Gear quality is of vital importance in precision manufacturing. Gear hobbing and gear milling are two dominant gear manufacturing processes, and product performance, cost, and manufacturing efficiency rely on the selection between them. Given that the industry is grappled with an ever-growing pressing need for flexibility and cost reduction and efficiency improvement through to 2025, establishing the best choice between the two represents a fundamental challenge to manufacturers.

This article is designed to provide an extensive review of comparing gear production processes. LS Manufacturing will have a complete comparison of the significant differences between gear milling and hobbing on technical capability, precision machining, sizes that can be utilized in batches, and overall cost.

By doing so, you can effectively select the most cost-efficient and effective process based on your specific production needs, thereby maximizing your return on investment and your competitiveness within the market. To save you time, here’s a quick overview of the core conclusions.

Gear Milling vs. Hobbing Core Quick Reference

| Comparison Dimensions | Gear Milling | Hobbing |

| Process Principle | Indexing, tooth-by-tooth cutting | Generating, continuous cutting |

| Flexibility | High, different tooth shapes can be produced by simply changing the tool program | Low, specialty hobs are utilized for one-off gears |

| Productivity | Low, suitable for small batches, prototypes, and large-module gears | Very high, suitable for medium- to large-volume manufacture |

| Machining Accuracy | High (dependent upon machine tool and tooling) | Very high, excellent consistency |

| Initial Investment | Quite low (general-purpose machine tools can be employed) | High (it needs a special hobbing machine) |

| Cost Per Unit | Economical for small lots, more for big lots | Uneconomical for small lots, very low for big lots |

It is largely dependent on balancing the volume of production, flexibility needs, and cost in deciding whether to use gear milling or hobbing:

- Chosing gear milling: Ideal when you need ultimate flexibility to accommodate a wide variety of products, small series (such as prototype work, special repair), or large-module gears. Its advantage lies in flexibility, not high-volume productivity.

- Chosing gear hobbing: When you're manufacturing standard gears in high quantities and in large lots, it's the obvious cost-saver. Its higher productivity and uniform high accuracy can lead to substantial unit cost savings.

Overall, milling allows flexibility and complexity, and gear hobbing handles scalability and efficiency.

Why Trust This Guide? Real-World Experience From LS Manufacturing Experts

Analysis and conclusions here are rooted deeply in over two decades of on-the-ground experience by LS Manufacturing in the field of precision gear manufacturing. We are not couch intellectuals who love theory; we've fought through the same issues and figured out solutions.

LS Manufacturing's legacy is built on thousands of on-time delivery of successful projects. From rapid mass production of high-torque wind turbine gearboxes to rapid prototyping of complex aerospace industry gears, our product lines vary from advanced five-axis milling centers to very efficient gear hobbing machines.

This comprehensive set of processes enables LS Manufacturing to make objective, bias-free comparisons strictly on a practical basis, untainted by the built-in biases of the equipment providers. For example, by applying high-efficiency hobbing instead of traditional milling to an engineering machinery gear design, we reduce the unit cost by 40% and lead time by 60% without sacrificing accuracy. This is because we understand well the limitations and cost benefits of every process.

All our findings presented in this article are drawn from real machining information, try-and-error experience, and efficiency criteria from our workshops. We strive to translate this precious experience into a simple decision-making guidebook so that you have the best-informed choices on advanced process alternatives.

What Are The Fundamental Principles Of Gear Milling And Hobbing?

In accurate gear manufacturing, milling of gears and hobbing are two significant gear-cutting processes. It provides a basis for the selection of optimum that their basics should be known:

