5-axis CNC machining services offer an optimal solution to the burning issue of manufacture concerning the efficient and effective manufacturing of curved shapes. When it comes to manufacturing blades in turbines and medical goods, conventional machining processes that involve 3 axes and setup procedures ensure error margin, longer machining time, hence resulting in an increment in the cost involved due to manufacture complexity.

The major problem with this technology is associated with natural restrictions generated by conventional machining practices. In 3-axis machining, there exist movement restrictions because this technology does not involve complex movement of space. The major competitors in this industry lack the required equipment used in 5-axis machining; this becomes an issue with respect to required precision associated with the current manufacturing technology at hand.

5-Axis CNC Machining Services Quick Reference Guide

| Section | Key Points |

| What It Is | 3+2 CNC machining. The axes of the machine are labeled A and B, or A and C. |

| Key Capabilities | Complex contours, undercuts, single-setup machining, high-precision parts. |

| Common Processes | Milling, drilling, contouring. |

| Materials | Metals - Al, Ti, Steel, Plastics, Composites. |

| Design Benefits | Reduced setups, faster prod, better accuracy, complex geometries. |

| Industries Served | Aerospace, Medical, Automotive, Energy, Defense. |

Therefore, the 5-axis CNC machining will be able to manufacture complicated and precise pieces by just a single processing thanks to the motion of the cutting tool/work piece in 5 axes. This technique reduces processing time; it also guarantees accuracy in the product, with desired geometric configurations that are usually required for medical/aero parts.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

5-axis CNC machining technology has the ability to make complex parts in a single setup. It can work out of the conventional principles of manufacturing involved in continuous rotation of tooling in order to cut the pieces. The greatest advantage of this technology is within its capability of offering the complex pieces a platform within which they can be developed within a single setup, thus offering efficiency and reducing errors within the processes of manufacturing. The subsequent sections shall discuss how this technology works.

The insights shared herein are hammered out from over a decade of practical experience in producing over 50,000 custom 5-axis machined parts. Each project, from aero-engine impellers to medical implant molds, has taught us something critical. We've learned how to optimize toolpaths for titanium, maintain stability for thin-wall aerospace structures, and ensure precision that meets the strictest industry benchmarks, including those from the Aluminium Association (AAC) and Metal Powder Industry Federation (MPIF).

Every tip and guideline here is born from both triumph and costly early trial. We share knowledge verified by cutting oil, metal chips, and rigorous inspection-not just textbook theory. Our goal is to provide the trusted, practical expertise we use daily, helping you navigate the complexities of 5-axis machining with confidence and achieve outstanding results.

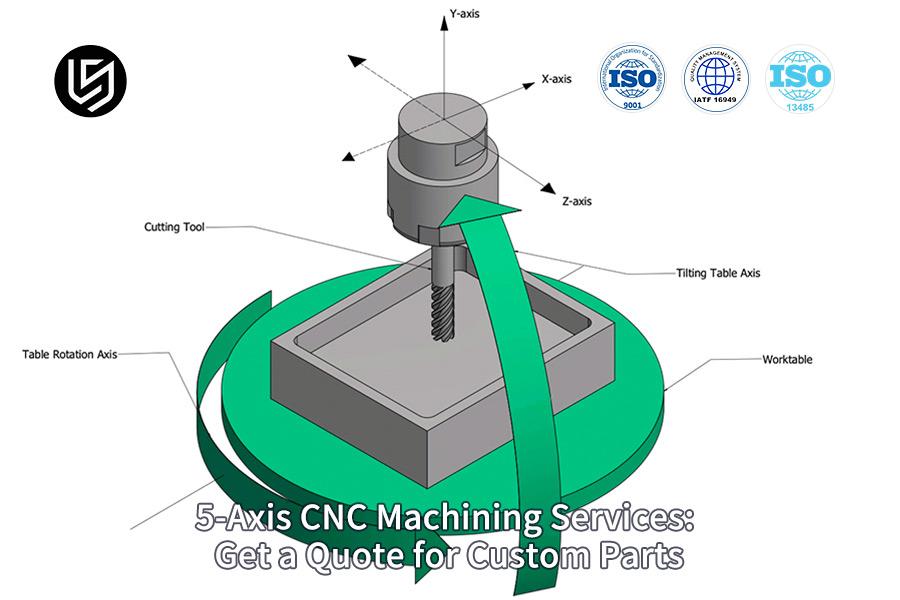

Figure 1: Quotation for complex component manufacturing via precision 5-axis machining by LS Manufacturing

Why Can 5-Axis CNC Machining Achieve One-Time Forming Of Complex Parts?

