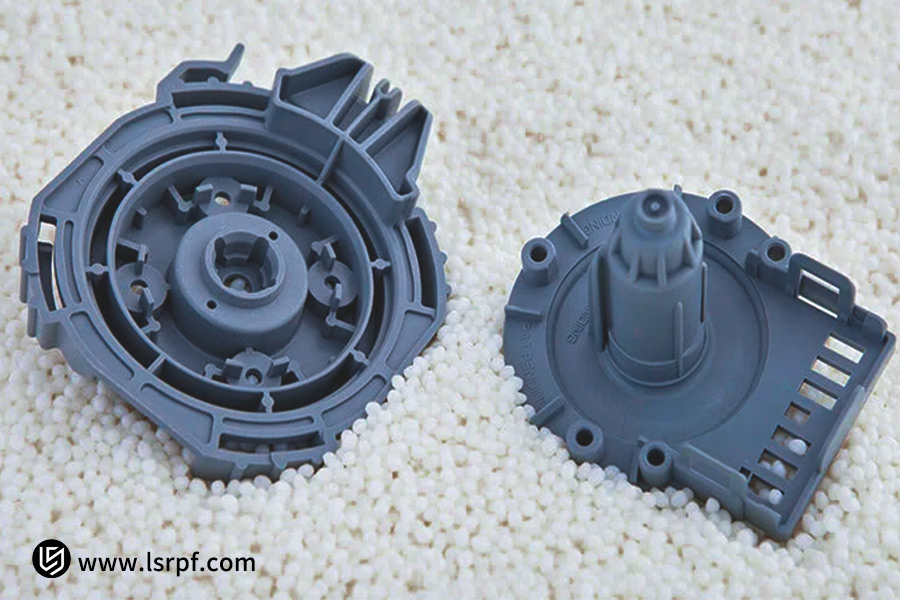

As a cornerstone of modern manufacture, plastic injection molding holds a top place among bulk manufacture in terms of high efficiency, precision, and ultra-low unit cost. Plastic injection molding technology permeates the entire process from concept prototype design to bulk production of the final product, and acts as an important link in enabling innovative designs and enhancing product competitiveness.

Whether it is complicated precision parts or everyday consumer goods, injection molding technology is the core of all these. In this field, LS Precision Manufacturing, with its deep understanding and vast experience in high-precision injection molding processes, stands tall.

Not only are we experts at manufacturing, but LS Precision are committed to providing customers with integrated solutions from design optimization and material selection to production so that every project maximizes cost savings and efficiency gains. For your convenience, below is a summary of our key findings.

Plastic Injection Molding Quick Reference Table

| Dimension | Brief Description |

| Principal Process Types | Conventional Injection Molding; Two-Color/Multi-Color Injection Molding; Insert Molding; Micro-Injection Molding; Structural Foam Injection Molding |

| Principal Material of Application | Thermoplastics (such as ABS, PP, PC, Nylon); Thermoplastic Elastomers (TPE); Some Thermosets |

| Principal Applications | Auto Components (Interiors, Lamp Shades); Electronic Housings (Mobile Phones, Home Appliances); Medical Devices; Consumer Goods (Toys, Containers) |

| Cost Structure | Mold Cost (One-Time, Primary Cost); Unit Cost (Material Cost, Cycle Time, Volume of Production); Cost of Post-Processing |

Plastic injection molding is the obvious first choice for mass production with high efficiency and conformance since the significant cost is the huge mold investment, but by mass production the unit cost can be reduced drastically.

The final cost depends heavily on the product design complexity, the material, and the number being produced.

Why Trust This Guide? Practical Experience From LS Experts

The advice provided herein is the result of the extensive technical experience of LS Precision Manufacturing over many years in plastic injection molding. LS Precision possess a full range of advanced injection molding machines, such as Engel and Arburg machines. The extremely precise machines form the technical foundation for achieving micron-level tolerance control, complex multi-component molding, and mass production that is stable and efficient. This technological experience guarantees all of our advice to be realistic and practical.

Above all, it is supported by successful projects across a range of markets. From high-tech medical equipment to consumer electronics housing with large production runs, LS Precision have had "hands-on" experience solving diverse design issues, material traits, and cost requirements. Therefore here what you're studying isn't just theory knowledge, but learnings which you can directly transfer into your own project work to avoid failures and enhance your solutions.

How Can I Quickly Obtain Accurate Injection Molding Quotes Online?

A complete plastic injection molding quotation used to be time-consuming and exhausting. LS Precision Manufacturing's new on-line quotation system turns the whole process into a rapid and open quotation experience of plastic injection molding service requests.