1. Gear Milling:

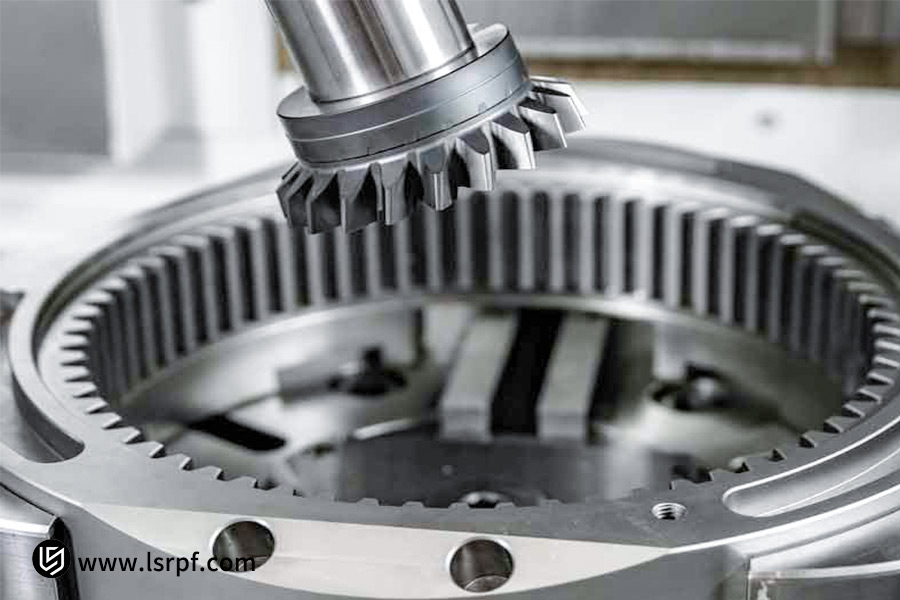

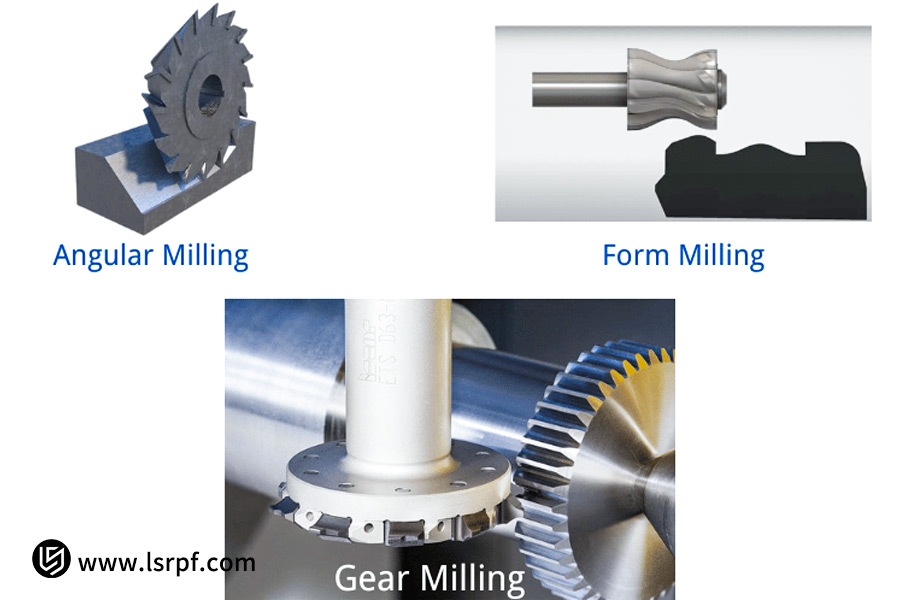

Gear milling utilizes finger-shaped or disc-shaped milling cutter, and its working method can be termed as "tooth-by-tooth machining." The cutting is done when the cutter is in rotary motion, and after the machining of each tooth slot, the workpiece is precisely indexed and advanced to the next position and then the operation is repeated until all the tooth slots are machined.

The process gives very great flexibility, especially on five-axis machining centers. With simple tool and program modification, production of special-shaped gears like helical and bevel gears can be achieved. It finds applications in prototyping, low-series production, and high-module gear manufacturing.

2. Gear Hobbing:

Gear hobbing is a highly efficient "continuous generating" operation. The hob, a structurally helical gear itself, is constantly turning with the workpiece (gear blank) at a prescribed speed ratio, simulating a meshing helical pair. As it turns, it constantly contours the tooth form of the workpiece during the process.

This constant cutting action significantly improves production efficiency compared to indexed milling and is optimally suitable for the high-production manufacture of standard tooth profiles, e.g., transmission gears for use in the automotive sector.

Milling is higher in flexibility and best suited to high-mix, small-lot production; while gear hobbing is higher in efficiency and set up for mass production. At LS Manufacturing, we fully understand the intuitive logic of these two gear cutting operations and, based on that knowledge, create the most cost-effective process solutions for our customers.

What Are The Advantages Of Gear Milling In Terms Of Precision And Surface Quality?

