Gear machining services offered to the automation industry or heavy machine industry because the accuracy, dependability, or optimal performance of the gears directly impacts the performance of the system or machine as a whole. In regard to the engineer/purchaser of the gears, issues such as noise, wear, or pitting are involved.

The origin of all these challenges would normally begin with the selection of suppliers that do not have the capability of performing precision engineering. The matter of fact is that it would be rather difficult for the normal producer of the goods and services marketed by the business to live up to the high standards of the geometric specifications, let alone the specifications measured in microns. The aim of this essay is to put the spotlight on the nature of the services offered along with the justification of the charges received by way of the cost of gear machining.

Gear Machining Services Quick Reference Guide

| Category | Key Processes | Common Materials | Typical Applications |

| Gear Cutting | Hobbing, Milling, Shaping, Broaching | Steel, Cast Iron, Brass, Plastics | Automotive, Industrial Machinery |

| Gear Finishing | Grinding, Lapping, Honing, Shaving | Alloy Steel, Tool Steel Aerospace | Aerospace, Precision Instruments |

| Gear Forming | Forging, Stamping, Powder Metallurgy | Steel, Aluminum, Sintered Metals | Heavy-Duty Drives, Consumer Goods |

| Non-Metallic | Injection Molding, CNC Machining (Non-Metal) | Nylon, Delrin, Composites | Food, Medical, Low-Noise Gearing |

| Post-Process | Heat Treatment, Deburring, Coating | Various (Post-Treated) | All (for Durability/Performance) |

Gear machining involves a broad process, which includes cutting, finishing, and forming operations of various metals and plastics used in different industries, which include the automotive industry, aerospace, among others. This process includes prototyping, mass production, adding secondary processing, depending on the required service, which may include heat treatment. It is a right mix that retains precision, strength, and function.

Figure 1: Custom gear production solutions for various gear types by LS Manufacturing

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

There are literally several hundred articles available on-line that discuss how gears can be machined. So why must you read what follows in this article, in my opinion? We are not theorists, but rather in the midst of a battle zone each day in our shops, fighting alloys that are difficult, and geometries that are more complex due to the needs of gearing. This article actually discusses what we are doing, and it’s no theory.

Our unmatched real-world experience has been based on the stringent industry standard in the form of guidelines provided in the following bodies: ASTM International and the Aluminium Association (AAC). It would be difficult to get an accurate count on the number of projects that we have achieved. It varies from Aerospace application gears, where the notion of failure does not even exist, to heavy-duty equipment drives. With every gear delivery, our real-world experience has enhanced the world over.

All these recommendations and tips developed within the article are made based on this vast knowledge and tried out in a challenging trial of cutting fluids, metal chips, and quality assurance. We would like to share some of the best practices developed out of a vast implementation and share knowledge pertaining to various materials and their machining as well. This knowledge benefits us and can benefit you to become great.

How Exactly Does A Gear Machining Service Operate To Ensure The Highest Precision?

Our commitment to achieving the highest degree of accuracy begins with the recognition that every accurate part translates into a controlled closed-loop process rather than a set of discrete actions. By LS Manufacturing's definition, the highest degree of quality for our gear manufacturing services means the integrated process of predictive analysis, real-time process observation, and accurate verification from material to finished part.

- Data-Driven Basis & Machining: The path to flawless precision gear machining can be ensured with qualified material backed by impeccable setup, all of which is made possible with our database for optimization. The cutting conditions of the CNC machining process are no more dependent on graphs but on data-driven analysis. The most important idea about the data-driven approach concerning the CNC machining process has to do with ensuring maximum tool path velocity efficiency, speed, and feeds with the very first process itself.

- Real-time in process control: The attainment of true accuracy is maintained while constantly being updated. The process of simultaneous measurement, carried out in modern sensors and probes used in CNC machining, makes it easier to determine tool wear and work-piece size. This enables immediate micro-adjustments, a critical capability for maintaining precision control in complex operations like hobbing or grinding. The key point to note in this connection is the prime importance of our process of adaptive manufacturing: every process is to provide a product right first time.

