Broken lathe machine gear halts production lines, causing daily losses of tens of thousands of yuan. It creates a dilemma where OEM parts take weeks for delivery, and local repairs lack precision. The root cause is the traditional supply chain's slow response and non-professional manufacturers' inability to provide ready-for-use, durable parts due to an insufficient understanding of material properties and precision processes.

LS Manufacturing specializes in the manufacture of precision gears on an emergency basis, promising "5-7 day express delivery." From selecting and processing the materials to testing, we keep the whole process precisely controlled in order to restore production promptly and strive to surpass the performance of the original OEM. We will explain below how to turn this downtime crisis into an opportunity to upgrade equipment performance, saving your time.

Figure 1: Lathe gearbox for emergency replacement situations by LS Manufacturing

Lathe Gear Repair Solution Quick Reference Table

| Module Classification | Core Content Summary |

| Current Fault | Sudden destruction of an important gear of the line results in machine downtime. |

| Current Challenges | Long delivery time for OEM spare parts; difficult to guarantee the quality of local repairs. |

| Solution | Precision lathe gear offers the following customized services, which are delivered within 5-7 days. |

| Quality Assurance | Full control over the selection of materials, heat treatment, and precision manufacturing processes. |

| Core Value | Quick restart of production, with gears performing better than OEM standards. |

By breaking through the inadequacy of traditional models both in terms of timeliness and quality, this technology has now become the optimum choice for enterprises to strike a balance between efficiency and reliability. Being technologically driven, it truly accomplishes repair results that are both rapid and robust, able to directly minimize unplanned downtime losses.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

The LS Manufacturing team has accumulated high-standard process experience across industries in lathe gear manufacturing. These practices enable us to deeply understand the complex relationship between material property, heat treatment process, and dynamic load.

Starting from material selection and optimization of the tooth profile, to process stability control in the course of mass production, we transform practical technical insights into concrete solutions, making sure that each gear produced corresponds not only to the parameters but also can hold strong for long-time operation.

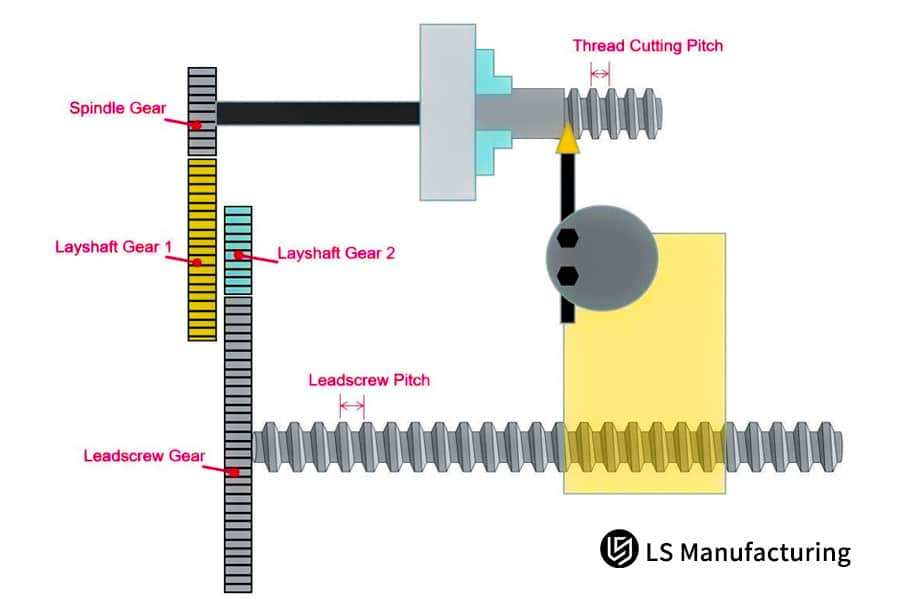

Figure 2: Precision engineering solution for gear replacement by LS Manufacturing

Why Does Lathe Gear Damage Cause Such Serious Production Disruptions?

