical applications for a long time. Rather than selling you parts, we offer you gears that are made as mission-assured components, thus, directly enhancing your system's uptime, safety, and performance, and at the same time, lowering total lifecycle costs and program risks. Our skills make gear reliability not just a recurring problem but a source of fundamental advantage.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Why should you read another article on gears when there are thousands of them online? Our knowledge is not just theoretical but practical. Our shop is a practice field where we deal daily with manufacturing gears from aerospace alloys and advanced polymers under close tolerances. We are not just familiar with the specifications; we rely on being able to use them flawlessly for our mission, where the failure of a single component is not an option.

Among our extensive experience of over ten years, we have often referred to the Wikipedia for basic engineering si, principles and the Aluminum Association (AAC) for material standards. Our focus has been on extremely demanding applications. We have made one of our gears satellite deployment mechanisms that are to be operated in space, and another robot actuators that require zero-backlash performance in repetitive surgery. Every project has revealed through us physically what heat-treating, micro-geometry optimization, and consistent surface integrity in volume production are, and the knowledge will continue to accumulate.

Every suggestion given here has been supported by our experience, fighting against the elements and materials, subjected to rigorous quality checks and performance in the field. We are happy to share our experience in choosing gear alloys, controlling processes, and validating designs, which can be a very expensive exercise for anyone to learn otherwise, more so if trial and error are involved. This is the science that we put into practice to ensure dependability at what is really important.

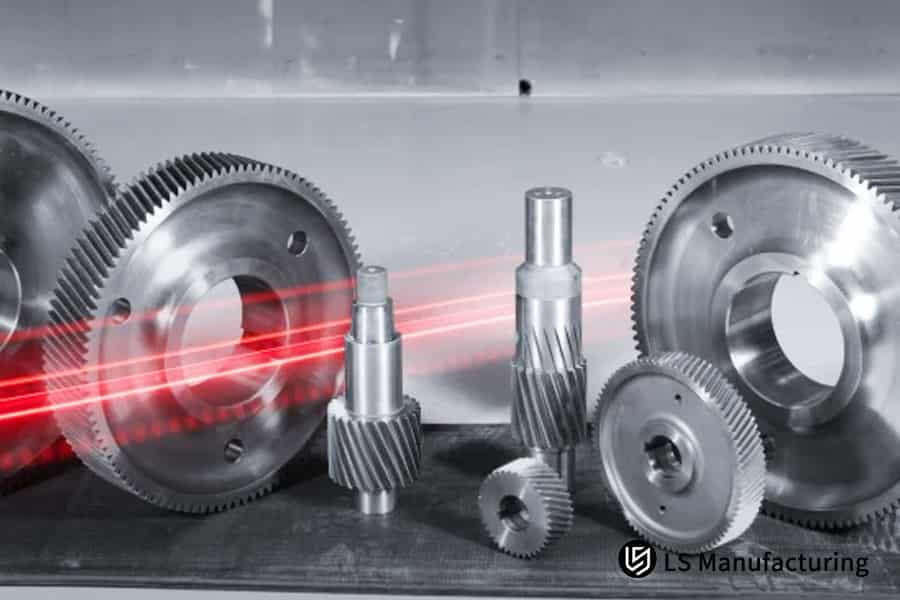

Figure 1: Gear machining precision metal and polymer gears for aerospace, robotics, and precision gear solutions.

What Special Technical Requirements Must Critical Mission Gears Meet?

