5-axis CNC machining materials presents numerous dilemmas to the producers of the project involved in handling complex projects. The project design, which comprises details such as the end product, ensures easy influence of material choice on the cost of the CNC machining process, timelines, and the quality of project solutions faced with over-budgeted and underperforming challenges due to inappropriate choices.

The common approach to material selection traditionally followed by 5-axis CNC machining procedures is based generally on standards or formulas that are not particularly relevant to the context of 5-axis machining. A likely result may be the over-design or under-design approach because of the absence of exactness in material properties concerning processability as well as cost-effectiveness. This particular article tries to solve the said critical problem with more than twenty years of experience from the background of LS Manufacturing in the area of R&D.

5-Axis CNC Machining Materials Quick Reference Table

| Material Category | Key Materials | Key Properties | Primary Applications |

|

Metals |

Aluminum (6061, 7075, etc.) |

Excellent machining qualities |

Automotive, aerospace, general engineering |

|

Stainless Steel (304, 316, etc.) |

Dense, corrosion-resisting, hard to machine |

Use in hospitals, food service |

|

|

Titanium |

Restores strength, compatability, and resistance to temperature |

Aerospace, medical implants, defense |

|

|

Inconel & Superalloys |

Extreme heat resistance, high strength |

Turbine blades, aerospace components |

|

|

Plastics |

Acrylic (PMMA) |

Optical clarity, easy to machine |

Displays, lenses, rapid prototypes |

|

Nylon |

Strong, wear-resistant, and highly durable |

Gears, bearings, structural parts |

|

|

Polycarbonate |

Impact-resistant, transparent, strong |

Safety equipment, automotive parts |

|

|

Composites |

CFRP (Carbon Fiber) |

Lightweight, high strength, stiffness |

Automotive, sports equipment, aerospace |

|

GFRP (Glass Fiber) |

Good strength, corrosion resistance |

Boats, wind turbines, structural |

|

|

Advanced Materials |

Ceramics |

Hard and able to resist higher temperatures |

Specialty components, cutting tools |

|

Graphite |

Excellent electrical/thermal conductivity |

EDM electrodes, heat sinks |

