Automated 5-axis machining is the solution to the current manufacturing dilemma. If you are troubled by tight delivery times, difficulty finding skilled workers, idle nighttime capacity, and accuracy and efficiency problems brought on by multiple clamping operations, it's because conventional models rely too much on manpower and fragmented processes.

The following article will show how to change the equipment into continuously profitable production capacity by analyzing the "unattended manufacturing unit" which is integrated with robotic loading and unloading and intelligent CNC. To save your time, the following will elaborate on why it is the inevitable choice for your intelligent manufacturing upgrade.

Automatic 5-Axis Machining Essay Quick Reference Table

| Module Theme | Key Points Overview |

| Core Value | Implement unmanned production 24/7 and turn investment in equipment into continuous production capacity to directly improve profit margins. |

| Pain Points Solved | Overcome delivery pressure, labor shortages, idle capacity at night, and accuracy and efficiency issues caused by multiple clamping operations. |

| Core Technology | Integrate 5-axis CNC with robotic loading and unloading and a central control system into one complete, intelligent manufacturing unit. |

| Key Benefits | Dramatically improve equipment utilization (OEE), ensure batch-to-batch consistency, and reduce overall cost per unit by as much as. |

| Implementation Way | Full-process service, from assessing the current status to customizing unit solution integration and commissioning and personnel training. |

| Return on Investment | Generally pays back the investment in 12-18 months and thereafter continuously contributes marginal profits. |

Conventional productions rely on skilled workers and face discontinuity of the production process. In contrast, an "unattended manufacturing cell" with a highly collaborative automated 5-axis machining is built up in a systematic way. It maximizes the potentials of the machining centers to make the accuracy and stability of machining extremely high, while changing fixed equipment assets into core productivity creating value 24/7 by maximizing efficiency of equipment and OEE.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

The insights and solutions in this guide are rooted in the decade-plus experience of LS Manufacturing in automated 5-axis machining, meaning we've machined high-precision engine impellers for use by our aerospace clients and manufactured critical surgical components for medical device companies. These experiences with challenging projects have laid a firm foundation for our capability to solve complex manufacturing problems.

Accumulated delivery of over 50,000 pieces with complicated workpieces has established a systematic technical knowledge base. For example, we have optimized packages of cutting parameters for Incon 718 alloy and developed a chatter suppression process for thin-walled components. Our quality management strictly follows the IATF 16949 standard, from programming to inspection, making sure that each step meets the demands for accuracy and reliability.

We continuously observe the world's state-of-the-art developments and keep contact with organizations such as the Society of Manufacturing Engineers(SME) to integrate advanced intelligent manufacturing concepts into local practice. Combining practical experience and authoritative standards, we provide already-proven end-to-end automation solutions. In choosing this guide, you are choosing a reliable partner with a wealth of successful case studies.

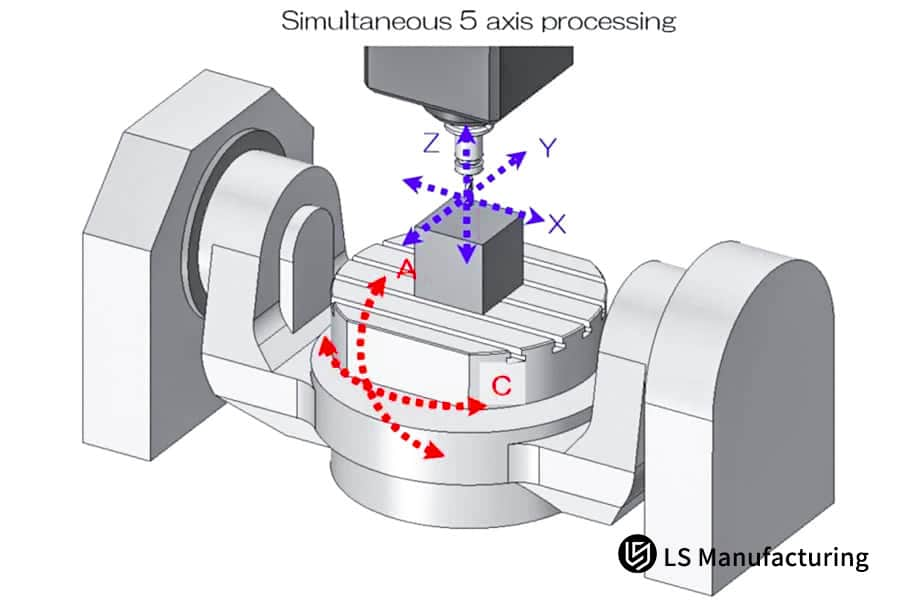

What Is Automated 5-Axis Machining?