Obtain an accurate quotation in three easy steps:

- Visit the quote page on the LS Precision official website;

- Upload your 3D file (i.e. STEP or IGS format) directly in;

- LS Precision provides basic requirements such as target level of production and material of choice.

LS Precision's system will then use intelligent algorithms to conduct an automated Design for Manufacturability (DFM) analysis of your design and offer you an exact quote in minutes. Our online quote is not an estimate and meticulously breaks down every detail of the cost of plastic injection molding, including material cost, production mold cost, and per-unit cost of mass production, so you have a complete understanding of each cost.

This not only gives you unmatched speed (24/7 response time, with costs in minutes estimated) but also complete price transparency. You are able to make informed and wise decisions without going back and forth and waiting.

LS's online quote system, through intelligent analysis of 3D files, translates the historically time-consuming quoting process into mere minutes of automatic procedure. With today's need for efficiency and transparency of price, it is definitely the option to have a genuine injection molding quote.

Injection Molding Process Selection: Which Molding Solution Is Best For Your Product?

Since there are various plastic injection molding processes, the most appropriate molding solution needs to be selected in order to increase product performance, control costs, and improve production efficiency. Bad decisions can lead to flaws, cost overruns, or lengthy production schedules.

1. Two-color injection molding:

If your product contains a combination of hard and soft material or multi-colored design (e.g., two-color buttons or soft rubber grips), two-color injection molding is the best. It is a single-piece molding process that eliminates post-assembly.

2. High-speed injection molding:

For manufacturing thin-walled structural parts (e.g., packaging and housings), high-speed injection molding provides high-volume production at very short cycle times with high speed.

3. Insert molding:

If your product contains metal inserts or electronic components inside, insert molding would be selected so that there is maximum interlock between the insert and plastic.

4. Micro injection molding:

For very small high-precision parts (e.g., medical catheter connectors and optical lenses), only micro injection molding technology can meet their extremely high dimension requirement.

When selecting a process, consider product geometry, material characteristics, volume of production, and cost. LS Precision's experienced staff of experts can provide in-depth analysis and solution verification to ensure your plastic injection molding process investment is the ideal solution for your product requirements.

There is no one process that will be perfect for all products. The key to successful production and the overall expense of plastic injection molding is the proper alignment of the product's requirements.

What Are The Key Factors Affecting Injection Molding Costs? How Can They Be Optimized?

Precise plastic injection molding cost management is vital to the success of large-scale production. Cost is not a stand-alone number; it is an integrated result affected by a variety of parameters like material, mold, complexity of design, and batch size. Information on these parameters and their optimization can significantly increase the product's competitiveness in the market.

1. Material selection:

Material selection is the cost structure element with high impact in plastic injection molding. The engineering plastics (e.g., PC and Nylon) are significantly more expensive than the general-purpose plastics (e.g., PP and ABS).

Optimization Suggestions: Since performance is guaranteed, choose cost-efficient material or negotiate with the suppliers on the amount of recycled material to use.

