5-axis CNC machining is a core technology in modern manufacturing facing the increasing challenge of making complex parts with curved surfaces, angled holes, and other complicated geometries. In the past, it usually required several setups to finish such components using conventional 3-axis methods. This increases production time, involves higher costs for fixtures, and possibly precision errors due to repositioning.

The most apparent benefit of 5-axis machining is its ability to process complex parts with just one setup. Such "5-axis linkage" freedom eliminates accumulation errors and greatly enhances efficiency. By introducing advanced 5-axis systems, LS Manufacturing can help customers make a leap forward in both precision and productivity, thus unlocking greater potential for innovative designs.

To fully leverage those benefits, the core principles behind 5-axis technology and its disruptive advantages have to be understood. So, to save your time, let's get down to the key findings.

5-Axis CNC Machining Core Advantages Quick Reference Table

| Comparison Dimensions | Limitations of Conventional 3-Axis Machining | Solutions for 5-Axis CNC Machining | Core Value Created for Customers |

| Machining Capacity |

complex-curved surfaces and structures of irregular shape effectively. |

Complex shape machining at multi-angle can be finished in one clamping. |

It promotes design freedom, breaking through the limit of geometry. |

| Machining Accuracy |

A number of clampings introduce the possibility of accumulated errors that affect accuracy. |

Single clamping avoids datum conversion and hence assures high accuracy. |

Improves the quality and consistency of the product. |

| Production Efficiency | Frequent clamping and debugging, long auxiliary time, low efficiency. | Reduce clamping time to achieve efficient continuous production. | Significantly shortens production cycles, which accelerates time-to-market. |

| Cost Control | High cost of fixture and labour, which is difficult to control in general. | Tooling and fixtures should be reduced to optimize the total cost per piece. | It reduces overall costs and strengthens competitiveness. |

| Surface Quality | Poor quality in the machining , with the generally curved surface machining needing post-processing | Higher quality of surface finish and detail. | Fewer subsequent processes due to higher quality finished products. |

In a nutshell, 5-axis CNC machining will help systematically solve the bottlenecks in capability, precision, efficiency, and cost presented by conventional 3-axis machining through its core capability: "one-time setup, complete machining."The adoption of 5-axis technology is strategic for high-end manufacturing and smart production.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Among today's information glut in 5-axis machining technology, added value is assured for this guide, since all its content comes from the hands-on experience built up over time at the front line of production at LS Manufacturing. Our experience does not come from textbooks; instead, it is sharpened by fighting high-temperature alloys, micron tolerances, and complicated geometries every day.

We have finished tens of thousands of 5-axis CNC machined parts with complicated details in the last decade alone, and each project deepens our material property knowledge, tool selection, and process parameter control. That includes optimizing the cutting scheme for high-temperature alloys, controlling the deformation of aluminum alloy machining, balancing quality with efficiency for small batches with several varieties of products.

This guide is a distillate of this practice, summarizing successful cases and reflecting on early lessons learned. The following are some practical methods that have been repeatedly validated by cutting, coolant, and measuring equipment with the aim of helping customers avoid those pitfalls we encountered. Please be assured that what is presented here are the core techniques we continuously use daily, hoping to provide practical reference for your 5-axis machining projects.