Fully automated 5-axis machining actually represents more than equipping a 5-axis machine tool with an operator; instead, it is building a highly collaborative and intelligent manufacturing unit. Its core is 5-axis CNC automation, while its eventual achievement is the lights-out manufacturing advanced production model. Compared with conventional 5-axis machining, this constitutes a qualitative leap in the aspects of continuity, consistency, and manpower. The main manifestations are its system composition and advantages in the following 3 aspects:

- Integration of the Robotic 5-Axis Machining System: The core is the seamless connection that makes industrial robots and 5-axis machining centers achieve full automation of workpiece flow from blank warehouses to a machine tool table, then to the pallet of finished products. This not only liberates operators from repetitive loading and unloading work but also ensures that 24-hour continuous operation is possible.

- Scheduling of an Intelligent Control System: The system consists of a central control unit that is capable of intelligently scheduling the machining tasks, real-time monitoring of tool life and equipment status, automatic alarm in case of abnormalities, and switching to backup programs. All this makes the whole course of production transparent and predictable, transforming management from relying on human experience to data-driven processes.

- Lean Production Process Optimization: Linked into a high-efficiency production line, the automated 5-axis unit connects several machines together, greatly reducing waiting time between processes by optimization of cycle time. It eliminates instability in processing caused by manual intervention, which delivers unparalleled consistency during batch production and significantly reduces the overall cost per unit.

In a nutshell, the automated 5-axis machining is a great systemic innovation that essentially changes the conventional precision manufacturing workflow. By deeply integrating high-performance 5-axis machine tools, industrial robots, and intelligent sensors, it turns the intermittent production formerly dependent on human experience into a data-driven and continuous process with a central control system as its core.

What Are The Major Benefits Derived From Investments In Automated 5-Axis Machining?

Faced with fierce competition, the business decision-makers of the modern manufacturing industry have to calculate the real return on any investment with accuracy. Investment in automated 5-axis machining is not just equipment upgrading but a strategic move toward reshaping core competitiveness. The core value thereof is the benefits of automated machining. It transforms advanced equipment into stable and predictable capacity and profits. In particular, its advantages are clearly presented from the following dimensions:

| Advantage Dimension | Core Value Summary |

| Maximize the Use of Assets | Reaching 24/7 seamless production unlocks the value of 5-axis equipment. |

| Product Quality Consistency |

Precise robot operation fully excludes human error, which greatly improves yield rates. |

| Long-term overall cost reduction | Though initial investment is required, it leads to clear ROI through savings in terms of labor, scrap, and management costs. |

| To enable complex process capabilities | Realize high-precision machined, multi-faceted, and irregularly profiled complex parts in one clamping setup. |

To put it another way, the interrelated value system involves improving the profitability and market competitiveness of an enterprise, making better use of equipment, quality stability, optimizing the whole efficiency, and even more complicated manufacturing. It brings not only improvement in efficiency but also a key step in building future manufacturing barriers.

What Role Do Automated 5-Axis Machining Systems Play In Collaboration?

A precision automatic 5-axis CNC machining system operates like a finely tuned clock—not as standalone devices, but as an integrated unit functioning in seamless cooperation. At its core lies the concept of CNC Machine Tending, where robotic loading and unloading are intelligently merged with machining functions to achieve efficient, continuous, and “unmanned” production. The working principle of automated machining system can thus be visualized as a closed-loop process driven by a highly collaborative team, structured as follows.

| Process Stage |

Collaborative Work Summary |

| Intelligent Scheduling and Material Preparation |

The main control system gives the order, and then the robot accurately picks up the workpiece to be treated from the blank hopper. |

| Precise loading and unloading | The robot moves the blank to the 5-axis machine tool's worktable, automatically clamps it, and positions it, while at the same time removing the finished part. |

| 5-axis intelligent machining | The machine tool automatically closes the door after the robot leaves and begins multi-angle and high-efficiency precision machining according to the pre-set program. |

| Flow and Cycle of the Finished Product | At this stage, the robot deposits the finished part into the hopper of the finished products and goes back for the next load, repeating the cycle. |

While the 5-axis machine tool is machining one part, the robot simultaneously prepares for loading and unloading another part. Precisely optimizing this cycle time, seamlessly integrating communication protocols between devices, and developing intelligent control software are core LS Manufacturing technologies that make sure the entire system operates continuously, efficiently, and reliably as a whole.