Lathe gear damage during manufacture is much more than the failure of a simple component; it's more of a sudden stop in the "heart" of the transmission system, and it easily triggers a global production disruption. A critical lathe machine gear replacement was not done in a timely manner could result in production losses far exceeding the value of the part itself. This severe interruption of production is especially reflected in the following three aspects:

Chain effect of precision loss

Gear damage directly undermines the accuracy and stability of the machine tool transmission chain. Abnormal spindle speed and feed unevenness may result, thereby completely losing control over workpiece machining accuracy, thus producing a batch of defective products with dimensional tolerance. Long and expensive recalibration and compensation of the geometric and positioning accuracy of the machine tool are usually involved after gear repair to restore machining capability.

Risk of spreading secondary damage

The impact force due to the fractured or seized gear could be transmitted either in the forward or reverse directions along the chain of transmission. It can lead to further damage of other meshing gears, high-precision spindle bearings, and even overload damage of servo motors. This greatly expands the scope of repair from simply replacing a gear to a major overhaul of the entire transmission system and drastically increases both time and costs.

Exponential increase in overall costs

The direct loss from production interruption is the loss of output value during downtime. Deeper costs, however, include high labor and outsourcing costs involved in emergency repairs, contract penalties, and customer reputation losses due to delayed delivery, and extra overtime and logistics costs to catch up with deadlines.

The failure of lathe gears is not about the simple physical replacement of just one part, but rather a comprehensive test of production planning, product quality, and equipment availability along with overall costs. Thus, gear maintenance and early warning in equipment management always amount to a strategic investment of sorts to avoid larger production disasters.

What Are The Clear Signs That Your Lathe Gears Need To Be Replaced Immediately?

In daily operation, lathe gear wear doesn't happen overnight; it will indicate problems through some obvious "signals." Finding these warning signals as early as possible is rather important, to avoid serious equipment damage and sudden production interruptions. If you notice any of the following abnormalities while machining, you should immediately stop the machine for inspection, for these are signs which, in general, mean that the gears are at the point of failure:

| Sign Category | Specific Manifestations and Impacts |

| Abnormal Noise and Vibration | The steady metallic friction or impact noise emitted from within the gearbox, or abnormal vibrations of the whole machine tool, signal serious abnormality of gear meshing clearance. |

| Loss of Machining Accuracy | If there appear vibration marks, dimensional instability, or increased pitch error regularly on the workpiece surface, then this directly reflects a decrease in transmission chain accuracy due to wear on gears. |

| Gearbox Overheating | When touching the gearbox housing, it feels very hot, and the degree of temperature rise is much higher than usual. It usually results from the occurrence of pitting and wear that raises friction, leading to lubrication failure. |

| Visible Tooth Surface Damage | If any of the following conditions-severe pitting, spalling, cracks, or plastic deformation-are observed on the tooth surface during downtime inspection, the gear should be replaced without delay. |

If you observe these signs, then broken lathe gear repair is urgent. Any delay may raise the problem from a simple replacement of one gear to a major overhaul reaching bearings, spindles, and even the whole transmission system. Timely preventive maintenance is much more cost-effective and efficient in comparison with reactive, forced major repairs.

Why Can't Traditional Gear Procurement Solutions Solve Your Urgent Problem?

The traditional procurement solutions for gears can rarely provide an immediate solution when the gear failure brings the lathe to a standstill and may even turn a small repair window into a longer wait. The use of conventional channels in replacing the gears of CNC machines usually means lengthy periods of downtime for an indefinite outcome. Limitations of the two traditional channels are compared below:

| Procurement Solution | Core Drawbacks | Impact on Emergency Repair |

| OEM Procurement | High cost. Long lead time-usually 4-8 weeks. It's cumbersome to order parts from the OEM. |

Although this route ensures that parts are authentic, the wait is too costly for companies with production downtime. |

| Local Non-Standard Machining | Lack of professional testing, non-standard materials and processes, short gear life, poor reliability. | While offering faster response, quality is not guaranteed, can easily lead to rapid failure after installation and secondary downtime. |

At present, high-latency OEM parts and low-reliability local machining cannot satisfy modern production's need for rapid recovery and stable operation. Therefore, finding an alternative supply chain that can guarantee both speed and quality has become one of the main strategies in the reduction of equipment downtime risk.

