For most startup founders, procurement managers, and R&D engineers, a good product idea is usually followed by a crippling blow in its early stage. Traditional injection molding requires tens or even hundreds of thousands of yuan in mold investments, as well as a lead time of months. Not only does it waste precious capital, but it can also cause you to miss transient market windows. Witnessing a good idea falter is certainly the most maddening aspect of innovation.

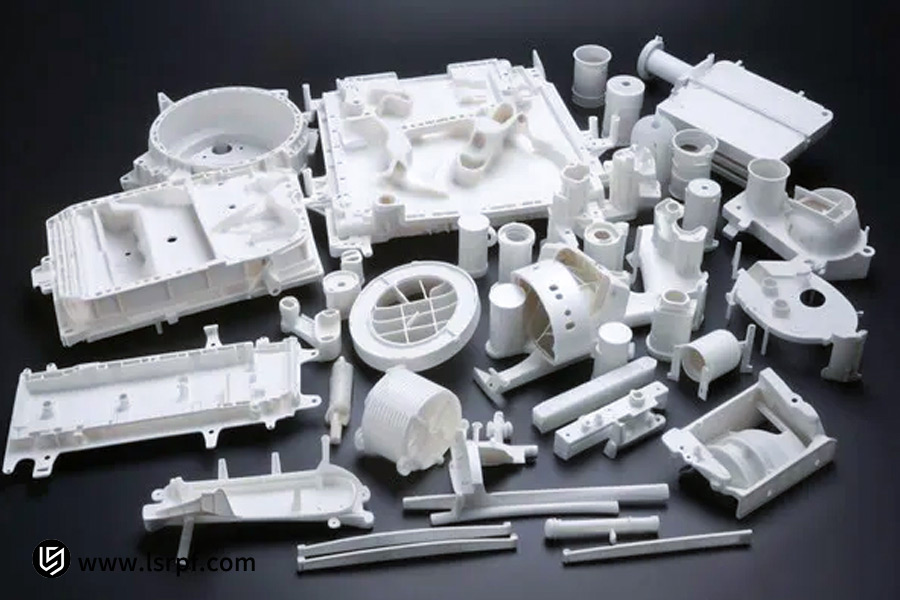

Foreseeing this pain point, LS Manufacturing is committed to breaking the deadlock. We perform low-volume injection molding, and with it, we provide a customized, cost-effective, and revolutionary solution. This lowers the barrier of entry exponentially, enabling mass customization of plastic parts in terms of time.

Whether for the conceptualization of a product, pilot production in small series, or market research, you can instantaneously convert your ideas into a physical product at minimal cost and risk, thereby taking a dominant market position. To save you time, here’s a quick overview of the core conclusions.

Skip High Mold Costs Core Quick Reference Table

| Dimension | Traditional Model Pain Points | LS Manufacturing Solution |

| Core Concept | With mass production in mind, it entails enormous initial capital and is inherently rigid. | With pilot orders and small batch orders in consideration, it must be agile, cost-effective, and versatile. |

| Cost Structure | High mold fees (tens or hundreds of thousands of yuan) with hidden expenses like maintenance of molds and conversion. | Minimize the mold fees considerably or even to zero, so that on-demand manufacturing is facilitated and financial risk is minimized. |

| Lead Time | Long cycle time (weeks or months usually) can result in very rapid market opportunity loss. | Extremely rapid delivery (500 units produced in 3 weeks, for instance) permits rapid product launch and validation. |

| Applicable Scenarios | Suitable for bulk manufacturing of finished products. | Suitable for producing prototypes, testing the market, small orders, crowdfunding operations, etc. |

| Partner Value | An indefatigable parts supplier. | A strategic partner that facilitates innovation, offering end-to-end support from technical advice to rapid delivery, allowing imaginative ideas to move into the market smoothly. |

By choosing LS Manufacturing's low-volume injection molding solutions, you are no longer compelled to haggle good ideas to high up-front capital costs and long lead times. It's reduced-risk, quicker product creation, allowing you to focus precious cash and time on product tweaking and testing to market, with an early advantage in a competitive market.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

All the analysis contained in this guidebook is predicated on the ten years of experience with small-batch injection molding that LS Manufacturing has accumulated. We've managed to successfully launch over 500 innovative projects into existence, many initially being a modest prototype burdened by the expenses of conventional molds.