Figure 1: A 5-axis machine tool being tended by a robotic cell by LS Manufacturing

How Does LS Manufacturing Solve High-Precision Blade Machining Challenges For Its Aerospace Customers?

In the aerospace industry, accuracy in the machining of engine blades directly influences aircraft performance and fuel economy. This severe challenge befalls one of the world's well-known aerospace component suppliers: one machining cycle for a titanium alloy blade exceeds 5 hours; unattended production at night shift is not possible, and fluctuation in the manual clamping accuracy causes a persistently high scrap rate that severely restricts capacity expansion and delivery schedules.

Customer Dilemma

These are 3 major pains in the processing of titanium alloy blades in the conventional 5-axis machine tool:

- The complex curved surface processing requires frequent tool changeovers and manual intervention, with an average of 5.2 hours per piece;

- Night shifts must be completed on site by technical personnel, with less than 60% capacity utilization;

- The repeatability error of manual clamping is as high as ±0.1mm, causing only 91.5% of blade profiles to pass, with scrap losses reaching over 300,000 yuan per month.

LS Manufacturing Solution

We have custom-designed for them an intelligent machining unit, integrating a 6-axis industrial robot:

- The automatic identification and clamping of the blade blank are completed via the high-precision vision positioning system, with positioning errors controlled within ±0.01mm;

- Equipped with an adaptive cutting module which is able to adjust feed rate in real time according to tool wear to suppress machining vibration amplitude below 0.5μm;

- Developed a dedicated fixture library that supports rapid switching between 12 blade models, reducing changeover time from 45 minutes to 8 minutes.

Results and Value Creation

There were 3 major breakthroughs achieved after implementation.

- Establish a "lights-out production line", increasing night shift capacity utilization to 95%;

- The single-piece processing cycle was shortened to 2.1 hours and overall capacity was increased by 200%;

- Product qualification rate maintained steadily over 99.8%, with quality cost savings of over 3.6 million RMB per year. Automation investment by the customer was recovered within 18 months, and space was reserved for upgrading processes for future blade models.

This case reflects the important function of LS Manufacturing 5-axis automation technology in the aerospace components machining. With deeply integrated robot integration and intelligent techniques for solving industry problems in terms of precision and efficiency, it builds a replicable intelligent manufacturing paradigm.

Let automated 5-axis technology take over your production capacity and precision!

Which Industries Are Best Suited For Automated 5-Axis Machining?

With high precision, high efficiency, and flexible production, this automated 5-axis machining technology has become the core support for modern high-end manufacturing. Industries solution that have extremely high demands for complex surface processing, multi-process integration, and batch consistency have achieved breakthroughs in quality and efficiency concerning the high-value parts machining with automated 5-axis systems, injecting strong momentum into industrial upgrading.

Medical Device Industry

The 5-axis machining in the manufacturing process of orthopedic implants would automate complicated shapes, such as the spherical hollow structure of the acetabular cup and the multi-directional curved surface of the femoral condyle of the knee joint, in one operation. Notably, micropores 0.5mm in diameter on the surface of implants made of titanium alloy would be uniformly machined through A/C axis linkage control of the tool tilt angle, which would promote bone growth by 30%, decrease the single-piece processing cycle from 3 hours to 50 minutes, and fully meet batch production needs.

Automotive Powertrain

The 5-axis system performs continuous B-axis rotation in association with XYZ linear interpolation, which is able to achieve seamless cutting of 0.2mm thin-walled blades of such complex components as a turbocharger impeller. An adaptive cutting module ensures real-time tool load monitoring, maintaining blade profile errors within ±0.03mm, thus offering a dynamic balance level of G2.0. Compared with conventional processes, it has already achieved a 40% improvement in yield to meet the annual production capacity requirement of 100,000 units.

Energy Equipment Manufacturing

During the processing of the main pump impeller of a nuclear power plant, the 5-axis technology finishes the deep cavity machining of S-shaped twisted blades through the coordinated 360° rotation of the C-axis of the worktable and ±110° oscillation of the A-axis of the tool. High-pressure internally cooled tool holder suppresses the occurrence of thermal deformation in cutting. The residual stress on the surface of the Inconel 718 impeller is reduced by 50%, and the overhaul cycle has been greatly extended for over 80,000 hours.