Figure 3: Custom gear sets that ensure reliable lathe operation by LS Manufacturing

How Does LS Manufacturing Achieve Its 5-7 Day Emergency Delivery Commitment?

By deeply integrating digitalization, standardization, and concurrent engineering principles for both speed and quality, our mature and efficient system of manufacturing emergency gear has allowed us to 5-7 day delivery gear. This efficient system is built on the following four core pillars:

24/7 Emergency Response & Intelligent Process Planning

We have a dedicated channel for emergency orders. Once we have your drawings, the system springs into action. Our mature gear process database matches optimal machining parameters and tool paths in an automatic manner, requiring hardly any manual programming, hence reducing the preparation time from hours to minutes.

Dedicated Production Line on High-Precision CNC Equipment

The emergency orders will be treated as the highest priority in production on our 5-axis machining centers to achieve "dedicated production line". This does not only avoid queues of production but also assures continuity of the process flow from raw material to finished products, maximizing downtime with maintained accuracy of gear profile.

Concurrent Inspection and Quality Processes

Quality inspection does not take place only after machining is done. While machining, critical dimensions for this are measured online, and immediately after machining, a final verification is performed by using a CMM. This "simultaneous machining and inspection" model for sure guarantees a high pre-processing pass rate without wasting the time that would have been spent waiting for centralized inspection in traditional processes.

Standardized post-processing and logistics integration

The inventory and workflow standardize common gear materials and heat treatment processes. After the machining is finished, the gears can enter into the predetermined post-processing directly, for instance, carburizing and quenching, gear surface grinding, which will perfectly coordinate with our logistic partners to confirm delivery dates in advance.

To sum it up, our quick delivery is not a boast; it comes from precise process control, advanced technical equipment, and ample process data. We keenly understand the losses brought about by stoppages, and thus, through this systematic capability, we make sure you get not only a fast-delivered gear but also a reliable, high-quality component ready for instant installation to really help you get into production as soon as possible and reduce your loss.

How Do Our Precision Gears Achieve Or Even Surpass The Performance Of Original Equipment Manufacturer Parts?

Each LS Manufacturing lathe gear is not merely a copy, but an optimization and upgrade of its performance. Based on our systematic technological investment in materials, processes, and quality control, its performance advantages are reflected in the following four key aspects.

- Materials Science: We make use of high-quality alloy steels such as 20CrMnTi and 42CrMo, which have been vacuum-treated to eliminate impurities. Under such conditions, the materials have a finer grain with a more consistent makeup to avoid early pitting and fatigue cracking in the gear, thus laying a solid physical foundation for a long service life.

- Heat Treatment Process: We use a computer-controlled deep carburizing and quenching process to precisely control the depth of the carburized layer and the surface hardness gradient. It gives the surface of the gear tooth high hardness of HRC58-62, thus resistant to wear, while the core still has excellent toughness to impact loads, thus well balancing the performances of wear resistance and fracture resistance.

- Precision Manufacturing: The tooth profile and direction are precision-ground and shaped with imported CNC forming grinding machines. In the process, accuracy in tooth profile and direction will not only reach ISO 5-class or higher but also effectively optimize the meshing contact area through micro-edge modification and greatly reduce the noise and vibration of transmission with the improvement of transmission smoothness.

- Comprehensive Inspection: Each batch of gears leaving our gear measurement center is 100% inspected to get full tooth profile, tooth direction error curve, accuracy report, etc. This serves not only to meet the requirements of tolerance but also to have a complete quality archive for traceability in performance and high consistency.

The gears we deliver maintain perfect interchangeability while providing significant advantages in load-bearing capacity, fatigue life, and transmission comfort. This means your equipment is not only able to rapidly return to operation but achieve more stable, longer-lasting, and quieter performance, thus realizing a true value upgrade.

Figure 4: Technical diagram illustrating lathe gear system replacement by LS Manufacturing

How We Saved A Million-Dollar Order For A Medical Device Manufacturer?

