5-axis machining services typically create a big problem to manufacturers due to information asymmetry. It is an everyday thing to find a situation where the promised precision of 0.02mm is in reality 0.05mm, and the delivery time that was supposed to be 7 days turns to be 15 days. All these issues always lead to project delays and quality costs of a great amount, thus production efficiency and product reliability get seriously compromised.

5-axis machining services at LS Manufacturing are the very solutions to these problems. On the basis of 12 years of focused experience we have created a systematic solution that averse the problem. Our tested methodology not only guarantees consistent outcomes but also realises the precision of machining to within ±0.01mm, maintains the delivery time at 98%, and a first-pass yield beyond 95% to our clients.

5-Axis Machining Services Quick-Reference Guide

| Section | Key Point in One Sentence |

| The Pain Point (What) | Manufacturers suffer from a lack of information when deciding on 5-axis suppliers, which results in missed precision, late deliveries, and high quality costs. |

| The Root Cause (Why) | The main reason is the absence of a systematic evaluation framework. This leads to an excessive dependence on price or brand rather than on actual capability. |

| Our Solution (How) | We provide a reliable supplier assessment system comprising 8 dimensions. This system is the result of 12 years and 186 complex part projects, and it guarantees reliable outcomes. |

| Critical Dimension: Equipment | It is crucial to check the real capability of a machine tool along with the calibration status and technology integration to ensure the accuracy is guaranteed. |

| Critical Dimension: Process | It is very important to evaluate the supplier's technical planning, simulation, and optimization processes for a complex geometry and first pass yield. |

| Critical Dimension: Quality | There is no questioning the need for a very strong in-process control system and the final inspection procedure to be consistent in the part conformity. |

| Critical Dimension: Project Management | To be honest, a transparent communication and a proactive risk, management process are the main factors for on-time delivery. |

| Client Outcome | By means of this orderly method, the clients are able to pinpoint such partners who can give ±0.01mm precision, 98% on-time delivery, and >95% first-pass yield. |

We address the major problem of information asymmetry when choosing a 5-axis machining partner. Our well, thought, out framework allows you to discover suppliers whose capabilities are certified, rather than just their promises. This largely saves you from expensive surprises and guarantees the level of precision, reliability, and punctuality that your projects require. In the end, we facilitate manufacturing results that align with your timeline, budget, and product quality, thus turning a very risky procurement step into your competitive advantage.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

The web is flooded with advice on 5-axis machining services, most of which are generic. The real selection is, however, a matter of cutting through sales pitches. This guide is a result of experiences at the production line, where overcoming everyday difficulties such as complex geometries or compliance with ISO 9001 quality management systems, determines real capability, rather than merely claimed specifications.

We don't base our authority on theory but on battle-tested experience. Among our qualified shops, only those that machine mission-critical components have passed our rigorous capability testsfrom dynamic accuracy to environmental and regulatory compliance, such as meeting the Environmental Protection Agency (EPA) guidelines for machining fluids, which doesn't allow any compromises. The checklist that we use was created through the long process of partner vetting.

This practical checklist is a faithful reflection of the decades of experience that has been invested in it. With it, you can be sure of systematically assessing your suppliers through real, tried, and, tested criteria that would not only comply with rigorous standards like ISO 9001 but also help you find a partner who is committed to precision, reliability, and punctual delivery of your most demanding projects.

