CNC machining applications have a great deal of relevance when it comes to providing solutions to the problems related to the manufacturing sector. Certain issues related to the handling of difficult material, the geometric model, and manufacturing standards have to be dealt with by the organizations. Therefore, the solution to these issues cannot be accomplished by relying solely on the traditional technology; therefore, it also influences the competitiveness and rapidness of development in manufacturing.

This happens because there exists a gap with respect to understanding and knowledge about the processes that take place within the industry. This will imply that the manufacturing solutions are not able to fulfill the requirements. This article will proceed to elaborate how the CNC machining process brings innovation to the aerospace industry, Automobile industry, and Healthcare industry so that the correct solutions are achieved.

CNC Machining Applications Overview

| Section | Topic | Key Points |

| Pain Points | Manufacturing Challenges | Special materials, complex geometries, strict industry standards. Slow development cycles, reduced product competitiveness. |

| Core Problem | Root Cause Analysis | Lack of deep industry-specific knowledge and cross-disciplinary technical experience. Solutions are not precisely matched. |

| Proposed Solution | Custom CNC Applications | An analysis on the use of CNC applications for the aerospace, automobile, and medical field sectors. Cases for custom solutions by LS Manufacturing. |

| Article Focus | Analysis & Application | Discloses how proper and relevant machining systems of CNC machining help in promoting technological developments. |

It also examines the competency of CNC machining in fulfilling the toughest problems faced in the industries. The diagnosis of the problems currently faced in the industries will be identified as to its true form, where the root cause of all the problems lies in the aspect of the lack of knowledge, and the solution lies within the special applications pertaining to the CNC machining. This is applicable in all industries.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

The reason you can trust this guide is that it has been developed from real-world experience over the last 15 years at LS Manufacturing, as opposed to just knowledge, states bob glick. We have done the machining of threads within the aerospace community where failure of those threads is failure of the mission, and failure is not an option, failure of our products where failure tolerance is micron levels, and failure means loss of life.

Our background is based on over 50,000 detailed parts produced. We have enough experience with this level of production to know where the best value for the titanium properties exists and also how to best machine aluminum following the Aluminium Association (AAC) guidelines formulated by the Aluminum Association. We have learned from some of our own painful but expensive errors so that you won’t have to.

The source for this handbook is the fact that all the information in the book has been derived from successful experiences in all fields. From the perspective of the National Association for Surface Finishing (NASF) requirements on surface integrity or from the ultra-tight tolerance perspective in the automotive industry, we have experiences that work under harsh conditions. We would like to share the knowledge on how we can deal with the challenges on CNC machining on a day-to-day basis.

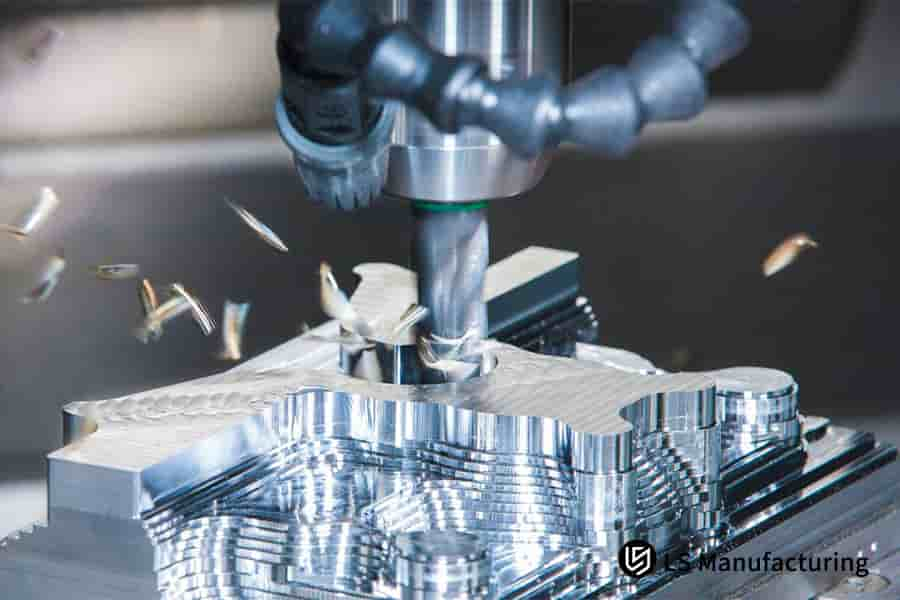

Figure 1: Custom CNC machining for industrial brand components by LS Manufacturing