5-axis CNC machining principle basically allows for the fabrication of complicated components in one setup. This manufacturing technique goes beyond other techniques because it allows for continuous tool orientation relative to the workpiece. In their essence, the core advantage is letting complex parts are formed in one step - a process that reduces both the time of production and potential errors. In the following sections, the mechanisms and benefits that make this possible are outlined:

The Nature of Interconnected Movement

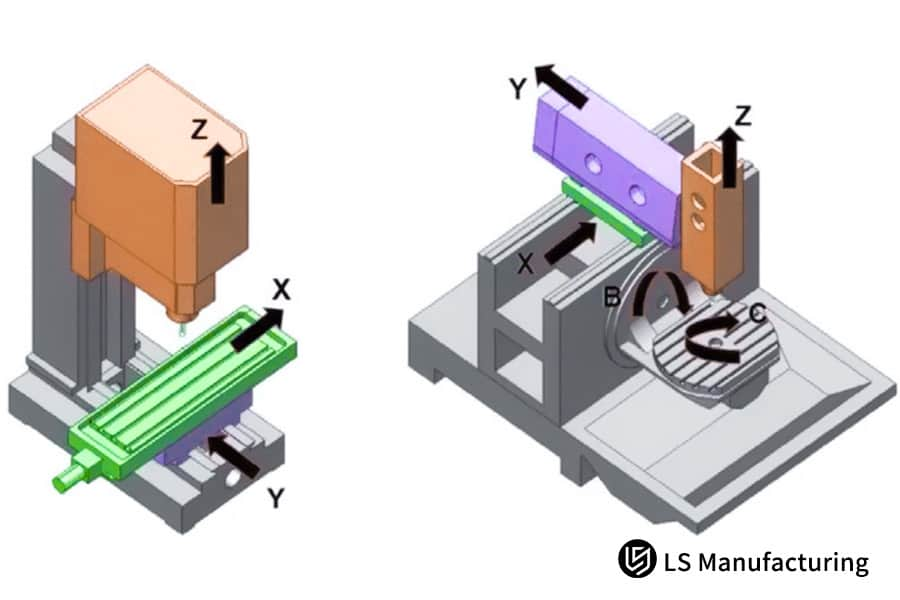

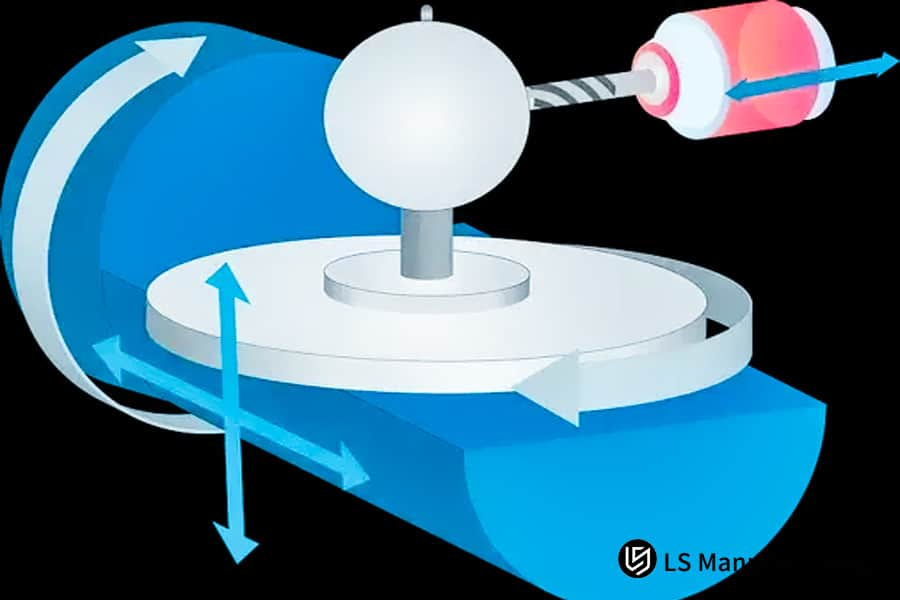

The 5-axis linkage technology makes this possible. By this point, the machine had the ability to move on the X, Y, and Z axes, and also the ability to rotate on two other axes: the A and C axes. Nevertheless, the rotation capability of the A axis is on the X-axis, while that of the C axis is on the Z-axis. This machine thus has the ability to cut the material from any angle.