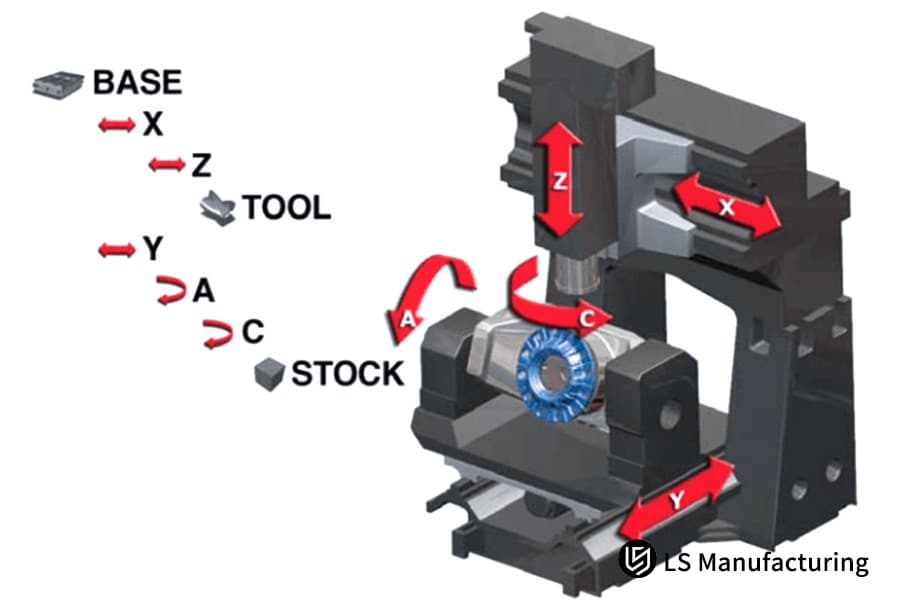

Figure 1: Explaining 5-axis CNC machining multi-axis synchronous machining for precision industrial parts manufacturing.

How Can Equipment Configuration Be Used To Verify The True Capabilities Of A 5-Axis Machining Supplier?

The major risk in sourcing arises from the discrepancy between the equipment listed by a supplier and their actual capability of production. The direct consequence of this is a drop in quality that cannot be consistent and project delays. However, we can fix this by giving you a straightforward, fact-based way of verification that goes beyond what is claimed to see the real performance, thus having a reliable precision 5-axis machining as a basis:

Solve Unverified Static Accuracy Claims

As a result, we do not put ourselves at risk of trusting uncertified machine specifications by allowing only recent laser interferometer calibration reports. Such documentation offers accurate evidence that positioning accuracy (≤±0.008mm) and repeatability (≤±0.005mm) are at the required level for 5-axis machining services which are dependable, thus, removing any doubt when choosing a supplier.

Solve Hidden Kinematic Inaccuracy

We solve the issue of a big discrepancy between the static specifications and the dynamic performance of the machine by our RTCP test which is documented and shown to the customer. Machining a bore with an extreme precision on a slope of 30° confirms the real volumetric accuracy. The positive result of such a test is a confirmation of the use of the integrated 5-axis complex parts with complicated contours, thus, avoiding costly geometric errors in your final components.

Solve Post-Process Scrap and Rework

By qualifying the supplier's usage of the integrated in-process measurement system, e.g. a Renishaw probe, we are able to prevent the occurrence of the quality failures at the last minute. Such a system helps to keep the part quality by continuously adjusting for tool wear and thermal drift, which ensures that you get quality 5-axis machining results from the very first part to the very last one. Therefore, it is a direct protection of your project timeline and budget.

Solve Unplanned Production Disruptions

We can reduce unexpected 5-axis machine downtime and scrap by checking the supplier’s tool life and spindle load monitoring systems. A strong, data-driven management policy can predict tool failure well in advance, thus meeting the reliability and throughput requirements of production-scale 5-axis work and on, time delivery of your orders.

This structure literally solves the main problem of unconfirmed supplier capability. We give you the technical, specific checks that change your sourcing from a mere gamble into a data-driven decision, thus ensuring that you will get the shops delivering consistent precision 5-axis machining results to your critical projects.

How Does The Experience Of The Process Technology Team Affect The Quality Of Parts Machining?

Although high-end machinery is a must, it is the talent of the technical team that truly unleashes its capability and defines final part quality. The following describes a methodical approach to assess this very crucial yet frequently ignored factorchanging subjective judgment into objective proof during the supplier CNC machining vetting process:

Solve Inefficient Programming and Poor Surface Finish

By verifying advanced CAM skills, we cut out costly trial-and-error and get better results.

- Strategic Toolpath Generation: We evaluate the capability of the engineer in designing optimized, continuous 5-axis toolpaths that reduce tool engagement and deflection, thus effectively dealing with the issues of vibration and unstable surface quality on complex contours.