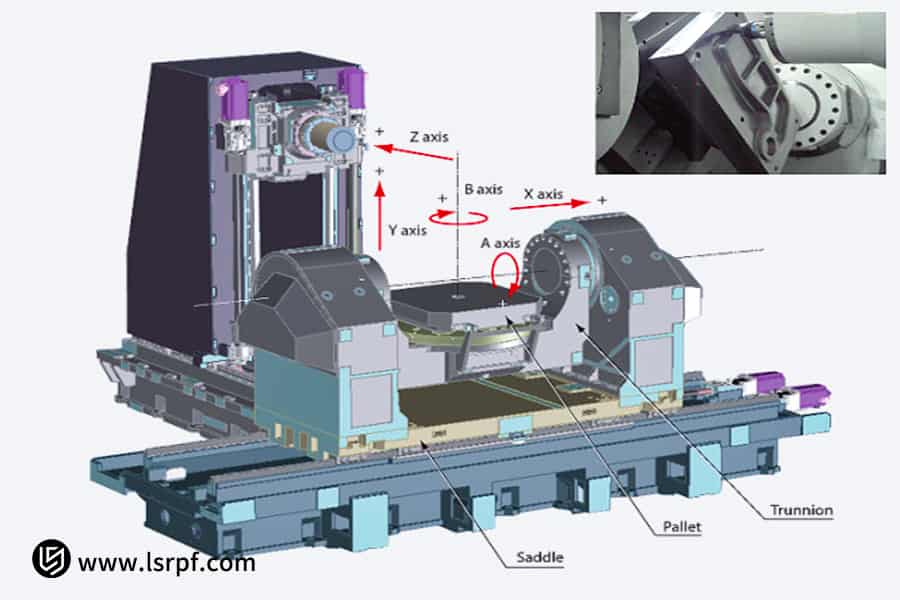

Figure 1: Optimized 5-axis numerical control machining system by LS manufacturing

Why Is 5-axis CNC Machining The Best Solution For Manufacturing Complex Parts?

First, we need to understand: what is 5-axis CNC machining? Speaking in a simple manner, in 5-axis machining, two rotary axes are added to the 3 axes of linear movement of a classic 3-axis machine tool. The most commonly applied two added rotational axes, A, B, or C axes operate in addition and with the capability to provide the same linear movements as conventional 3-axis machines.

This helps the tool move not only conventionally but from almost any angle to approach the workpiece. What makes this technology so revolutionary is the following two main advantages:

1. One-time setting, 5-side machining:

In the machining of complicated parts with conventional 3-axis machine tools, many re-clampings of the workpiece have to be done. 5-axis technology coordinates the rotation of the tool and worktable so that all 5 faces and even more complex angles of the workpiece can be machined in one setup, basically eliminating the loss of precision and efficiency bottlenecks owing to multiple clampings and realizing "lean manufacturing."

2. A Qualitative Leap in Capabilities for Machining Complex Surfaces:

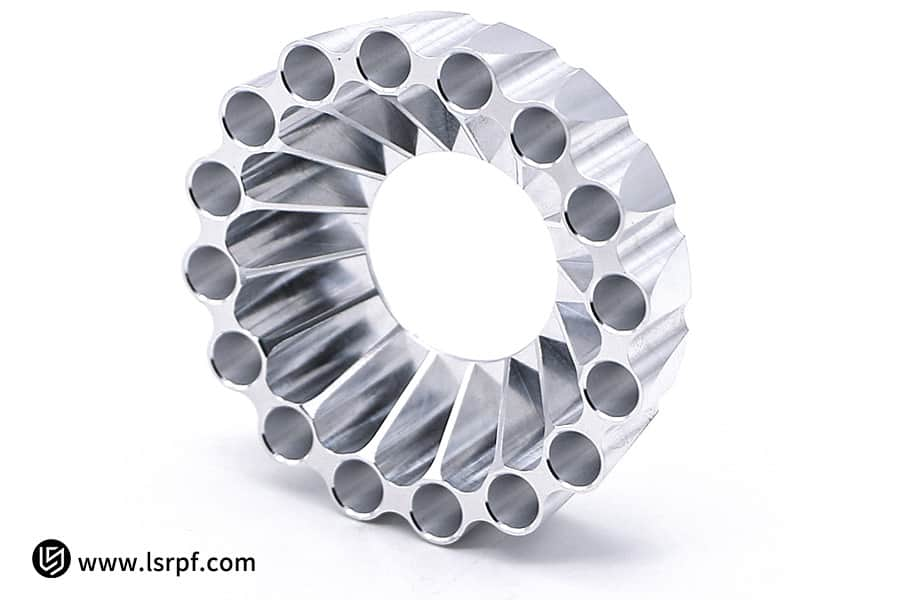

5-axis machining can keep a tool vertical to the machining surface or at the best cutting angle during the machining of complicated curved surface geometries for such parts as impellers, turbines, and precision molds. Thus, it can ensure higher machining accuracy and a better surface finish, and improve machining efficiency drastically, which cannot be offered by 3-axis machining.

In a nutshell, 5-axis CNC machining irreplaceably enables "one-time clamping." It possesses the ultimate handling ability in complex geometries and perfectly solves not only the machining challenge of multi-axis linkage but also achieves the best balance among accuracy, efficiency, and cost. This forms an ultimate solution and cornerstone of high-end manufacturing in modern complex part manufacturing.