In economic and technical optimization of gear cutting, gear hobbing, due to its unique continuous generating principle as well as high automation potential, notably outshines indexing milling in efficiency of mass production. The efficiency advantage directly translates into lower production cycles and lower unit prices. Below is the explanation of the causes of this efficiency.

1. Higher Precision Control:

The five-axis machining center affords micron-level accuracy control, with errors in tooth profile constantly under control to 10μm. The CNC precisely controls the machining parameters for each tooth groove, offering better pitch accuracy and shape consistency.

2. Better Surface Quality:

Gear milling uses the high-speed milling method. By virtue of optimized speed and feed parameters, it yields smoother surfaces on the teeth and, thus, reduces surface roughness and the requirement for follow-up finishing.

3. Greater Flexibility for Complex Tooth Profiles:

Unlike hobbing, gear milling demonstrates greater flexibility in machining many custom tooth profiles using simple program changes without sacrificing precision using dedicated tools.

4. LS Manufacturing's Practice:

At LS Manufacturing, where we have high-performance gear hobbing machines and automated production cells, we convert the efficiency advantage of gear hobbing into tangible benefits for our customers. For example, in mass-producing transmission gears for an automobile parts customer, our efficient hobbing process combined with automated production lines reduced lead times over 60% compared to the original milling solution without compromising consistent high precision or product quality.

Comparing gear hobbing to milling, gear milling offers significant advantages of precision control, surface finish, and machining of complex tooth profiles that make it extremely suitable for high-precision, low-volume gear manufacturing.

Why Is Gear Hobbing More Efficient?

In economic and technical gearing processing analysis, gear hobbing clearly outshines indexing milling when it comes to efficiency in mass production due to its special principle of continuous generating as well as great possibilities for automation. The efficiency directly results in lower production cycles as well as lower unit cost. Below are the causes of this efficiency.

1. Continuous Generating Principle:

Gear hobbing is based on a continuous cutting operation, where the hob and workpiece are rotated at a fixed ratio of speed, imitating the gear meshing process. The continuous generating motion eliminates idle time from repeated indexing in milling, resulting in continuous cutting.

2. Highly Automated Production:

Modern gear hobbing equipment is easily integrated with automation systems, using robotic arms for automated loading and unloading, and can operate continuously for dozens of hours. This automated production model significantly improves equipment utilization and significantly reduces single-piece processing time.

3. Optimized Cycle Time:

Gear hobbing's superiority over milling is also reflected by its improved cycle time. For example, LS Manufacturing has achieved over 60% productivity improvements over traditional milling on automotive parts customers' high-volume production through advanced hobbing processes.

4. LS Manufacturing's Successful Practices:

We apply high-performance CNC gear hobbing machines and robot-based automated production cells to transform gear hobbing efficiency advantage into actual value for our customers at LS Manufacturing. For example, in the production of high volumes of transmission gears for one of our automobile parts customers, our efficient hobbing process, combined with robot-based automated production lines, reduced lead times over 60% from the original milling solution while maintaining product quality through stable, high precision.

Gear hobbing with its generating principle of continuous type and production characteristic of automatic nature has efficiency advantages of unprecedented kind in mass production and is therefore a central part of technical and economic evaluation of gear processing.

How Do The Cost Structures Of Gear Milling And Gear Hobbing Differ?

In technical and economic analysis of gear machining, cost structure is a prime concern in process choice. Cost differences between gear hobbing and milling are primarily described in terms of a number of dimensions that include equipment investment, operating efficiency, energy use, and maintenance. The following table summarizes briefly the comparison of the major cost factors for the two processes.

| Cost Factors | Gear Milling | Gear Hobbing |

| Initial equipment cost | Relatively low, machine tools with general purposes could be applied (i.e., a four-axis gear milling machine has a ceiling bid price of approximately 200,000-300,000 RMB per unit). | High initial equipment cost: CNC gear hobbing machines require large investments (i.e., a ceiling bid price for a single unit is 1.5 million RMB). |

| Production Efficiency and Unit Cost | Indexing machining is less efficient and suitable for prototypes and small series. | Continuous rolling has high efficiency, with substantially lower unit cost for large series. |

| Energy Consumption and Maintenance Costs | General-purpose machine tools possess moderate energy consumption and acceptable tooling costs. | Specialized equipment consumes more energy and involves higher manufacturing and maintenance costs for specialty hobs. |

| Value Added of Flexibility in Process | High flexibility allows for easy adjustment to diverse tooth profiles and minimal changeover cost. | Low flexibility. There has to be the use of special hobs for special gears and is suitable where there is standardized high-volume production. |