- Precision for Complex Geometry: We go over the approaches to difficult parts (e.g., impellers), making certain that hub-to-blade transition machining is one of the techniques being employed in order to actively control part deformation to within 0.02mm, thus achieving dimensional accuracy.

Solve Unpredictable Outcomes and Low First-Part Success Rates

We avoid waste and hold-ups by checking process planning that is structured and based on experience.

- Proven Process Framework: We make it a condition that there be planning documentation outlining the step-by-step procedures, from fixturing to in, process checks, that are based on past successful projects, hence ensuring the repeatability of success and tackling the problem of variability in 5-axis machining services.

- Optimized Parameter Database: We make sure that a proprietary, material, specific machining database is being used. This database embodies the hard-won experience that is applied to standardize speeds, feeds, and tool selection, thus directly addressing the problem of inadequately performing setups and shortened tool life.

Solve Unforeseen Production Challenges and Rework

We reduce the likelihood of a project failure by checking if the team has the capability of solving problems on an empirical basis.

- Critical Issue Resolution: We ask for real examples where engineers pinpointed the root problem and came up with a solution to a failure (e.g. chatter, thermal distortion) thus proving their capability of solving problems that are real and can threaten the selection of how to choose 5-axis machining services.

- Continuous Improvement Proof: We ask for some very specific examples of process optimization such as reduction in cycle time or increase in yield, demonstrating the kind of attitude that is geared towards discovering and implementing solutions to the challenges of efficiency and cost.

This method addresses the issue of selecting a supplier solely on the basis of their purported expertise. It is a clear, step-by-step CNC machining vetting process that helps you find engineering partners whose teams not only prevent errors but also optimize results and ensure the highest reliability of your 5-axis machining services, thus directly safeguarding your project's schedule and budget.

Figure 2: Machining a precision metal component with coolant for industrial parts and supplier capability demonstration.

Does The Quality Control System Ensure The Stability Of Dimensional Accuracy?

A solid quality system is the essential factor that links a machine's capability with the production of parts that consistently meet specifications. A partial system results in random dimensional variations, assembly issues, and expensive product recalls. Here is a checklist to help you audit a suppliers quality infrastructure in a data-driven manner, step by step, showing how to go from mere claims to confirmed 5-axis process control for achieving dependable precision 5-axis machining:

| Evaluation Dimension | Concrete Verification Method (Actionable Check) |

| 1. Inspection Equipment Capability | Check that the CMM (e.g., Zeiss) is capable of certified volumetric accuracy of ≤ ±0.002mm to be able to perform quality control of your quality 5-axis machining work. |

| 2. First-Article Inspection (FAI) Rigor | Make sure the FAI protocol is such that 100% of all the critical features shall be inspected, not just the sample, to set a standard of zero defects. |

| 3. In-Process Control Methodology | Review the statistical process control (SPC) plan, which should be backed up by recorded sampling (e.g., 1 part per 50) and real, time charting of key dimensions. |

| 4. Data Management & Traceability | Demand the availability of a historical inspection data bank for similar 5-axis machining parts that can prove the control of batch variation within ±0.01mm. |

| 5. Gauge Management & Calibration |

Verify that all inspection instruments ranging from Coordinate Measuring Machines (CMMs) to hand gauges are included in a formal, documented calibration procedure with traceable certificates. |

This audit changes the nature of quality from a promise to a measurable, controlled process. It gives a definitive 5-axis machining supplier checklist to a tolerance for dimensional stability, ensuring that you are working with suppliers who have systems that actively prevent variation. This approach addresses the root cause of quality escapes, resulting in predictable, high-integrity outputs necessary for complex 5-axis work and critical assemblies.

Figure 3: Showcasing precision 5-axis machining equipment and turbine parts for industrial manufacturing and supplier selection.

How Does The Supplier's Project Management Ensure Reliable Delivery Times?

