5-axis medical device manufacturing has the advantage of being the one to provide solutions to the most significant challenges of the industry. We solve the problem of how to get the surface roughness on a medical implant to be around Ra0.4μm or higher directly, ideally for the success of the osseointegration. On top of that, our technique ensures the cutting edge of surgical tools can remain extremely sharp even after 200 sterilization cycles, thus greatly increasing the wear and tear resistance of the instruments as well as the safety during operations.

Through our certified ISO 13485 quality system, we can offer a complete manufacturing solution that completely removes the issue of 0.3mm mismatch between patient-specific implants and CT scan data. Our combined method, from biomaterial validation right up to sterile cleanroom production, is able to give a first-pass yield of 99.2%. Having control over the entire process is what makes it possible for each and every part to be in compliance with the strict regulatory requirements for accuracy, biocompatibility, and full traceability.

5-Axis Medical Device Manufacturing Quick Reference Table

| Topic | One-Sentence Description |

| Overview | 5-axis CNC machining refers to a machining method whereby the tools move simultaneously along 5 different axes to create very complex shapes. |

| Key Advantages | It results in high precision, flexibility, and efficiency in the production of intricate medical parts with excellent surface finishes. |

| Medical Applications | Typical applications are orthopedic implants, dental prosthetics, surgical instruments, and patient-specific custom devices. |

| Core Technologies | This depends on sophisticated CNC machines, CAD/CAM software, along with real-time monitoring systems for precise operations. |

| Material Compatibility | It is compatible with biocompatible materials such as titanium, stainless steel, PEEK, and cobalt-chrome alloys. |

| Quality Assurance | Comprehensive testing methods like CMM and ISO 13485 certification are used to ensure compliance with medical regulatory standards. |

| Implementation Challenges | The main difficulties include the high cost of initial investment, technical complexity, and the requirement for skilled operators and maintenance. |

| Industry Trends | Upcoming developments include automation, combined manufacturing with 3D printing, and AI-driven process optimization. |

We address major issues by providing the means for precise manufacturing of complex medical devices with tight tolerances and excellent surface finishes. Our expertise guarantees compliance with strict regulations (e.g., ISO 13485), shortens the time-to-market, and manages costs through the use of advanced 5-axis technology. We thus facilitate healthcare innovation and enhance patient outcomes by providing dependable, high-quality components in an efficient manner.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

The internet is brimming with articles on 5-axis machining. Why should you read this one? Simply put, we are practitioners, not theoreticians. For more than ten years, our team has been working continuously in the treatment of medical components, where the main materials are titanium and PEEK, dealing daily with intricate shapes. Here, the consequences of failure are not measured in the number of rescue parts but in the patients health. Our knowledge is carried at the factory level, not only acquired from books.

Most of the custom implants or surgical tools that we make become a new experience to us. We figured out which tool paths save the integrity of thin-walled orthopedic implants, how to hit extremely tight tolerances on the articulating surfaces, and which are the best strategies for prototyping and production. We develop these experiences into reliable and repetitive processes for the production of life-saving devices, conforming to the guidelines of the Society of Manufacturing Engineers (SME).

Our company complies with ISO 13485, and these processes guarantee that there is always traceability and quality. We also incorporate procedures of excellence from organizations such as Metal Powder Industry Federation (MPIF) when dealing with advanced materials. This manual imparts our experience of how to reconcile precision, productivity, and adherence to regulations. We are the reliable ones you should turn to for help in figuring out the intricacies of medical device manufacturing, from an idea to a certified piece.

