Gear cutting is the basis of precision transmission, and its quality determines the performance of the equipment directly. In most cases, gears are the pain points in the industrial robotics and automation industries: not enough precision, short life, and long lead times. Its root cause lies in the limitation of processes and the lack of deeply collaborative partners.

The paper will illustrate in-depth analyses-from material science and innovative design to advanced manufacturing processes-of the full-process capability in precision gear cutting at LS Manufacturing, focusing on how best to provide high-performance, highly reliable, cost-optimized gear machining solutions. Allow me to save your time as I present the content of the article below.

Gear Cutting Technology Quick Reference Guide

| Module Category | Core Points |

Specific Explanation |

| Cutting Principle | Material Removal and Forming Mechanism |

The excess material is removed point by point through the relative motion of a tool and workpiece along the involute, and other tooth profiles. |

| Processing Method | Hobbing/Shaping/Milling Multi-Process Adaptation | Hobbing is suitable for high-volume, high-efficiency production, shaping fits great for internal teeth/narrow spaces, while milling meets high-flexibility requirements. |

| Tool Technology | Coating and Geometry Optimization | Employing TiAlN coating for wear improvement and optimization of the rake angle for balancing vibration reduction and chip removal. |

| Material Consideration | Machinability and Synergy in Heat Treatment | The heat generated by the cut should be controlled to avoid changes in metallographic structure for carburized steels like 20CrMnTi. |

| Precision Control | Dynamic Accuracy and Error Compensation | Using the online detection and temperature compensation technology, the pitch error is stably controlled within ISO 5 level. |

| Development trends | Dry cutting, intelligent monitoring | Use micro-lubrication technology equipped with vibration sensors to promote environmental friendliness and predictive maintenance. |

From a single technology of machining, modern gear cutting has developed into a systems engineering approach, bringing together materials science, dynamics, and intelligent monitoring.Success in matching exactly the process method and tooling system according to batch size, accuracy, and operating conditions, incorporating heat treatment deformation control and intelligent compensation in the whole process for synergistic optimization, is the key. It is this systematic thinking that provides core competitiveness in creating high-reliability gear manufacturing.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

LS Manufacturing has accumulated fifteen years of technical experience in precision gear cutting since its foundation and is deeply involved in R&D of gear transmission systems in key fields like aerospace and high-end medical equipment. By strictly upholding the standard of ISO 13485 for Medical Devices in manufacturing medical gears, we can make sure that implantable device transmission components are biocompatible and reliable. For the manufacturing of aerospace gearboxes, we wholly meet strict specifications set by the International Aerospace Quality Group (IAQC), adopt adaptive cutting technology, control the tooth profile error of turbine drive gears within ±0.005mm.

Based on our experience in serving high-end industries, we have built up our knowledge base in gear cutting, covering material properties, tool paths, and thermal deformation control. For example, we apply a special helical interpolation process to control the roughness of the tooth surface to Rz≤3.2μm in the manufacturing of low backlash transmission required for robot joints.

Ultrasonic vibration-assisted cutting technology is applied to raise the machining efficiency of hardened steel gears with HRC60 by 85% without micro-cracks for heavy-duty wind turbine gears. The following guide has been prepared by synthesizing the measured data and summaries of fault analyses of precision gears supplied to tens of thousands of customers. While cutting tooth gears, we do not merely focus our attention on theoretical parameters; we emphasize performance stability in extreme conditions such as high speed and load.