How Does CNC Machining Achieve A Perfect Balance Between Lightweight And High Strength In The Aerospace Field?

The claim for eternal innovation within the aerospace industry, as it relates to the highest level of performability, inevitably turns around the innovation cycle for aeroapce CNC machining. This is key for the production of these parts with the basic need to include lightweight manufacturing solutions.

Precision for Complex Structures

With the help of the process of 5-axis CNC machining aerospace applications, the engineering team is capable of achieving complex high-strength structural forms with the removal of the irrelevant aspect of weight in the component parts of high strength alloys, since such aspects of the structure are irrelevant, thus very important for high-strength parts machining in the aircraft or propulsion system. Joints, as well as the presence of bolts, can also be eliminated.

Advanced Material Processing

Today’s aerospace CNC machining is also adept at processing hard-to-machine materials such as titanium and advanced composites. When it comes to machining composites, the machining done around the edges and interfaces is of utmost importance to preserve the fiber and achieve flawless assembly. This capability enables the use of these superior strength-to-weight ratio materials, directly contributing to effective lightweight manufacturing solutions without compromising performance.

Integrated Design and Manufacturing

The synergy between topological optimization software and CNC machining unlocks groundbreaking designs. Engineers can algorithmically generate organic, weight-optimal shapes that are only producible through CNC machining aerospace applications. The CNC process then accurately fabricates these complex geometries, resulting in components that are significantly lighter yet mechanically robust, epitomizing the balance achieved in high-strength parts machining.

Performance and Certification Success

Real-world examples from the industry can be cited with regard to engine mounts or structural brackets. These not only indicate success on the performance front but also assure a 15% to 30% reduction in weight using sophisticated strategies adopted in aerospace CNC machining. Most importantly, a strict procedure is maintained in the entire process to ensure the lightweight manufacturing solutions comply with aviation certification requirements.

In conclusion, aerospace CNC machining plays the critical role that is needed to harmonize lightness and weight/strength. It is the high-strength parts CNC machining and the solution to the challenge of creating lightness as a result of mastering complex geometry and high-tech material through aerospace CNC machining.

How Can The Automotive Industry Meet Electrification Demands With CNC Precision?

Today’s fast transition into electrification and intelligent solutions is changing precision standards in the automobile segment. In this perspective, meeting the challenging specifications necessary in an electric solution would require sophisticated CNC machining automotive industry that provides high reliability in complex components necessary in vehicle safety features.

| Application Area | Key Components | CNC Machining Role & Value |

| Electric Powertrain | Controller Housings, Sensor Bodies Enables | Ensures thermal management, electromagnetic performance, and precise tolerances for maximum efficiency and power density. |

| Battery & Chassis | Battery Trays, Structural Parts | Provides robust, leak-proof, and lightweight precision parts mass production essential for safety, range, and vehicle integrity. |

| Enabling Technologies | Controller Housings, Sensor Bodies | Enables high-volume, high-consistency automotive parts CNC machining for the reliable function of all vehicle control systems. |

In essence, advanced automotive parts CNC machining is a critical enabler for new energy vehicles manufacturing. It bridges the gap between innovative design and scalable, high-quality production, ensuring the durable and precise components needed for a successful electric and autonomous future.

What Special Biocompatibility Requirements Does Medical Device manufacturing impose on CNC machining?