At LS Manufacturing, we understand that just the equipment price or unit process price alone is not sufficient to identify the cost of ownership. We provide customized cost optimization services to customers in the form of technical and economic assessment of gear machining. For example:

- To high-mix, low-volume manufacturing, LS Manufacturing guides customers to take advantage of gear milling flexibility at the absence of the expensive specialty tooling. With optimized toolpaths and programming, we are accurate while being within costs that are reasonable.

- For long-duration, high-volume batch production, LS Manufacturing recommends low-cost gear hobbing alternatives. By helping customers adopt automatic gear hobbing units, even with the up-front cost being high, the extremely high production efficiency and high-precision stability reduce the unit cost, ultimately guaranteeing them a more than 30% reduction in total cost of ownership.

Understanding the cost differences between gear hobbing and milling is necessary to allow for the optimal process choice decision and enhance cost savings and efficiency gains.

How To Select The Optimal Gear Manufacturing Method Based On Production Batch?

When producing precision gears, the selection of gear cutting process is a direct determinant of production efficiency and cost control. Following is a batch size of production decision guide to allow you to equate the optimal processes for producing gears.

1. Small batches (<100 units)--Gear milling is ideal

- Process advantage: Gear milling does not require dedicated tools and can produce different tooth profiles using program changeovers, with a minimum investment in equipment.

- Applications: Tailor-made products, repair components, and prototyping.

- Economical efficiency: Prevents expensive special tooling, keeps production cost per unit under control.

2. Medium to large-batch production (>500 pieces)--Gear hobbing is preferred

- Process advantages: Steady-state generating process allows efficient processing, best suited for mass-produced assembly.

- Applications: Mass-produced gears such as industrial reducers and motor vehicle transmission.

- Economical efficiency: With increasing batch sizes, unit costs decrease significantly, resulting in high return on investment.

3. LS Manufacturing's specialized consulting services:

We conduct expert comparative process examination of gears and provide customers with the optimum solution based on the following parameters:

- Product life cycle and projected amount of production;

- Quality requirements and degree of accuracy;

- Delivery cycle and investment budget;

- Process requirements subsequent to and equipment compatibility.

Selection of the right gear cutting process is a careful deliberation of production batch size, technological needs, and economic benefits.

LS Manufacturing's established industry practice provides customers with scientific selection recommendations to ensure that technological needs are met while realizing the maximum economic benefits.

What Are The Limitations Of Gear Hobbing In Complex Gear Manufacturing?

Technical and economic analysis of gear manufacturing shows that gear hobbing, while very much advantageous in conventional gear manufacturing in large quantities, is highly disadvantaged by technical restraints in the manufacturing of intricate gears. These are primarily derived from the basic principles of the process and demand a logic combination of gear milling and gear hobbing.

1. Dedicated tool limitations and tooth profile complexity:

Gear hobbing relies on special hobbing cutters, and each gear parameter (module, number of teeth, helix angle, etc.) requires special tools. Special hobbing cutters are expensive and time-consuming for non-standard tooth forms gears, special tooth profiles, or involute profile modifications. Gear milling uses universal tools, which allow machining complex tooth profiles through program setup.

2. Inadequate machining path rigidity and flexibility:

Gear hobbing's generating motion path is relatively stiff, and therefore sophisticated tool path modifications are an issue. Tool access is limited in cutting interior gears, multi-link gears, or interfering geometry. Five-axis flexibility in gear milling makes these sophisticated structures simple to work with.

3. Difficulties in Machining Internal Gears and Special Structures:

For internal gears, face gears, or close gears, gear hobbing is usually not possible. Here, gear milling is a more reliable alternative, since its cutting tool can approach the workpiece from multiple directions and makes machining operations difficult to accomplish using conventional gear hobbing.

4. LS Manufacturing's Hybrid Process Solutions:

LS Manufacturing provides the optimal process mix to customers by way of scientific economic and technical evaluation of gear machining. For example, in an aviation gear project, we employed gear milling to complete roughing and root cutting of high-advanced tooth profiles, followed by completion with a specialized hob specifically designed to the application, for feasibility and maximizing the efficiency of production.