What Are The Working Principles And Core Technologies Of 5-Axis CNC Machining?

How Does 5-Axis CNC Machining Work?It is based on 3-axis linear motion and two rotary axes for coordinated movement, such as A/C axes or B/C axes. It allows the tool to cut the workpiece from any direction. The The Working principle of five-axis CNC machining core technologies are mainly reflected in the following two major aspects:

1. Mechanical Structure Configuration:

The main configurations are: cradle type and swivel type. In the cradle-type structure, multiangle machining is realized based on the rotation of the worktable, while in that of the swivel type, processing is carried out via oscillation of the spindle head. Thus, the latter type can be better fitted in the process of dealing with large and heavy workpieces. Different structural forms determine the range and characteristics of machining performance.

2. RTCP Core Function:

Basic to the idea of 5-axis machining is tool tip following technology. It calculates for, in real time, the change in position of the tool tip given by the rotation of the tool and allows the programmer to define only the tool end-effector trajectory, which the machine tool calculates from the required motion of each axis. This function makes sure that even during the machining of complex curved surfaces, the tip of the tool always moves precisely along the set trajectory.

Accurately selecting machine tools and deeply optimizing the RTCP parameters perfectly combine excellent mechanical performance with intelligent control, enabling the perfect forming of complex parts in one setup. It is just this deep integration of "hardware + software" at the core of how 5-axis machining achieves the goals of high-precision and high-efficiency processing and also is an important guarantee for the creation of value for our customers.

What Advantages Does 5Axis Machining Have Over 3-Axis Machining?

The foremost benefit of 5-axis CNC machining lies in the fundamental breakthrough of machining freedom and capability through adding two rotary axes. To further illustrate the comparative differences between 5-axis and 3-axis CNC machining,the table below presents a comparative analysis from four key dimensions, which is central to understanding 5-Axis vs 3-Axis CNC machining:

| Comparison Dimensions | Limitations of 3-Axis CNC Machining | Advantages of 5-Axis CNC Machining |

| Clamping and Precision | Complex parts require multiple clamping operations, leading to extended machining time and introducing cumulative errors. | Multi-faceted machining is completed in a single setup, significantly reducing machining time and fundamentally eliminating repetitive positioning errors. |

| Geometric Forming Capability | Complex curved surfaces and angled features are difficult to handle efficiently, limiting design space. | This feature easily achieves one-time forming of complex geometries, providing unlimited possibilities for product innovation. |

| Machining Stability and Quality | Deep cavity machining requires long cutting tools, which are prone to vibration and affect surface quality. | Shorter, more rigid cutting tools can be used, significantly improving cutting stability and surface finish. |

| Machining Accessibility | Machining features such as deep cavities, undercuts, and angled holes is difficult or even impossible. | The cutting tool can approach the workpiece at the optimal angle, perfectly solving the accessibility problem of machining special features. |

5-axis machining greatly improves efficiency and accuracy since the number of setups is reduced, the occurrence of cumulative errors is eliminated, and consistency is maintained as a result of using short tools. It overcomes geometric limitations, turning complex designs into reality. The 5-axis investment is an important juncture to enhance production efficiency and reduce costs. More importantly, it is a strategic step to drive innovation and occupy the high end of the value chain.

Figure 2: High-accuracy CNC machine tool workstation by LS Manufacturing

What Are The Major Differences Between 5-Axis And 3-Axis CNC Machining, And How Is A Selection Made?

If one wants to make a comparison between 5-axis and 3-axis CNC machining, the point is to know their essential difference. 3-axis machining is basic 3-dimensional linear motion, while 5-axis machining achieves complex forming through 5 degrees of freedom linkage. Specific comparisons can be made in the following aspects:

| Comparison Dimensions | 3-axis CNC Machining | 5-axis CNC Machining |

| Machining Difficulty | It can perform single-sided machining for simple geometrical shapes. |

An overall machining for complex curved surface and multi-angle features can be done by it. |

| Machining Accuracy | Multiple clamping operations will easily lead to cumulative errors. | A single clamping avoids repeated positioning errors. |

| Production Efficiency | Because the production of complex parts involves several clamping operations, it requires more auxiliary time. | Saving clamping times will achieve continuous production efficiency. |

| Fixed Fixture Requirements | Several sets of dedicated fixtures are needed, which tends to be costly. | Simplify fixture design and reduce tooling costs. |

| Programming Difficulty | Relatively simple programming; entry barrier is low. | Requires professional 5-axis programming skills and experience. |

| Cost Structure | Low investment in equipment but possibly higher overall cost. | High investment in equipment but better total cost per unit. |