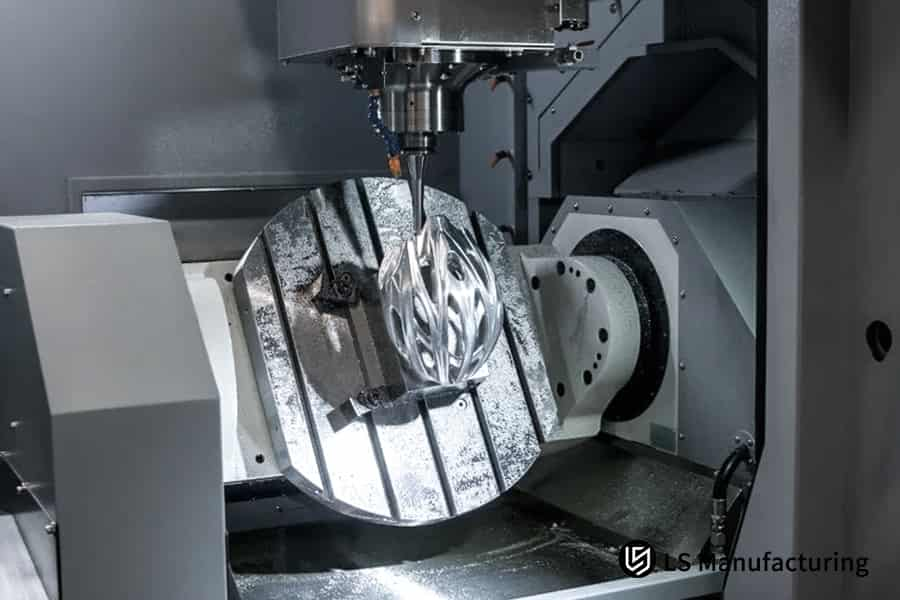

Figure 1: 5-axis machining medical-grade titanium alloy surgical device manufacturing.

What Special Technical Requirements Must Be Met For 5-Axis Machining Of Medical Equipment?

Medical device manufacturing is an area that requires extraordinary accuracy, surface, and biocompatibility conditions that literally stretch conventional machining capabilities to the limit. Here in this paper, we have elaborated our method of overcoming such issues via various integrated technical solutions, with a focus on precision medical machining execution:

Achieving Sub-Micron Surface Finishes for Osseointegration

More than just regular milling, we use an elaborate multi-stage process. Following initial 5-axis contouring, a separate non-contact tool path strategy is designed particularly for the final passes, thus reducing tool pressure to a minimum. Then a mechanical polishing method exclusive to us with medical-grade abrasives is used. We employ digital in-process monitoring of the surface topography to always produce Ra 0.15μm, which directly enhances bone cell adhesion on implants.

Maintaining Tool Edge Integrity for Surgical Sharpness

When cutting edges have to be small with radii below 10µm, we go for micro-grain carbide tools that are equipped with special coatings. What really makes the difference is our dynamic 5-axis milling strategy that keeps the tool engagement angles at the optimum and constant levels thus preventing edge chipping. Spindle power consumption is used as a wear indicator for the tool, on which basis the CNC program is automatically compensated, thus ensuring every produced edge meets the sharpness specification.

Ensuring Structural Integrity Through Sterilization Cycles

We make parts mechanically robust right from the CAM stage. For those instruments that endure more than 200 autoclave cycles, we analyze the thermal and stress variations during the cycles and identify the areas that are most likely to fail. In the case of machining, we modify feeds and speeds and use certain tool paths that completely remove subsurface micro-cracks and residual stress that could lead to failure during repeated sterilization, thus, ensuring long-term performance of the instrument.

Managing Complex Geometries with Unified Accuracy

When the anatomy is complex, our method fully utilizes 5-axis medical device manufacturing capabilities to machine the whole surface of the part in a single setup. We perform on-machine verification with probing to generate a real-time error map. The CNC program then dynamically changes the subsequent toolpaths to correct any machine or fixturing deviations, thus ensuring that the final part is within the very tight tolerance of ±0.02mm consistently.

Our documentation presents clear, verified methodologies used during the medical grade CNC machining. It is one of the ways that we set ourselves apart in that we not only acknowledge the challenges but also specify how the work is done that results in solving them. We point out that it is by integrated process design and continuous in-process verification that the focus on precision and the sustained achievement of biocompatibility is possible.

What Specific Requirements Does The ISO 13485 Quality System Impose On Medical CNC Machining?

The ISO 13485 standard requires the implementation of a proactive, risk, based quality management system for medical device manufacturer. The paper explains how this standard influences machining processes, thus making the first parts of the standard more practical and more straightforward to verify by regulatory authorities and also by the clinical end, users.

| Requirement Area | Implementation in CNC Machining |

| Full Process Traceability | We hold electronic records for each of the 128 quality nodes, starting with raw material certification and going on to final inspection, thus we can prove complete lot and unit history. |

| Unique Device Identification (UDI) | In accordance with MDR/FDA requirements, a unique UDI is given and marked on each implantable part through 5-axis machining or laser engraving. |

| Process Validation & Control | Every 5-axis CNC services program is validated, and critical parameters such as tool wear and surface finish are monitored in real, time using statistical process control (SPC). |

| Corrective & Preventive Action (CAPA) | A unified ERP-MES system helps our staff to perform a root cause investigation and contain any non-conformance within 2 hours, thus the same issue will not be repeated. |

| Supplier & Material Control | Materials are only taken from approved suppliers and are checked upon receipt to confirm that they comply with ASTM/ISO material standards, and another check is done before the release to production. |

| Infrastructure & Calibration | Regular, documented calibration of all 5-axis CNC machines and inspection equipment keeps measurement integrity and process capability at a high level. |

This framework takes the ISO 13485 machining principles and turns them into a powerful operational backbone. We assist clients in overcoming the major challenge of tightly combining quality management with 5-axis medical machining, thereby not only achieving compliance but also providing a thoroughly auditable, dependable, and efficient production process from which risks are minimized and time-to-market is accelerated for complicated medical devices.