The solution, which focuses on "precision, efficiency, and reliability," will not only solve the universal pain points faced by mass production in complex components but will also allow cross-project reuse of process parameters because of digital twin technology, opening up a way toward sustainability within high-value parts processing in strategic industries such as aeronautics and new energy.

Figure 2: Continuous 5-axis machining in lights-out operation by LS Manufacturing

How To Evaluate The Return On Investment Of Automated 5-Axis Machining Solutions?

Labor cost savings

In this way, the automatic 5-axis can save labor by 2-3 people per shift due to robotic loading and unloading, as well as intelligent monitoring. If we consider the Yangtze River Delta region, it will reduce annual expenditure by around 400,000 yuan just by saving labor; hidden expenses such as night shift allowances and staff turnover can be avoided.

Capacity Improvement Value Calculation

5-axis technology can achieve more than a 60% reduction in machining time for complex parts through multi-faceted machining in one setup. Take mass production of aerospace impellers as an example: monthly capacity will increase from 80 units to 240. Assuming a unit gross profit of 5,000 yuan, this amounts to an annual revenue increase of 9.6 million yuan and greatly accelerates investment recovery.

Quality and Cost Optimization Effect

Through automated systems, machining accuracy within ±0.01mm can be controlled stably, while scrap rate is reduced from 8% to less than 1%. Given the annual implant project output of 20,000 units for this medical device company, the reduction in scraps helped avoid a loss of over 3 million yuan and reduced significantly the risk of customer claims.

The investment return assessment should be related to real production data in 5-axis machining. The cost of automation can be tailored to your product portfolio, capacity requirements, and quality indicators at LS Manufacturing. The benefit calculation models help you grasp the investment rhythm accurately in order to make it a win-win situation both in technological upgrades and economic benefits.

What Are Some Common Mistakes In Choosing Automation Partners?

In intelligent manufacturing transformation, how to choose a 5-axis machining supplier is a key decision. Many companies decide only based on either brand or price, while ignoring system integration capabilities or industry adaptability, which greatly reduces their investment returns. Scientific partner selection needs comprehensive evaluation from 3 dimensions: technology ecosystem, service system, and industry understanding.

Pitfall 1: Overemphasis on equipment parameters vs system integration

In the pursuit of the lone performance index for 5-axis machine tools, some companies overlook the compatibility of 5-axis machine tools with the production systems already in use. A high-quality supplier should be able to seamlessly integrate with PLC/MES using an OPC UA protocol for example in order to achieve real-time data acquisition and avoid information silos. Once, because the newly purchased equipment of an automotive parts company could not be connected with the quality inspection system that was already in use, it was necessary to invest an additional 800,000 yuan in secondary development.

Myth 2: It neglects the sustainability of technical support

Automated systems require continuous optimization and maintenance, while the speed at which the supplier reacts directly influences downtime losses. In this respect, benchmark companies request 24/7 remote diagnostic services and maintain an inventory of critical components. Thanks to the guarantee of a supplier for on-site repairs within 4 hours, one customer from the aerospace industry could make sure that less than 0.5% of unexpected downtime would be experienced, saving more than 2 million yuan annually.

Myth 3: Lack of Industry Process Knowledge

General-purpose machinery often cannot meet the industrial needs. Specialty suppliers should have process know-how, such as chatter suppression in 5-axis milling of medical devices and deformation control for thin-walled aerospace components. One manufacturer of orthopedic implants found that one of its suppliers did not have a cutting database for titanium alloys, and tool lives reached only 60 percent of the standard.

Basically, the selection of partners should be for the long-term goal of creating a win-win manufacturing ecosystem. In this respect, we recommend that enterprises insist on industry case data from suppliers, go on field trips to inspect the operation of existing projects on site, and verify system stability by simulating production during their decision-making process.

Figure 3: Automated 5-axis cell designed for unmanned production by LS Manufacturing

For A Factory Like Ours, What Are The Preparations Needed In Order To Achieve "Unmanned Production"?

Instrumentation upgrade

Data Architecture Building

Based on that, the foundation of Industrial IoT can be built: deploying an industrial 5G network to realize full-equipment interconnection; connecting CNC systems and MES data flows using the OPC UA protocol; and configuring edge computing gateways for real-time process optimization. Our data platform, tailor-built for medical implant companies, increased production data collection efficiency 3fold, with fault prediction as high as 92% accuracy.

