For the majority of overseas buyers, finding a reliable CNC turning factory in China often involves a set of all-too-familiar challenges: shockingly unpredictable quality, miscommunications and slow responses, unpredictable delivery lead times, and the aggravation of "no one to blame" when things go wrong. These problems not only consume extra time and costs but also directly jeopardize your project schedule and product quality.

LS Manufacturing completely understands these issues and offers a "one-stop service" with a complete ecosystem centered on your ultimate success. We are committed to making it an efficient, hassle-free, and worry-free experience from accurate responses to initial questions, open communications throughout production, rigid quality assurance, to on-time delivery of completed parts. With LS Manufacturing, you not only have a supplier, but a strategic partner committed to the success of your project. To save you time, here’s a quick overview of the core conclusions.

LS Manufacturing One-Stop CNC Turning Service Core Quick Reference

| Core Dimensions | Key Commitments |

| Global Competitiveness | Leveraging China's established manufacturing foundation, we provide globe-class solutions with unyielding cost-effectiveness and guaranteed safe and reliable supply chain. |

| Professional Expert Support | With Design-Factory (DFM) optimization, we deliver exact product performance and quality through complete end-to-end quality control and accuracy manufacturing workshops. |

| Seamless Delivery Experience | With the strength of effective response processes and lean production management, we deliver on time and keep transparent progress tracking. |

| Holistic Value Enhancement | With the resources optimized and the responsibility roles defined appropriately, our one-stop service completely erases unnecessary hidden cost of communication, quality, and management. |

Selecting LS Manufacturing is not purchasing a supplier; it's an investment in a strategic partner dedicated to your success. We take the headaches of complicated supply chain management out of your way with broad-spectrum security in technology, quality, and delivery so that you can at last have a streamlined, transparent, and hassle-free procurement process and concentrate on your business.

Why Trust This Guide? Real-Life Experience From LS Manufacturing Experts

What is presented in this guidebook is not theoretical; it is the culmination of decades of thick build-ups in the realm of precision manufacturing. LS Manufacturing has hands-on experience in all industries and with thousands of complicated components, creating a complete body of knowledge system from technology and material science R&D to manufacturing processes.

LS Manufacturing technical personnel possessing not only the vanguard of CNC turning technology experience but also a deep appreciation for international procurement quality standards and true pain points ensures every recommendation we present is rigorously proven and converted into immediate stable and reliable mass production solutions.

True trust comes as a result of LS Manufacturing's several successful histories of successful solving of challenging customer problems. Whether it's solving a precision valve core supply emergency for a European medical device manufacturer or executing the prototyping and shipping of an urgent order for an industrial customer within 48 hours, such true challenges have honed our quick response and problem-solving methods.

LS Manufacturing's shared processes, standards, and commitments have been employed day after day and refined in real co-operation scenarios, in order that the "one-stop service" which you may observe is not blue-printed notion but an unobtrusive pledge by a tried partner with real case-hands, who is capable of offering value to you.