Improving Accuracy and Efficiency

The first impact resulting from the technology is improved machining accuracy. This is because, with the technology, the process is completed under one clamping, thus eliminating potential mistakes that could result from a number of set-ups required to accomplish the task if carried out through 3-axis machining, to say a few. Besides, it enables a machine to apply short-cutting tools, hence reducing vibrations and allowing faster feeding speeds.

Technical Implementation and Variations

High-performance machines need proper configuration. There are mainly two types of them. The first is the table-table or cradle system machine, and the other one is the head-head or tilting spindle machine. A cradle system is common for smaller precision parts as in this system, the part to be machined is fixed on two tilting axes, which rotate with the part to be machined. But in the case of the tilting spindle machines, which are common for heavy parts, the cutting head rotates the parts to be machined. The result for both machines is different.

Simulation and Path Optimization

Modern precision 5-axis machining makes use of high-precision software simulations of machining paths through advanced CAM software. The CAM software ensures optimal collision-free tool path simulations that deploy machine motion capabilities fully. Simulation allows for visualization of machining processes involving an optimal cutting position of the cutting tool on surfaces that go beyond conventional 3-position movement of the cutting tools.

The 5-axis CNC machining system is an invention that completely changes the processing involved in the manufacture of complicated items. Addition of 5-axis linkage technology in a device enables it to support the most important function-allowing complex parts are formed in one step, directly contributing to an improved machining accuracy. The entire concept of a 5-axis CNC machining principle is an invention for the function that is needed in modern processing.

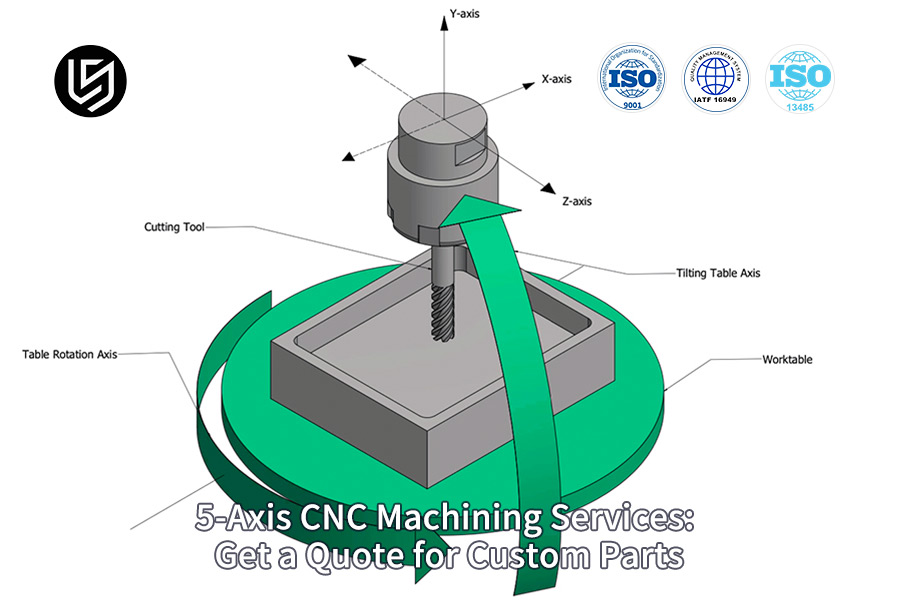

Which Industry Applications Require 5-Axis CNC Machining Services The Most?

