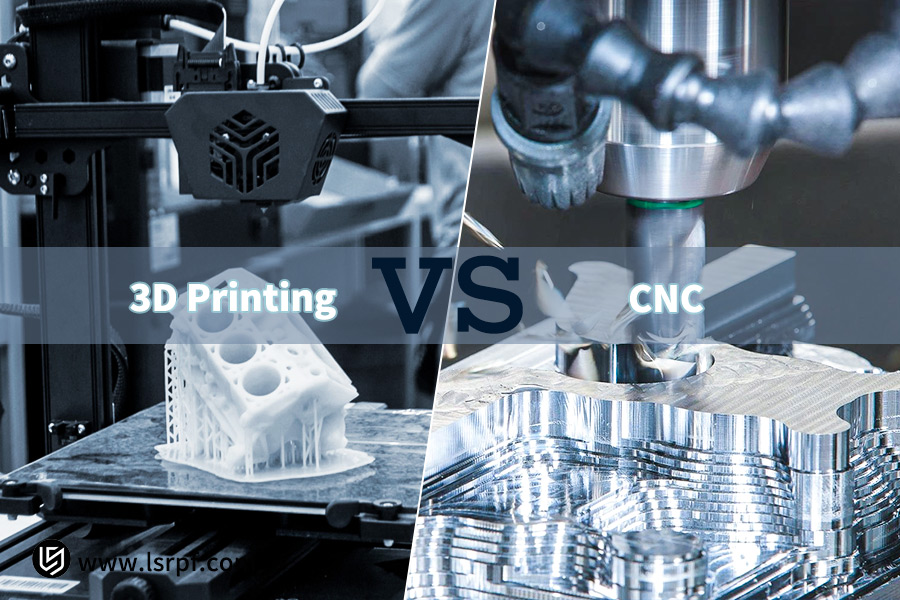

With the competitive plastics manufacturing industry of today, selection of the proper manufacturing process for your plastic components is no trivial matter; it significantly affects the ultimate cost of the product, development cycle, and the performance. Presented with a bewildering array of options, CNC machining and 3D printing, two dominant technologies, seem to leave decision-makers in a dilemma: whether to opt for the high precision and good material properties of CNC machining, or for the rapid prototyping and unparalleled design freedom of 3D printing.

Actually, there is no technology perfect for all applications; there is an optimum application for every process. Utilization of the wrong one can lead to escalating cost, delayed delivery, and even product failure. That's where seeking the services of dual-capability experts like LS Precision Manufacturing comes in. At LS Precision, we do more than offer manufacturing services; we are your technical partner, ensuring that every part is produced in the most cost-effective and efficient manner. To save you time, here is a quick overview of the core conclusions.

Plastic Part Manufacturing: CNC Machining vs. 3D Printing Comparison Table

| Features | CNC Machining (Subtractive Manufacturing) | 3D Printing (Additive Manufacturing) |

| Technical Principles | Parts are made by removing material from a solid blank. | Materials (resins, plastic powder/filaments) are built up layer by layer to form parts. |

| Core Advantages | High precision, good material properties, and smooth surface finish. | Unparalleled design freedom, high speed, and suitability for complicated structures. |

| Materials and Performance | A very wide range of materials is available for use, with dense solid parts having high strength and stable performance. | Material choice is relatively limited, and interlayer adhesion can be very poor, depending on the printing technology. |

| Cost Efficiency | High per-part cost, suitable for small to medium-volume production. Costs primarily result from machine tool hours. | Low per-part cost, suitable for prototypes, small series, and customised production. Costs primarily result from material consumption. |

| Production Speed | Extended first-part preparation time (programming and clamping), suitable for batch production. | Very high first-part speed, making fixtures unnecessary, makes it suitable for rapid prototyping and single-part production. |

The key to choosing CNC machining is achieving a balance between strength and accuracy, on the one hand, and speed and complexity, on the other:

- Choose CNC machining: When you require high-strength, high-accuracy, high-quality surface finishes for functional end-use parts in small- to medium-volume production.

- Choose 3D printing: when development speed, design iterations, or complex part geometries are the priority, and production requirements are single units or small series.

LS Precision Manufacturing, having expertise in both processes, can provide you with the most impartial and cost-effective technical direction to ensure project success.