In selecting between gear milling and gear hobbing, the restrictions of gear hobbing in advanced gear production are essentially dependent on its use of specialized tools, inadequate machining versatility, and diminished structural flexibility.

How Does LS Manufacturing Enhance Customer Value Through Integrated Solutions?

In the manufacturing of gears, optimal selection of gear cutting process typically breaks or makes the costs of production and competitive position of an enterprise. The real-life case example below indicates how LS Manufacturing provides customers with integrated solution innovations via a scientific comparison of gear production processes.

1. Customer Dilemma:

One of the top automobile components suppliers had an entrenched production bottleneck. Their one-shot hobbing process for all gear models kept intricate gear manufacturing 25% overbudget, with a highest possible scrap rate of 8%, and resulted in ongoing delivery delays. This imposed upon customer satisfaction and prevented them from securing high-value-added orders.

2. LS Manufacturing Solution:

Through systematic contrast and technological comparison of gear manufacturing techniques, LS Manufacturing designed a hybrid milling-hobbing production line:

- Conventional gears are made by economical hobbing, retaining the advantages of mass production.

- Five-axis milling is used in special-shaped and complex gears, with enhanced processing flexibility.

- An intelligent process scheduling platform is designed to automatically figure out the optimal machining path based on gear type.

3. Results and Value:

This exact process integration has given hitherto unseen benefits:

- Cost Reduction: Through hobbing vs. milling cost difference optimization, total cost of production was reduced by 30%.

- Efficiency Improvement: Efficiency in production improved by 40% and lead time reduced by 50%.

- Quality Improvement: Scrap was reduced from 8% to below 2%, significantly improving product quality uniformity.

By contrasting scientifically engineered cutting processes and hybrid line production design, LS Manufacturing not only eliminated the customer's pain points through individual processes but also transformed cost, efficiency, and quality through optimizing the choice of gear cutting processes, creating a sustainable competitive advantage for the customer.

What Are The Common Quality Challenges In Gear Manufacturing?

In technical and economic gear machining examination, quality stability directly influences product life and total cost of manufacturing. Gear hobbing in the past and gear milling nowadays, both face the same quality challenges.

1. Tooth surface accuracy and consistency control:

Tooth profile mistake and tooth guide deviation are common issues, especially when gear milling a wide range of gears. The tool wear will have a direct impact on tooth surface accuracy. Besides that, heat treatment-induced distortion of the tooth profile can occur after machining.

2. Surface integrity defects:

Scratches, chatter marks, and tooth surface burns are common. While such flaws are difficult to completely remove in mass production, they may lead to considerable gear fatigue strength and wear resistance reductions, impacting product life.

3. Dimensional stability in mass production:

Temperature fluctuation, tool wear, and fixture relaxation during large-scale mass production can all lead to dimension drift. Consistency of the first to the last part is one of the quality control matters of significance.

4. LS Manufacturing's Quality Assurance System:

Multi-level quality control practices are adopted by LS Manufacturing to achieve product stability:

- Implementation of an online inspection system for real-time monitoring of tool condition and variation in cutting force during gear milling.

- Using precise machinery for performing full-size testing of the gears before and after heat treatment.

- Verifying quality information on statistical process control (SPC) basis to warn early and prevent defects.

In the technical and economic system of gear processing, such quality problems require special process solution and establishment of effective quality system.

LS Manufacturing combines superior technology and strict control to solve traditional quality problems in gear processing well and provides customers with high-quality gear products that guarantee stable performance and trustworthy durability.

How Will Gear Processing Trends Impact Your Business In 2025?

Forward to 2025, gears manufacturing industry is rapidly transforming into smart, efficient, and green processes. These trends will have a direct impact on the comparison parameters for comparing gear manufacturing processes, that is, comparing milling and hobbing, where even more parameters will need to be considered.

- Intelligent production: Web-based manufacturing lines and self-governing systems will be common, significantly increasing equipment utilization and production flexibility by tracking data in real time and smart scheduling.

- High-Precision Machining: With the growing demand for new energy vehicles and other industries, gear precision demand rises continuously. Interconnection of high-speed machining technology and precision control systems is the key in realizing tooth profile accuracy.

- Green Manufacturing: Environmentally friendly technologies such as dry cutting are becoming ever more popular, saving coolants but also largely saving on the cost of waste disposal and offering a win-win option to economic and environmental benefits.