In precision manufacturing sectors like CNC gear replacement, which rely on continuous equipment operation, a single unplanned downtime can destabilize an entire enterprise. We succeeded in preventing a leading medical device manufacturer from an impending crisis, illustrating perfectly how speed and quality in manufacturing can be directly translated into core business value for our clients.

Client's Problem

The sudden failure of the spindle gear on one core machining center brought an entire automated production line to a grinding halt. Replacement OEM gear took as long as six weeks for delivery, which was undoubtedly a disaster—a million-dollar order was imminent, and day after day came with a high risk of default and loss of a key customer, hence jeopardizing the company's reputation.

LS Manufacturing Solution

We immediately put our plan for an "emergency channel" into operation upon receiving the call for help on Friday afternoon. Drawing analysis was completed and access to a dedicated process database was attained by our technical team in just two hours to ensure smooth production without interference. We finished the manufacturing of the gear using precision CNC gear grinding and parallel quality inspection within 5 working days and completed the necessary heat treatment and comprehensive testing to produce a new gear, superior in performance to the OEM part.

Results and Value

Once the gear was delivered, the client was back in production within only 2 hours and was able to deliver a million-dollar order on time, thus avoiding huge losses financially and reputation-wise. More importantly, this feat has sealed our strategic partnership with their end customer.

This successful lathe gear replacement case has solidified our reputation as a high-end emergency gear manufacturing partner. It has proved that in critical moments, a reliable manufacturing partner is not just a supplier but also a strategic cornerstone to guarantee the resilience of the client's supply chain and business success. We provide not just a gear, but an emergency solution to ensure the continuity of our clients' operations.

Precisely replace broken gears and quickly restore production. Get the solution!

Are Custom-Made Non-Standard Or Older Lathe Gears An Even Greater Challenge?

With custom lathe gears, especially the older versions, we possess immense experience and technical reserves that help us to turn what you may perceive as a unique challenge into a reliable opportunity for performance restoration or even upgrade. Our capabilities stand mainly on three key technological pillars:

- Precise reverse engineering technology: It can quickly acquire all the geometric data of damaged gears with high-precision 3D scanning and physical mapping, including module, pressure angle, helix angle, and displacement coefficient, guaranteeing that the restored gear perfectly matches the original installation dimensions.

- Design Improvement Based on Failure Analysis: They carefully observe the wear patterns of old parts, such as pitting, tooth breakage, and scuffing; analyze the root causes of failure; and perform targeted optimizations in the design of new gears. For example, adjusting the heat treatment layer depth, modifying the tooth profile to reduce stress concentration, improves their lifespan and reliability.

- Mature Database of Special Processes: We have a mature database for the machining and heat treatment process parameters of special materials commonly used in older equipment or special tooth profiles, such as early grades of alloy steel and non-standard modules. This will ensure that every step in the manufacturing process-from the selection and heat treatment of the material-is precisely controlled in order to guarantee consistent performance, even for rare or niche gear specifications.

We solve by technological means not only the problem of "having" or "not having" but also that of "good or bad." No matter how special or old your equipment is, we have the capability and confidence to provide you with a "heart" that goes beyond mere restoration, surpassing even the original, giving critical equipment a new lease on life.

What Are Three Possible Pitfalls That You Should Avoid When Selecting An Emergency Equipment Supplier?

Many companies in a hurry start production as quickly as possible with any available partner and later face secondary standstills in case of premature gear failure or poor precision, which turns out to be even more costly. One of the most common causes of failure of CNC gear replacements is inadequately judged key competencies of the supplier. Here are three core pitfalls to watch out for:

Lack of material and heat treatment guarantees result in a short gear life span

If the supplier cannot provide clear material certification, such as an original manufacturer's material certificate and standardized heat treatment process reports, then it goes without saying that the gears are defective right at their source. Manufactured using substandard steel, or treated with rough heat treatment like uneven quenching, the surface hardness of the teeth will be poor. With poor wear resistance, it will break under load. The lifespan will be far shorter than expected and cannot fundamentally solve your downtime problems.