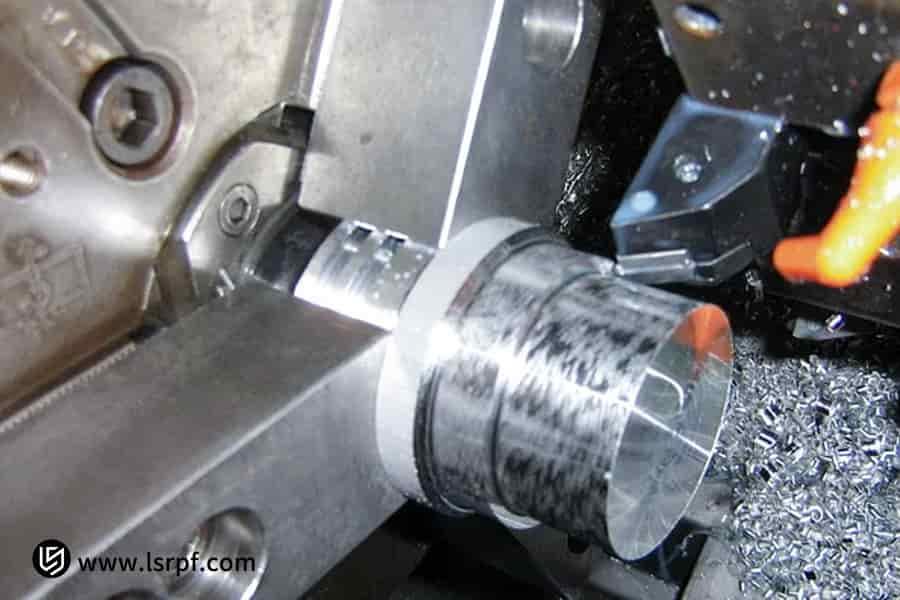

Figure 1: Current CNC turning production by LS Manufacturing

Why Has Choosing A Chinese CNC Turning Supplier Been A Global Trend?

Choosing a Chinese CNC turning supplier is now a strategic choice for world-class manufacturers to drive their supply base to the optimum. It's not merely a cost factor in the traditional sense but is constructed on the complete benefits provided by an even more advanced manufacturing landscape. China has been found by world-class manufacturers to have unbeatable supply chain integrity, technical prowess, cost savings, and quick response.

As a modern enterprise with its roots well-established in this business, LS Manufacturing is the paragon of this phenomenon. We seamlessly bridge our home, systemic edge with overseas superior quality and service levels to provide value over expectations. Specifically, the following stable set of core competencies drives this global trend:

- Unparalleled Supply Chain Integrity: China's highly advanced industrial system gives smooth and efficient sourcing from raw materials through precision components, radically reducing lead times for production preparation.

- Deep Technological Human Resource Pool: Sufficient numbers of engineers and skilled personnel provide adequate technical backup and innovation capability for top-of-the-line CNC turning suppliers in China.

- Enhanced Cost-Effectiveness: There is no compromise on quality, and we possess an advantage of cost of ownership that is even more competitive by virtue of economies of scale and cluster industry advantage.

- Industry Leading Rapid Response Capability: Customer-oriented, adaptive, and streamlined partnership structures enable customers to rapidly react to changes in market demand and accelerate product launch.

In brief, by choosing a Chinese CNC turning partner, you are choosing a more efficient one, a more effective one, and a cost-advantageous development path. At LS Manufacturing, not only do we fully utilize such domestic advantages, but also make these advantages transferred into tangible values to you by our customer-first service philosophy and globally consistent quality inspection, and we are your best strategic partner.

What Will Your CNC Turning Question Spark In Our Professional Response System?

When you place a CNC turning request, you trigger a lot more than a computation; it triggers officially the effective and professional inquiry process of LS Manufacturing. We are aware that a proper and reliable initial reply is the cornerstone to project success, and as such we aim for velocity, technical correctness, and commercial suitability. Your personal LS Manufacturing CNC turning request will be professionally addressed as follows:

- Single-Point Contact for Dedicated Engineer: Your single point of contact will be a technical background and market experience sales engineer who you will send your requirements to directly.

- Project Requirements Checklist: We will have all the key parameters like materials, tolerances, production quantity, and post-processing requirements agreed with you so that there are no future issues and there will be a clear requirements checklist.

- Parallel Technical Review Team: Meanwhile, as your sales team works with you, our process engineers conduct a manufacturability review (DFM) of the drawings, identify potential risks, and give optimization recommendations.

Briefly, the moment you submit your enquiry, an interactive working cycle surrounding you is initiated. That is to say, the CNC turning quotation you get is not a price list, but an expert solution that brings together technological insight and commercial feasibility, which gives you a good basis for smooth collaboration in the future.

Figure 2: Precision CNC milling update by LS Manufacturing

How Do Our Engineers Add Value To Your Turned Parts During The Design Phase?

When producing customized CNC turned components, true value usually is in the design process. That is precisely our center value of the LS Manufacturing engineering team—we listen to your concept and convert it into lowest cost and most reliable product through rigorous review of design for manufacturability (DFM).

Upon releasing your design drawings to us, our engineers will directly become involved in an expert Design for Manufacturability (DFM) analysis process that enhances your project design in three major areas:

- Material and Process Matching: Based on the part function, we will provide suggestions for more machinable and cost-effective replacement materials, eliminating over-specification or incorrect selection.