Due to the high accuracy and consistency in continuous, complex, curved surfaces, deep cavities, narrow grooves, or multi-angle irregularities, 5-axis machining technology can optimize the whole manufacturing cost of a product. If the structure of a part is simple, 3-axis machining can be an economical alternative. Only by proper analysis of the requirements of the product and an exact match between machining capability and manufacturing objectives can the right choice be made.

In Which High-Value Industries Is 5-Axis CNC Machining Technology Specifically Applied?

5-axis CNC applications is pivotal in industries that require geometric complexity, high precision, and superior material performance. Serving as a core enabler for advanced manufacturing, key applications include:

- Aerospace: Used for manufacturing engine impellers, turbine blades, and thin-walled structural components. 5-axis technology enables high-precision, single-setup machining to meet stringent mechanical and reliability standards.

- Medical Devices: Applied in producing orthopedic implants such as knee or hip joints and customized prostheses. It ensures anatomical accuracy, superior surface quality, and biocompatibility necessary for successful surgical applications.

- Molds and Automotive: This technology is ideal for complex injection molds, high-gloss interior components, and engine parts. It achieves high surface finish directly to reduce polishing time and accelerate the production cycles.

- Energy and Precision Instruments: Crucial in the making of turbine components, holders for optical instruments, and semiconductor chambers. It will solve the problems of deep cavities, complicated channels, and strict angular tolerance.

In a nutshell, 5-axis machining resonates with the goals of 'complexity-precision-efficiency' in high-end manufacturing. From aerospace engines to medical implants, it unleashes possibilities for innovative design. At LS Manufacturing, we apply this technology in our deliveries of reliable, avantgarde solutions for the most demanding applications.

What Are The Challenges In Realizing High-Quality 5-Axis Machining, And How Can They Be Overcome?

Most companies face 3 core challenges in performing high-quality 5-axis machining; these are high equipment costs, complex programming, and shortages of skilled personnel. Even for modern machines, integrated solutions have to be used to ensure consistently good results. These are addressed systematically in our LS Manufacturing 5-Axis CNC systems:

1. Equipment stability:

We have invested in and introduced high-end 5-axis machining centers from the German company DMG MORI and established a comprehensive maintenance system. The regular precision calibration and predictive maintenance ensure that the equipment maintains micron-level dynamic accuracy over a long period of time, providing a basis for high-quality machining.

2. Programming Skills

Senior CAM engineers will be able to use self-developed process databases together with intelligent algorithms to ensure interference-free toolpaths are generated automatically. In this regard, such technology will significantly optimize complicated surface machining strategies and improve programming efficiency by 40% and machining cycles by 30%.

3. Talent Development:

A structured training system and "dual-mentor" system are adopted to systematically cultivate technical personnel. We integrate the corporate knowledge base with practical projects, enabling our team independently to complete a whole process from design to delivery and provide professional turnkey solutions to clients.

Combining advanced hardware, intelligent programming systems, and a professional talent pool, we have created a complete precision manufacturing ecosystem. This mature system enables the transformation of even the most complicated designs into high-quality physical parts through micron-level precision, providing cost-effective and reliable end-to-end services.

Figure 3: 5-axis coordinated machining in progress by LS Manufacturing

How Does The 5-Axis Machining System From LS Manufacturing Solve Specific Industry Challenges?

The value of LS Manufacturing comes in with the transformation of advanced technology into 5-axis CNC machining solutions that address the real pain points of the clients. The following successful case study of the drone propeller explains how we address the process challenges of high-quality 5-axis machining and create value for our core clients.

1. Client Challenges:

Once upon a time, an innovative drone manufacturer was faced with the task of designing a new high-lift propeller. Due to its complex twisted airfoil and rigid dynamic balancing requirements, conventional 3-axis machining cannot guarantee surface accuracy; therefore, the aerodynamic efficiency was poor. Before cooperating with us, trial production with a few of its suppliers was less than 60%, seriously influencing the process of launching new products.