Why Trust This Guide? Practical Experience From LS Experts

The conclusions in this guide are not theoretical, but derived from LS Precision Manufacturing's day-to-day practice. Having spent more than a decade manufacturing plastic parts, we've completed thousands of cases in the medical device, automotive, and consumer electronics industries. We know that textbook process comparisons are miles away from being able to deal with complicated real-life problems.

As an instance, LS Precision had a customer rethink a prototype that was seemingly perfect for 3D printing. Our materials experts reviewed the part, and it would need to withstand 80°C temperatures and particular torques in real-world use, which common printing materials would not be able to meet. We wound up recommending a CNC-machined nylon solution. Somewhat more expensive, it ensured prototype functionality at a saving to the client of redoing the project from the beginning at great cost.

It's this project-acquired experience that enables LS Precision to see beyond the simple technical parameter comparison and provide truly objective, reliable, and cost-effective manufacturing solutions for the entire lifecycle of your product.

What Is The Fundamental Difference Between CNC Machining And 3D Printing?

Simply put, the basic difference between them is similar to "sculpting" and "building Lego."

- CNC machining is "subtractive manufacturing": it starts with a solid block of plastic sheet or bar, as a sculptor would, and uses precision tools to progressively cut away excess material, gradually building up the part that's been created.

- 3D printing is "additive manufacturing": it builds up material such as plastic filament or powder, layer by layer, precisely, from the bottom up, based on a 3D digital model, until the part is constructed.

This inherent distinction, of course, leads to gigantic differences in their capabilities. The following is a brief comparison table:

| Features | CNC Machining | 3D Printing |

| Material Form | Solid Sheet, Rod | Plastic Filament, Resin, Powder |

| Precision/Strength | High strength, high precision, dense parts | Good precision, potentially weak interlayer strength |

| Speed | Long first-part preparation time, suitable for mass production | Very rapid first-part speed, suitable for rapid prototyping |

| Cost | Machine Hours and Labor | Material Consumption |

If you require a high-precision, high-strength end part, then CNC machining is the preferred option. However, if rapid prototyping, complex structures, or small-batch trial production are your goals, then 3D printing tends to have the speed and cost advantage in the 3D printing vs. CNC machining fight. Understanding this fundamental difference is the initial step in making the proper decision.

How To Choose The Best Option Based On Your Project Budget?

"Is 3D printing cheaper than CNC machining?" It depends on the quantity you wish to produce. To make a cost-effective decision, you need to know first the cost structure of the two processes. The cost of CNC machining is equipment depreciation, material, programming, labor hours, and post-processing. 3D printing is equipment, material, and some post-processing labor intensive.

The fundamental cost distinction lies in upfront costs. CNC machining entails custom programming and setup for every new part, which suggests high fixed costs. 3D printing, however, has low setup costs; it is able to print as soon as the model is created. As things stand, the correlation between the volume of production and the cost per part is essential:

- Low-volume production (typically 1-50 parts): 3D printing clearly has the advantage. It has a nearly constant cost per part, without having to pay expensive CNC setup fees, which lowers the total cost.

- Medium to high volume production: At these higher volumes, CNC machining's high setup cost is well amortized. Its high cutting speeds and lower cost of material per unit decrease CNC machining cost per part by a significant margin, which eventually falls below that of 3D printing.

3D printing is actually less expensive if you are prototyping or manufacturing small series. But the minute quantities rise above a certain point, CNC machining is the less expensive process due to economies of scale. Coming to a good decision starts with a realistic volume prognosis.

Strength And Durability: Which Plastic Parts Can Last Longer?

3D printing and CNC machining are two of the most common product development and low-volume manufacturing technologies. Between them, there is a tremendous difference in the mechanical properties of plastic parts, which has a direct influence on the reliability and application scenarios of the end product.

1. Essential Differences:

- CNC machining employs virgin engineering plastic sheets (i.e., ABS, PC, and nylon) as material and generates a shape through cutting. Since the material is inherently isotropic, mechanical properties of the material are identical in every direction, leading to part strength closer to original material properties.

- 3D printing, and FDM technology in particular, builds parts by depositing material layer by layer. The process produces anisotropic part properties with interlayer bond strength significantly weaker than XY plane strength. The interlayer bonding is weaker in the Z axis direction, and therefore parts are more prone to failure under loading perpendicular to the layering direction.