The requirement from the side of the medical institution to provide a safe product for the patients requires specific procedures. For this reason, medical devices CNC machining has to meet certain rigid standards concerning biological safety. It is not quite alike compared with industries.

| Requirement Category | Specific Focus | CNC Machining Implications |

| Material & Biocompatibility | Implant Materials (e.g., Titanium, PEEK) | Only strict and biocompatible manufacturing processes, including material certification and avoidance of contamination, must be performed on implantable components. |

| Precision & Standards | Knowledge Surgical Instruments and Device Housings | Manufacturing must comply with exacting medical-grade machining standards to achieve the ultra-tight tolerances and surface finishes critical for device function. |

| Process & Cleanliness | Entire Manufacturing Workflow | Whole CNC machining medical device manufacturing process requires Clean environments and processes validated for Sterility and Reprocessability. |

Thus, in conclusion, the application of medical components production in medical devices CNC machining is not just restricted to metal-cutting activities. It is a discipline defined by uncompromising biocompatible manufacturing and adherence to medical-grade machining standards throughout the specialized CNC machining medical device manufacturing ecosystem.

How Can Electronic Devices Achieve Miniaturization With Precision Machining?

Smaller and more robust tactics are worthy of innovations taking place for 5G technology and IoT at their increasing pace in both cases. This creates a critical need for electronic communication component machining that enables device miniaturization manufacturing while uncompromisingly supporting superior performance.

- Enabling Signal Integrity: The factor that enables the signal integrity: High-precision cavity machining is foundational for filters and waveguide components. The inner wall of the cavities will contribute to the strength of the signal. Micromachining will generally pertain to the precision that has been obtained during the CNC machining in manufacturing. The accuracy at the level of a micron will be required for the cavities.

- Managing Thermal Performance: One of the critical challenges, which need efficient management, is the heat generation resulting from an extremely high level of integration of electronics. Through specialized electronic communication component machining, intricate and efficient heat sinks and cold plates are produced. This facet of miniaturization manufacturing involves creating complex micro-channel geometries that maximize surface area within a minimal footprint, ensuring that high-performance chips remain cool and stable under continuous operation.

- Facilitating Miniaturized Assembly: A system-in-package and deep-integration process requires very minute structural and interface components. This is where CNC machining in manufacturing excels, producing microscopic connectors, shielding enclosures, and mounting platforms. It also has the scope to integrate multiple processes in a single microscopic component, thereby resulting in decreased size and overall characteristics.

Highly advanced CNC machining in manufacturing industries and finds high importance in the present day and age of electronics. The machining process is highly helpful in enhancing the high-precision cavity machining process with regard to signal integrity and the advanced electronic communication component machining, which is highly crucial for the entire sector in the successful miniaturization manufacturing.

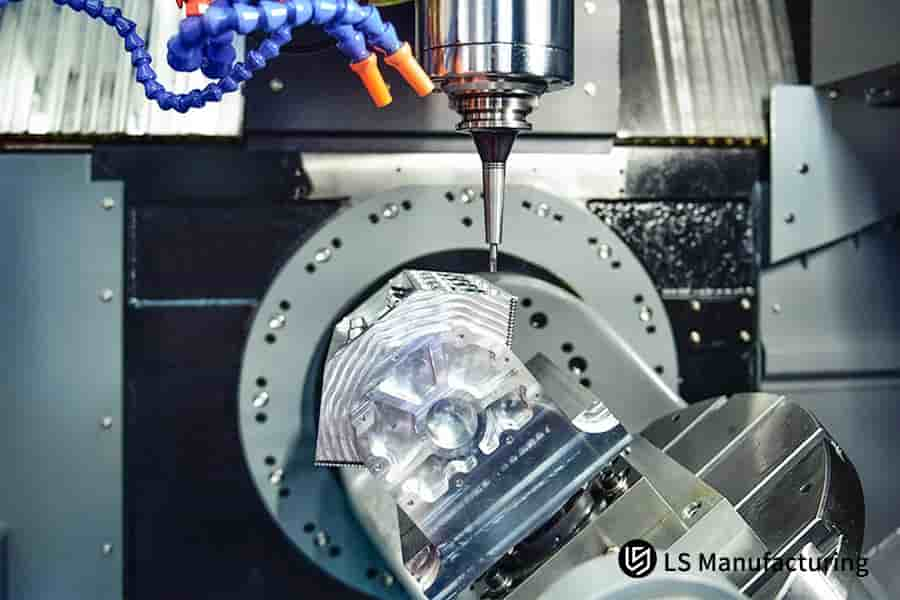

Figure 2: Custom CNC manufacturing for automotive, aerospace, and medical device production by LS Manufacturing