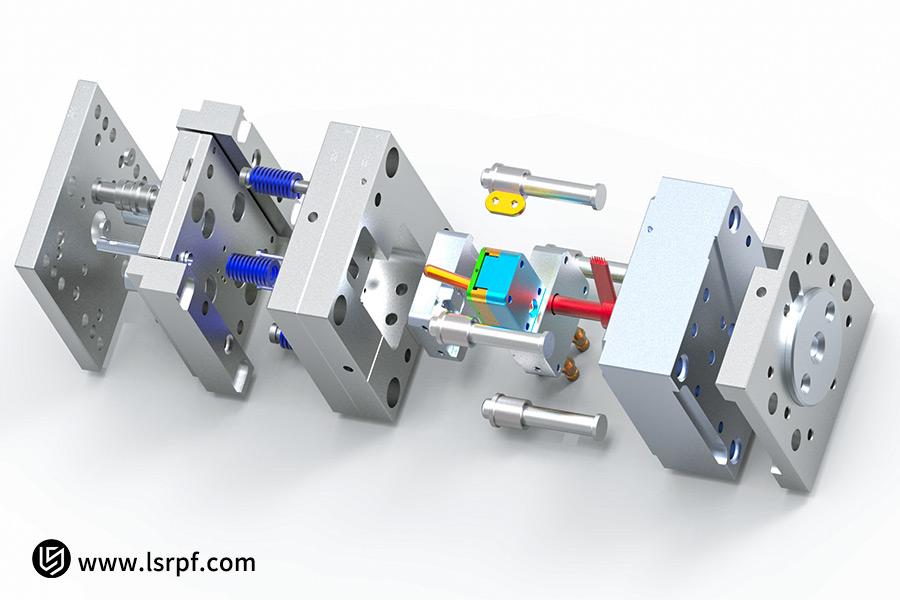

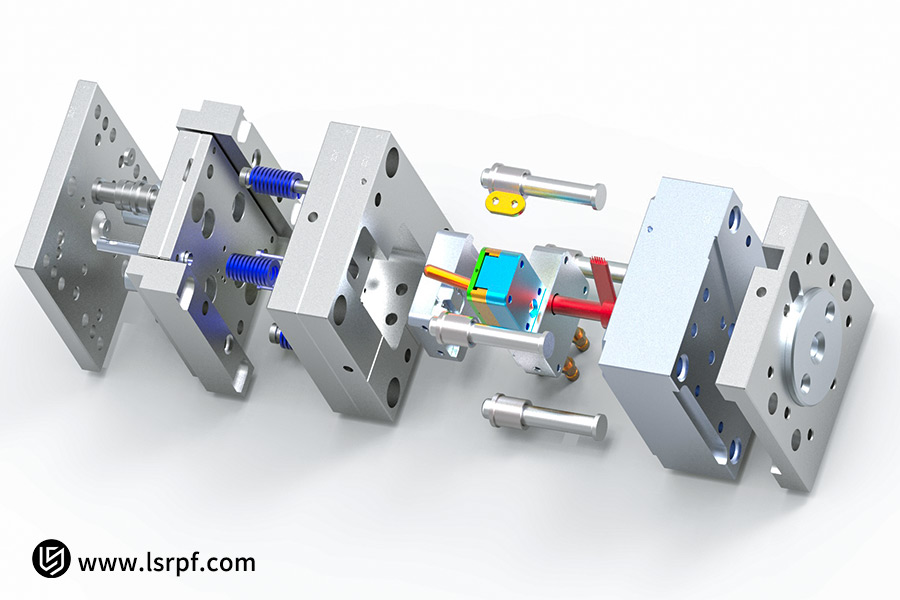

2. Mold complexity:

Mold complexity is a direct factor influencing initial investment. Multi-cavity precision mold with sliders and lifters will be expensive.

Optimization Suggestions: Simplify product design, eliminate unnecessary undercuts and complex structures, and use standard mold bases. This can significantly lower mold costs.

3. Production batch:

Production batch size has significant impact on unit cost. Large-volume production reduces the mold cost significantly, while trial production in small lots raises unit costs.

Optimization Recommendations: Plan production accordingly and perform design verification ahead of time through CAE simulations to remove additional cost of trial-and-error mold modification.

Plastic injection molding cost optimization is a process. Success lies in starting at the design source, together with experienced suppliers, and pursuing an integrated policy of materials selection, design minimization, and production scheduling to ensure quality while achieving optimum cost control.

What Are The Key Aspects Of A Professional Design Assessment?

Prior to production of your product, there's a professional design review so crucial to the success of a project and avoiding costly errors. LS Precision offers a free design review, its broad-based engineering knowledge and manufacturing experience at your disposal to analyze your product carefully and achieve the optimum balance between manufacturability, cost, and quality.

LS Precision expert design review encompasses the following general key factors overall:

- Mold Feasibility Analysis: It analyzes the demolding feasibility of the product geometry, filtering out design flaws such as undercuts, thin walls, and non-homogeneous thicknesses that can compromise mold life and operational efficiency.

- Structural Optimization Suggestions: Process-wise, we offer suggestions such as draft angle optimization, rib design, and fillet design for enhancing part strength and minimizing quality issues such as shrinkage and deformation.

- Cost Control Solutions: With solutions such as material selection guidance, design simplification (e.g., part reduction), and standard part utilization, we methodically reduce plastic injection molding costs without impacting performance.

A thorough design review fills the gap between manufacturing and design. Not only does it decrease the risks earlier, but also serves as a powerful tool of cost reduction as well as efficiency. Avail LS's free testing service today to support your product's entry to the market in an improved way.