Precision gear manufacturing for aerospace and robotics must deliver products capable of operating reliably where no failure is allowed. This article discusses the top, notch technical specifications for mission-critical gear manufacturing and the rigorous engineering controls necessary to achieve them, thus laying down a proper set of rules for a system of dependability.

| Application | Core Technical Requirement | Quantified Performance Specification | Essential Engineering & Process Control |

| Aerospace Transmission Gears | Extreme Durability under High Load & Stress | Surface hardness HRC 58-62; Case depth 0.8-1.2mm; Full compliance with AGMA 2001. | Controlled carburizing and quenching processes to a lethal breeding of hardness gradient and core strength. |

| Robotic Joint Gears | Ultra-High Positioning Accuracy & Long-Term Reliability | Transmission error ≤3 arc-minutes; Validated fatigue life exceeding 2 million cycles. | Usage of refined profile modification to reduce mesh error, regularly achieving <1.5 arc-minutes. |

| System-Level Validation | Verified Performance in Operational Extremes | Testing under specified thermal, vacuum, and dynamic load conditions. | The use of a strict procedure combining FEA simulation, accelerated life testing, and precision metrology. |

Successfully obtain dependable results, thoroughly regulate the heat treatment parameters to control the material properties and carry out micro-geometry optimization for operational accuracy. The last check should be a test that reproduces the most challenging conditions of the application. This paper presents the practical, data, driven framework that is indispensable for the controlled high-precision gear machining in the environments of the toughest competitive and operational challenges.

How Can Micrometer-Level Precision Control Be achieved For Aerospace Gears?

Micron-level precision in aerospace gear manufacturing is a must rather than a nice, to, have when it comes to system reliability and performance. This article reveals the combined engineering methods that are absolutely necessary to achieve and hold such tight tolerances. It is centered around the real processes that lead from specifications to measurable results:

Precision Machining with Advanced Equipment

The start point is 5-axis gear grinding machines with a positioning accuracy of ≤±3μm. This capability, at the heart of high-precision gear machining, belts the conformity to ISO Grade 3 or better for profile and lead deviation, thus setting the standard for all further precision gear solutions.

Real-Time Metrology and In-Process Correction

An integrated online measurement system directly measures key parameters like cumulative pitch error and keeps it within 15μm tolerance continuously. Having this feedback data instantly on hand, an adjustment to the CNC program can be made immediately, which is the essence of the feedback loop in high-precision gear machining that can compensate for tool wear and machine drift during the production schedule.

Thermal Management and Environmental Control

Our process uses aimed temperature compensation systems to combat heat deformation, which is one of the main error causes in the first place. The temperature control in our process helps keep the thermal distortion under 5μm, which is very important not only for gear profile machining but also spacing and fitting of very tight tolerance transmission systems.

Specialized Techniques for Large-Scale Components

When it is about large gears over 500mm in diameter, the main concern is to keep the helix angle deviation under control. We follow the procedure of providing tailored fixturing and grinding in several passes so that lead error stays within 8μm, thus ensuring consistent patterns and load distribution for the whole aerospace gear manufacturing range.

This method is more than just meeting the specifications by utilizing predictive process control and empirical verification side by side. It is the deterministic accuracy that is essential for mission-critical applications and thus confers the competitive engineering advantage in high-value aerospace and defense projects.

How Can The Fatigue Life Of Robot Joint Gears Be Improved?

Increasing the fatigue life of gears in joint is very crucial in robotics gear manufacturing. We combine advanced material technology and precision gear solutions for the exact purpose of solving the main problem of extending the service life under high cycle loading. The same targeted custom gear engineering services that bring you this engineering are essentially reliability and reduction of total cost of ownership. The tried and tested method is as follows:

Premium Material Selection & Microstructure Control

- Core Material: We never use anything but 18CrNiMo7-6 alloy steel for the core because it offers excellent core toughness and fatigue resistance.

- Grain Refinement: We implement a very tight microstructure standard to guarantee fine grain size ≥ Grade 8. This key advanced gear machining control drastically slows down this gear crack initiation process.

Ultra-Precision Tooth Flank Finishing

- Surface Quality Goal: The main focus is on achieving an extremely smooth tooth surface. Our precision gear solutions require final surface roughness of Ra ≤ 0.4μm.

- How We Achieve It: The technique that we adopted for this is our state-of-the-art grinding and honing processes that not only reduce stress concentration points, but also wear.