What Are The Unique Challenges In Processing Large Structural Components In Energy Equipment Manufacturing?

There is a need for the production of large parts processing for energy equipment, such as wind energy reactors, nuclear reactors, and other types of equipment. Notably, the area with respect to the processing of large parts for energy equipment has its own issues.

Scale and Accuracy

The most problematic aspect, as far as the manufacturing of heavy structural components is concerned, is the requirement for achieving the order of micrometer levels of accuracy. The principles of deflection, vibrations, and thermal considerations increase exponentially with scale size. It is a significant aspect that the advanced methodologies, such as machining and fixturing and measuring, should be employed to make the gargantuan structural components feasible for the scale size for which they are designed.

Complex Geometry Machining

The components related to the energy parts, like the housing of the turbines, or the body of the generators, have a complex internal structure, irregular surfaces, along with curved surfaces having a complex structure. Conventional machining procedure is not fit or capable enough to carry out the given job. This is where multi-axis linkage CNC machining is required. Machining in this case helps the continuous motion of the machining tool in several directions, a significant process for carving complex structures like geometrical shapes out of a large component within a single session.

Material and Logistics Handling

This is a problem because of the size and weight of the workpieces, posing material handling in the manner that the material handling equipment has the ability to raise the material to the machining station, as the material can weigh several tons. Second, the machined components are made of alloys. The reasons are that the material to be machined is hard, containing hardening elements.

Therefore, to be successful in large parts processing for energy equipment, one must incorporate size, complexity, and force into a process. This is achieved through investing in infrastructure with size, solutions to physical force, and multi-axis linkage machining capabilities, which form the essence of a successful process in the energy industry.

How Can Industrial Robots Improve Motion Accuracy Through Precision Machining?

The applications of industrial robots have been mostly reliant on the accuracy of geometric design for the fundamental mechanisms. Achieving this demands robot components precision machining that prioritizes flawless geometry and long-term stability to ensure reliable motion accuracy control.

Foundations of Kinematic Accuracy

The error-free geometric features in the components such as housing and joint arms get the highest priority. Robot components precision machining helps create components with no error, resulting in guaranteed perfect orthogonality, concentricity, and planeness at the mounting surface. It also eliminates the concept of error stacking because the addition of a specific error in various details helps create a positional error, forming the foundation stones for the motion accuracy control of a robot.

Enabling Dynamic Performance

Output flange components and gear shaft components need the capability to bear heavy torques in this category of transmission system components. The essential requirements of high-performance parts manufacturing go beyond micron-level CNC machining tolerance capability. These parts also want expertise gained from a certain process. Strategic heat treatment is employed to further enhance their resistance against wear and tear. Furthermore, residual stress relief processes preclude changes in dimensions.

Validated Process and Results

Robot-manufacturing CNC machining case studies and their results can be referred to for insight into the affected areas. For example, in the case where the wave generator of the harmonic drive is machined with roundness values of <5μm and better surface finish, it leads directly to reduced backlash and smoother motion. It goes without saying that the resultant benefit, accrued due to strategic parts processing, will go on to directly lead to performance advantages in robotic systems.

Ultimately, improved robot performance is simply an immediate consequence of quality components that are better. Special robot components precision CNC machining and high-performance parts manufacturing that include expertise in geometric control and material science-make sure the required motion accuracy control, as evidenced through real-world success CNC machining case studies.