Figure 2: 5-axis machining medical-grade metal surgical device manufacturing.

How To Achieve Precise Anatomical Matching For Customized Implants?

Custom made patient-specific implants must be the physical realization of the patient's anatomy with a manufacturing accuracy of the order of the micron. This medical imaging to custom medical implants machining association is the key that allows solving the twin challenge of ensuring anatomical matching with perfection and achieving biomechanical functionality:

From Medical Imaging to Machining Blueprint

- Data Segmentation & 3D Reconstruction: Using software that allows converting patient CT/MRI scans into a precise-sealed 3D model of the anatomical structure.

- Implant Design & Virtual Fitting: Digitally designing the implant within the reconstructed anatomy, thus ensuring an optimal fit and necessary surgical clearance.

- Path Generation for Complex Surfaces: Using advanced CAM software for automatically generating efficient, collision-free 5-axis contouring strategies from the complex surfaces of the implant.

Executing Precision with Sub-0.1mm Tolerance

- High-Fidelity Machining: We used 5-axis precision machining in a single setup to fabricate the implant's unique shape very accurately, thus eliminating errors due to multiple re-fixturing.

- In-Process Verification: On-machine probing was used to scan the critical contours mid-process, thus the changes in toolpath can be immediately made during the process to keep the critical ±0.1mm match tolerance.

- Surface Integrity Control: We perform finishing operations specifically biocompatible material to get a surface that encourage incorporation and still maintain dimensional accuracy.

Validating Biomechanical Performance & Fit

- Finite Element Analysis (FEA) Integration: The FEA of the product was carried out to check the physiological loading of the model, then with the help of topology optimization, the stress shielding was reduced to less than 15%.

- Physical Fit & Form Verification: Anatomical models were made by 3D printing from the patient data which were used for the physical pre-surgical fitting of the implant.

- Dimensional Final Inspection: A CMM scanner was used to generate a complete 3D deviation report which serves as a quantifiable evidence of the matching accuracy of the original patient model.

This methodology outlines a closed-loop process from scan to 5-axis medical part. We close the loop from scanning to parts manufacture. We tackle the anatomical matching problem of the customer which is also verifiable along with biomechanical efficacy, resulting in anatomical matching with verifiable biomechanical efficacy, through integrated engineering and 5-axis medical device manufacturing, thus each implant combining precise fit and long-term clinical performance.

How Does 5-Axis Machining Of Surgical Instruments Ensure Reliability For Long-Term Use?

One of the major factors affecting the long-term reliability of surgical instruments is their capability to maintain cutting sharpness and structural integrity even after many procedures and sterilization cycles. This paper elaborates on the integrated technical approach needed to overcome the two intertwined challenges of extreme sterilization resistance and the maintenance of instrument durability in surgical tool machining:

Material Selection and Stabilization for Core Integrity

We deal with material degradation by choosing the best powder metallurgy high speed steel (PM-HSS). At the heart of the 5-axis machining process is a proprietary multi-stage vacuum heat treatment. This tightly controls the austenitizing and tempering cycles so that a hardness of HRC 62-64 is uniform and stable throughout the cross section of the tool, thus eliminating the soft spots that would result in wear or failure under cyclic stress.

Achieving and Maintaining Cutting-Edge Precision

Constant edge shape conformity is vital to performance. We have 5-axis grinding technology with diamond/CBN wheels on dedicated CNC tool grinders. The tool lies down on the bed, and a 5-axis simultaneously moves the grinding wheel to achieve perfect surface finish and accuracy. The grinding procedure constitutes using dynamic axis interpolation to keep exact rake and clearance angles over the whole flute length. Such a fine edge radius tolerance of 0.005mm causes very uniform and slightly changed cutting forces and the generation of the heat during tool working.