Advanced Surface Strengthening Technology

- Shot Peening Process: We apply shot peening under controlled conditions only on the critical tooth root fillet area. This method in robotics gear manufacturing gives us compressive stresses that are beneficial, as studies have shown that it can increase bending fatigue strength by 30%.

- Process Expertise: Our parameters for robot joint gears are carefully adjusted to achieve a perfect balance of surface strengthening and the maintenance of geometric integrity.

Comprehensive Residual Stress Engineering

- Targeted Stress Field: In fact, apart from peening, we totally consider the molecular, level stress profile. Our custom gear engineering services are capable of producing the highest level of compressive residual stresses (in the range of -400 to -600 MPa) in highly stressed areas, thus enhancing the fatigue strength of robot gears.

- Result: The tough work of this biological stress shield causes the crack to be unable to propagate freely, so that we are able to increase gear life from 1 million to more than 3 million cycles and thus confidently achieve the 10-year robot servicing target.

This systematic protocol deep technical mastery in gear machining excellence. We don't just specify standards; we engineer and validate the entire manufacturing chain to deliver guaranteed durability for demanding robotics gear manufacturing applications, thus setting a new level of reliability in performance. Our solutions are rigorously proven to ensure that robots can function at peak efficiency over their entire design life without compromise.

Figure 2: Handling high-precision metal gears for aerospace and robotics engineering applications.

What Specific Requirements Does AS9100 Certification Impose On Gear Manufacturing?

First and foremost, an AS9100 gear supplier needs to put a quality management system in place that is thorough and comprehensive. This paper illustrates only the very detailed and strict controls required by AS9100 for the aerospace compliance, effectively turning standard clauses into manufacturing procedures that can be followed. To that extent it has become an indispensable guide to guaranteeing the quality of the components and complete traceability when used in highly reliable applications.

| Requirement Category | Specific Mandate (Quantified/Direct Statement) |

| Material Traceability | Complete material traceability to the original heat or melt lot number must be established. |

| Thermal Process Control | Every heat, treatment temperature-time curve must be 100% recorded for each batch. |

| Quenching Process | The control and recording of the quench delay time must be, generally, not more than 15 seconds. |

| Process Monitoring | A written process control plan, such as one with 32 quality inspection points, is necessary to meet the requirement. |

| Part Documentation | An accurate, detailed record of the inspection for each gear including at least 28 data points should be available. |

| Validation & Testing | Certified documentation is required for all NDT testing and final product verification results. |

AS9100 turns quality protocols into data, driven mandates for precision gear machining. Meeting the requirements involves having measurable controls e.g. a quench delay of ≤15-second, and complete material traceability, which results in a documentable data chain. Being an AS9100 gear supplier, we help our customers achieve these tough aerospace compliance standards by process control and paperwork integration, hence, reliability is assured in the case of high-value gear machining applications.

How Does Gear Modification Technology Improve Transmission Smoothness?

In order to get the smoothest transmission of a high-precision gear system, one has to go through the elimination of the sources of excitation at mesh impact and stress concentration due to misalignment which are the two major causes of the problem. This paper explains a method that is focused and practical; it does not just throw forth the general ideas but, rather, it thoroughly documents how micro-geometry adjustments by calculation can solve the problems that have been identified.

Problem Analysis: Pinpointing Excitation Sources

At the initial diagnosis, it was figured out that there were two main drivers of instability. The impact excitation was a result of the deflection that happened when the teeth entered/exited, whereas the slight misalignments were the cause of the unwanted edge, loading. Instead of making general modifications, our method was to focus on getting rid of these exact events and thus having each change serve a clearly functional purpose geared towards transmission optimization.

Precision Modification Strategy Development

We devised a protocol to rectify errors along two axes. Relief at tip and root, targeted by a very small amount (0.01-0.02mm), was given to the teeth in order to help them to absorb shock at the time of first contact. At the same time, a controlled crowning operation is carried out along the tooth flank (0.005-0.008mm crown amount) which helps to load centralization thus allowing compensation for a possible misalignment. This precision gear machining strategy transformed the theoretical benefits of gear modification technology into quantifiable, manufacturable specifications.