Figure 3: Precision CNC machining of metal parts in a factory by LS Manufacturing

LS Manufacturing Aerospace Field: Precision Machining Of Titanium Alloy Brackets For Satellites

Modern satellite technology requires materials and components that must be extremely light with a strong structure. A prime aerospace customer was working on the tough project of manufacturing a titanium satellite bracket under the pull of conflicting demands. This presented a perfect LS Manufacturing aerospace case studies aerospace industry solution.

Customer Challenge

One of the most essential brackets that had to be produced based on the request of one of its clients was related to a communication satellite. As part of this component, it boasts an optimized topology structure along with a complex geometry. Conventional manufacturing methods struggled with the complexity and, more critically, were unable to prevent part deformation during the titanium alloys precision CNC machining process, which threatened the component's dimensional accuracy and final performance.

LS Manufacturing Solution:

To overcome this, LS Manufacturing employed a dual-strategy approach. First, engineers conducted finite element analysis (FEA) to further refine the design for manufacturability without compromising performance. Then, the part was produced using advanced 5-axis satellite structural component manufacturing techniques. This allowed for continuous, stable machining from optimal angles, applying controlled cutting strategies specifically developed for titanium to manage heat and stress, thereby minimizing distortion.

Results and Value

The end result has proven to be no less than a resounding success. The final titanium bracket held the ability to withstand the creation of no less than 40% of the reduced weight, thus meeting the stringent requirements set for the bracket design. The success of the positive outcome of the case study on the titanium alloys precision machining has now been succeeded by the success of the satellite within the process of its orbital launch as part of which the bracket held its own role.

This project stands as a prime example within LS Manufacturing aerospace case studies. It is for this reason that the specific project has already illustrated the efficiency of the combination of design optimization and the satellite structural component manufacturing. Regarding the particular project, a significant role has been played by the degree of lightness and strength of the component.

Let LS Manufacturing's cutting-edge CNC machining technology give each of your critical components ultimate lightweighting and strength beyond limits.

Why Choose LS Manufacturing As Your Industry-Specific CNC Machining Partner?

In today's competitive marketplace and manufacturing sector, it is important to have the right CNC machining partner, and that is where LS Manufacturing comes in. That is why LS Manufacturing is a better strategic partner:

- Industry-Specific Solutions: Since they have a combined experience of two decades in this particular industry, LS Manufacturing has formed industry-specific groups based upon their areas of interest. Their know-how and expertise in this particular industry, coupled with the experience about material science, helped their team to create the solutions pertaining to the CNC machining industry applications as per the operating norms laid down in this particular industry.

- LS Manufacturing's professional advantages: Competitive Advantage: The entire range of equipment the company has, along with the excellent quality management systems the company maintains, is the reason for the competitive advantage the company attains. These have resulted in the company providing the best manufacturing services to its clients, thus making the companies their preferred business partners.

- Technical and quality integration: The service includes the entire development process and the final quality test. This particular service plays a crucial role in the professional advantage, where all sides are assured to gain the advantage of engineering, and this results in the clients receiving the best quality.

- Extensive application knowledge: LS Manufacturing’s expertise directly translates into superior results across diverse CNC machining industry applications. Their extensive knowledge and experience in the concerned domain could be termed the best to deal with the most challenging tasks associated with the concerned industry.

Ultimately, selecting the LS Manufacturing company for your CNC machining partner in a relationship that is characterized by experience, precision, and reliability. The ability to ensure industry-customized solutions and utilize their core professional advantages is a guarantee for them to provide the best value and manufacturing support for advanced industries.

How Do I Get Started On My Industry-Specific Processing Project And Get Customized Solutions?

Beginning a project linked to complex machined parts can end up being a rather cumbersome task for most manufacturing companies. LS Manufacturing streamlines this journey with a structured, collaborative process designed to turn your concept into a reliable, high-quality part, beginning with comprehensive professional machining consultation.

- Initial Consulation and Analysis of Requirements: It begins with a discussion with you. Our engineers undergo a professional machining consultation to understand the function of your component and requirements, as the aim is to understand your needs completely. This foundational step ensures we grasp not just the what but the why behind your design, setting the stage for effective project initiation guide.