While the industry revolution awaits by 2025, LS Manufacturing's forward-thinking philosophy of intelligent, high-precision, and eco-friendly manufacturing is helping customers get the most from gear manufacturing process comparisons, hobbing vs. milling decision making, and being poised to take advantage of a competitive edge.

Why Choose LS Manufacturing As Your Gear Processing Partner?

In the delicate science of gear manufacturing, selecting the right gear cutting process is what matters most to production expenses and product quality. LS Manufacturing, with its deep technical expertise and industry vision of visionary thinking, has become a strategic partner to numerous leading firms.

1. Comprehensive Process Expertise:

LS Manufacturing not only recognizes the advantage of hobbing over milling, but also possesses a deep familiarity with the optimal application situations for both. From high-volume production in standardized parts to highly sophisticated custom gears, we present to you the most cost-effective solutions based on a detailed examination of gear cutting process selection.

2. Innovative Hybrid Process Solutions:

LS Manufacturing surpasses the limitations of traditional single-processing methods and creatively integrates the advantages of milling, gear hobbing, and other processes. Through this scientific integration of processes, we have been successful in helping customers cut production costs by 30% and improve production efficiency by 40%, fully demonstrating our excellent capabilities in process optimization.

3. Continuous Optimization:

LS Manufacturing provides you not only machining capacity, but a partnership throughout the life of the product. From early process planning to continuous improvement in manufacturing, and then on to future technology advancements, we partner with our customers to sustain their continued competitive advantage.

Choosing LS Manufacturing is not only to acquire professional gear machining services, but also having a strategic partner that is familiar with gear cutting process selection and able to optimize the advantages of gear hobbing over milling.

FAQs

1. Is gear milling suitable for high-volume production?

While gear milling is extremely flexible and easy to use for quick changes of machining programs to accommodate different tooth profiles, its indexing operation creates longer processing times per item and relatively low production efficiency. For high quantity production (e.g., more than 500 pieces per year), LS Manufacturing recommends gear hobbing. Gear hobbing utilizes the concept of continuous generating in an effort to make machining economical and reduce unit cost by over 30%. Its precision in machining that is stable also make it suitable for mass production.

2. Can gear hobbing meet the precision requirements of demanding applications?

State-of-the-art CNC gear hobbing machines employ sophisticated servo control systems and temperature compensation technology to achieve ISO Class 6 and higher. LS Manufacturing adopts optimized hob design and process engineering. Expertise in difficult applications like new energy vehicles and aerospace, we ensure gear profile error controlled within 5μm and tooth surface roughness up to Ra 0.8, fully satisfying the most demanding industry requirements.

3. How to evaluate the total cost of gear machining?

In addition to the direct investment in equipment, the total cost would also have to include latent factors such as tool deterioration, energy consumption, labor, and quality. LS Manufacturing uses its own proprietary economic model of analysis to allow the customer to be able to quantify their performance: i.e., with production rates of 1,000 pieces, gear hobbing can achieve 40% reduced unit cost compared to milling. Moreover, by adopting preventive maintenance practices, utilization of the equipment can be increased to 85%, maximizing lifecycle costs.

4. Can LS Manufacturing handle urgent orders?

LS Manufacturing's flexible production line configuration and intelligent scheduling system can react in a timely way to meet urgent demands. In a case study, when LS Manufacturing encountered a 48-hour delivery request, it cut the usual 7-day lead time for production down to 45 hours by applying parallel processing methods and computerized cell coordination. This achieved on-time delivery without compromising accuracy, allowing customers to react quickly to mitigate unexpected supply chain disruptions.

Summary

This artical comparatively examines the technical character, accuracy performance, cost structure, and applications of the key differences between gear hobbing and gear milling. On the basis of deep data and real customer cases, it illustrates the direct advantage of scientific process selection to save cost of production and improve efficiency of production.

Leveraging our sophisticated process expertise and significant hands-on experience, LS Manufacturing has been successful in assisting many customers in the most well-informed decision when comparing gear manufacturing processes, and they have realized significant benefits of a 30% savings in manufacturing cost and a 40% improvement in productivity.

If you are looking at alternatives for gear manufacturing or want to optimize your current process, wait no more! Get in touch with our professional team for a complimentary, tailored process analysis and solution.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.