2. Differences in Material Properties and Performance:

- CNC parts possess superior strength and heat resistance. For example, CNC-machined PC prototypes will remain stable at a temperature of 90°C, while 3D-printed parts will deform at a temperature of around 60°C. CNC-machined parts are compact in structure and can be used where the application is exposed to loads, friction, and heat resistance.

- Nylon also reacts differently in both processes. CNC-machined nylon sheets retain the original material properties, while nylon parts that are produced with Selective Laser Sintering (SLS) 3D printing, though being very strong, do not tend to be as dense as those that are produced with CNC machining.

3. Strength Considerations in Practical Applications:

For parts that must withstand screw tightening forces, CNC machining is much superior to 3D printing. 3D-printed plastic parts crack when screwing, while CNC-machined parts can safely screw them in.

For complex structure features, 3D printing can realize complex features such as hollowing and internal intersection easily, but such structural points are weak points in terms of strength. Where CNC machining will make it difficult to machine complex hollowing structures, the final product is closer to the finished product in terms of usability.

When your plastic part needs to bear structural loads, friction, or elevated heat, CNC machining is the more reliable choice. When the part is complex and strength requirements are not severe, 3D printing is a faster, more flexible option.

Pursuing Ultimate Appearance And Precision? The Ultimate Surface Finish Comparison

When ultimate fit and product cosmetics are paramount, the choice of manufacturing process directly determines the level of ultimate quality. When it comes to the production of complicated plastic parts coupled with high precision as well as visual requirements, there exist significant gaps between 3D printing and CNC machining.

1. CNC: Near-perfect Mirror-Level Performance

CNC surface finish is one of its significant advantages. Because CNC parts are machined directly from dense sheet metal with a spinning tool, they naturally possess excellent surface quality, with a nearly mirror-like finish. Their dimensional accuracy can be held consistently within ±0.025mm, and therefore, they are a necessity for products requiring precise assembly or having stringent aesthetics.

2. 3D Printing: Inevitable Layer Markings and Post-Processing Challenges

Most 3D-printed parts, and especially those made via FDM printing, exhibit visible layer lines on the surface. While high-resolution resin printing can mitigate this, the surface remains stepped in nature. A CNC-like finish can be achieved with lots of time-consuming and labor-intensive post-processing in the form of sanding, polishing, and painting, which is labor-intensive and costly and can undermine dimensional accuracy.

3. How to Choose for Your Project?

- If your project requires a lovely appearance, high-gloss finish, or extremely precise, seam-free fit, CNC machining is a safer and easier option.

- If aesthetic requirements are less stringent, or if complex internal geometries are more important than surface finish, 3D printing offers the potential for faster iterations.

For high-end visible end-use parts, the increased quality that a higher CNC surface finish provides is usually worth the additional expense.

Complex Design vs. Rapid Iteration: Which Process Offers Greater Freedom?

When designs break the conventional mold and call for the creation of parts with complex internal cavities and motion mechanisms built in, traditional manufacturing processes are usually at a loss. In the creation of intricate plastic parts and in enabling rapid design iteration, 3D printing provides disruptive advantages, making it a clear complement to CNC machining.

1. Geometric Complexity: 3D Printing's "Dimensionality Reduction Attack"

3D printing and CNC prototyping follow completely different logics to deal with complicated geometries. CNC is limited by tool paths and angles and therefore difficult to machine complex cavities, interlocking components, or integrated assemblies economically. 3D printing, however, follows layer-by-layer build-up to easily achieve designs that are impossible or prohibitive cost by traditional means, e.g., conformal cooling channels and lightweight lattice structures after topology optimization, actually achieving "design-as-production."

2. Rapid Iteration: Speed Determines Innovation Efficiency

Rapid prototyping is the single most significant advantage of 3D printing. Physical parts can be 3D printed by engineers just hours after a digital model is altered. This speed allows the completion of many iterations of "design-verify-optimize" in record time. In contrast to CNC, which takes multiple steps like programming, clamping, and tool setting, 3D printing has much lower iteration costs and times.

3. Which should you choose for your project?

- Pushing design innovation and extreme complexity boundaries: 3D printing allows nearly complete freedom and is thus the process of choice for pushing design innovation boundaries.