5-axis machining industry applications are critical in fields where compromise cannot be made to the sophistication and integrity of machine parts. It's considered innovative technology to the CNC machining service that applies in producing machine parts with intricate geometry and finish or from hard materials. Technology with the advantage of making this possible with minimal setups makes it an important resource in valuable fields, where it offers efficiency in the CNC machining service cost.

| Industry | Key Applications & Requirements | Why 5-Axis is Essential |

| Aerospace | Aerospace parts processing such as turbine blades, structural frames, and lightweight components. The precision in tolerance is very high, with geometrically complicated shapes and heavy materials used, such as titanium. | Allows processing components in a single setup for complex shapes, optimal angles of difficult materials, and accurate weight reduction and strength definitions. |

| Medical | Precision manufacturing of medical devices, such as orthopedic components, surgical utensils, and dental components. This is because it involves high precision for surface finishes, which deal with biocompatibility and accuracy. | Allows the making of complicated shapes in custom medical parts produced from biocompatible materials like titanium or PEEK with high accuracy, namely in microns. |

| Automotive | High-performance automotive parts processing such as engine blocks, turbocharger housings, prototype molds, and so on. There will be a large volume of requirements in such a process with a certain degree of consistency or accuracy in relation to that. | This will help in the manufacture of complex parts such as cylinder heads, and this will mean that there will be lighter vehicles with longer mileages. |

| Emerging | Sectors parts of turbines, optical apparatuses, et analysis devices for apparatuses. Relier au produits with complex channels, lenses with complex shapes, et small beams. | Enable creates products with complicated shapes like impellers et molds for optical components owing to being a crucial key for innovative Green Tools et analysis devices for apparatuses. |

Ultimately, as has become clear in this brief analysis, the market demand for 5-axis CNC machining services is most evident in relation to industries driven by technology in relation to concerns about complexity and quality. Beginning with the required aerospace parts processing down to the required automotive parts processing and others in between, it is clear that this service has remained unparalleled in its benefits regarding consolidation as well as its accuracy.

Figure 2: Utilizing 5-axis CNC machining to produce custom complex parts by LS Manufacturing

How To Evaluate The Technical Strength Of A 5-Axis CNC Machining Supplier?

A proper 5-axis machining supplier evaluation is very crucial for succeeding in your project since your part quality, accuracy, and lead time are all dependent on this. It is not just an evaluation involving the pricing consideration but also extends far beyond that since an evaluation will be done on the CNC machining technology strength offered by your supplier since this will involve an assessment on their ability and quality control processes, thereby implying that your supplier is capable enough to be your custom CNC parts manufacturer.

| Evaluation Dimension | Key Criteria & Questions | Purpose & Rationale |

| Technical Infrastructure | Types of machine tools which could be studied: Brands, Types, Age groups, and availability regarding accuracy calibration of machine tool work. Availability regarding Auxiliary machine tools such as coordinate measuring machine or tool preseter. | For verification of your specified tolerance parameters, material, and sizes. High-quality, up-to-date machines are the backbone of CNC machining technology strength. |

| Expertise & Certification | Review engineering experience for expertise or technical certifications and a quality management system (ISO 9001, AS9100, or ISO 13485). | Review technical problem-solving expertise and process capability control as a bibliographic function. Relevant processing quality certification related to the manufactured products of a supplier offer a non-negotiable supplier selection criteria related to that industry. |

| Proven Capability & Validation | Review examples of past work, check for references with clients, and what proves even more significant – a test part run for a genuine custom CNC parts manufacturer. | Apparently, for purposes of determining proof versus mere claim. A test part provides a clear result concerning machined precision and end product quality, directly verifying their claim of capability. |

A complete 5-axis machining supplier evaluation must take into account all the key factors. This integrates the objective information garnered from the machine audits and processing quality certification with the subjective proof from the case study and processing test. In conclusion, identifying a competent supplier fundamentally translates to identifying a supplier whose CNC machining technology strength and supplier selection criteria are exactly matched with the technology requirements of your task.

What Are The Core Cost Elements Included In A 5-Axis CNC Machining Quote?

A cost breakdown 5-axis machining cost analysis is a fundamental aspect of a budget. The cost of such a sophisticated technology will not be a simple solution but a series of interlinked factors. Anaccurate quotation analysis will necessarily involve a clear explanation of the interplay between the benefits derived from a 5-axis CNC machine and the intrinsic operating cost of the technology that underlies it. The core CNC machining pricing elements can be categorized as follows:

- Machine and Equipment Costs: Essentially, the prime cost that is involved is in relation to the high-tech machines. Probably, this is what is implied in this costing segment as regards extremely high-tech machines that reflect the cost of the high quality of the machines in terms of the efficiency calculated in relation to the machines. It is for this reason that the high-capable spindles, the high-tech controllers, as well as the cutting tools that have made machine time a major consideration in CNC machining pricing elements.