Unreliable delivery in complex machining is frequently a result of reactive, non, transparent project management issues aside from production delays. Such situations lead to expensive program disruptions. A 5-axis management system that is proactive and visible to everyone and that can recognize and address the risks beforehand, hence, a reliable on-time delivery machining forms the core of such a system. The following framework explains how to test this capability:

Ensure Real-Time Schedule Transparency & Control

We fix the "black box" of production status issue by granting access to a real, time ERP or MES dashboard. This makes it possible to track a job's progress towards the achievement of critical milestones and, thus, to the earliest possible intervention if necessary. This level of disclosure is essential for 5-axis machining services which are reliable as it is normal to have complex multi-stage workflows.

Verify a Proactive Risk Mitigation Protocol

We get the handle on unforeseen delays by reviewing the supplier's official risk management plan. It should list, among other things, secondary material sources that have been pre-qualified and give details of a buffer strategy for long, lead items. A protocol that has been verified helps you to know that your project time plan is safe if an unexpected situation occurs because potential disruptions that have already been identified are under control and not that you are just on the way to them.

Mandate Structured Communication Cadence

We close communication gaps that hide delays by setting up a formal communication protocol. It lists the scheduled updates (e.g., bi-weekly) with documented action items, so that everyone involved is on the same page. Such a disciplined approach goes without saying for local 5-axis machining partnerships that depend on very tight collaboration.

Audit Capacity and Load Management

We do not allow suppliers to commit beyond their means through the review of their forward load planning. By capacity utilization analysis over similar 5-axis work, you can be sure that they have a realistic, dedicated, and thus available bandwidth for your project, in other words, going from a generally vague promise to a delivery date-backed by data and thus a real commitment.

This approach fixes the root of the problem of delivery anxiety by looking at the supplier's system of management of the delivery process with control and anticipation rather than just at their words. It gives a solid basis for choosing the partners, who, by their ability to foresee and control, will always be on-time delivery machining, thus the timeline of your program will be actively managed instead of merely hoped for.

How To Assess A Supplier's Expertise In Materials And Tooling?

Suboptimal material and tooling strategies significantly contribute to hidden cost drivers. They cause short tool life, poor surface finish, and unsteady machining times. This handbook shows the way to assess a supplier's hands, on, data, supported research capacity, a major factor that separates a true quality 5-axis machining and cost-efficient provider:

Solve Inefficient Material Machining & High Cost

We take out the guesswork and wasted running time by our proprietary machining database verification.

- Parameter Library Verification: We check the parameter sets documented and optimized for specific alloys (e.g., TC4 at 60-80 m/min) to confirm the expertise that inherently works to solve the problem of slow, cautious cuts that increase cost.

- Process-Driven Tool Selection: We check the rationale of the choice of tool material and geometry per operation, going further than just catalog specifications to strategies that allow a good metal removal rate while still keeping tool life for 5-axis work smooth and predictable.

Solve Vibration, Poor Finish, and Tool Failure

We prevent quality issues stemming from poor dynamic stability by assessing tooling system integrity.

- Tool Holder Balancing Audit: We ask for evidence that holders for 5-axis machining services are balanced to G2.5 or better, thus solving the problem of chatter and poor surface finish at high RPM.

- Presetter & Data Management: We confirm the deployment of a tool presetter that automatically inputs precise tool length/radius data into the CNC, thus negating manual errors and guaranteeing first-piece accuracy.

Solve Unpredictable Tool Life and Process Variability

We get leading, edge, predictable results by reviewing the implementation of continuous improvement best practices.

- Tool Life Monitoring & Optimization: We examine the evidence of a supplier who uses wear pattern analysis to extend tool life (e.g., from 4 to 7 hours for S136 steel), thus demonstrating the solving of the problemm of fluctuating consumable costs.

- Technical Collaboration Evidence: We evaluate whether their collaboration with tooling manufacturers for application engineering support signifies a proactive approach to solving unique 5-axis machining challenges.

This assessment acts as a vital step for your 5-axis machining supplier checklist. It goes beyond surface claims to reveal the applied technical know, how that guarantees process stability and cost control, thus providing a sure, fire method of how to choose 5-axis machining services based on real, bottom-line expertise.