- Optimization of Tolerance: Appropriately analyze the requirement for every tolerance zone, controlling critical tolerances within a suitable range without sacrificing performance, significantly reducing machining complexity and inspection expense.

- Improvements in Structure and Manufacturability: In structurally weak parts such as sharp edges, deep blind holes, and thin walls, we recommend improvement measures to practically strengthen parts and avoid machining defects.

By using this pro-active co-operative method, we can help you optimize your solutions before the first run of production. Not only does this provide optimum performance and quality to your single-piece CNC turning components, but also involves considerable cost savings through optimized machining practice, realizing optimal value in actuality.

Figure 3: CNC turned precision components by LS Manufacturing

How Do We Guarantee The Accuracy Of Each Part By Having A Strict Quality Control Program?

We at LS Manufacturing are a precision CNC turning company committed to breaking manufacturing myths, we truly believe deep in our heart that high quality is not "selected" by final inspection but "created" by a systematic quality control process running through the life cycle of products. Our precision guarantee system is designed especially to bring you maximum confidence in "Made in China." Specifically, our quality control program consists of the following four major steps to guarantee error-free implementation:

1.Source Control: Raw Material Incoming Inspection

Every raw material must be strictly analyzed prior to warehousing it in the warehouse. We employ a spectrometer for analysis of material composition so that the material certificate is the same as the final product with no disparity whatsoever, eliminating even a chance of wrong or contaminated material from the source, thereby having a solid foundation of future stability in the processing.

2.Accurate Verification: Full First-Article Inspection

Prior to loading every batch into manufacturing, the very first part is to be inspected with the utmost severity. We inspect and verify all dimensions using high-precision coordinate measuring machine supplemented by optical profilometer to carry out microscopic inspection of surface roughness and fine details, generating very accurate inspection report. Mass production only commences after ascertaining 100% conformance to your design drawings.

3.Process Monitoring: Statistical Process Control and Inspection

Our inspectors carry out in-process checks at a predetermined interval during batch processing, the key measurement dimensions, and strike them against the SPC control chart. Immediate verification of process stability is ensured this way. As soon as a data drift trend occurrence is detected, appropriate action may be taken prior to the manufacture of products out of tolerance, hence the realization of preventative quality control.

4.Final Confirmation: Final Inspection and Document Traceability

Every finished section is examined one final time prior to shipping. We do not merely check major dimensions in triplicate, but also conduct a thorough visual examination. Every lot of parts which meets acceptance is shipped with a complete documentation package of quality records such as inspection reports and material certificates to ensure traceability and provide you with irrefutable proof of delivery.

From material to final product, our multi-level quality control process forms a solid closed loop to guarantee precision. It is not only LS Manufacturing's guarantee as a reputable precision CNC turning company but also the enthusiasm we infuse into each individual client, above and beyond.

How Does Our Workshop Convert Your Designs Into Precision CNC-Machined Parts?

In LS Manufacturing, turning your design concepts into high-precision CNC-machined components depends on the complete integration of hardware, software, and management within our shop. It is more than a collection of equipment, but a systematic expression of our core manufacturing capacity, so that every precision component is imbued with increased consistency and reliability. Specifically, the conversion process is expressly executed by the following four basic elements:

1. High-Speed Multi-Axis CNC Turning Center:

Our main tooling consists of a high-speed multi-axis simultaneous turning center with the ability to carry out multiple processes such as turning, milling, drilling, and tapping in one operation. Not only does this eliminate secondary clamping errors to a great extent and ensure complex coaxiality and positional tolerances, but it also increases the machining efficiency as well as total uniformity to a great extent.

2.Automated Unloading/Loading and Online Inspection:

To ensure the stability of large-scale manufacturing and reduce human intervention, all our large-scale production lines are installed with robotized automatic unloading/loading machines. Combining with on-machine probes and tool breakage monitoring systems, automatic precision compensation and anomaly alarm is executed in the machining process to ensure 24/7 uninterrupted production with constant quality.

3.Optimized Tool Specialization and Management:

We possess a science-based optimized tool management system, scientifically selecting and pre-setting the optimum cutting tools for different materials and process conditions. Real-time tool life monitoring and centralized sharpening allow us to provide optimal cutting parameters in every step of the process, thus ensuring surface finish and improving tool life.