- Custom Solution Design and Feasibility Analysis: As soon as the clarity regarding the needs develops, CNC custom solutions can be created. This can comprise the most appropriate solution regarding the production process, the choice of materials, designing custom fixtures, designing custom tool paths, and conducting the entire analysis regarding the feasibility of the production.

- Prototype Development and Transparent Quotation: For this issue, the answer is to move on with the development of the prototype. We provide a detailed, clear quotation that outlines all costs, timelines, and process steps. This transparency is a core part of our project initiation guide, giving you complete visibility. Once you have approved the document, we shall proceed with the development process for the production of the first article sample.

- Verification, Ramp-up, and Support: The prototype is evaluated and checked. We can together check the finished product against the requirements. We move ahead with the mass production process only when we are successful at the verification stage. Our support continues post-delivery, offering insights for design-for-manufacturability improvements and ensuring the long-term success of your CNC custom machining solutions.

By partnering with LS Manufacturing, a clearly defined and established process has now been put into place to ensure a course of action from conceptual to complete and back again, if need be, with confidence and success in knowing that the beginning and end result of each of your projects will be maximized for success through our project initiation guide.

Figure 4: CNC turning of a precision metal gear by LS Manufacturing

FAQs

1. What are the differences that exist within the CNC machining services offered by different sectors?

These are the divergence points for the material to be used, the level of accuracy, the requirement for certification, and the production batch sizes. We will address the process and control for the different industries in line with the divergence points above:

2. What kind of certifications are required for the production of medical devices?

Under manufacturing related to medical devices, it is necessary to take into consideration the certification of a quality system. This should follow the ISO 13485 guidelines. For specific types of medical devices, it is necessary to obtain FDA, CE, or modified compliance approval. Our staff employs comprehensive medical qualifications with a great deal of medical experience with regard to certification.

3. There are some specific requirements in the production of aeronautical components?

Aerospace parts must meet standards AS9100, whose standards for certification, material, and traceability are incredibly demanding. It is on the above that the process for the total quality management approach for the aerospace industry has been defined.

4. What is the measure of optimization of small-batch and multi-variety production?

For the optimization of production scheduling and planning, we use Flexible Manufacturing Systems along with Rapid Changeover Systems. Therefore, we are able to carry out cost-effective production service delivery even in the context of the smallest batch orders of production.

5. What steps do you take in order to procure the intellectual properties pertaining to your machining solutions?

We have confidentiality agreements and secured document management systems put in place. Our clients' data is all encrypted so that all the technical solutions and designs are secured.

6. How do you deal with the issue of developing new products?

We are professionals offering the DFM analysis service and are part and parcel of the process and therefore involved in the early stage identification of potential manufacturing defects.

7. Would you like rapid production of samples, and small production orders?

Moreover, in order to respond quickly to customer needs, we provide for rapid response delivery services so that, in the case of samples with prototypes, the delivery of the prototypes takes just 3 days, besides the fast turnaround from trial production on a small scale to production on a large scale.

8. What is the process followed in mass production to obtain equal quality?

The process follows the methodology of statistical process control as in SPC, and it has on-line testing facilities. The quality traceability system has been established to ensure consistency and traceability of quality for massive production.

Summary

By the industry application analysis, it is confirmed that the technology used by LS Manufacturing is presently at the forefront in the field of development of products. LS Manufacturing, with its rich experience in the respective industries, is providing you with the maximum possible benefit in the form of services to provide the manufacturing benefit to your company in the contemporary market situation.

You can take advantage of the services offered by the team of industry experts at LS Manufacturing to provide you with tailored solutions related to the processing. It is in your favor regarding the success of your product that we make use of our experience. You can take advantage of the free design and manufacturing feasibility analysis services offered by LS Manufacturing CNC machining.

To address the risks of large-scale production involving complex curved surfaces and monolithic molding, explore innovative CNC machiningapplications in your product manufacturing today!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.