- Thermal Management for Stability: Thermal management for stability is one of the essential processes involved in achieving the required levels of accuracy. In our project, we have used properly calibrated furnace machines which have functions of multicycles in attaining the desirable material qualities. This specific process is actually very important in ensuring the elimination of any form of distortion of the gear.

- Full Validation-Comprehensive Verification and Certification: The last stage involved within the validation process is absolutely valid. Dimensionally tested to the extent that the component is 100% tested using high-accuracy Coordinate Measuring Machines (CMMs), each component that passes this quality inspection is validated. In addition, an electronic copy is made to be able to trace the validity of its quality requirements.

The precision gear machining performed by us cannot be replicated in a well-established integrated cycle encompassing data-optimized planning, flexible CNC machining, heat treatment aimed at stress relief, and quality inspection performed by CMM. This internal feedback process focusing on ‘data’ is the only means to guarantee precision control on the quality of gear machining performed by us.

What Are The Key Factors Affecting Gear Manufacturing Costs?

The final quote will entail the assessment of personal cost drivers. The gear machining price cannot be estimated with a single number but a number of different related variables. We will discuss these cost factors for you how and where your money is being spent, and how these spending habits can aid in optimizing spending activity. The variables that affect gear machining cost are:

| Factor | Description | Impact on Cost |

| Material | Cost of processing the raw material into an alloy (for instance, aircraft steel as compared to steel) | High. Directly impacts raw material cost and machinability. |

| Design & Precision | Overall gear complexity, gear module, and desired AGMA quality class of gear (Class 12 vs. Class 8) | Very High. The stringent requirements regarding tolerance levels accelerate exponentially based on processing time in machine shops. |

| Process & Volume | Machining process requirements (5-axis machining, 3-axis machining, and others). | Medium to High. Complex process complexity increases setup, while volume allows for cost amortization. |

| Post-Processing | Required treatments: hardening (carburizing), grinding, coating, etc. | Medium; Will add some processing tasks based on required performance. |

To give a brief overview, final gear machining price depends on material, design requirement, technology used, and requirement of further processing. LS Manufacturing, which are reliable gear machining suppliers, are benefited because we analyze these cost factors when deciding on the process complexity in which we are supposed to invest for getting the cost vs performance ratio.

How To Obtain An Accurate Gear Machining Quote?

Securing a precise and competitive gear machining quote requires clear communication and detailed information from the outset. The accuracy of the quotation would depend on the quality of the initial inquiry made. For obtaining the best quotation in the shortest time span, just follow the steps below:

- Prepare a Comprehensive Inquiry Package: Begin by providing complete technical documents. Essential items include detailed 2D drawings with all tolerances, 3D CAD models, material specifications, heat treatment and surface finish requirements, and your target annual volume. This comprehensive data allows us to thoroughly evaluate your custom gear machining project, eliminating guesswork and ensuring the quote addresses all your needs.

- Engage with Collaborative Review and DFM Analysis: After your inquiry has been received, rather than giving answers to a number of questions immediately, a collaborative review and DFM analysis-Design for Manufacturability review by a group of sales engineers is undertaken. The goal of this review is to determine production issues and material efficiencies that would improve performance or reduce the cost of performance.

- Receive a Detailed, Transparent Quotation: Once the technical evaluation process is complete, a detailed quotation will be provided to you. This quotation separately lists every aspect of the cost, right from material to machined, setup, tooling, finished, and inspected, and there are no hidden charges involved. This is optimized DFM analysis, which provides you with every clarity you desire on what you are paying for in your gear machining quote.

In a nutshell, get a quote, which entails value engineering, can be achieved involves an effective description for an inquiry as well as being a partner with us. In light of a professional DFM analysis, goes beyond simple pricing to offer a transparent, optimized solution for your custom gear machining project, ensuring clarity and confidence before production begins.

Figure 2: Accurate gear manufacturing services and their pricing details by LS manufacturing

What Is The Core Difference Between Precision Gear Machining And Traditional Machining?