4.CAM Process Database Optimized and CAM Programming:

We are supported in our programming by a process parameter database with high development, bought for decades of years for CAM programming. With simulation of cutting paths and optimal spindle speed and feed selection, we avoid machining interference from the beginning and improve equipment efficiency and process stability.

From intelligent tools to lean management, all of our workshop processes are structured with the intention of perfectly translating your design intention into real products. Have a glimpse at this experienced manufacturing ability system that is the guarantee of core confidence that LS Manufacturing will always be capable of producing high-quality, highly consistent precision parts with its clients.

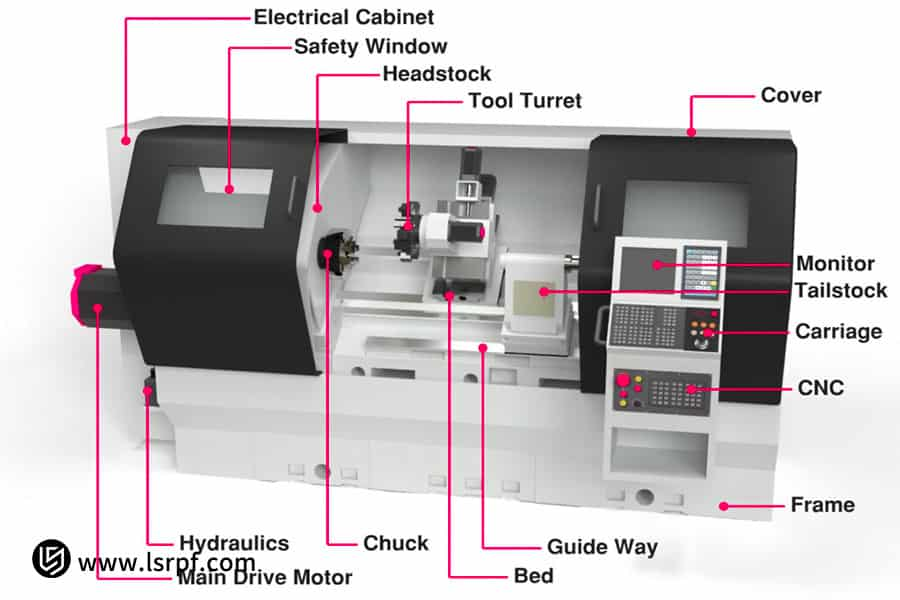

Figure 4: A CNC chucking machine by LS Manufacturing

How Do We Ensure That Your Orders Are Delivered On Time Or Even Ahead Of Schedule?

We well understand that on-time delivery is the essence of supply chain reliability. Not just lip service here at LS Manufacturing, but a hard and fast commitment upon systematic supply chain management and forward planning. With us as your reliable CNC turning service provider in China, we can ensure your production schedule is not disturbed by the following multi-dimensional strategies:

| Guarantee Link | Measures and Value |

| Smart Production Progress Management | We utilize a highly advanced ERP system to generate customized tracking numbers for your orders. From warehousing of materials right up to final packaging, each process is updated in real-time at the same time, allowing us to forecast and resolve possible bottlenecks in advance so production is never hindered. |

| Supply Chain and Logistics Collaboration | We have formed strategic alliances with leading logistics providers, allowing us to pre-book shipping space and coordinate best routes for transportation depending on your urgency and cost preference, offering double security for timely delivery and cutting transit time by nearly half. |

| Flexible Production and Buffer Mechanisms | When scheduling our master production schedule, we maintain safety stock for priority materials and maintain adequate reserve flexible capacity for priority orders. This buffer mechanism is one that will weather the ups and downs of markets or unexpected events so your orders proceed as planned. |

With the profound embedding of management, collaboration, and technology, our supply chain management system makes timely delivery from a goal into a quantifiable and traceable benchmark on a daily basis. Choosing LS Manufacturing's China CNC turning services is choosing a trusted partner who treats your schedule as their own.

How We Helped A European Medical Device Company Overcome A Precision Valve Core Supply Crisis?

One of the established European medical equipment firms was plagued with inconsistent quality of precision brass valve cores delivered by its main vendor. Since it is a precision CNC turning specialist firm, LS Manufacturing employed its systematic quality solutions to help the customer successfully address this supply chain problem.