LS Manufacturing Aerospace Industry: 5-Axis Machining Project For Engine Mounts

In the aerospace industry, machining complex titanium thin, walled structures is one of the biggest challenges associated with controlling part deformation, which is highly related to the final assembly and the performance of the parts. The present case study shows how LS Manufacturing's precision 5-axis machining approach solved a bottleneck issue for a critical engine component:

Client Challenge

The part was a titanium (Ti-6Al-4V) engine installation bracket, with thin walls (2mm) and a very tight deformation tolerance of ≤0.05mm. The client's former suppliers couldn't maintain product consistency, resulting in only a 65% acceptance rate for the parts. This caused an average delay of 3 weeks for each batch delivery, thus, critically, stopping the final aircraft assembly line and increasing the costs due to rework and fast logistics.

LS Manufacturing Solution

We implemented a specialized 5-axis CNC machining approach that was mainly stress management, focused. A bespoke 3-point flexible fixture reduced the clamping distortion, and to enable stable, deep, cavity machining the conical 6xD long, reach end mills were utilized. The process steps were divided into 36 with optimized lower consistent radial engagement. Most importantly, an in-process touch probe system was installed to provide real-time verification of critical features, which allowed immediate corrections to be made and ensured quality 5-axis machining stability throughout the cycle.

Results and Value

First article acceptance hit 98%, with batch deformation controlled within 0.03mm. The lead time was cut down from 28 to 16 days, with 100% on-time delivery being achieved. The reliable 5-axis work eliminated the client's assembly backlog, yielding annual quality cost savings of roughly ¥800, 000, and the consistency of their parts and dimensional accuracy ensured that the final product's integrity was kept.

This case illustrates that advanced 5-axis machining challenges can only be effectively dealt with through integrated process innovation, rather than just having capable machines. Our method, which merges custom tooling, adaptive fixturing, and in-cycle verification, supports a technical approach that is able to provide predictable, high-performance results for the most demanding 5-axis machining services in the fields of aerospace and other precision industries.

Click the button below to let 5-axis machining technology define your high-precision manufacturing standards.

Which Key Aspects Should Be Prioritized During The On-Site Audit?

A meticulous on-site audit is the ultimate step to confirm a supplier's operational integrity beyond what is stated on paper. This article offers a focused inspection procedure that aims to reveal the critical, often hidden, production control and consistency risksan absolute necessity for thorough CNC machining vetting process.

| Audit Focus Area | Key Verification Action & Success Criteria |

| 1. Machine Tool Calibration & Maintenance | Check that preventive maintenance logs and full calibration certificates (for example, laser interferometer reports) are available for the 5-axis machines that will be used, and make sure that the machines have been continuously maintained to the specified accuracy levels. |

| 2. Production Environment Stability | Confirm temperature and humidity control records, which are normally set at a temperature of 20±2°C and humidity at 50%±10%, and are thus the basic conditions for stable precision 5-axis work and thermal drift of parts prevention. |

| 3. Tooling & Presetting Management | Check the calibration of the tool presetter and computer system through an audit in order to ensure that the accuracy of tool life tracking can be maintained at more than 90%, which is a key factor for the achievement of the predicted performance when working with complex 5-axis machining services. |

| 4. Live Process & Part Verification | Randomly select 2-3 in-process parts and witness on-machine or CMM inspection of key features, comparing results to the shop traveler to validate real-time process control and reporting accuracy. |

This actionable 5-axis machining supplier checklist transforms an audit from a facility tour into a risk-discovery tool. By executing these focused checks, you directly assess a supplier's day-to-day discipline, providing a concrete methodology for how to choose 5-axis machining services based on observed, verifiable practices rather than marketing assurances.