The point of difference is based on the systems related to tolerance, consistency, and performance output in terms of overall performance. While both produce gears, how gear machining works at a high level focuses on predictable, microscopic accuracy and superior material properties, directly impacting longevity and efficiency. There is a definite observable categorization related to the best gear manufacturers and the average workshops related to the necessary elements:

| Aspect | Precision Gear Machining | Conventional Machining |

| Equipment | Uses specialized, accurate CNC gear hobbers, grinders, and lathes Involves closed loop control, SPC, and in-process verification. | Often relies on general-purpose or manual machines. |

| Process Control | Uses a combination of closed-loop systems, SPC, in-process verification. | Involves the need for the human factor. |

| Engineering | By using special processes such as hard finishing or honing processes. | Primarily discusses primary shaping for primary size requirements. |

| Final Outcome | Ensures a strong fatigue strength, functioned with a lower noise level, and a longer lifespan. | It may influence noise level, loading capacity, and lifespan. |

The difference, in the ultimate analysis, hinges on the emphasis on certainty and basic shaping. The technological advantages regarding equipment and basic engineering control of precision gear machining is thereby directly related to the concreteness of the added value of technology itself. This quality comparison explains why gears are essential for demanding applications where reliability is critical.

How Can Custom Gear Machining Meet Specific Application Requirements?

True engineering value is realized when a component is not just manufactured, but specifically designed and built to address the unique challenges of its final environment. Our custom gear machining services are built on this principle, delivering purpose-engineered solutions for a wide range of specific applications.

Application-led design consultation

The analysis would begin in your application. The engineering would try to come to an understanding regarding working conditions like cycles, speed, noise levels, temperatures, and space with the higher management. All this would be done to ensure that the resulting custom gear machining specifications are applicable to your system.

Integrated Material and Process Engineering

All the variables are optimized for the application. For extremely stressful environments, for example, we could call out a heavy-duty alloy steel, which would necessitate a very deep case carburizing process. For a robot, for example, which would require lightness and optimal movement capabilities in order to optimize its performance, a specialized composite material with an unconventional tooth arrangement would be the solution. This holistic approach to materials, geometry, and treatment is central to our advanced gear machining services.

Advanced Finishing for Guaranteed Performance

The last step in ensuring that the work of guaranteed performance is achieved involves a number of finishing operations that are performed by professionals who handle such areas of expertise. In this case, we would have to perform the super-finishing operations or even the honing process for the gear that would be needed by the application requesting a specific application. The prototypes would be tested in order to try out the performance.

In summary, meeting specific applications requires moving beyond standard specifications. The application services provided by our company related to gear machining services have been identified for the purpose of adding value for our customers. The whole process would involve application technology consulting, material process development, and validation. It simply would not be possible to get a better mechanism that would help us assure that gear optimization solutions are that which we provide related to a light aircraft gear, a heavy torque industrial drive, et cetera.