The experts at LS Manufacturing understand that omitting mold expenses is not just idle talk. Behind it is a large, field-proven concept: from tool cost reduction by means of standardized mold bases and intelligent nesting to optimizing hundreds of process parameters for different materials (e.g., PP, ABS, and PC), we've accumulated valuable know-how in helping customers save up to 90% of their upfront investment without sacrificing quality. We went through the mountains you are ascending and have reached the summit.

Selecting trust means dealing with a partner who has enormous practical expertise so that your project is built on a stable and healthy ground.

Why Isn't Traditional Large-Batch Injection Molding Suitable For Small-Batch Production?

When your need is for just a few hundred or a few thousand pieces, run-of-the-mill high-volume injection molding just can't compete. It's not that the technology itself is outdated, but more that its economics underlie assumptions which are necessarily at odds with your need. The ability to understand the fundamental differences between low-volume and high-volume injection molding is the first step to being able to make an informed decision. The flaw of the traditional model is comprised of the following three main pain points:

1. High mold costs, stifling innovation in the cradle:

The conventional injection moulding depends on the peculiar hardened steel tools designed for each product. The production and build are complicated and time-consuming and cost tens or hundreds of thousands of yuan. For new products whose success is unpredictable, this significant upfront investment is a huge financial burden and deters the majority of brilliant ideas.

2. Long lead times, missing market opportunities:

It typically takes 8-12 weeks or more to produce, commission, and fine-tune a precision steel mold. In the rapidly moving market today, taking that long means that it may never get to the market before the optimal time to be in the market is past.

3. Rigid minimum order quantities (MOQs) create financial and inventory pressures:

In order to minimize hefty mold costs, factories assign enormous MOQs, typically in tens of thousands. This literally causes tremendous inventory pressure, holding back large amounts of working capital, and immediately turning a huge amount of pre-produced inventory into trash whenever product changes are needed.

Taking a system designed for millions of units and implementing it for trial production in small lots is excessive. This is why LS Manufacturing specializes in making refined costs and processes of small batch injection molding—to provide you with a more precise and lighter "scalpel," not a "scalpel."

How Does LS Manufacturing Achieve "Skip High Mold Costs"?

Facing the enormous investment in traditional steel molds, how can we lower the entry barrier? This is not magic, but the outcome of three core technology systems for small-batch manufacturing. Together, they change the cost equation for small-batch injection molding, making "eliminating high mold expense" feasible.