2. LS Manufacturing Solution:

The engineering team pinpointed dynamic balancing accuracy as the main determinant of performance. Based on extensive experience in high-speed aerospace impellers, we used a German DMG MORI 5-axis machining center and advanced CAM software to derive an optimal toolpath fitting precisely on the airfoil surface. We also selected high-strength aluminum alloy materials and a proven library of cutting parameters to ensure that high-precision, integral propeller forming is conducted within one setup.

3. Results and Value:

In fact, this very product had been a success upon first delivery: the yield rate soared from less than 60% to 98%, with dynamic balancing performance far exceeding the client's expectations. This helped customers cut their new product launch time by 50% while also helping their products quickly attain leading market positions owing to their superior flight performance.

All 5-axis CNC machining systems are equipped with high-class hardware, professional techniques, and rich experience. It changes those high-quality machining challenges like complicated programming and dynamic balancing into the core competitiveness of products through systematic solutions, ensuring that customers can enjoy their competitive advantages in the market.

How To Maximize Cost-Effectiveness Through Optimization Strategies In 5-Axis Machining?

Improving 5-axis machining efficiency and cost optimization is a systemic project, and the core lies in the deep integration of advanced equipment performance with refined process strategies. We have achieved simultaneous optimization of machining cycle time and cost by establishing a scientific process parameter library, intelligent toolpath planning, and modular fixture solutions. The main optimization methodology undertaken by us covers the following dimensions:

- Toolpath Optimization: Intelligent CAM programming reduces non-cutting movements to a minimum while maximizing efficient material removal, consequently reducing cycle times and improving equipment utilization.

- Smart Fixturing: Modularity in zero-point positioning systems may allow for fast changeovers in the absence of dedicated fixtures, thereby supporting small-batch production.

- Tool Management: Precise choice of tools depending on material and machining stage, together with monitoring their life, precludes premature failure and guarantees maximum performance.

- Machining Strategy: High feed rates for roughing and high-speed precision for finishing assure both efficiency and superlative surface quality.

Cost-effective 5-axis machining requires transforming machinery potential into real benefits by implementing systematic process optimizations. Our integrated approach, combining top-class machinery with proven technical expertise, secures substantial unit cost and lead-time reductions while maintaining or improving quality standards.

Figure 4: CNC machining process for intricate components by LS Manufacturing

What Are The Major Competencies On Which A Focus Should Be Placed When Dealing With A 5-Axis Machining Service?

The right choice of the service provider for the 5-axis machining makes all the difference between success and failure for big projects involving complex products. Other than the equipment itself, the system, constituting hardware, software, and talent, should be a mature one that a reliable partner like LS Manufacturing has established with its 5-axis CNC machining. To make your project successful, we recommend focusing on the following core dimensions:

1. Equipment Foundation and Precision Assurance:

Check their brand, age, and precision maintenance record of the 5-axis machine tool. The high-level equipment with stable and regular calibration will be the physical foundation that guarantees long-term dimension stability of the parts and avoids batch quality problems caused by equipment precision drift. These would be brands like DMG MORI or Haas.

2. CAM Programming and Simulation Capabilities:

Professional 5-axis programming is needed. The service provider shall use advanced CAM software for accurate toolpath planning. Stringent cutting simulation is put in place to ensure 100% elimination of the risk of tool-workpiece/fixture collision during machining. This is a precondition to guarantee safety in machining and a high first-pass yield.

3. Project Experience of the Engineering Team:

Operating and programming experience is closely related to the capability of handling unexpected problems. We consider the experience of the team in years and successful case studies in machining similar complex parts, such as impellers or precision molds, within your industry. The more experience one has, the better they are at process optimization, efficiency enhancement, and dealing with special material challenges.

4. Compre-hensive quality control system:

The suppliers shall possess the capability for complete quality inspection and traceability. First-piece and critical dimensions are to be inspected with precision inspection instruments like CMMs and laser interferometers. The establishment of complete quality archives will be done in such a way that, in case there is some problem in tracing quality, it shall be possible.

The major advantage of LS Manufacturing in 5-axis CNC machining systems is comprehensive development. It invests not only in top-ranking hardware but also in cultivating a team with experienced engineers, establishing a rigorous process database, and a complete quality control system. This ensures that we can manufacture complex designs into high-quality products with high precision and efficiency for our clients, thus making us your trustworthy partner in manufacturing.