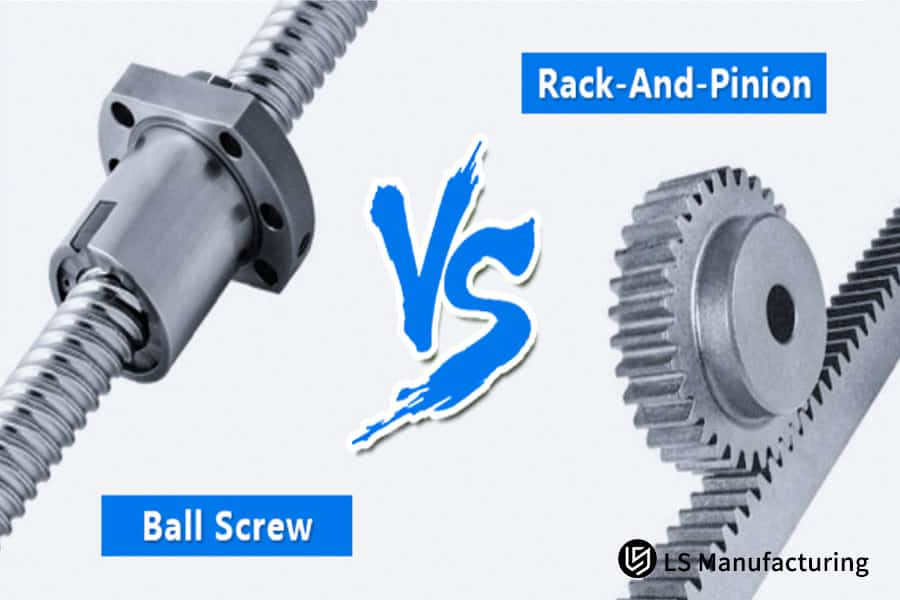

Figure 3: Contrasting ball screw and rack and pinion manufacturing methods by LS Manufacturing

A Successful Case Study Of LS Manufacturing Customizing High-Load Titanium Alloy Gears For The Aerospace Industry

In the scenario wherein the leader of an aerospace firm found himself facing a performance hurdle with a significant transmission part, more than a supplier what the leader needed is more than a supplier. Furthermore, one of the problems that the leader of this firm faced has been eliminated with the arrival of engineers with a proposed solution regarding how one can transform this gears design issue into a performance issue and how more technical collaboration will lead to a solution of this performance issue.

Client Challenge

Some of the customer demands were to provide the basic gears that were to be used on the high altitude actuator system within the UAVs that the customer owns. The said gears were being used in conditions that had very high cycles and temperature variation levels. The very first samples produced were those with micron-level deformation at the point when the testing began on ground conditions. Such were posing very severe threats to the overall safety of such aircraft since it had experienced considerable delays.

LS Manufacturing Solution

In fact, the process began with the analysis of failure in metallurgy. From analysis to the solution itself, our engineers had to understand that the current standard process related to the heat treatment process could in no way be linked to the phase change process in the titanium alloy. Our proprietary process developed in-house related to the process of vacuum heat treatment involves several steps. At the same time, the engineers further optimized the process of 5-axis CNC machining in the critical reduction process.

Results and Value

The produced gears fulfilled the requirement for a reduction in weight by 15% and not only fulfilled but surpassed the fatigue life requirement by a large margin of 200%. The requirement for 100% quality was strictly followed. The aforementioned customized ordered part shows that in solving the problem associated with the production schedule for the client, there has been an establishment of the business relation for the UAV.

Any For instance, in the case example, the need to address the critical performance sectors like the aerospace industry would necessitate a business partnership with either the company that possesses superior skills or the skills of the engineers, as indicated below: There are many organizations trying to solve the manufacturing or production aspect, but the proposal will act as a science solution as a whole to be successful from the parts/projects point of view.

In need of specially designed and ultra-reliable gears? We will provide correct solutions.

What Core Capabilities Should Be Considered When Selecting A Gear Machining Supplier?

This selection of the best gear machining suppliers is considered a core decision, having wide impacts on your final product. You can check the below-mentioned guide to make sure you choose the best supplier for your most critical projects and acquire the needed knowledge on how to select the best suppliers, with better knowledge of their core competencies rather than the final price.

Technical and Engineering Support Capabilities

Next to the machinery, the next most important factor would be engineering expertise on the part of the supplier. Interview the experience of their tech people in DFM, metallurgy, and process improvement. It's a big plus if the partner really looks at your designs to see if they have suggestions to perhaps increase the performance or reduce costs.

Manufacturing Technology and Quality Certifications

The equipment list and quality system must be assessed. In today’s world, what is required is a CNC hobber, grinding machine, and/or machining center that possesses multi-axis capability. Most importantly, it must be equipped with a quality management system that ensures the quality of its equipment and more importantly, its certification in quality, specifically in ISO 9001. Finally, the quality standard of the aerospace market requires an AS9100 quality management system.