- Labor and Programming Costs: It requires expertise not only to get the benefits of 5-axis CNC but also expertise in programming and simulation programming of the collision avoidance system in a CNC machine. These employees are among the most qualified people working in any field and cost a lot; secondly, there is the programming cost related to programming complex routes for the 5-axis machine and are crucial in arriving at the 5-axis machining cost analysis.

- Material and Overhead Costs: These are comprised of material-quality aluminum or titanium alloy and then various consumables such as coolants and fixtures. However, while non-negotiable material costs are one thing, there is a cost associated with the overheads that include quality control processes such as CMM, project management processes, facility management processes, right down to ISO 9001 certifications and so on, that are more so at an infrastructure/requirement level rather than a processing cost optimization.

- Optimization and Volume Factors: Processing cost optimization directly affects the quote. This involves design for manufacturability (DFM) recommendations to facilitate easier machining, optimal batch size to offset higher setup costs per piece, and optimal part nesting. Comprehensive and accurate quotation analysis by an experienced supplier will point out such aspects, how optimization can fully utilize 5-axis technology to optimize costs.

In conclusion, the cost of 5-axis CNC services is made up of the synthesis of investment in advanced technology, skilled personnel, good materials, and strong systems. It is crucial tounderstand the concepts involved in the CNC machining pricing elements, as this empowers the client to partner with the manufacturer on processing cost optimization. In conclusion, with an accurate quotation analysis, the benefits of 5-axis CNC is well represented, considering the benefits accrued from this technology.

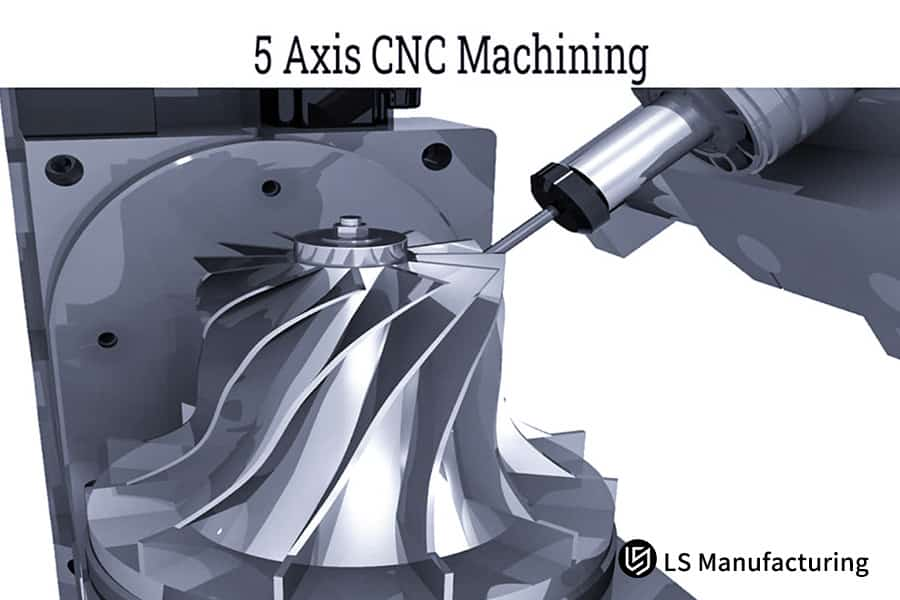

Figure 3: Advanced 5-axis CNC process for fabricating custom components by LS Manufacturing

Aerospace Field: 5-Axis Precision Machining Of Aluminum Alloy Waveguide Cavities For Satellite Communication

LS Manufacturing success case proves specific engineering in aviation. The challenges of taking up such tasks - in this case, the production of a satellite component - are an achievement in themselves. At the same time, 5-axis machining technology application was used strategically to overcome these challenges, something that will be underlined in detail in the following overview of the journey throughout the project.