Figure 5: Precisely fabricated metal parts using CNC technology by LS Manufacturing

FAQs

1. What is the minimum tolerance that can be achieved by 5-axis CNC machining?

Our 5-axis system can stably achieve a tolerance of ±0.01mm with a highly rigid machine tool structure, temperature control compensation, and precision tool setting technology. In addition, through process optimization, the tolerances for key features such as impeller tenons can reach ±0.005mm, and the system is equipped with a three-coordinate measuring machine to perform full-process quality verification.

2. Is 5-axis machining only suitable for mass production?

Quite the contrary. With modular fixtures and a quick tool change mechanism, our FMS is designed for agile production. It can therefore switch efficiently from small-batch or even single-piece prototype manufacturing to medium-batch production, greatly shortening the R&D cycle. This makes the FMS an ideal choice for prototyping innovative products.

3. Is programming in 5-axis highly complicated and time-consuming?

While this is more complex programming than for 3-axis machining, our experienced CAM team uses software like HyperMill and PowerMill for the automatic optimization of tool axes and collision avoidance. We make numerous calls to different process libraries in programming, using various intelligent templates to increase efficiency and ensure safety.

4. What materials can you process?

We can process a wide variety of materials, including aluminum alloys, stainless steel, titanium alloys, high-temperature nickel-based alloys, engineering plastics such as PEEK, and composite materials. We have a mature library of cutting parameters tailored to the characteristics of different materials and can also arrange surface treatments such as anodizing and passivation.

5. Is 5-axis machining equipment very expensive?

You don't have to incur millions upfront in equipment costs. By partnering with us, you can turn world-class 5-axis capabilities-such as the value of DMG MORI equipment-into a competitive advantage. That's basically turning fixed costs into variable costs, dramatically lowering the financial risk while optimizing the use of capital.

6. How do you ensure collision safety in 5-axis simultaneous machining?

Safety comes first. After programming, professional software VERICUT is used to carry out full-process machine tool simulation, making precise verification of possible interference between the tool holder, spindle, workpiece, and fixture to eradicate collision risks at their root, thus fully ensuring the safety of either the machine or the workpiece.

7. How long does it take to receive a machining quote from the time a 3D model is provided?

We have established an efficient and rapid quotation process. For parts of common complexity, you can get a detailed quotation, including process analysis, price, and delivery time within 24 hours. For extremely complex projects, we will also provide an initial response within 8 working hours.

8. What types of 5-axis machining do you support?

We fully support high-precision 3+2 fixed-axis machining, which is suitable for polyhedral parts, and continuous 5-axis linkage machining for complex curved surfaces. The best comprehensive machining solution, taking into account the geometry, accuracy, and efficiency requirements of your part, will be suggested and realized by our engineers.

Summary

5-axis CNC machining is the solution that can conclusively handle challenges related to the manufacturing of high-precision and complex parts. It revolutionizes the conventional ways of manufacturing with unparalleled flexibility and precision. Equipped with the latest 5-axis machining systems, an experienced team of experts, and a mature quality system, LS Manufacturing has become a trusted partner among many industry leaders.

For parts beyond the capability of conventional machining or for product quality and production efficiency improvement, please do not hesitate to contact us immediately for a free technical assessment and quote by our 5-axis machining experts at LS Manufacturing. Let us empower your products with core technologies.

📞Phone: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website: https://lsrpf.com/

Disclaimer

The content on this page is for informational purposes only. LS Manufacturing makes no representations or warranties, express or implied, regarding the accuracy, completeness, or validity of the information. It should not be inferred that third-party suppliers or manufacturers will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type, or processes through the LS Manufacturing network. The buyer is solely responsible for this information. For parts quotations, please specify the exact requirements for these parts. Please contact us for more information .

LS Manufacturing Team

LS Manufacturing is an industry-leading company specializing in customized manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precision CNC machining , sheet metal fabrication , 3D printing , injection molding , metal stamping , and other one-stop manufacturing services.

Our factory boasts over 100 state-of-the-art five-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries and regions worldwide. Whether it's small-batch production or mass customization, we can meet your needs within 24 hours. Choosing LS Manufacturing means choosing efficiency, quality, and professionalism.

For more information, please visit our website: www.lsrpf.com .