Poor gear accuracy arises due to the lack of appropriate testing procedures

An unrigorously tested gear is a time bomb. Without the specialized equipment such as gear measuring centers and coordinate measuring machines, the supplier can only depend on his experience in assembly. The result is invisible errors in tooth profile and direction. Even though such a gear can be installed, it will result in increased equipment noise and vibration, loss of machining accuracy, and will, in essence fail to meet the requirements of precision transmission.

Vague delivery time commitments render emergency repairs meaningless

Vague promises, such as "deliver as soon as possible" or "about a week", mean absolutely nothing in an emergency. Suppliers not having clear production plans and effective processes are extremely vulnerable to internal problems that may delay delivery; and your whole emergency repair plans may completely spiral out of control with waiting time possibly extending beyond waiting time of the original manufacturer.

A reliable emergency gear supplier needs to be quick, but more importantly, it should have core technical strength for gear longevity and precision, project management capabilities that are trustworthy and punctual. This ensures that every emergency purchase you will make is a reliable guarantee for production recovery, not the beginning of another problem.

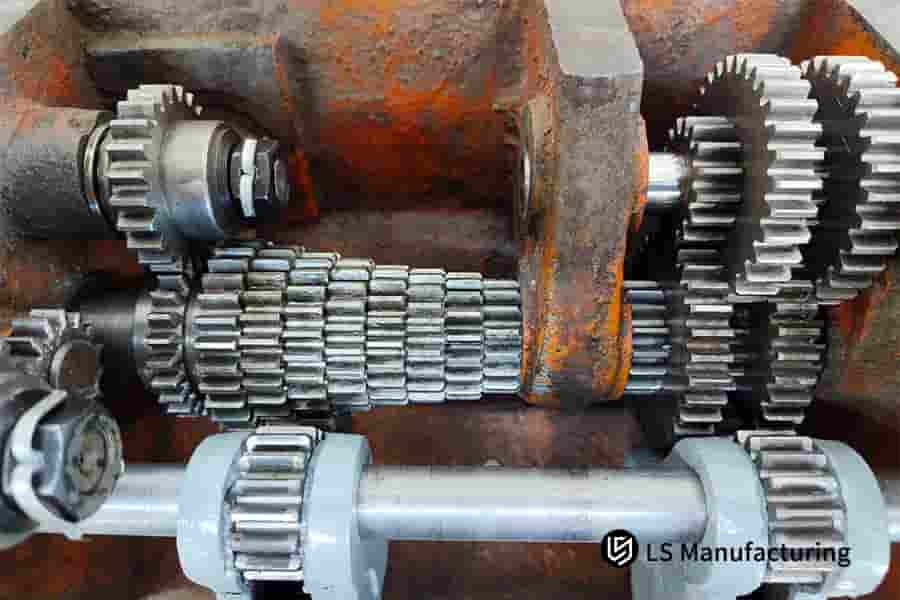

Figure 5: Example image of rusted lathe gears that need repair by LS Manufacturing

What Are The Easy Steps To Start Your Emergency Gear Replacement Project Now?

You don't need to worry about complicated procurement processes. The path of collaboration with us is very simple and efficient. Initiate your 5-7 day gear delivery process with just a phone call or a message; leave the rest on us. From contacting us to resumption of production, it involves only these four crystal clear steps:

- Requirements: Just call us on the phone, online customer service, or email, with gear drawings 2D/3D, equipment model, or photos of damaged gears. Then our professional engineers will connect with you right away to confirm all technical requirements and make sure everything is accurate.

- Confirm the right quote and delivery time: We will provide a formal quotation in one hour, including an itemized quotation of detailed costs, materials used, and a guaranteed 5-7-day delivery period. This order would then take immediate effect upon confirmation and enter a dedicated, expedited channel of production.

- We perform precision manufacturing with parallel quality inspection: No action is required from you at this stage. We mobilize resources across the entire process: from precise material cutting to CNC machining and controlled heat treatment, with precision testing during manufacturing of gears to ensure accuracy and performance meet standards, all the way to timely delivery.

- Your receipt of the gears and rapid resumption of production: You will be delivered a package comprising completely new high-precision gears, a full material report, and a certificate of conformity. The gears are ready for use straightaway, and your equipment will be back in efficient operation in no time, thus reducing losses from downtime.