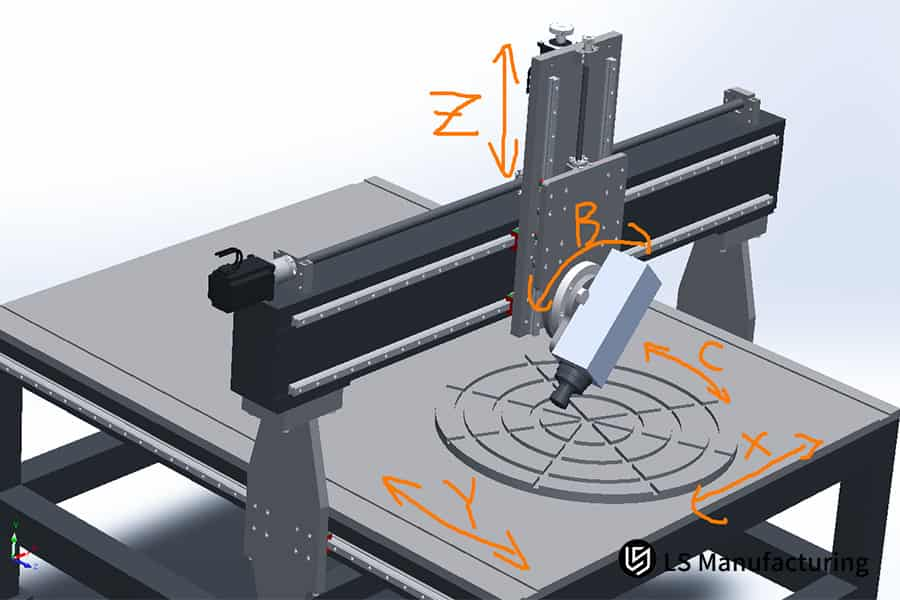

Figure 4: Illustrating precision 5-axis machining principles for manufacturing process education and technical demonstration.

Why Choose LS Manufacturing As Your 5-Axis Machining Partner?

Choosing a partner for complex parts is more than just evaluating their brands of machines, it must be a partner with capability and reliability to deliver solutions to manufacturing challenges. The proper choice is your safe way to avoid a disaster of prototypes, product launch delays, and cost overruns. LS Manufacturing turns the guesswork in this decision into an assured result by the systematized, data, supported method of precision 5-axis machining:

Solve Precision & First-Part Success Uncertainty

We take away the dimensional uncertainty by having calibrated DMG 5-axis machines equipped with Renishaw on-machine probing in a closed-loop manufacturing cell. This arrangement makes it possible to do testing in real time during the process and therefore gathers data for just, in-time tool path correction. We helped a medical customer by this means to get the sphericity of a joint implant from 0.02mm down to 0.008mm effectively improving the product performance and its reliability. This skill guarantees that our results are constantly on a high level so that we can be considered a trustworthy supplier of local 5-axis machining.

Solve Process Inefficiency & Unpredictable Lead Times

We avoid expensive trial-and-error and schedule slippage by using a proprietary process database of 186 complex part histories which we have built. This database allows our engineering team (with an average experience of 8 years) to use pre-tested strategies for difficult materials and geometries from day one. The systematic application of the acquired knowledge directly focuses on and resolves the typical issues of low yield and prolonged timelines, thus securing the stability that we promise with our 5-axis machining services.

Solve the "Near Me" Compromise Between Proximity and Capability

Choosing a conveniently located 5-axis machining services near me often entails giving up on specialized capability. We fix this compromise by bringing deep technical expertise to the local level. Our facility is not only capable of general machining, but it is also specially designed for very complex, very precise work. In other words, clients get the great logistical and communication advantages of a local 5-axis machining partner without having to give up the advanced technical solutions needed for their mission-critical components.

We fix the main problem of finding a complex machining source which is finding a partner whose capabilities are as dependable as their promises. We achieve this by combining integrated metrology, empirical process intelligence, and localized expertise, thus, we offer a transparent, results-oriented cooperation that takes the risk out of your most challenging 5-axis machining projects and assures results.

How To Initiate The Technical Integration Process With Potential Suppliers?