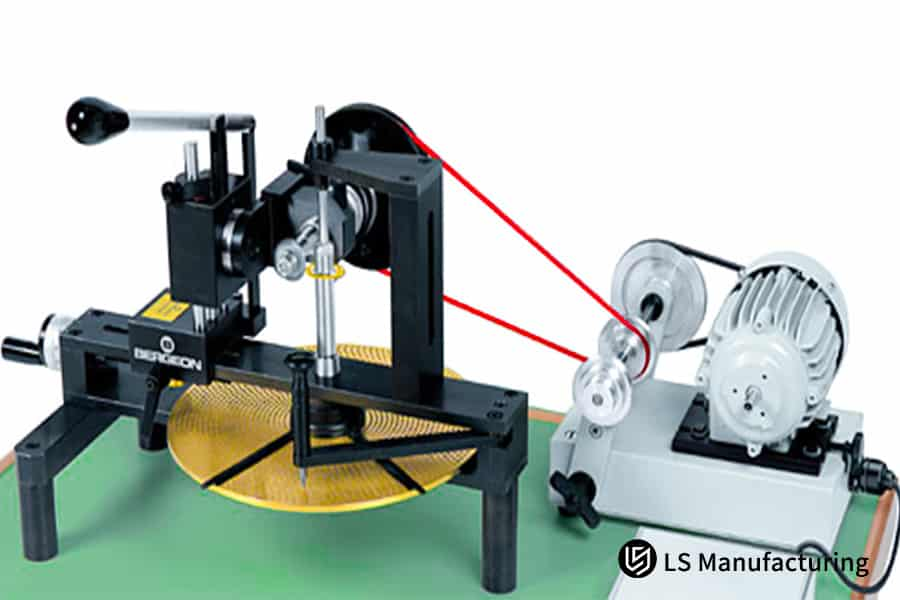

Figure 1: Technical demonstration of precision gear machining by LS Manufacturing

How To Choose The Best Material For Your Gear Application To Optimize Performance?

One of the most critical strategic decisions during the preliminary stages of gear design is material selection, which will determine its ultimate performance, reliability, and cost. Applications may differ greatly in strength, wear resistance, corrosion resistance, or noise characteristics. Proper gear materials selection can avoid premature failure or insufficient performance from the very beginning. Several typical materials are summarized in the following table for their characteristics:

| Material Type | Core Characteristics & Typical Applications Summary |

| 4140/42CrMo Alloy Steel |

It has high strength with good toughness; hence, it can find applications in heavy-duty gears in heavy machinery after quenching and tempering. |

| 9310 Carburized Steel |

Very high surface hardness combined with good core toughness when carburized; for use in high stress gears, particularly in aerospace and high-performance gearboxes. |

| Brass |

Excellent corrosion resistance and good machinability; used principally in low-load, corrosion resistant instruments or small transmission applications. |

| Engineering plastics (such as POM) | Self-lubricating, lightweight and low-noise, it is an ideal choice for light-load, low-noise or lubrication-free applications. |

Success in gear design lies in the perfect match of materials to operating conditions. No material could be described as "best" for general application but rather "most suitable." Professional manufacturing engineers at LS Manufacturing provide material selection analyses based on your load, speed, environmental requirements, and cost targets to ensure that your gears perform exceptionally well through their lifetime.

How Does Great Gear Design Reduce Both Cost And Enhance Performance Before Manufacturing?

Excellent gear design lies at the very root of ensuring functionality and constitutes one of the core levers for the control of gear machining costs by improving overall performance right at the source of product development. A manufacturing-oriented design strategy can lead to the dual optimization of quality and economic benefits by avoiding subsequent difficulties in machining at the drawing stage itself. The added value brought about by excellent gear design comes mainly from the following approaches:

Efficiency in cut improves with the optimization of parameters

Selection of the optimum gear parameters, such as module, pressure angle, and helix angle, represents one of the most important keys to reducing cutting resistance and avoiding overcutting phenomena. In this respect, machining time can be shortened, and tool wear can be reduced due to this; this directly minimizes gear cutting costs. This systematic approach enhances production efficiency by extending tool life and further contributes to sustainable and economic manufacturing operations.

Modification of tooth profile ensures performance of service

This advanced design methodology effectively compensates for microscopic load-induced deformations during gear operation and avoids strategic stress concentrations at the tooth ends through optimization in tooth profile modifications. With the use of such engineering solutions, the gear system exhibits superior fatigue resistance, considerably lower noise levels in transmission, and proactively avoids any chances of early failure.These integrated improvements ensure superlative operational reliability throughout the product lifecycle besides setting a robust foundation for durable power transmission systems.

Topology reduction and material use efficiency

Advanced computational analysis through topology optimization systematically removes material redundancies from the components while precisely maintaining the requirements for structural integrity and strength. This intelligent approach to design achieves drastic weight reduction, enhances material utilization efficiency, and saves raw material consumption considerably. Furthermore, this process, by minimizing unnecessary material volume, will contribute effectively to reducing machining operations and associated production time, thus comprehensively reducing costs through the manufacturing cycle while optimal mechanical performance is maintained.