Engineering for Repeated Autoclave Stress

One way of thermal fatigue can be avoided is by the tool design studied for stress concentration points. There is the use of very precise 5-axis grinding technology wheel paths together with cooling strategies at the same time to perform polishing impact residual compressive stress on the very surface and just below the surface. These compressive residual stresses locally balance the tensile ones brought about by cyclic heating/cooling (autoclaving) thus significantly prolonging the service life of the tool beyond 200 cycles.

Validating Performance Through Accelerated Life Testing

Trustworthiness has to come from proof. To verify the validity of the whole manufacturing process, the instruments after completion are subjected to a series of tests, such as automated cutting simulation against bone, compound materials, followed by immediate autoclave cycling. Cutting force is monitored digitally; a sustained increase beyond a set threshold indicates edge degradation, providing quantifiable data on instrument durability and validating the entire manufacturing methodology.

This paper presents a systems-engineering approach to reliability as the main theme. We take care of the client's issue of unpredictable tool failure by combining material science, precision 5-axis machining, and engineered stress management into a manufacturing process that has been verified, thus guaranteeing stable performance and lowering the cost of the life cycle of the critical surgical instruments.

What Special Process Controls Are Required For Processing Medical-Grade Materials?

It is a fact that strictly controlled machining of medical grade materials is very different from the usual metalworking to the extent that higher standards are needed to preserve the biocompatibility of the material and its mechanical properties. Herein, the author specifies the particular, measurable parameters of the process that are indispensable for the assurance that the material processing will not cause a compromise in the quality of the finished medical device.

| Material & Challenge | Key Process Control & Implementation |

| Titanium Alloys (e.g., Ti-6Al-4V) | Keep the processing temperature under 150°C through high, pressure coolant and dosing of high-speed 5-axis contouring parameters in order to avoid alpha, case formation and micro-cracking. |

| Cobalt-Chrome Alloys | Control the temperature and avoid microstructural changes such as sigma phase precipitation by using Minimum Quantity Lubrication (MQL) with selected ester-based fluids during 5-axis finishing. |

| Medical Plastics (e.g., PEEK, UHMWPE) | Apply exclusive tool profiles and dry machining with cold air to control heat and avoid polymer degradation or melting, thus securing dimensional stability and surface quality. |

| Stainless Steel (316LVM) | Use controlled, sharp cutting tools and specific chip-breaking strategies to prevent work hardening and keep the structure of austenite which is very important for corrosion resistance. |

This system turns material science into practical machining protocols. We respond to the most important customer challenge of continually having certified biocompatibility and material performance by creating and testing a database of validated, material-specific 5-axis techniques that allow the as-machined component to satisfy both design intent and regulatory requirements.

Figure 3: Custom medical implants machining titanium alloy medical implant manufacturing.

LS Manufacturing Orthopedics Division: 5-Axis Machining Project For Custom Knee Implants

The orthopedic implant case study explains how we addressed a very important challenge in patient-specific care: transforming complex anatomical data into a high-precision, biocompatible custom knee replacement by means of disciplined 5-axis medical manufacturing:

Client Challenge

A medical device OEM wanted a patient, specific femoral implant in medical-grade Ti-6Al-4V ELI. The biggest challenge was to make a sub-0.2mm anatomical fit and a Ra μ0.4m surface finish to facilitate osseointegration. Their former 3-axis machining supplier delivered a 0.5mm fit error leading to a loss of money due to surgical revisions, patient timeline delays, and their custom implant program regulatory submission was at risk.

LS Manufacturing Solution

We started our integrated digital workflow by changing the patient CT data into a certified 3D model. To machine the complex condylar geometry we used 5-axis precision milling in a single setup, employing dynamic toolpaths to ensure consistent cutter engagement. The next validated polishing process not only yielded the critical surface finish but also ensured that the dimensional integrity was intact, thus directly addressing the root causes of the previous failure.

Results and Value

The resulting implant exhibited a 0.15mm anatomical match and a Ra 0.3μm surface finish. This precision-driven outcome allowed the surgeon to perform the operation in 40% less time, and it also facilitated the client's regulatory approval, resulting in both FDA 510(k) and CE marking. The project was a proof, of, concept for a dependable, scalable pathway for their complex patient-specific device portfolio.

This is an example of our single-source responsibility in taking complex design intents to certified devices. We address the critical client challenge of delivering predictable, first-pass success in high-stakes custom knee replacement projects by seamlessly integrating digital engineering with proven 5-axis medical manufacturing execution, which means we guarantee both clinical efficacy and an accelerated time-to-market.

How Does A Sterile And Clean Production Environment Ensure The Safety Of Medical Devices?