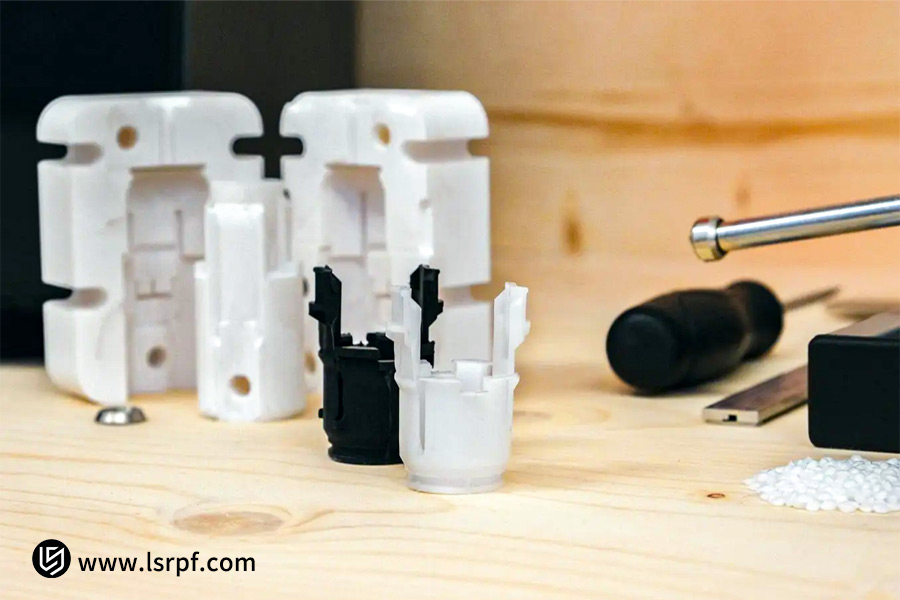

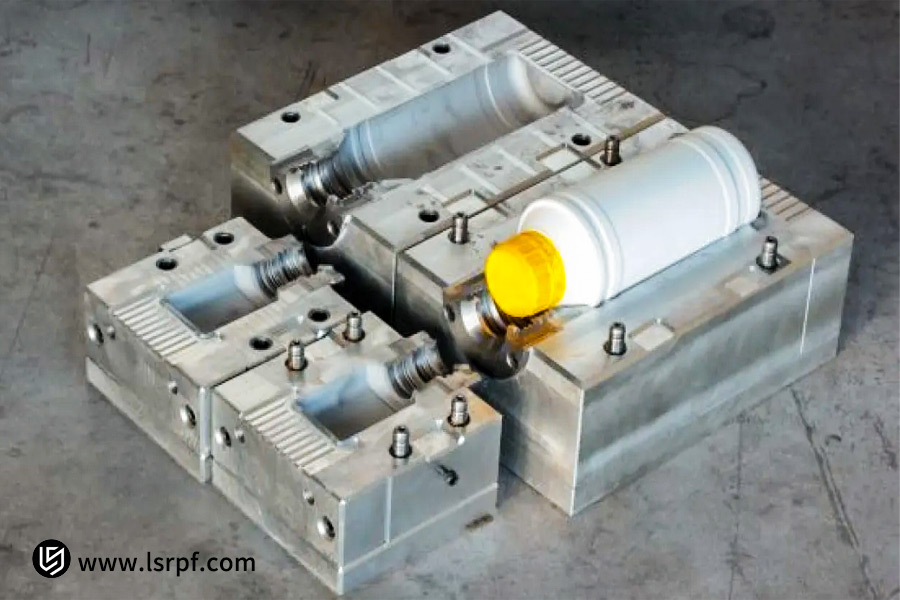

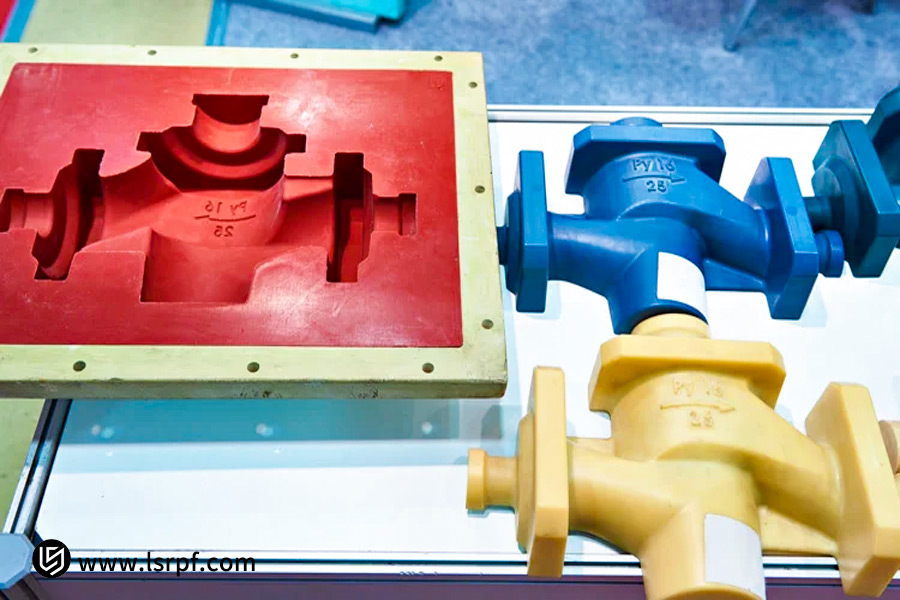

1. Rapid Aluminum Mold Technology:

We primarily use high-speed aluminum molds to replace traditional steel molds. On the cost side, aluminum mold material and processing expenses drop 60%-80% as opposed to steel molds, and production cycle times shorten by 2-3 times. While theirs is brief, their thousands to tens of thousands of injections life exactly fits prototype checking, small batch trial manufacturing, and crowdfunding shipping, achieving best reliability affordability balance.