In a word, great gear design bridges theory with practice. With extensive experience in gear design, LS Manufacturing's engineering team will be able to help you achieve simultaneous optimization of both performance and manufacturability in the design phase, reasonably controlling the cost of gear cutting and effectively improving product reliability from the source.

Hobbing, Shaping, Or Milling? How to choose the right method of gear cutting?

The right choice in gear cutting methods will balance three major factors: machining efficiency, precision, and cost. Each gear machining process has its unique capability boundary. Understanding the characteristics of each process is the very foundation for developing the best technical approach. For comparison, the following table briefly outlines the characteristics of three mainstream processes:

| Process Method | Principle and Applicable Scenarios |

Economic Characteristics |

| Hobbing | Continuous generating method; recommended for high-efficiency, high-volume machining of external cylindrical and helical gears. |

Extremely low unit cost for large batches but calls for highly specialized cutting tools. |

| Shaping | imulates gear meshing and is preferred for machining internal gears, double gears, and shoulder gears. |

Comparatively speaking, its efficiency is low, but it can resolve some structural problems. |

| Milling | Indexing with general-purpose cutting tools; suited for manufacturing prototype, small batches, and extra-large module gears. |

Highest flexibility: no special cutting tool is necessary in small batches. |

In general, choices of gear cutting methods are made according to batch size, types, and precision. Gear hobbing is the most effective method for machining external gears in large volumes; shaping can solve the problem of internal gear machining or special structures, while milling offers unrivaled versatility. LS Manufacturing has a great deal of experience in every process of gear machining and can recommend, according to your needs, an economical and efficient technical solution for you.

Figure 2: Coolant application in precision gear machining by LS Manufacturing

What Precision Grade Do Your Gears Require? (ISO1328/AGMA2000)

Gear machining precision grade is one of the key indicators of gear quality, which determines directly the smoothness of transmission, noise, and life. A deeper understanding of the grade classification found in standards such as ISO 1328 or AGMA 2000 is important for any precision gear customization and cost control. Different grades mean different application scenarios and different prices; appropriate selection of grade is the key to the best cost-effectiveness. Comprehensive consideration should be made in the following aspects when selecting precision grade:

Application scenario determines the basic grade

Relationship of Inspection Items and Cost

Balancing Overall Performance

In a word, the choice of the precision class of gear machining is a very important techno-economic decision. LS Manufacturing, equipped with high-precision machining equipment and a comprehensive inspection system, can reliably achieve ISO 6-7 and above precision gear customization, and provide the most cost-effective precision level recommendations and solutions according to your specific operating conditions.

How to Improve Gear Life and Reliability Through Heat Treatment and Surface Finishing?

Heat treatment and surface finishing are cores in the complete chain of gear machining processes, determining the final performance and service life of gears. These subsequent processing greatly improves the wear resistance, fatigue resistance, and load-carrying capacity of gears by changing the physical and chemical properties of the material surface, thus guaranteeing high-reliability transmission. It should be noted that the performance of gear products is improved mainly by the following two kinds of processes:

- Heat treatment technology optimizes material properties: Carburizing and quenching produce a high hardness, wear-resistant layer on the gear surface with toughness in the core to resist impact loads. In the case of precision gears where high control over deformation is needed, it is possible to obtain a high-hardness surface layer by nitriding, with very small distortions.

- Surface treatment technology improves service performance: Shot peening after heat treatment introduces compressive residual stress into the tooth surface, improving the gear's bending fatigue strength and contact fatigue strength significantly. Grinding and polishing of the tooth surface reduce the surface roughness and thereby minimize meshing noise and wear.

Precisely because of these performance demands, understanding what is gear cutting must extend beyond basic shaping to include essential value-added stages like heat treatment and surface finishing. LS Manufacturing provides fully integrated services spanning from customized thermal processing to final finishing; through precision parameter matching and rigorous step-by-step quality control, every gear is engineered to reach its full potential, ensuring optimal durability and long-term operational reliability.