A controlled production environment is key to medical device safety, it helps to prevent contamination which could compromise sterility and hence patient outcomes. This paper describes the detailed cleanroom manufacturing operational protocols that are maintained throughout the manufacturing process which help to preserve the integrity of devices all the way to their final sterile packaging:

Environmental Parameter Control & Real-Time Monitoring

- Precision HVAC Systems: Stringent conditions at 20°C ±2°C and 45% RH ±10% are maintained to prevent microbial growth and bring about material stability.

- Continuous Particle Monitoring: Laser particle counters, coupled with data acquisition systems, give real, time data of air suspended particulates (≥0.5µm), thus ensuring the maintenance of ISO Class 7 (ISO 14644-1), compliant environment at all times.

- Differential Pressure Management: By maintaining positive air pressure at the space components level, contaminants from the less clean areas outside the critical zones are prevented from entering.

Contamination Control During Processing & Handling

- Regimen for Personnel & Material Flow: Continuous personnel gowned-up and material entering through dedicated airlocks equipped with staged decontamination protocols.

- Tooling & Process Isolation: Critical finishing and assembly stations are equipped with localized laminar flow hoods, and 5-axis finishing of implants is often carried out in enclosed machine chambers that maintain a purified micro environment.

- Validated Cleaning Procedures: All fixtures and work surfaces are cleaned with approved cleaning agents in accordance with documented and audited SOPs to remove residues.

Ensuring Sterility Through Final Packaging

- In-Line Packaging Integration: The final packaging operation is carried out in the cleanroom's critical zone to eliminate the risk of exposure after inspection and before sealing.

- Package Integrity Testing: We regularly conduct seal strength and dye penetration tests on the packaging to confirm the barrier's effectiveness in preventing microbial ingress.

- Biological & Process Validation: The whole sterile packaging process, depyrogenation to sealing, is formally validated to ISO 11607 standards to confirm sterility is maintained until point of use. This guideline describes contamination control in a closed-loop system.

We mitigate the CMs extremely high risk of 5-axis medical product contamination by implementing and validating an integrated cleanroom manufacturing system that also provides the documented evidence for regulatory audits and thus guarantees the delivery of safe, sterile devices on a consistent basis.

Figure 4: 5-axis milling large aluminum alloy industrial mold manufacturing precision parts.

How To Establish A Complete Traceability System For Medical Devices?

A strong traceability system is essential not only for patient safety but also for regulatory compliance and efficient quality management. Such a system should be capable of creating a complete and detailed chain of data for every component that is also unchangeable, thus it needs to go beyond just documentation. The following text describes the combined data architecture and the technologies necessary to meet the 5-axis machining challenge of providing real end-to-end device traceability:

Granular Data Capture at Every Manufacturing Node

The bedrock of this is to have a regular, systematic recording of the more than 32 crucial data points at each process stage. In 5-axis CNC medical manufacturing, sensor devices can directly record program codes, tool IDs, and in-process measurement results. Material certificates, batch numbers, inspection reports are, along with the job, linked digitally. Consequently, a precise digital twin of the part's production history is formed, which paves the way for an instantaneous remedy to any manufacturing parameter query.

Unique Identification and Data Structuring for UDI

UDI compliance is realized by the assigning of a permanent, nicely shareable unique identifier (GS1-compliant) to every single device unit. This UDI works as the main key in our database, a key that is used for accessing all granular process data that have been linked. The format of quality records follows the Single Device Identification (SDI) model, which is a model that defines the organization of information by the particular device version, production lot, and serialized unit so as to support traceability both at the lot and unit levels.

Ensuring Immutability and Secure Data Integrity

Critical 5-axis machining quality records are routed through a permissioned blockchain node in order to prevent loss or tampering of data. An immutable audit trail is created when a cryptographic hash of each unit's entire dataset is produced and stored on the chain. This discloses any post-facto alteration immediately, and proves record integrity beyond a doubt, which is helpful for FDA audits and internal quality reviews.

This paper describes our comprehensive data architecture. We address the client's difficulties of preparing complex audits and the slow failure investigation by providing a system in which device traceability is automatic, data is tamper-evident, and the entire history of any part can be obtained within minutes, thus, directly facilitating risk management and compliance requirements.

Why Choose LS Manufacturing As Your Medical Device Manufacturing Partner?

This paper illustrates how LS Manufacturing's engineering solutions can overcome the critical challenges of producing complex medical devices that require stringent regulatory compliance. Our main objective is to convert technical specifications into dependable, compliant hardware through precision manufacturing and comprehensive quality assurance. The core technical reasons are as follows:

Precision Machining of Complex Bio-Compatible Geometries

- Challenge: Producing entirely monolithic parts of titanium or PEEK with complicated internal channels or contoured surfaces.