2. Flexible Production and Intelligent Scheduling:

We possess a range of short-batch injection molding equipment designed for short-batch injection molding. With Small and Medium-Sized Die Change (SMED) technology, we enable smooth order shift. You are now able to produce merely 500 pieces without the burden of a minimum order of 10,000. This flexibility in production becomes the pillar for cost-effective small-batch injection molding management and prompt delivery of a wide variety of products.

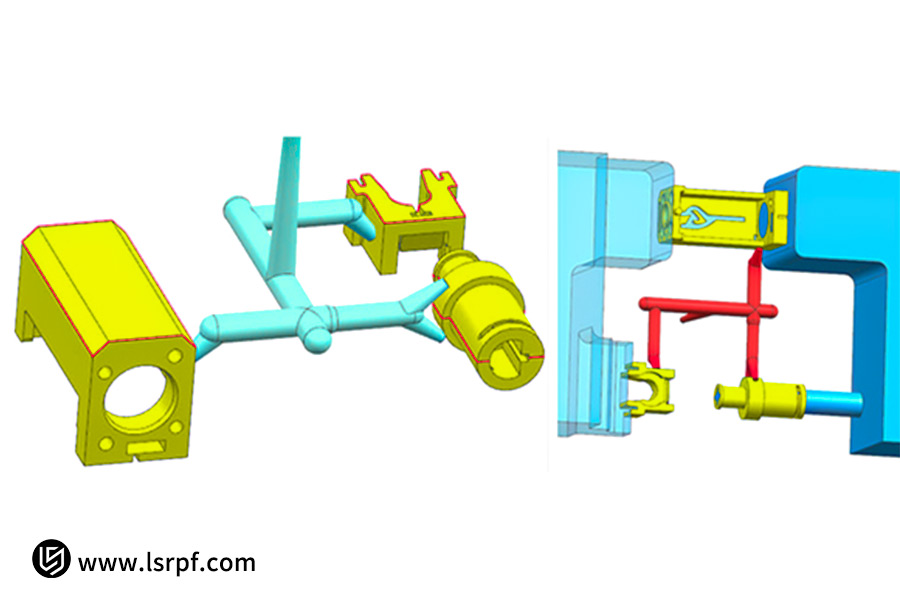

3. Digital Design and Simulation (DFM):

Before we cut the first aluminum piece, our engineers conduct thorough Design for Manufacturability (DFM) analysis, based on digital simulation to accurately predict filling, cooling, and potential defects. This ensures a first-hit success in mold design, basically negating the unnecessary cost and time lag of repeated mold redesigns and testing, saving you invaluable trial-and-error time.

With the combined effect of the three factors, LS Manufacturing not only eliminates the high costs of molds but also provides an entire, quick, precise, and waste-free low-volume injection molding process solution.

Besides Molds, What Other Hidden Costs Are There?

While looking for small-batch plastic part vendors, nothing more than mold or one-piece quotations are being considered at the tip of the iceberg. The real cost whirlpool actually lies beneath the surface. In order to really measure the costs of small-batch injection molds, you have to find and manage these oft-overlooked "hidden costs."