1.Client's Challenge:

The client's original Asian supplier had poor product consistency, and inconsistent critical valve core dimensions caused frequent assembly line shutdowns, bringing a scrap rate of up to 15%. This not only caused production downtime but also put the client under the double pressure of delays in delivery of the product as well as damage to market reputation.

2.LS Manufacturing Solution:

We immediately created a dedicated team and made systematic adjustments by leveraging LS Manufacturing's CNC turning experience:

- First, we optimized turning process parameters to improve machining stability;

- second, we designed a dedicated full-inspection fixture to use 100% inspection for critical dimensions;

- Third, we implemented a whole batch traceability system so as to have end-to-end quality control from raw materials to finished products.

3.Results and Value:

After the implementations of the improvements were introduced, the client's received parts qualification level significantly increased from 85% to 99.8%, and the assembly line interruption problem was completely removed. The client has upgraded us from a replacement supplier to a strategic core partner from this successful collaboration.

This example is best used to show that LS Manufacturing not only provides precision components, but also quality solutions that basically resolve supply chain issues at their core, creating ongoing value for customers in the form of expert technology and services.

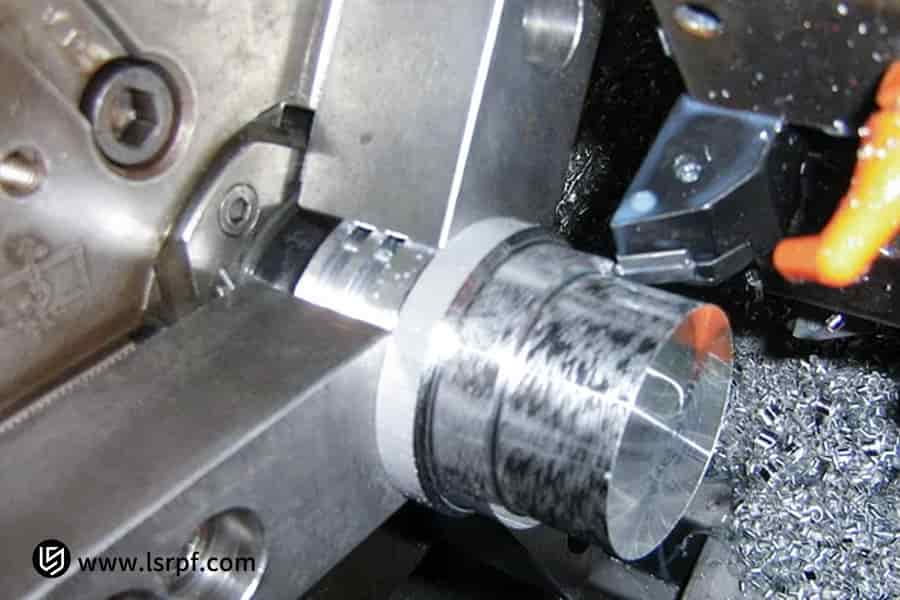

Figure 5: High-precision part turning by LS Manufacturing

How Many Hidden Costs Can You Eliminate By Utilizing A One-Stop Service Compared To A Piecemeal Supply Chain?

If you choose a few Chinese CNC turning suppliers to form a supply chain, the apparent unit price advantage will be outweighed by the hidden costs that follow. Being one-stop service provider partner, our recommendation is to weigh carefully the true cost behind this move from a total cost of ownership perspective. It will expose you to the following high-level hidden costs:

- Communication and Management Costs: Time and man-hours are consumed in continuous communication with different suppliers, coordination of timelines, and quality checking.

- Quality Variability Risk Costs: Differences in process quality specifications and quantities of quality checks among suppliers render product quality uncertain and increase the risk expense cost in online screening, rework, and even customer back.

- Time Delay Costs: The supply chain is complex; delay at one stage can affect the entire project timeline, causing production halts or loss of market opportunity.

- Accountability Costs: In the event of delivery or quality issues, fault can readily be shifted back and forth between different suppliers, and solving the issue becomes costly and time-consuming.

LS Manufacturing's single-source approach eliminates the back-end costs strategy by bundling assets, simplifying processes, and clarifying responsibilities. Our strength lies in delivering the finest total cost of ownership and project risk management even when our bid price on each item is not the lowest, so you can enjoy a productive, open, and trouble-free buying experience.