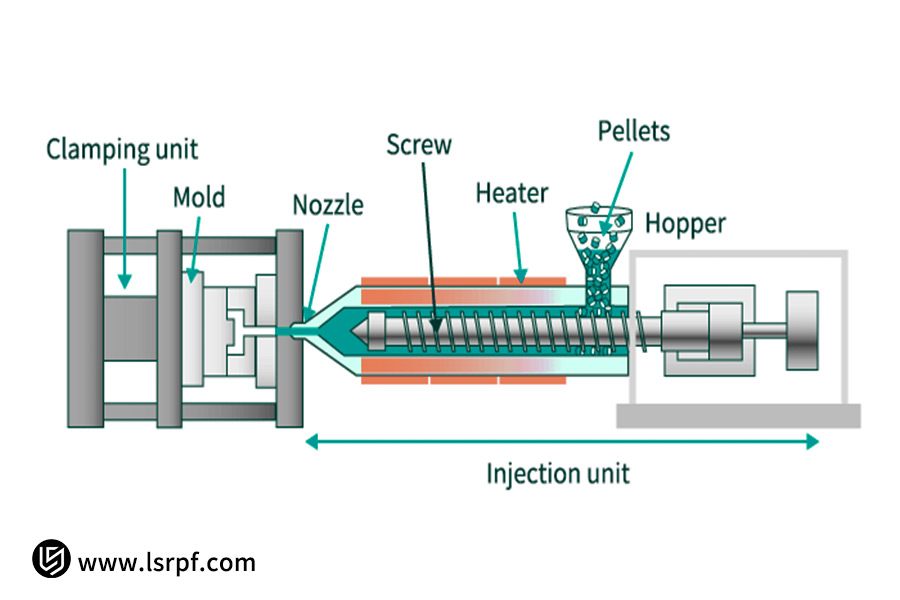

How Does The Choice Of Injection Molding Equipment Affect Product Quality?

The quality of the end product relies directly on plastic injection molding machine performance and precision. Not only is equipment a production tool, but it also plays a significant role in ensuring that the design intent is achieved and consistency is maintained within the product.

1. Attributes of different tonnages and models of injection molding machines:

Plastic injection molding machines of different tonnages and specifications are paired with different production capacities and precision ranges. Micro parts with consistent sizes and close tolerances are best made by small precision injection molding machines, while automotive parts are best suited for large machines.

2. The effect of performance of equipment on product precision and surface finish:

The precision of the injection control, stability of clamping force, and equipment repeatability all directly influence the dimensional consistency, internal quality, and surface finish (e.g., avoidance of defects such as flash and underfill) of the product. Quality defects such as warpage and shrinkage, even with a flawless design, can be resulted from improper equipment selection.

LS Precision Manufacturing is aware of this, and as a result has invested heavily in state-of-the-art equipment, including totally electric and electric-hydraulic hybrid plastic injection molding machines from Engel and Arburg.

LS Precision's machines have better control accuracy, production stability, and efficiency, which form a solid foundation for the manufacture of our high demand products.

How Do We Ensure The Quality Consistency Of Injection Molded Products?

In high-volume injection molding production, extremely uniform quality for all plastic injection molded items is a systematic process. It requires not just precise machinery but also a scientific and strict quality control mechanism at all stages of production.

LS Precision Manufacturing rigorously ensures quality stability by three core processes:

1. Raw Material Testing:

By the raw material testing stage, LS Precision monitor every batch of raw material coming in for such key indicators as melt index and moisture content so that material properties are in accordance with standards at source.

2. Full-Process Monitoring:

LS Precision employ full-process monitoring throughout the whole production process. Sensors on advanced injection molding machines monitor real-time process data regarding process parameters such as injection pressure, speed, and temperature. SPC analysis checks that the production is in control.

3. Product inspection:

While checking the finished product, LS Precision Manufacturing use accurate tools such as calipers, coordinate measuring machines (CMMs), and image measuring instruments to precisely assess the critical dimensions of plastic injection molded products. We conduct functional tests, including appearance and assembly, to ensure that all indicators meet the requirements of the customer.

LS Precision uses rigorous quality control throughout raw materials to finished product, as well as data-based process monitoring, to provide customers with sure confidence of high-volume, highly consistent products.

LS Case Study: How To Reduce Injection Molding Costs For A Home Appliance Company By 30%?

LS Precision has extensive experience in the injection molding field. In one instance, when producing parts for a home appliance company, we overcame challenges and difficulties, and reduced their injection molding costs by 30%. The details are as follows.

1. Client challenge:

A prominent home appliance maker was facing cost issues common among plastic injection molders with product enhancements: complex present component designs, long production runs, and inefficient use of materials. They ultimately worked with LS Precision and achieved significant cost savings through systematic optimization.

2. LS Precision's revolutionary solution:

As an experienced plastic injection molding company, the LS team first addressed mold design:

- The original design, requiring sliders and tough core pulls, was made efficient by collaborating with the customer, and they achieved a natural release system. That reduced the cost of mold manufacturing and maintenance significantly.