Simulation-Driven Parameter Optimization

The defining of parameters was an iterative process supported by computer calculations. We used advanced transmission error (TE) simulation software to model the gearing under load and thus figured out how changing the relief length, amount, and crown profile impacted the TE curve. The aim was to reduce the amplitude of the TE fluctuation. This virtual prototyping gave us the possibility to confirm a profile with the idea of optimizinglevel of the efficiency before starting physical high-accuracy gear machining, thereby significantly cutting the cost of the traditional trial and error method.

Validation Through Measured Performance Gains

It has been demonstrated that the refined profile implemented after the simulation was really effective. The noise level has been drastically lowered from 75dB to 68dB, and vibration classification has been improved from grade G6 to G4. This validated our model's accuracy and demonstrated that our engineered gear solutions, rooted in simulation-informed specialized gear fabrication, directly translate into superior functional performance and smoother operation.

This example highlights our ability to solve a specific transmission issue deeply by combining analysis, simulation and precision execution. Our report offers a solid proof of our problem-solving method, setting apart our product by showing how we achieve performance improvements that can be measured through applied engineering precision and advanced gear manufacturing techniques.

Figure 3: Gear machining a high-precision large metal gear for aerospace and robotics engineering applications.

LS Manufacturing Aerospace: Customization Project For Satellite Solar Panel Drive Gears

The requirement for the extremely precise and dependable motion in space vacuum poses unparalleled material and engineering challenges. This aerospace gear case study details our resolution of a critical thermal stability failure for a satellite solar array drive mechanism:

Client Challenge

A satellite manufacturer needed a drive gear (module 0.5, ISO quality 3) with a maximum transmission error of ≤2 arc-min throughout a temperature range of -100°C to +120°C. Components of a previous supplier which were suffering from dimensional instability, got seized during thermal cycling, resulting a six-month project delay and putting the satellite's mission-critical application at risk. The situation highlighted the requirement for precision gear machining with excellent material science.

LS Manufacturing Solution

We designed a solution that utilized C17200 beryllium copper alloy due to its stable thermal properties. The main innovation was an optimized heat treatment schedule: solution annealing and then exact age hardening, combined with vacuum carburizing to keep distortion under 5µm. This advanced gear fabrication process brought about microstructural uniformity, which means that the gears behaved consistently when tested in our custom-built extreme-temperature test platform, proving our engineered gear solutions.

Results and Value

These final gear components exhibited a transmission error that barely fluctuated, going only up to 1.5 arc-min, over the whole range of temperatures, and the life was confirmed to be more than 15 years in orbit. The dependable performance made it possible for the client's program to continue and complete on time, and through our solution, a further cost saving of direct 2 million RMB per satellite was made by avoiding future failures and guaranteeing timely deployment.

Through comprehensive material science and specialized gear fabrication integration, this project demonstrates our ability to tackle extreme engineering challenges. Moving from an undefined failure situation to a physics-based, data-validated solution, we showcase the technical profundity that is necessary for real mission-critical application success and gaining long-term partnering trust.

Contact us to challenge the limits of cutting-edge gear precision performance and explore in-depth technical analysis.

How Does Material Selection In Gear Manufacturing Affect Performance?

Selecting the optimal gear material is a fundamental engineering decision that directly affects a gear's load capacity, lifespan, and operational efficiency. Instead of sticking to generic standards, our selection process is based on a science-driven approach, tailored specifically to application envelopes:

Methodology: A Systematic Selection Process

Our method is supported by a proprietary materials database and analytical framework.

- Application-First Analysis: We start defining the dominant failure mode (e.g. bending fatigue, wear, impact) and the operating environment (temperature, lubrication, contaminants).