| Cost Categories | Hidden Pitfalls of Traditional Models | LS Manufacturing's Integrated Approach |

| Material and Scrap Expenses | Typical materials can be recommended by suppliers for convenience, generating scrap; higher defect levels result in hidden losses. | Accurately recommending alternative materials based on demand and streamlining the injection molding process can reduce scrap at the source. |

| Secondary Assembly and Processing | Secondary processing like painting, screen printing, and assembly from different suppliers is costly and human-error prone. | One-stop post-processing companies provide painting, assembling, and other processes, which eliminates the hassle of going through different parties. |

| Logistics and Management Expenses | An unbundled supply chain results in several logistics and warehousing expenses; communication and time expenses are frequently underbudgeted. | Integrated project management brings together production and logistics, offering lucid and open-ended progress reports and drastically lowering your management load. |

| Time opportunity cost | Procrastination and perpetual trial and error can cause you to lose critical market windows, the most expensive cost. | Rapid response and electronic DFM analysis guarantee first-time project success, quick product launch, and win in the marketplace. |

For small batch manufacturing, the lowest "unit price" is not necessarily the lowest total cost of ownership. Not only are you getting a manufacturer by choosing LS Manufacturing, you're getting a strategic partner committed to lowering your total cost of ownership through integrated services and capability. This is what you should value most when looking for a small-batch plastic parts supplier.

Case Study: How LS Manufacturing Completed A Trial Production Of 500 Sets In 3 Weeks?

This real-life case study of LS Manufacturing presents a clear picture of how we bridge our technology expertise to actual business benefit for our customers. The following is a real case study on how we completed the trial production of 500 sets of products within 3 weeks. It deeply demonstrates the professionalism of the LS manufacturing team. I hope it will be helpful to you.

1. Customer Dilemma:

A tech-wearable firm desperately needed 500 sets of advanced housings for the critical crowdfunding platform shipping and first-market test. However, the traditional supplier quoted a steel mold with up to 200,000 yuan and eight weeks for manufacturing. That must have been outside their budget and would have caused them to lose the best opportunity for crowdfunding.

2. LS Manufacturing Solutions:

To meet this challenge, we tailored an extremely bespoke low volume injection molding service:

- Comprehensive Design for Modification (DFM) Collaboration: Our team of engineers intervened before mold production (DFM stage), optimizing the buckle and rib structure of the housing based on the properties of the aluminum mold, ensuring ease of demolding as well as mechanical integrity, thus ensuring success from the outset.

- Rapid Tooling and Flexible Manufacturing: Using rapid aluminum mold technology, we completed mold production and proofing within two weeks. Afterwards, using a flexible manufacturing line specially configured for low volume injection molding, we completed the injection molding of 500 sets of products within one week, simultaneously completing initial quality inspection and packaging.

3. Outcome and Value:

Through this cooperation, the client not only obtained the product but also:

- Extreme Cost Optimization: The total investment was only 30% of the traditional solution (200,000 yuan), significantly alleviating initial financial burdens.

- Speed grasps the opportunity: From contract signing to delivery, it took three weeks. The client was able to deliver to crowdfunding supporters on time or even ahead of time, essentially fulfilling their promise and obtaining their first set of valuable seed users, setting a solid base for future growth.

This LS Manufacturing example shows how professional small-batch injection molding capabilities can be directly aligned with a competitive advantage in the marketplace.

Is My Product Suitable For Small-Batch Injection Molding?

You ask yourself: Is my project suitable for this model? Indeed, researching the possibility of rapid customization of plastic parts tells you you're on the right path for successful product development. As a professional small-batch injection molding service supplier, we recommend that you consider the following typical situations:

1. Do your needs suit the following cases?

- Product Development and Validation: You need creating testable functional prototypes to fine-tune them and secure funds.

- Market Testing and Crowdfunding: Produce 500-5,000 units to get feedback from the market or earn crowdfunding rewards.

- Niche/Customized Products: Well-defined target market but small volume, e.g., specialist equipment, limited-production products, or bespoke components.

- Spare Parts and Repair Market: Providing repeated low volume replacement parts for already-outdated equipment.

- Medical Device Pilot Production: Completing small-volume pilot production and registration processes before initiating large-scale clinical production.

2. Simple Decision Reference:

If your needs possess the following characteristics, then using a small-batch injection molding company like LS Manufacturing is an intelligent choice:

- Order Size: Typically ranging from 100 to 10,000 units.