You can easily transform the pressure of emergency gear manufacturing into our efficient and reliable standard operating procedures by taking just one simple first step. We know time is money. So we take advantage of the simplest collaborative interface, which ensures the most reliable solution in the shortest time and with fewer communication costs to immediately stop downtime.

FAQs

1. I don't have gear drawings only damaged old parts. Can you make them?

Absolutely, we can help with professional reverse engineering. We undertake comprehensive mapping of old parts using a high-precision coordinate measuring machine to accurately acquire all geometric parameters, with the guarantee that manufactured gears will be exactly as those in the original design. Sometimes, we can even optimize the design based on wear patterns to extend service life.

2. Does the 2.5-7 day lead time include weekends?

Yes, this lead time is 5-7 calendar days. We offer 24/7 production service, and urgent orders will be prioritized. For particularly urgent orders, we also have an expedited channel; we will coordinate resources to strive for delivery in the shortest possible time.

3. Do your gears have any quality guarantee? What certification documents are provided?

We offer a strict quality assurance. Each gear leaves the factory with a complete set of certification documents, including raw material quality assurance certificates, heat treatment process reports, tooth profile and direction accuracy inspection reports to make sure performance is transparent and controllable and quality traceable.

4. Are prices higher than for OEM parts?

Competitively priced: With our prices being highly competitive, we usually outbid the competition while guaranteeing or even surpassing OEM quality. More importantly, our rapid delivery can recover significant losses caused by production stoppages at overall costs much lower than waiting for original parts.

5. How can I confirm that the gears you manufacture are a perfect match for my equipment?

Before starting production, we will provide a form to confirm the gear parameters, including module, number of teeth, and pressure angle. We will not start production until we receive your confirmation in writing to rule out mismatched products from the very start.

6. Do you support small-batch or single-piece production?

Of course. Single-piece and small-batch emergency production are our core services. We have established a flexible, rapid production line with no minimum order quantity, specially set up for your prototype verification, spare parts replacement, or emergency repair needs.

7. My equipment brand is relatively niche; can you handle that?

No matter how niche the brand of the equipment or how old the model is, this is our area of expertise. Boasting extensive customization experience and a strong technical team, we have successfully solved gear supply problems for plenty of non-standard and discontinued equipment.

8. If I submit my request now, when is the earliest the production can start?

Production preparation begins right after the confirmation of the order. Normally, if it is within working hours, from confirmation to preparation of materials and completion of programming, it takes just about 2-4 hours at most, after which the substantive machining can be initiated with minimal waiting time.

Summary

Lathe gear breakage should not escalate into a long-term disaster in production. As your reliable partner in precision gear manufacturing, LS Manufacturing has transformed its promise of "delivering high-performance replacement gears within 5-7 working days" into a stable and predictable solution through its mature process database, rigorous quality control system, and efficient emergency response mechanism.

Contact us anytime! Our emergency service team is standing by every day for 24 hours. It will only take a phone call or an online message to connect you with a professional engineer within 30 minutes to quickly confirm the technical parameters and start the tailor-made production process. From precision blanking to CNC machining, from heat treatment to comprehensive quality inspection, we will put your order first to ensure rapid production recovery and reduce your losses in downtime.

📞Phone: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website: https://lsrpf.com/

Disclaimer

The content on this page is for informational purposes only. LS Manufacturing makes no representations or warranties, express or implied, regarding the accuracy, completeness, or validity of the information. It should not be inferred that third-party suppliers or manufacturers will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type, or processes through the LS Manufacturing network. The buyer is solely responsible for this information. For parts quotations, please specify the exact requirements for these parts. Please contact us for more information .

LS Manufacturing Team

LS Manufacturing is an industry-leading company specializing in customized manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precision CNC machining , sheet metal fabrication , 3D printing , injection molding , metal stamping , and other one-stop manufacturing services.

Our factory boasts over 100 state-of-the-art five-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries and regions worldwide. Whether it's small-batch production or mass customization, we can meet your needs within 24 hours. Choosing LS Manufacturing means choosing efficiency, quality, and professionalism.

For more information, please visit our website: www.lsrpf.com .