Customer Challenge

A leading aerospace company needed a waveguide cavity for a low-orbit satellite that included extremely tight tolerances, an internal Ra0.4μm finish, dimensional tolerances of ±0.005mm, and absolute reliability of operation following thermal cycling. Traditional multi-step manufacturing approaches could not be expected to meet quality expectations for this type of aerospace precision machining nor offer reliable high-precision cavity manufacturing.

LS Manufacturing Solution

Our solution utilized a German 5-axis machining center dedicated for high-speed spindles and in-process metrology. The design and manufacturing of a customized fixture with optimization of the cutting strategy enabled the complex part machining to be machined in one setup. We also employed Minimum Quantity Lubrication (MQL) to control heat, ensuring the dimensional stability critical for the cavity's demanding performance specifications.

Results and Value

The project outcome was nothing short of revolutionary in character. The yield amount increased from 85% to as high as 99.8%, and the component lead time reduced by 50%. The direct financial value that was provided to the client was approximately estimated to be around 1.2 million RMB per year. This earned LS Manufacturing a "Premium Supplier" award, creating a long-term strategic relationship that underlines the value delivered through advanced aerospace precision 5-axis machining capabilities.

It demonstrates how 5-axis machining technology application solved high-precision cavity manufacturing problems and, on top of that, achieved the customer's objectives: to manufacture cavities with high precision, thus standing as a certain LS Manufacturing success case in complex part machining for the aerospace industry.

Handling complex components? Click here to place your order for a 5-axis machining system today!

Why Choose LS Manufacturing As Your 5-Axis CNC Machining Partner?

Selecting the right manufacturing partner is crucial for project success. LS Manufacturing advantages are built on a foundation of technological excellence, rigorous quality control, and deep engineering expertise. As dedicated precision manufacturing experts, we provide comprehensive reliable processing services that turn complex designs into reality. Here’s why we stand out as one of the premier 5-axis machining partners in the industry.

- Advanced Technology and Unmatched Precision: Unique precision, repeat positioning within ±0.002mm for several DMG MORI 5-axis machining centers, a workshop full of state-of-the-art hardware. Advanced tooling and in-process measurement enable the handling of tight tolerances and elaborate geometrical features; altogether this makes precision manufacturing experts true .

- Certified Quality and Process Reliability: We employ a dual-certified quality managing system according to ISO 9001 and AS9100 specifications, implanting the most stringent standards into every stage of production. The process makes sure that traceability and consistency in application-from the most mundane to space and medical applications that are deemed critical-are maintained. It forms the backbone of our reliable processing services, with every part guaranteed to meet high quality standards.

- Expert Team and Proactive Support: Our core engineering team comes with more than 10 years of average industry experience. These invaluable DFM insights, coupled with a 24/7 rapid response mechanism, help us in providing the customers with end-to-end technical support. In fact, this human touch makes us far more than 'just vendors' but true collaborative 5-axis machining partners committed to the success of your project-right from prototype to production.

- Proven Performance and Tangible Value: We turn that commitment into a 99% on-time delivery rate and continuously high customer satisfaction. Added value is more than a quote, and that's truly key to total cost reduction through efficiency, yield, and peace of mind. Ensuring performance centered around the key facets of the LS Manufacturing advantages we provide to every customer.

In other words, LS Manufacturing incorporates technological capability, certified quality systems, and expert collaboration in order to provide exceptionally high value. We are so much more than just a supplier; we are committed 5-axis machining partners and precision manufacturing experts you can depend on. For more complete contact for CNC quote and to experience for yourself our reliable processing services, reach out to a representative today to explore how we can help make your next project succeed.

How To Reduce 5-Axis Machining Costs Through Design Optimization?

Effective 5-axis machining design optimization stands as the most powerful tool for keeping a lid on manufacturing expenses without compromising part functionality. By incorporating Design for Manufacturability principles early in the development cycle, large cost savings can be realized. A focused cost reduction plan that harmonizes design intent with machining reality can hugely simplify production, which has a direct effect on driving down the bottom-line cost and significantly improving efficiency in a 5-axis CNC machining quote.