- Data-Driven Matching: Our materials database compares the properties of materials (strength, toughness, hardenability) with the requirements of the applications to find the most suitable alloys.

- Holistic Evaluation: Performance, manufacturability (e.g. compatibility with precision gear machining), and total cost are taken into consideration to make the final selection, which, therefore, ensures that the chosen alloy is capable of leading performance optimization effectively.

Case Example: Achieving Weight and Strength Targets

The customer was looking to decrease the transmission inertia at high speed without compromising the durability.

- Initial State: The components made of a standard alloy had reached their performance limit.

- Our Solution: We advised on and confirmed the change to a reinforced steel grade having a higher strength-to-weight ratio.

- Quantifiable Outcome: The strategic gear material selection led to a 20% reduction of weight and a 15% increase in bending strength, thus directly improving the system's dynamics and power.

Validation: Ensuring Performance Integrity

Specification is followed by a thorough verification to lower the risk of implementation.

- Prototype Testing: Sample gears are subjected to accelerated life testing to simulate real-world loading conditions.

- Microstructure Analysis: We check that the heat treatment is done properly so that the core material properties correspond to the performance prediction models.

- Manufacturing Feedback: We work so closely with our production team that we know the chosen material is still compatible with the advanced gear fabrication process for consistent quality.

Such a structured, data-to-validation approach is a proof, point of our intensive material science component performance translation. We tackle the crucial weight-strength-efficiency trade-offs by offering a deterministic selection pathway, a major differentiator for engineers who are faced with advanced gear performance optimization challenges.

Figure 4: Displaying high-precision metal gears for aerospace, robotics, and automotive precision gear manufacturing solutions.

How To Obtain Accurate Quotes For Gear Manufacturing?

Getting a quick and accurate manufacturing quote for precision gears has always been a long process of manual estimation, which frequently results in very vague figures or even unexpected cost overruns. We fix this by turning quotation into a deterministic, parameter-driven engineering analysis, hence, from the very first point of contact, there is clarity and predictability:

Foundational Inputs: Parametric Analysis for Baseline Definition

The first move of the process is to have the online platform analyze the core gear specifications. By entering the critical parameters such as module, number of teeth, face width, and required accuracy grade (e.g., ISO 8), the system can draw up a very accurate cost estimation baseline. Thus, this preliminary step determines the vital precision gear machining operations that are the core of the precision gear quote reflecting the real manufacturing complexity, not only the volume discount.

Engineering Context: Integrating Material and Process Logic

The main factor affecting the cost is the ability to trace the production step from the design. The system checks the selected material (e.g., 4140 steel vs. C17200 beryllium copper) with which it is associated the respective processing, such as heat treatment and hard-finishing. It then maps the accuracy grade to the necessary specialized gear fabrication sequence, automatically calculate the cost differential between grinding, shaving, or honing to meet the specified tolerances and surface finish.

Dynamic Output: Delivering Actionable Technical-Commercial Data

In a matter of minutes, the online quoting engine automatically combines all parameters and generates a detailed cost breakdown, along with providing a single price. The lead, time projection is broken down by process stage and the cost structure (material, processing, finishing) is clearly presented. Such level of transparency gives engineers the ability to thoroughly evaluate trade-off decisions, thus if they understand the effect of a tolerance or material choice change on the final project time and cost, they can easily decide.

Rather than just giving a price, we also supply a verified manufacturing plan to show how deeply we are involved in the integration of design intent with production reality, thus enabling not only the prediction of results but also a reliable partnership in advanced gear manufacturing.

Why Choose LS Manufacturing As Your Gear Manufacturing Partner?

Choosing a gear manufacturing partner for the performance of critical applications requires more than just the basic capability of machining; it typically involves the proven track record of a company that can turn design intentions into real-world performance under operational conditions. Through the integration of technical expertise, testing, and a traceable process, we are able to provide this level of confidence:

Partnership Foundation: Technical Expertise and Proven Experience

Our partnership has been laid upon a base of 20 years of concentrated application experience and a systematic knowledge base.