- Need for quick validation of design concepts: 3D printing is the best solution for rapid prototyping since it shortens development cycles by orders of magnitude.

- Targeting high-strength, high-accuracy final parts: Where CNC can also serve design complexity and material properties are improved, CNC is the best process.

In cases where novelty in design, complex internal geometries, and rapid prototyping are necessary in projects, the freedom and flexibility of 3D printing cannot be matched, and hence it is an innovation-worthy tool.

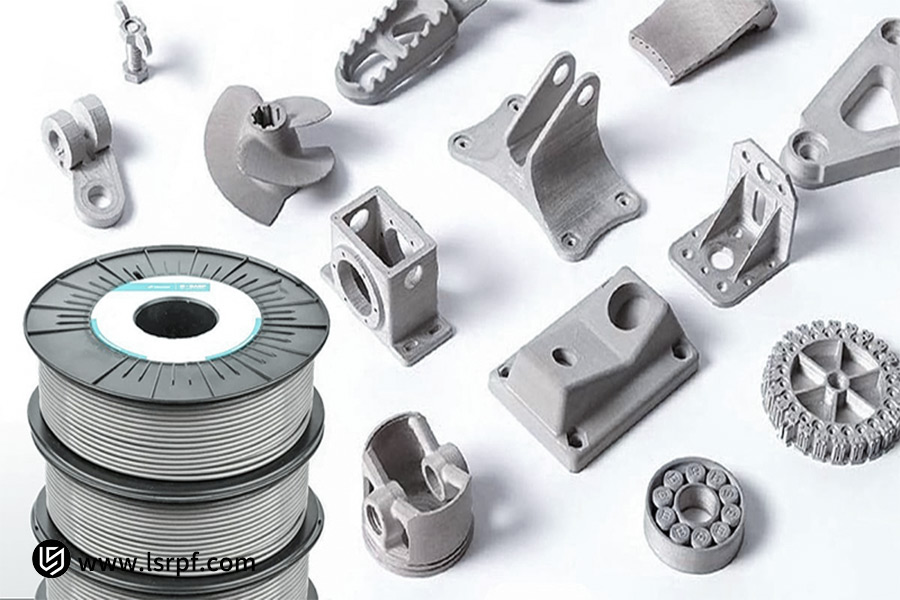

Material Selection: From General-Purpose Plastics To High-Performance Engineering Plastics

Materials are the physical structure of a part, and different processes produce different "material toolboxes." The best material and process combination is the master key to fulfilling the requirements of the final application. Both 3D printing plastics and CNC machined plastics are both performance- and usability-centric.

1. CNC Machining: A Wide Selection of High-Performance Engineering Plastics

CNC machining works directly from solid bar stock or sheet stock, and there are a broad range of plastics that are CNC machinable. They include:

- General-purpose materials: such as ABS (high toughness), PC (impact resistance is high), and POM (sliding polycarbonate, rigidity is high, and low friction).

- High-performance specialty plastics: i.e., PEEK (strength and temperature resistance), PTFE (Teflon, highest chemical resistance), and others sheets of nylon. These meet strict specifications such as chemical resistance, temperature resistance, and food-grade status.

2. 3D Printing: Specialized Materials Focused on Process Compatibility

3D printing materials should be compatible with their base materials for molding. Principal alternatives are:

- Base materials: PLA and ABS filaments, used in the validation of prototypes.

- Engineering materials: Nylon 3D printing is typically done using SLS technology, creating parts with good mechanical strength and low weight. Other high-performance materials include ULTEM (PEI, high heat resistance).

- Specialized materials: It is possible to achieve high-precision models using photosensitive resins, along with specialized materials like rubber-like and biocompatible materials.

Nylon 3D printing stands out in terms of its capability to achieve complicated, integrated structures, although material properties (density and isotropy, for example) will be slightly less than those of equivalent CNC-machined nylon components.

LS Company Success Story: Choosing A Manufacturing Solution For A Drone Shell

Having been presented with an order by a customer for 500 high-performance drone shells that need to be high strength, lightweight, and aesthetically pleasing, with complex internal snap-fit designs, LS Precision rightly implemented a hybrid manufacturing solution using both 3D printing and CNC machining, thus surmounting the double hurdles of volume cost prohibitions and aggressive delivery schedules.