- Our Solution: We employed integrated 5-axis machining centers along with CMM validation.

- Integrated 5-Axis Strategy: Simultaneous contouring removes the need to reposition the workpiece and thus, the organic shapes become flawles.

- Toolpath Optimization: The algorithms evenly distribute the cutting forces on the thin walls and thus harmonic distortion is avoided.

- In-Process Metrology: The on-machine probing helps to ensure the release of final unclamping is only done when the critical interim dimensions are in control.

Systemic Quality Assurance from First Article to Lot Release

- Challenge: Being able to maintain both traceability and statistical control for a low-volume, high-mix production environment.

- Our Solution: We have created a closed-loop digital thread that connects design, execution, and verification.

- Digital Traveler System: The material certification, machine logs, and inspection results are just some of the files that get embedded into a component lot's unique digital history.

- Statistical Process Control (SPC) for Low Volume: Implement moving-range control charts that are specifically designed for small batches and thus able to detect process drift from very limited data.

- First Article Inspection (FAI) Depth: FAI reports help technical documents going beyond the checking lists by analyzing the dimensional correlation in order to predict the assembly performance.

Engineering for Global Regulatory Compliance by Design

- Challenge: A proactive design of the medical device manufacturing process which will satisfy FDA 21 CFR Part 820 and EU MDR audit trails.

- Our Solution: Regulatory compliance becomes part of process workflows itself, not only documented retrospectively.

- Controlled Environment Protocols: Our ISO Class 7 cleanroom provides particle monitoring linked to batch records; gowning procedures are validated.

- Validation Master Planning: Process validation (IQ/OQ/PQ) is based on risk-based principles (ISO 14971), limiting the focus to critical parameters.

- Change Control Rigor: Even a tooling substitution triggers a documented impact assessment on the Device Master Record (DMR) that is thoroughly analyized.

We provide the engineering rigor to take complex designs and make them into manufacturable, compliant products, thus representing the crucial link between innovation and delivery that works. Our capability as a medical device manufacturing partner is confirmed through our expertise in 5-axis medical device manufacturing, integrated quality systems, and a forward, looking regulatory strategy.

FAQs

1. What is the minimum feature size achievable in medical device manufacturing?

The minimum feature size is 0.1mm, and the minimum hole diameter is 0.3mm, which meet the precision machining requirements for minimally invasive surgical instruments.

2. What are the certification requirements for implant surface treatment?

Surface treatment must go through ISO 10993 biocompatibility testing to confirm that cytotoxicity and sensitization are at an acceptable level.

3. How is precise matching between the implant and the patient's anatomical structure ensured?

With 5-axis machining based on reverse engineering from patient CT data, the matching accuracy is 0.1-0.2mm.

4. What manufacturing quality documents are required for medical device registration?

A complete set of DHF and DMR documents are required, including process validation and quality records.

5. How is the service life of surgical instruments verified?

Tool durability is confirmed by means of accelerated aging tests, thus performance after ≥200 sterilization cycles is at a standard level.

6. Do you support the mechatronic manufacturing of active medical devices?

We boast mechatronic manufacturing lines, thus we can also support the integrated processing of implantable device housings and internal structures.

7. How is medical device change management implemented?

We have a strict change control system in place, and all changes must be verified and any such changes must also be reported to the regulatory bodies.

8. What special requirements need to be met for international market access?

We comply with the regulatory requirements of the major markets such as FDA QSR and EU MDR thus facilitating global market access.

Summary

5-axis manufacturing of medical devices involves not only accomplishing very stringent technical precision requirements but also strictly following regulative standards. We can guarantee the safety, efficacy, and reliability of medical devices by using professional 5-axis machining technology, a complete quality system, and having a lot of experience in the medical industry. The professional medical device manufacturing system at LS Manufacturing offers customers complete end-to-end solutions from the design and development stage to mass production.

Contact the LS Manufacturing medical project team today if you want to get a free "Medical Device Manufacturing Compliance Assessment Report"! Our team of medical device professionals will thoroughly examine your product's technical specifications, regulatory routes, and manufacturing solutions, thus helping your product gain regulatory approval in no time. Make an inquiry now and also get medical device design optimization tips to ensure manufacturing feasibility.

Unlock precision for life saving devices with our certified five axis medical manufacturing solutions today.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.