Inefficient technical onboarding is one of the reasons for misalignment, which in turn causes inaccurate quoting, scope creep, and delays in a project even before it is started. A structured data exchange protocol is necessary to create a clear, shared understanding of the needs and capabilities. This framework outlines a step-by-step approach to help you have a full technical disclosure and alignment at the start of your project:

Solve Ambiguous Requirements & Scope Misinterpretation

We don't leave anything to the imagination and thus make sure everyone is on the same page by sending a standardized data package.

- Complete Technical Pack: We ask for the 3D (STEP) model, 2D drawing with GD&T, and a clear definition of the critical features (e.g., datum surface flatness of 0.01mm).

- Material & Post-Process Details: We confirm the exact 5-axis material grade, heat treatment state, and any secondary operations (anodizing, etc.) to be performed beforehand.

Solve Slow Response and Vague Proposals

We make sure no one is left hanging and the commitments are crystal clear by providing a prompt, detailed technical review.

- 24-Hour Preliminary Assessment: Our engineers perform an initial manufacturability assessment to highlight possible problems in your 5-axis machining services project.

- Transparent Quoting Methodology: We offer a 5-axis machining quotation with a comprehensive explanation, coming directly from a defined process plan and schedule, thus making a ballpark estimate history.

Solve Lack of Process Visibility Before Commitment

We build confidence and enable informed decisions by sharing our planned approach.

- Strategy Summary & Risk Mitigation: We outline the proposed machining strategy, fixture concept, and key inspection points for complex 5-axis work.

- Formal Q&A and Alignment: We have a technical clarification meeting to discuss the various aspects of the plan, Thus, we ensuring all specifications are understood before proceeding, a key benefit of local 5-axis machining.

This method addresses the fundamental issue of a project being started on the wrong assumptions. It changes the initial question from a simple request for quotation (RFQ) into a collaborative technical alignment thus giving you the precise understanding of the partner for 5-axis machining services near me thereby making a confident sourcing decision.

FAQs

1. What is the minimum order quantity (MOQ) for 5-axis machining?

LS Manufacturing can handle orders ranging from single prototypes to tens of thousands pieces batches with no strict MOQ or minimum order quantity. However, unit prices can be optimized for orders of 50 or more pieces.

2. How can I verify the supplier's actual machining accuracy?

You can get a third-party inspection report or trial machining verification. LS Manufacturing offers free trial machining to check the capabilities.

3. How can the acceptance rate of complex curved surface parts be ensured?

Through a combination of real, time measurement, process improvement, and vast experience, LS Manufacturing is confident in achieving an acceptance rate of ≥95% for complex parts.

4. What is the mechanism for compensation in case of delivery delays?

LS Manufacturing has a delivery guarantee policy. Delivery delays are compensated in accordance with the contract, thus ensuring customer protection.

5. Do you give suggestions on material selection and process optimization?

We deliver free DFM studies to assist in design optimization, cost reduction by 10-30%, and enhancement of part manufacturability.

6. How do you secure customers' design intellectual property?

We commit to NDA agreements, utilize encrypted file storage, and offer separate project spaces to make sure that designs are safe and that there is no leakage.

7. What is the shortest delivery time for emergency orders?

LS Manufacturing operates a fast track service channel. Simple parts can be delivered as fast as in 5 days and complex parts in 10 days.

8. Are you able to provide assembly and testing services after production?

We offer a wide range of services from machining to testing and assembly, thus, the delivery of the components that are ready to be used is guaranteed.

Summary

Choosing the best 5-axis machining partner is a technical choice that involves deep consideration of many factors. By doing thorough equipment checks, measuring process ability, conducting quality system audits, and evaluating project management, you will be able to spot the partners who really have the ability to manufacture complicated parts. LS Manufacturing suggests that you should concentrate on a supplier's technical skills and project experience, which is typically more crucial to ensure project success than just comparingprice quotes.

If you need a dependable 5-axis machining partner, don't hesitate to get in touch with the LS Manufacturing technical team right away. Just submit your part drawings to us and we'll give you a free process analysis report! Our team will come up with a comprehensive machining plan, an exact quote, and a delivery schedule within 24 hours to make sure your project goes well.

Partner with LS Manufacturing for expert 5-axis machining solutions that ensure quality and reliability

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.