How Do We Start Working With LS Manufacturing In The Easiest Way?

Beginning a working relationship with our knowledgeable LS Manufacturing CNC turning personnel is an easy, well-planned process. We recognize that transparent, uncomplicated communication is the foundation of successful cooperation and thus have divided it into three easy steps so that you may enjoy our fast and able one-stop shop from the start of your interaction.

- Prepare and Submit Your Requirements: Supply completed part drawings or 3D models, unambiguous material specifications, estimated annual demand, and price range. This will enable us to completely grasp your project's basic needs at a glance.

- Get Specialized Analysis and Quote: After receiving your material, the response process will be automatically initiated by your personal account manager. Your in-depth process analysis will be simultaneously carried out by our engineering team and delivered to you within 24 hours along with in-depth CNC turning quotation, manufacturability suggestions, and optimization strategies.

- Start the Project and Carry Out Technical Clarification: We will schedule a detailed technical clarification meeting to ensure that both sides have a mutual understanding of all information. Once all is confirmed, we can quickly begin first-piece prototyping or manufacturing.

Choosing to do business with LS Manufacturing not only provides you with an open CNC turning quote but also a panel of experts to guide you through it. Let us make it simple for you and make that initial step towards hassle-free cooperation with ease.

FAQs

1. How long from inquiry until receiving detailed quotation?

From being given a whole standard question, we make sure to offer whole quotation within 24 hours. The quotation includes professional process analysis and open pricing structure to facilitate a prompt and precise response to your requirement and allow instant project start-up.

2. What kind of material do you normally machine parts from?

We specialize in alloying a wide range of metals, including aluminum alloys, stainless steel, carbon steel, brass, titanium alloys, and specialty alloys. This enables us to meet the stringent material performance requirements of most industrial applications.

3. Minimum order quantity. Do you ship sample orders?

We offer very flexible order terms, accommodating the full range of services from single unit sample orders to volume production in bulk. This method is designed to best support your product from research and development prototype through market introduction.

4. How is my intellectual property and design drawing protected?

We regard our customers' intellectual property protection as one of our utmost priorities. In addition to the employment of legally enforceable confidentiality agreements, we also ensure maximum protection for your design drawings and valuable technical data through encrypted file transfer mechanisms and rigorous internal data control procedures.

5. Are secondary machining services offered besides turning?

Yes. We offer a true one-stop solution. Standard secondary machining processes such as milling, drilling, deburring, polishing, and other surface finishing (such as anodizing and electroplating) can all be conducted in our facility, thus ensuring on-time delivery and manageable quality.

6. What do you do if a problem is found upon arrival of the parts?

Once a problem is identified, we will instate our rapid response mechanism at once and mobilize a technical team for root cause analysis. At the same time, we will give top priority to re-production or remedial action to keep any disruption to your project schedule to a minimum.

7. Is your factory certified with internationally recognized quality system certifications?

Yes, our company is ISO 9001 quality management system certified, and some of our major production lines even achieve the auto industry's IATF 16949 standard. This ensures that our production processes are totally consistent with high-level international standards.

8. How do I track my order's production process in real-time?

You can track your order's progress in real time through your dedicated account manager or a secure online customer portal. Our ERP system clearly displays the status of all key stages of your order, from scheduling, processing, quality inspection to shipment.

Summary

Selecting a better CNC turning supplier is not just a price comparison, but it is also about finding a long-term partner who can maintain supply chain stability and create value for the product. LS Manufacturing, with its extensive one-stop service system based in China, wants to make your complicated procurement process easier and largely eliminate project risks along the whole lifecycle from R&D to mass production. This frees you up to direct your core energy toward the market and innovation, leaving precision manufacturing issues in the hands of our reliable expertise.

We welcome you to begin your streamlined collaboration journey today. Contact LS Manufacturing and Simply send partial drawings and specifications, and 24 hours later you will receive a fully completed solution personally crafted by the LS Manufacturing master team with an open and competitive quote and master manufacturability assessment. Allow us to demonstrate that in China you can also receive world-class precision turning service and a smooth, class-first experience, infusing rbust energy into the success of your projects.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.