Figure 3: Spur Gear Manufacturing Technical Specification Schematic by LS Manufacturing

How LS Manufacturing Increases Robot Gear Life By 40% And Reduces Noise?

Client Challenge

In developing its next generation of precision reducers, one industrial robot manufacturer faced excessive transmission noise and a deficient fatigue life in its core gear components during testing.This consequently prohibited the product from meeting the requirements of high-end markets and seriously hindered the project development process.

LS Manufacturing Solution

Firstly, our team optimized material selection, using high-performance carburized steel to enhance basic strength. Then, micron-level precision control of the tooth surface was attained by CNC scraping technology, combined with targeted techniques of modifying tooth profile to optimize load distribution. Meanwhile, adjustment of heat treatment parameters was undertaken to ensure the best matching between gear surface and core performance.

Results and Value

The above case illustrates that, in combination with precision gear customization methodology, LS Manufacturing gear cutting's capability enables performance optimization on the whole chain from material and process to design. LS Manufacturing provides systematic solutions to help customers establish technological barriers in the high-end transmission field and maximize product value.

Optimize gear-cutting conversion rates? Get a tailor-made solution now!

How Does LS Manufacturing Support A Seamless Transition From Gear Prototypes To Mass Production?

- Flexible prototyping capabilities: We utilize high-precision CNC gear machining centers, enabling rapid prototype production without specialized tooling. Digital programming and simulated machining ensure consistent precision in small-batch gear machining, providing reliable samples for design verification.

- Smooth Transition to Mass Production: Based on the accumulated process data in the prototype stage, we optimize the process route for mass production simultaneously.The modular production line configuration and flexible fixture systems enable rapid switching of processing tasks between different gear specifications on the same production line.

- Full-cycle quality traceability system: From the first prototype to mass production of tens of thousands of pieces, we establish a complete quality archive.Using the same testing standards and equipment ensures that mass-produced products have completely consistent performance with the prototype, effectively controlling quality fluctuations.

Via a flexible manufacturing system and standardized process, LS Manufacturing has helped many customers successfully shorten the time from sample verification to market launch. We firmly believe that small-batch gear machining is not only a necessity in trial production but also a very important data base for mass production, which provides a solid foundation for later large-scale production by refining processes early on.

What Are The Key Determinants Of The Delivery Time Of Projects In Gear Cutting?

- Design and Process Review Depth: Drawing feasibility analysis, process planning, and DFM optimization should be done before the project initiation. An experienced team can locate the potential problems right away, while complex designs or multiple revisions directly extend the initial development cycle.

- Supply Chain and Material Preparation Efficiency: The procurement cycle of special steels or imported materials is a major variable. In the case of standard materials, supplies are normally adequately available in stock, while supplies that are customized take a number of weeks in procurement, which determines the commencement date of production directly.

- Machining and post-processing complexity: Machining time will, of course, have a direct relationship with the precision grade of the gear, the method of heat treatment, and test requirements: High-precision gears require multiple clamping and testing processes; in the case of a carburizing and quenching process, strict temperature control will be required, and sufficient time should be allowed for these stages.

- Quality Inspection and Control Process: The tests that gears go through are many: dimensional, hardness, meshing noise, and many more. Although more time-consuming, a rigorous quality inspection system is essential for batch consistency.

- Production planning and supply chain collaboration capabilities: The completeness of ERP of suppliers and the outsourcing management capability may impact directly on the coordination efficiency between different stages. Efficient collaboration can greatly reduce waiting time.

In a word, the cost of gear cutting is closely related to the length of delivery cycles: blind compression of cycles may lead to quality risks, but scientific planning can achieve the best balance between efficiency and cost.When choosing gear suppliers, their ability for supply chain integration and the transparency of production plans should be considered first.

Figure 4: Operation of precision gear production machinery by LS Manufacturing

Besides Price, What Core Capabilities Should Be Considered When Selecting A Gear Cutting Supplier?

- Technical collaboration and DFM optimization capability: Top suppliers can perform manufacturability analysis for customers in the design phase, modify tooth profiles, and optimize parameters to enhance performance and reduce costs at the source. This would be impossible without such an approach; further processing will not only be difficult but also more costly.