Strategic Design Simplification

The first and most fundamental principles of DFM are designing for the tool. Here, where internal corner radii are specified no smaller than one-third of the cutter diameter, extremely fragile small tools and extraordinary tool changes can be taken away, streamlining the process. This proactive processing technology improvement through geometry simplifies programming and enhances tool life, directly contributing to effective DFM cost control.

Structural and Tolerance Rationalization

Design for robust features. Instead of increasing the thickness all over, thin walls can be stiffened selectively with strategic ribs. Thus, vibration and scrap are avoided. Further, restricting critical tolerances to functionally essential areas rather than applying these universally mitigates time-consuming, high-cost precision machining. This approach forms the bedrock of any practical cost reduction plan for complex components.

Consolidation and Standardization

The bigger advantage that one can realize for 5-axis machining is by being able to consolidate several parts into one complex, monolithic component. This would be besides standardization of features wherever possible, for example, hole sizes, thread types, and tool access directions that minimize setup time and tooling requirements. In fact, the mere consolidation will be going a long way to optimize the 5-axis CNC machining quote by reducing part count, assembly labor, along with project complexity in general.

Early Collaboration for Maximum Impact

The greatest leverage for 5-axis machining design optimization comes from collaborating with your machining partner during the design phase. Their expertise in processing technology improvement can identify potential production bottlenecks and suggest alterations that are inexpensive on the drawing board but costly to implement later. This partnership is the ultimate form of DFM cost control.

In conclusion, intelligent design is the first and most effective step in managing manufacturing costs. Through deliberate 5-axis machining design optimization and a partnership-focused approach to DFM cost control, projects can achieve streamlined production and significant savings. Implementing a thoughtful cost reduction plan that incorporates these processing technology improvement strategies will invariably result in a more efficient, predictable, and competitive 5-axis CNC machining quote.

Figure 4: Precision budgeting for multi-axis CNC turnkey projects by LS Manufacturing

What Technical Information Is Needed To Obtain An Accurate Quote?

A set of technical data helps in completing the process of preparing accurate quotes rapidly. The data required to complete a proper 5-axis machining quotation data helps in understanding all the necessary data required by the parts, through which the provider will obtain a proper estimation regarding the time and cost required. The necessary data required by the quick quotation guide are as follows:

Core Geometry Definition

The point of departure would be the 3D CAD model that would preferably be expressed in universal formats like STEP or IGES. The progressive definition of complex surfaces would require the addition of a 2D representation that would contain defining dimensions in terms of critical dimensions, geometric dimensional tolerancing, or GD&T, along with the finish details. These would all be part of the stringent technical document requirements.

Material and Post-Processing Specifications

The specifications pertaining to the material, such as material alloy, material types, and material certifications that must be met, may be critical. The other specifications, such as heat treatment processes, types of surface finish processes including the types and thicknesses of anodizing, may also be critical. Clear specifications in these areas are vital for preparing accurate quotes that cover the entire manufacturing workflow, not just machining.

Order Details and Additional Requirements

With the inclusion of the ordered batch size and completion time for production preparation to be optimized for production preparation, additional order requirements can also include considerations for First Article Inspection (FAI) result submittals, industry-specific requirements (e.g., AS9100 and ISO 13485), as well as other customer packaging options. This comprehensive data set forms the complete package of 5-axis machining quotation data needed for a responsible proposal.

Finally comes the matter of the speed and accuracy of quotes, which is also directly proportional to the kind of data you will be dealing with. The key is to keep a quick quotation guide where you will list down all the technical document requirements so that there will be no hold-ups on the turnaround time due to a query. The listing of all the requirements for the 5-axis machining quotation data will serve the most successful start for the project launch.

How Does The Quality Control System For 5-Axis CNC Machining Ensure Part Accuracy?

In ensuring that the precision assurance system process is guaranteed, there has to be a full multi-step process for the accuracy of the outcomes. This is beneficial in the process because this is not only the final outcomes process but also a way of ensuring the quality at each step of the production process. The final outcomes process for 5-axis machining quality control would have to be carried out under a proper 5-axis machining quality control process that corrects a good 5-axis CNC supplier.

Pre-Process Digital Validation

Before any metal is cut, the part program undergoes simulation in advanced software like VERICUT. This critical step performs a virtual dry run, detecting potential tool collisions, verifying toolpaths, and simulating material removal. It is the first and most cost-effective layer of the precision assurance system, preventing costly errors on the machine and ensuring the program adheres to the initial quality inspection standards.