Proven Track Record and Project Management Process

Searching for their portfolio to check case studies of their previous connections with cases similar to your business and reviews of their previous customers will also be important. Furthermore, their project management like yours and their communication should also be evaluated. Trustworthy suppliers will always demonstrate the transparent management of schedules and milestones of their projects to keep yours on track, which is a vital evaluation criteria for partnership success.

In short, how to choose a gear machining suppliers involves considering their problem-solving expertise in engineering, their technological skill in terms of quality system management expertise, and performance on specific jobs. TBy applying these evaluation criteria to understand a supplier’s true core competencies, you move beyond a transactional relationship to secure a strategic manufacturing partner that ensures the success and reliability of your critical components.

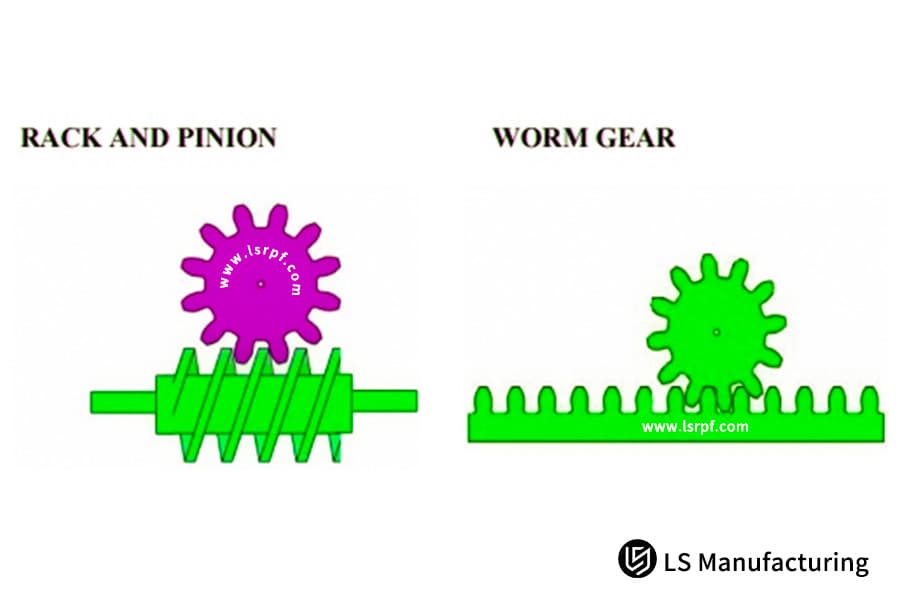

Figure 4: Describing worm gear mechanisms and their production processes by LS Manufacturing

How Do Excellent Gear Manufacturers Guarantee Product Quality And Delivery Time?

Regarding concerns for companies with critical component-based operations, the following two aspects of choosing the right gear manufacturer have proved absolute necessities: the quality of gears and assurance that your schedule will be met. With respect to our company, LS Manufacturing, we understand fully the importance of your requirements for your project management.

Integrated Quality Assurance through a Closed Loop System

It begins with a very thorough process of examination at different levels of production. The quality check in process is very strict in a constant statistical manner, finally completed during the final check to ensure that every item coming out meets an exacting quality assurance in every respect qualifying every single item a perfectly manufactured gear. Identify the role of metrology in creating a perfect gear.

Transparent Project Management for Predictable Delivery Time

We also possess the latest technology in terms of ERP and MES that ensures our clients are aware and in control of the entire process. The set of tools in the project management enables us to access all the orders until shipment as well as material allocation for the materials that the clients have ordered. We also possess a live view of the products that are manufactured as well as the consumption of the materials that we manufacture. Taking control of the schedules ensures that there is the correct delivery time for all the projects.

Operational Excellence and Proactive Communication

To ensure the timely delivery, which is not a function of our software since we will be determined on efficient and agile production capacity, your point of contact will be the team of dedicated staff doing the planning and project management on behalf of our company, ensuring that in this way, you are never left in the dark since the emphasis on your timeline will get its rightful place in our working context.