- Primary Need: Reduced cost of the mold, reduced time to market, and willingness to best manage risk of inventory and upfront investment.

If what you're not planning to do is to produce hundreds of thousands of parts at once and you want to get high-quality, quickly customized plastic components in a more flexible and cost-effective manner, our solutions are tailor-made for you.

What Does It Mean To Choose LS Manufacturing As A Partner?

It's not a purchase to choose a low-volume injection molding plant; it's choosing a partner that you and they will grow with. When you choose LS Manufacturing, you're getting more than a low-volume injection molding capacity; it's a partnership that lasts the life of the product.

1. You're the Lead, Not the Order Number:

LS Manufacturing provides you with a dedicated project manager and technical team with advisory service. With the review of the design up to the delivery of the production, we have a full understanding of your needs and communication runs smoothly with quick response. The end result of your projects is success.

2. Ultimate Speed and Flexibility:

We have an in-depth knowledge of the innovative product cycle process. LS Manufacturing has therefore cultivated a systemic response mechanism that can seamlessly incorporate your urgent needs and design changes, combined with your agile development process perfectly to gain a competitive advantage.

3. Completely Transparent Collaboration:

LS Manufacturing is built on trust through transparency. Through our partnership, we have transparent cost structures to which you find it easy to know where every expense originates without any surprise charges and maintain complete command over your budget.

4. Seamless Path to Mass Production:

When your product has been test-marketed and you need to scale up, we are your best ally. LS Manufacturing can easily support your transition from low-volume aluminum mold to high-volume steel mold with a smooth and stable supply chain.

Choosing LS Manufacturing is choosing a partner dedicated to your success. We are committed to being with you through every step from idea conception to market success with the professional small-batch injection molding capabilities.

FAQs

1. What is the lifespan of an aluminum mold? How many parts can it produce?

LS Manufacturing's quick aluminum molds are ideal for low-volume production with life typically in the range 5,000 to 50,000 shot cycles. The inference is that hundreds of parts to tens of thousands of parts are produced by a single mold multiple times, entirely end-to-end throughout the entire product life cycle from prototype testing and market test to small-batch release without having to pay additional for unused spare parts.

2. Is the cost per part high for small-batch injection molding?

By no means. Compared to traditional practices, LS Manufacturing erases the outrageous expense of steel molds altogether and puts more affordable mold cost on small quantities, cutting down the overall cost per unit (including amortization of the mold) by half. This arrangement maximizes your capital use and is optimal for pilot production and start-ups, achieving true low-risk and cost-effectiveness.

3. How long does it take from inquiry to sample receipt?

With our proven fast aluminum mold technology and flexible manufacturing procedures, LS Manufacturing can deliver first working samples in 2-3 weeks from final drawings for projects of average complexity. That's faster than months traditional methods would require, and we can fix your product iteration issues quickly and help you find market opportunity. Contact us now for a no-charge analysis.

4. What plastic materials do you support?

LS Manufacturing is a company that specializes in the support of mass production engineering plastics and specialty plastics such as ABS, PC, PP, Nylon, and TPU. Additionally, in the spirit of sustainable development, we have a series of green options such as bio-based or recycled material so that your components not only meet the mechanical performance needs but also agree to green design standards. Our experienced staff ensures customized services for specific requirements of your product.

Summary

With the high-speed economy of today, the ability to test and iterate rapidly is the recipe for product success. LS Manufacturing's low-volume injection molding gives you that kind of "agile manufacturing" capability. They entirely avoid the costly and time-intensive exercise of using yesteryear's manufacturing models so that you can push your ideas fast and at minimal risk and have a clean breakout from zero to one.

If you want to continue to do your shopping for a low-volume plastic components distributor, take the lower expense and more cost-effective path. Start now and contact LS Manufacturing, without charge or obligation.

Upload your 3D designs today, and we will provide you with a personalized cost estimate of cost and precise quote within 24 hours so you can have a clear understanding of how easily you can customize plastic components with our help.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.