Operations and Maintenance System Restructuring

Establish an organizational structure adapted to unmanned production: train the operations and maintenance team with mechatronics expertise, develop preventative maintenance procedures, and maintain a stockpile of key components. Thanks to our training system, clients could achieve unmanned production for 3 shifts in six months and increased OEE up to 85%.

By following this progressive roadmap to smart manufacturing, companies can effectively manage investment risks while accelerating returns. We recommend starting with a single demonstration line to validate how automated CNC works in practice, then expanding comprehensively as experience accumulates, ultimately building an efficient, transparent, and sustainable smart factory.

FAQs

1. Is the initial investment in the automated 5-axis machining system very high?

LS Manufacturing provides modular and customized solutions, so investment is flexible and controllable. By increasing processing efficiency by more than 30%, while reducing scrap rates below 1%, the recovery of costs for most customers is within 12 to 24 months. So, as a strategic investment, it has huge cost reduction and efficiency improvement in the long run.

2. Is system maintenance complex? What happens if a malfunction occurs?

We have a 24/7 remote monitoring intelligent diagnostic system and a network of more than 50 service points in the country. This allows our engineers to respond within 2 hours and get on-site in 4 hours, ensuring less than 0.5% downtimes.

3. Are there requirements as to minimum order quantities?

The system supports flexible production modes. Due to the use of rapid changeover technology, with a changeover time less than 10 minutes, it can handle orders ranging from 1 to 1000 pieces per batch efficiently without rigid MOQ restrictions, fulfilling all needs from R&D prototyping to mass production.

4. How is intellectual property security guaranteed during processing?

We sign legally binding NDA agreements. The system has a 3-layer access control system; it encrypts and stores the processing data throughout the entire process. It keeps an operation log for 10 years and provides a physically isolated network solution to ensure zero technology leakage.

5. Can 3-axis machine tools that already exist in the workshop be upgraded to automation?

We provide 3-axis machine tool automation retrofit services. With our robotic grippers, vision positioning systems, and intelligent control modules, customers can achieve automation upgrading at an economical cost of 30% compared to building a new system.

6. What is the usual lead time?

The delivery cycle for every standard automation unit is 8-12 weeks. For complicated, customized projects, it will not exceed 16 weeks. Utilizing concurrent engineering management and a pre-stock mechanism for key components ensures timely project delivery.

7. What is the order of precision achieved in your solution?

Our system incorporates Renishaw's online measuring and adaptive compensation technology to ensure that machining accuracy is stable within ±0.015mm. Critical feature dimension CPK ≥ 1.67 can satisfy the ultra-precision requirement in industries like aerospace, medical treatment, and so on.

8. Do you offer trial machining services?

We offer free trial machining. Welcome customers to bring samples to our national-level technology center for on-site verification of the machining effect and a complete test report to personally experience the technological advantages before making decisions.

Summary

Fully automated 5-axis machining is no longer the patent of big companies, but an inevitable choice for all manufacturers who want to increase competitiveness and achieve sustainable development. This is not only an upgrade in technology, but an innovative business model wherein its core value frees you from tedious pressures brought about by production management, enabling you to focus more on the market and innovation.

Now is the time to turn the potential into profit. Reach out to the automation experts at LS Manufacturing today to acquire a tailor-made unmanned manufacturing solution and ROI analysis report for your company. We are able to accurately measure your return on investment and enable that milestone to be taken toward smart manufacturing. Alternatively, you can arrange a visit to our automation demonstration center and see for yourself the future of efficient production.

📞Phone: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website: https://lsrpf.com/

Disclaimer

The content on this page is for informational purposes only. LS Manufacturing makes no representations or warranties, express or implied, regarding the accuracy, completeness, or validity of the information. It should not be inferred that third-party suppliers or manufacturers will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type, or processes through the LS Manufacturing network. The buyer is solely responsible for this information. For parts quotations, please specify the exact requirements for these parts. Please contact us for more information .

LS Manufacturing Team

LS Manufacturing is an industry-leading company specializing in customized manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precision CNC machining , sheet metal fabrication , 3D printing , injection molding , metal stamping , and other one-stop manufacturing services.

Our factory boasts over 100 state-of-the-art five-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries and regions worldwide. Whether it's small-batch production or mass customization, we can meet your needs within 24 hours. Choosing LS Manufacturing means choosing efficiency, quality, and professionalism.

For more information, please visit our website: www.lsrpf.com .