1. Customer Challenge:

The drone shell structures were complex with internal snap-fit designs, and the assembly tolerance requirement was tight. The 500 sets ordered by the customer were exactly in the middle of the cost range of both 3D printing and CNC machining, and selecting a low-cost mass production method was of the utmost importance. Furthermore, the project timing was extremely time-sensitive, and the traditional mold-opening and injection molding cycle could not meet the schedule requirement.

2. LS Precision's Solution:

LS Precision did not choose from the two options directly, but put forward a hybrid production plan in phases:

- Rapid Prototyping: First of all, by means of SLS nylon 3D printing technology, five prototypes of the housing were rapidly produced in three days. This allowed the customer to rapidly carry out physical assembly and functionality testing, and multiple rounds of design iteration were accomplished in a very short time, fully verifying the reasonability of the complex snap-on structure.

- Efficient Mass Production: Mass production was initiated with CNC machining following design validation. The CNC process offered more strength and surface finish, meeting the high mechanical and cosmetic requirements for drone enclosures. For a batch of 500 units, this solution was economical in comparison to full 3D printing or traditional mold making.

3. Project Outcomes and Value:

Through the use of this hybrid solution, the customer significantly saved prototyping time and cost, ultimately producing 500 quality parts and completing the project one week ahead of schedule. In this case study, it is easy to see that LS Precision uses the strengths of both technologies in a flexible manner to provide maximum value to its customers based on their specific needs (volume, complexity, timeframe, and cost).

Do you also have a project that is stuck under the selection of the manufacturing process? Contact LS Precision's specialist team today for a complimentary tailored solution.

FAQs

1. Which process is preferred for small-batch production (fewer than 10 parts)?

For fewer than 10 plastic parts, 3D printing is by far the most time and cost-effective method. This is because it doesn't require costly custom fixtures and molds or sophisticated toolpath programming, which gets rid of CNC machining's huge pre-production time and cost. Just upload 3D model, and the machine starts printing, allowing for actual rapid prototyping and on-demand manufacturing.

2. My part needs to withstand high impact. Which is more suitable, CNC or 3D printing?

If your part needs to absorb high impact, then CNC machining is the preferred method. This is because CNC parts are machined from solid engineering plastic stock and are isotropic, meaning that their mechanical properties (strength and toughness, for example) are equal and predictable in all directions and resist multi-directional impact very well. However, most 3D-printed parts possess poor interlayer bonding by nature. They would crack first between the layers under high impact, thus less reliable than CNC parts.

3. Does LS Precision offer post-processing and surface treatment services?

Yes, LS Precision offers a full range of professional post-processing services, which are vitally important to deliver finished parts. These services include grinding and sandblasting for enhanced tactile feel; painting and dyeing for coloration and branding personalization; silk-screen printing and film exfoliation for functional graphics; and even finish operations such as assembly. Our engineers will recommend the most appropriate post-processing option for your part application and process characteristics, so that the final product fully meets your end-use requirements on aesthetics, functionality, and durability.

4. Can I get quotes for both CNC machining and 3D printing?

Yes. This is among the basic and easy-to-use services offered by LS Precision. Simply upload your 3D design file (for instance, in STEP/STP format) on our official online quoting site. Our system utilizes intelligent algorithms to give you comprehensive, instant quotes, manufacturability analysis, along with delivery time estimates for both 3D printing and CNC machining within minutes. Side-by-side comparison allows you to make the best budget and timeline decision, with maximum transparency and efficiency.

Summary

There is no "best" plastic part process, but merely the "most suitable" one for your project. The key to choosing the right process is properly balancing five factors: design complexity, cost, volume, material properties, and lead time. CNC machining and 3D printing aren't substitutes; rather, they offer a powerful, complementary technology combination.

This is LS Precision Manufacturing's unique value proposition. Contact LS Precision now. As your technical partner, not only do we possess both state-of-the-art manufacturing capabilities, but we are also committed to providing you with a totally objective and professional analysis based on your project goals and cost-effectiveness overall so that your chosen process actually delivers maximum efficiency and value.

Upload your 3D file now and receive a free, detailed 3D printing and CNC machining quote and manufacturability analysis report from an expert in 60 seconds. Take one step closer to successful manufacturing!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com