In-Process Monitoring and Adjustment

Real-time process monitoring in machining is carried out as part of the machining process using machine probe systems that are available in Renishaw. This is utilized for compensation for tool wear, Work-piece alignment verification, and in-cycle dimensional verification. This rounds out the feedback process that is needed for instantaneous adjustments that are used in pro-active 5-axis machining quality control.

Post-Process Final Verification

The product goes through a final verification inspection, which is fully done using a Coordinate Measuring Machine (CMM) system. Here, the result obtained from the analysis of a Coordinate Measuring Machine is directly opposed to the final product from a Computer Aided Design and 2D specifications related to quality inspection in order to establish whether it has met or exceeded quality inspection standards and is ready for release into the market.

A reliable precision assurance system in 5-axis machining has to be based upon the trilogy of prevention, control, and verification. A quality process for 5-axis machining quality control is a closed-loop system based upon digital simulation, process verification, and final metrology verification or verification of the complete closed-loop system in assessing a potential partner in quality 5-axis machining as a measure of a professional and reliable source in the aspect of accuracy in a 5-axis CNC supplier.

FAQs

1. Minimum order quantity and maximum machined size?

We are prepared to handle orders in all sizes, from prototyping to production volume, having the capability to accept orders from 1 piece in certain orders. The maximum sizes in machining are 1500×800×500mm (L×W×H), depending on the part models.

2. What is the lead time?

The lead time-based complexity order is as follows: simple part samples, 5 to 7 working days; parts that have medium complexity, 7 to 10 working days; and highly complex parts, 2 to 3 weeks. Of course, we do have an expedited process that could work as short as 72 hours; some fixes depend on particular processes or requirements.

3. Is material certification provided? Are testing reports available?

Yes, we supply all orders with a complete set of quality documents which may include but is not limited to: MTC, FAIR, Full Dimension Inspection Report, Surface Treatment Certification, and so on. All this documentation is fabricated according to the ISO 9001 standard in order to provide full traceability at all times.

4. How would you go about design change requests?

We have in place a flexible change response mechanism whereby, upon receipt of a change request, our technical team will do a change impact analysis within 4 hours with respect to the change in processes, cost, and date of delivery. If there are major changes made to the project, they will mention the plan of change so that the client is informed.

5. Which are the surface treatments available?

We provide complete surface finishing services, such as anodizing in various colors-natural, black, and colored anodizing, electroplating including nickel, chrome, and zinc electroplating, sand blasting of different sand mesh sizes, passivation, electropolishing, and powder coating.

6. Under which procedures are intellectual property rights protected?

We have various protection mechanisms through the use of confidentiality agreements in the form of NDAs, storing the client's data on private encryption servers, access control mechanisms, and destruction of documents when needed in line with set procedures after completion of the production process. We protect the intellectual property of the client accordingly.

7. Do you expedite orders?

Option of accelerated production is readily available, complete with a rapid response team and equipment. Urgent order processing includes the following: priority process review, equipment booking, and key process monitoring. Depending on the order on hand, customized accelerated options are developed to hopefully reduce delivery times without sacrificing quality.

8. How are quality issues resolved?

First Piece Inspection, In-Process Inspection, Final Inspection of Products-we have applied a quality assurance process. If any quality problem crops up, our quality management team will initiate a source analysis within 2 hours and send a preliminary analysis report in 4 hours to identify a solution for it within 24 hours. For the interests of customers, we take the corresponding quality responsibility.

Summary

The unique advantages of 5-axis CNC machining in manufacturing complex parts are explained in depth after careful examination of this article. With support from advanced equipment, a whole quality management system, and rich experience, LS Manufacturing has become the trusted partner of many high-grade production enterprises. We are not only involved with machining but also with overall solutions starting right from design optimization.

Feel free to upload your 3D design file today to get a custom quote and to get your valuable technical input from our engineers! Whether it is precision components for aerospace or functional components of a medical device, be guaranteed that every project is right on target with our technical know-how and quality requirements.

Unleash the full potential of 5-axis machining and optimize your manufacturing landscape. Click to get a personalized smart manufacturing solution.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.