- Empirical Knowledge Base: Drawing on 158 complete projects, a proprietary process database of ours offers confirmed manufacturing parameters for different materials and shapes thus reducing the risk of new developments.

- Application-Specific Guidance: Based on this accumulating technical expertise, our early design input has become more targeted, facilitating design optimization in terms of manufacturability, performance, and cost even before precision gear machining gets underway, thus a true gear manufacturing partnership is established.

Verification Capability: Ensuring Absolute Conformance

We are committed to component integrity by metrology-led verification at each stage.

- Advanced Metrology: We have a Klingelnberg gear inspection center that is capable of giving full profile, lead, and pitch analysis with ±0.001mm accuracy and produces definitive compliance reports.

- Process Control: Inspection data is fed back to our advanced gear fabrication teams in real-time, enabling immediate process adjustment to ensure every lot meets the strictest mission-critical specifications.

End-to-End Service: Delivering Customized Solutions

We take care of the entire value chain so as to deliver a smooth final integration and performance.

- Integrated Workflow: Our turnkey offer includes design review at the start, custom gear manufacturing, heat treatment, finishing, and final validation, thus providing complete traceability.

- Performance Certainty: Such a comprehensive method reconnects design, manufacturing, and inspection thus it is ensured that the gears delivered achieve 100% of the application specification.

We drive dependable, top tier risky engineering capacity by combining extensive empirical knowledge with closed-loop process control. This paper describes our rigorous process of converting complicated demands into certification, ready components, thus giving an example of the deep technical collaboration that we are willing to provide besides specialized gear fabrication.

FAQs

1. What is the minimum module machining capability for critical mission gears?

LS Manufacturing can machine gears of any size, including micro-gears and large gears, with a minimum machining module of 0.2 and a maximum diameter of 800mm.

2. How to decide the gear accuracy class?

ISO 3-4 is a suitable standard for aerospace applications, whereas ISO 5-6 is for industrial robots. LS Manufacturing gives advice on how to get the most out of accuracy classes.

3. How long is the processing cycle for gears made of special materials?

15-20 days, conventional materials, 25-30 days, special materials. To accommodate urgent needs, LS Manufacturing has a fast track service.

4. How do you maintain the same level of quality in the production of gears?

Using SPC process control, the first-piece inspection, and online measurement, we guarantee a CPK ≥ 1.67 and accuracy fluctuation ≤ 0.005mm in serial production.

5. Do you offer gear profile modification design services?

We could accurately provide the profile and helix modification design of gear teeth, enhance the transmission performance through simulation analysis, and supply free DFM analysis reports.

6. How do you minimize deformation during heat treatment of gears?

We use vacuum heat treatment + pressure quenching process to maintain the heat treatment deformation of gears within 0.01mm, thus ensuring the stability of gear accuracy.

7. What is the maximum gear machining size?

The maximum outer diameter is 800mm, maximum module is 8. LS Manufacturing is equipped with the capability of large gear production.

8. Do you provide gear performance testing services?

We can offer various performance verification services, such as fatigue testing, noise testing, and efficiency testing, to verify that the gears are suitable for the real working conditions.

Summary

Manufacturing of critical mission gears need to be technically devised by experts and a very rigorous quality control system. We can assure the dependability of gears at very tough working conditions through scientific gear design, accurate machining processes, and a comprehensive verification process. LS Manufacturing's professional service system for critical mission gears can be your technical consultant throughout the whole process from providing technical consulting to mass manufacturing.

If you have the manufacturing needs of critical mission gears, do not hesitate to get in touch with the LS Manufacturing gear engineering team right now. Send your gear parameters in order to get a manufacturing plan that is professionally done and an accurate quotation! Our gear specialists will give you a complete technical analysis and optimization suggestions within 4 hours. Submit your request right now and get a free gear design inspection service.

Engineer your mission-critical applications with precision custom gears for aerospace and robotics.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.