In short, what we mean is that the commitment to being a reliable company at LS Manufacturing can be ensured by the integration of an effective and closed-loop quality assurance system, a technology-driven project management process that keeps everything transparent, and our client-partnership approach that takes the initiative. Taken in its totality, it means we are delivering more than high-quality parts at your trusted gear manufacturer.

FAQs

1. Is Minimum Order Quantity (MOQ) specified for gear machining?

Our production management system follows the Agile method of production without a minimum order quantity that we can guarantee. Additionally, we process orders for the production of individual prototypes in order to help lower the associated costs associated with the validation process that the client conducts. Our objective is to ensure it is convenient for the client to move from development to production through our production process.

2. What gear materials are you typically working with?

We have a materials library that holds a number of various metals and non-metals such as the varieties of carbon steels, alloy steels, varieties of stainless-steel alloys, brass alloys, and engineered plastics to name a few. Depending on the load, speed, and your costs of your processes, our engineers would inform you on the availability of equal or better performing materials with lower costs.

3. What is the best possible level of precision?

Since we have the imported advanced CNC gear grinding machines, advanced testing machines, as well as advanced processing technology, we can guarantee the quality to be within the quality level for gear precision in the range of AGMA 12 or higher. The quality level of the gears surpasses the requirements in the aerospace industry in terms of the smoothness of motion, noise level, as well as life.

4. How can my design drawings or intellectual properties be protected?

Our foremost concern and commitment revolves around the protection of intellectual properties, and from the very beginning of the communication process, we are able to come to an understanding regarding the very binding non-disclosure agreement contract with you, if required and agreed upon. These documents are transferred and managed by the strictly encrypted system followed by the hierarchical control process such that your foremost intellectual properties are accessed within the required limits.

5. In how many days can samples be collected following the first inquiry?

As general practice, in relation to standard designs and material gear samples, the standard processing time allowed for delivery would be around 2 to 3 weeks. However, this would be amenable to change based on the complexity of the gear and its production schedule. When it comes to our clients’ urgent projects related to the R&D stage of our product, apart from our standard processing time for delivery, we likewise have an express delivery process in manufacturing the sample.

6. Are there surface treatment and heat treatment services available?

Yes, we have a one-stop solution for the entire process of gear production. The process includes carburizing and quenching, tempering, and nitriding. The result of all these processes gives a positive enhancement of the strength of the gear basic materials. The processes consist of nickel plating, blackening, phosphating, and sandblasting. These processes are used to give a positive enhancement of the wear and corrosion resistance of the gear.

7. What if the gearing components are flawed after machining?

We work towards an object of 'zero defects' and give a guarantee for the delivery of 100% qualified products. Upon discovering a deficiency in quality, which is not the fault of the customer, we will immediately activate our quality emergency program since you will produce the qualified products on behalf of us free of charge with the highest priority for the earliest delivery to meet your project schedule.

8. Does one have a global shipping facility?

We fully support the international shipping service and have extensive experience in international supply chain management. We work in close coordination with a number of prominent international logistics companies like DHL, FedEx, and UPS, and can provide the best, cheapest, and fastest means of transport according to your time budget and get the merchandise shipped to any corner of the world.

Summary

The selection of the supplier for the machining of the gear for your business is one of the most critical elements of a technology and business transaction. By the time you have finished with the material presented in this article, you must have experienced that the need for precision in gear manufacture goes far beyond gear machining. Full professionalism in material science and process technology must include the procurement stage to the verification stage. With a profound knowledge base in technology and a service-driven service attitude, we at LS Manufacturing aim to win your trust as a technology partner.

Your project demands the best possible solutions in gears. Act now! Simply click on the button below to "Get Your Customized Gear Machining Quote" and send your drawings and specifications to our senior engineers, and we will send your free analysis and price quote in 24 hours! The success of your product can be greatly improved by the know-how and experience of LS Manufacturing!

Guaranteed delivery, guaranteed precision. Choose efficient and professional gear machining services to provide core support for your critical verification work.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.