- Completeness of process chain; technical profundity: It is required to check whether the supplier has full-process ability, including heat treatment and grinding. Taking LS Manufacturing gear cutting for example, its integrated temperature-controlled carburizing and precision grinding process can guarantee that the increase of gear fatigue life is more than 30%.

- Quality System and Data Traceability: The suppliers should be equipped with gear machining measurement centers, roughness testers and other testing equipment. They should be able to provide full-process quality inspection reports to ensure traceability of quality and attribute of problems.

- Industry experience and scenario understanding: The operational requirements are easily understandable to suppliers experienced in robotics, automotive, or aerospace gear projects, thus providing targeted solutions to reduce project risks greatly.

In this important decision on gear supplier selection, LS Manufacturing gear stands for not only excellent processing capability but also complete technological wholeness in the whole chain, from material to heat treatment and testing. Choosing a gear cutting partner with comprehensive strength will ensure the best lifecycle cost while guaranteeing quality.

FAQs

1. What is the maximum module and outer diameter range of gears you can process?

The range of our processing capability for modules covers 0.5-10 with an outer diameter of up to 800mm. In principle, the assessment of process feasibility needs to be performed according to each gear's specific complexity. Welcome to provide drawings for exact process plans and cycles of processing.

2. What are the common surface treatments used for the gears? How to choose them?

Common processes include phosphating to prevent rust, blackening for aesthetic purposes, and galvanizing for corrosion resistance. Choices will depend on the amount of rust prevention needed, aesthetic requirements, and how the parts will be assembled. We will recommend the most suitable solutions according to your application scenario.

3. Do you have third-party test reports on gears?

We support authoritative third-party testing (SGS and Bureau Veritas certification), and can provide a complete factory inspection report, covering tooth profile and tooth direction accuracy data to ensure all quality indicators are traceable and verifiable.

4. What is the requirement for a minimum quantity order for small batch gear processing?

We support highly flexible production, with the minimum order quantity as low as 1 piece, which can fully meet the needs of sample prototyping, R&D verification, and small-batch production without quantity threshold restrictions.

5. Do you provide gear design and profile optimization services?

We provide free DFM analysis and tooth profile optimization proposals that make microscopic modifications to the tooth profile and effectively reduce noise and improve the load capacity, ensuring gear performance and service life from the design stage.

6.How can I protect the security of my gear design drawing and intellectual property?

We strictly follow the NDAs and use encrypted file transfer and storage systems along with hierarchical access control to ensure that your intellectual property is absolutely secure both legally and technically.

7. What costs are in the gear quotation?

Material costs, machining fees, heat treatment/surface treatment fees, testing fees, and packaging and transportation costs are all to be clearly indicated in the quotation. It is a very transparent cost structure without any hidden charges.

8. Can progress updates be provided during the production cycle?

We will make proactive disclosure of the progress at each key milestone: material preparation, heat treatment, and testing. Photos or videos on site are shared upon request; you are free to have full control over the production status.

Summary

Enhance your product's competitiveness by amplifying it with professional gear. Upload your gear parameters or 3D drawings for a free manufacturability analysis and get an accurate quote by LS Manufacturing experts to start your journey of efficient and reliable collaboration.

📞Phone: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website: https://lsrpf.com/

Disclaimer

The content on this page is for informational purposes only. LS Manufacturing makes no representations or warranties, express or implied, regarding the accuracy, completeness, or validity of the information.It should not be inferred that third-party suppliers or manufacturers will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type, or processes through the LS Manufacturing network.The buyer is solely responsible for this information. For parts quotations, please specify the exact requirements for these parts. Please contact us for more information .

LS Manufacturing Team

LS Manufacturing is an industry-leading company specializing in customized manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precision CNC machining , sheet metal fabrication , 3D printing , injection molding , metal stamping , and other one-stop manufacturing services.

Our factory boasts over 100 state-of-the-art five-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries and regions worldwide.Whether it's small-batch production or mass customization, we can meet your needs within 24 hours. Choosing LS Manufacturing means choosing efficiency, quality, and professionalism.

For more information, please visit our website: www.lsrpf.com .