- LS Precision also increased mold cavities from 1/2 to 1/4, significantly improving single-run efficiency.

- In production, we optimized process parameters via scientific mold trials during production, decreasing injection molding cycle time by 15%. We suggested a reformulated PP material with similar performance but lower cost, saving material costs while maintaining product quality.

3. Final results:

By means of this sequence of accurate optimization interventions, LS Precision effectively assisted the customer in decreasing their total cost per part by 30%, as well as notably decreasing their defect rate.

Cost optimization is a systematic process. This case demonstrates that by deeply collaborating with an experienced plastic injection molding company and innovating in technology and manufacturing processes, significant cost savings can be achieved without sacrificing quality.

What Steps Are Included In The Full-Process Service From Design To Mass Production?

In modern manufacturing, the transformation of creative ideas into high-quality, mass-produced products is a comprehensive and professional process. As a one-stop-shop solution provider, LS Precision offers end-to-end services from concept design to delivery, facilitating seamless integration of every step, minimizing project risk, and accelerating time-to-market.

LS Precision's end-to-end services include the following key areas:

1. Product design optimization:

LS Precision R&D team, based on comprehensive manufacturing experience, provides customers with professional optimization recommendations on design, e.g., structural optimization and material selection, to ensure maximum manufacturability and cost-effectiveness.

2. Precision mold production:

With our own mold workshop and advanced processing equipment, LS Precision complete the entire mold design, processing, and commissioning independently, ensuring the precision and quality of molds, and providing a good basis for subsequent mass production.

3. Scaled injection molding manufacturing:

Supported by injection molding machines of globally renowned brands such as Engel and Arburg, LS Precision are well-equipped to cater to all the manufacturing needs from small- and medium-sized pilot productions to mass production to maintain production efficiency and product consistency.

4. Integrated quality control:

LS Precision have established a comprehensive quality control system. From incoming inspection of raw materials to the monitoring of the production process and product testing on completion, we follow quality standards at all levels, ensuring that each plastic injection molded product supplied is to the customers' specifications.

5. Other value-added services:

In addition to basic manufacturing, LS Precision also provide ancillary services such as assembly, packaging, and logistics, basically providing complete support from design to delivery.

Integrating our capabilities at every phase of the process, LS Precision offer seamless transition between all project phases, allowing customers to save on total costs, reduce project cycles, and eventually receive high-quality mass-produced products.

FAQs

1. Are free quotes and design reviews truly free? Are there any hidden fees?

Yes, established companies commonly provide free upfront quotes and design-for-manufacturing (DFM) studies. This is the initial step to getting clients. Most unforeseen costs are caused by too many design changes or special requirements at the end of the process, preventable with transparent communication in the beginning. LS Precision Manufacturing offers free quotes and design evaluations. Contact LS professionals.

2. Are mold fees and part costs quoted separately?

Yes, an average quote clearly delineates the one-time mold investment cost (mold fee) from the unit-by-unit plastic injection molding cost (part price). Mold fees usually dominate the costs of small-run production; part price has to be optimized in large-run production. If you still have questions about mold and parts fees, LS Precision has a professional quotation system to serve you.

3. What is the mold lifespan?

Mold life is material and product structure dependent. LS Precision Manufacturing use high-quality mold steel and precision machining with a mold life of 500,000 to 1,000,000 cycles depending on material and product structure. If you have any questions, please feel free to consult our LS Precision professionals.

4.Can I get a quote without detailed 3D drawings, only an idea or sketch?

It's difficult to quote. Without accurate information, any estimate is an educated guess. LS Precision recommend a start with a design service or doing initial 3D modeling in-house. This gives a foundation for estimating the cost of plastic injection molding. At the same time, you can also contact us LS Precision Manufacturing to design your 3D drawings for you. Come and have a free consultation.

Summary

The key to obtaining a proper, free custom plastic molding quote and the best of a design review is preparation. Proper preparation is in taking accurate technical documents, selecting a well-experienced plastic injection molding company and engineers, and being an active participant in communicating to obtain the best of the design. LS Precision possesses abundant experience in custom plastic molding.

Contact LS team of precision manufacturing experts today and upload your 3D drawings to receive a free, professional quote and a detailed Design for Manufacturability (DFM) analysis report. LS Precision's engineers will provide personalized process optimization recommendations to help you mitigate production risks, reduce overall costs, and quickly move your product from perfect design to perfect mass production!

Upload your design drawings now and get an instant plastic injection molding quote ( plastic injection molding price), let LS be your strong backing in pursuit of ultimate plastic injection molding precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com