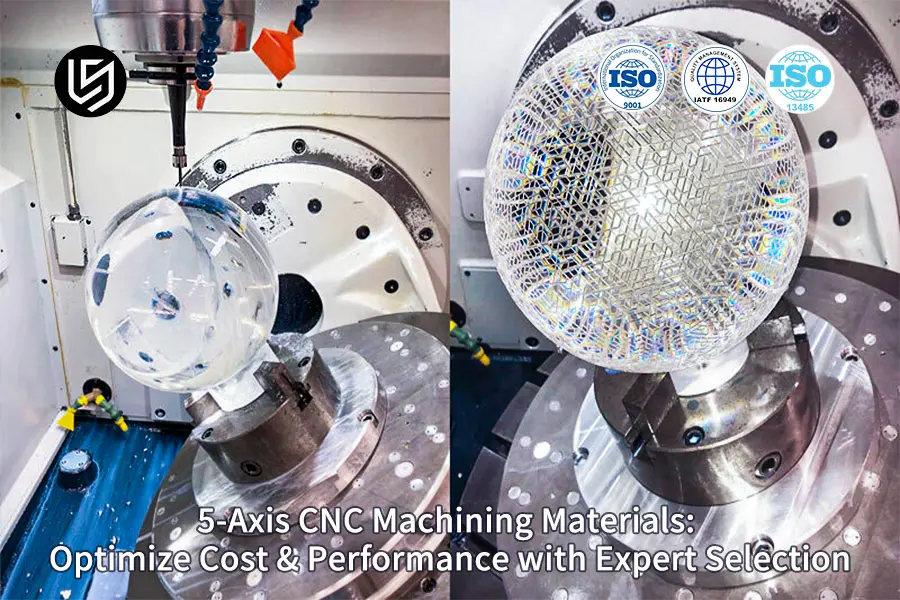

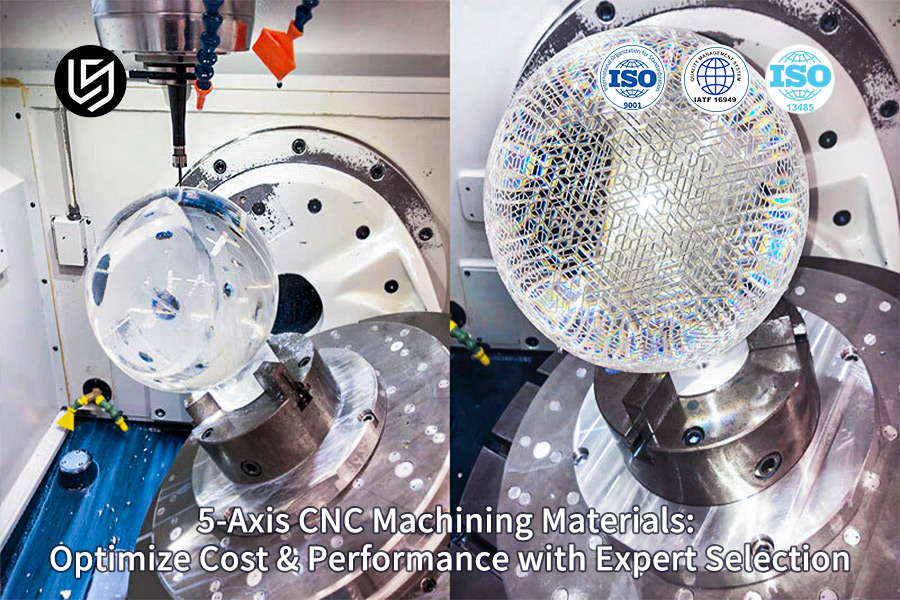

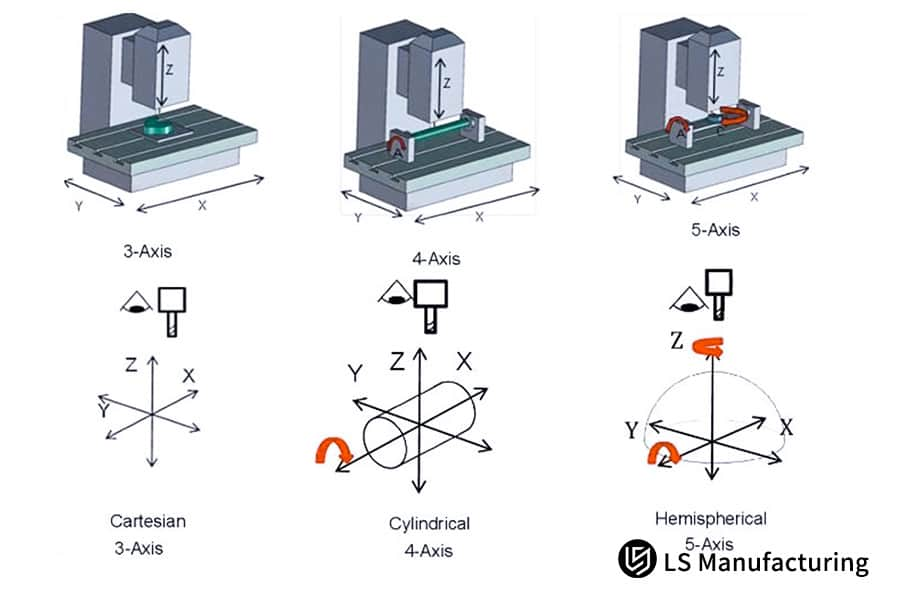

5-axis CNC machining can be done on different materials such as lightweight aluminum and superalloys that are difficult materials. One of the primary advantages consists of complex shapes that can be obtained in a single operation. However, it can be difficult to generate because of the latest CAM software and technology. 5-axis CNC machining can be applied in turbines, bodies of biomedical implants, and molds. It needs to be applied in industries that use high accuracy and complex shapes.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Our knowledge and understanding have come from the past eleven years of experience with 5-axis CNC machining materials. We have dealt with materials such as aerospace titanium materials, right through to healthcare materials that are made from stainless steel, in order to produce over 50,000 parts at a micron level of accuracy to be able to provide practical solutions.

Each strategy that we share has been proven with quality data analysis and meets safety standards of Occupational Safety and Health Administration (OSHA). We have created a large database on material performance, tooling, and machining conditions on more than 50 different materials. The database helps avert trial and error practices of clients, thus keeping their workplace environments safe, since safety matters are given priority at our company.

Our approach is grounded on the tenets of production process optimization put forth by American Production and Inventory Control Society (APICS) in the area of production. We like to think of ourselves as providing solutions for real-world problems like thermal distortion of aluminum materials or tool failure during Inconel production. It is the systemized way of working that has helped our clients lower costs by 15-25%.

Figure 1: Custom complex components in varied materials and surface treatments by LS Manufacturing

How Does Material Selection Affect Cost And Performance In 5-Axis Machining?

5-axis CNC machining materials is an important task, and the output of the task would directly impact the performance as well as the economy related to the end product. In our organization, at LS Manufacturing, a database that comprises more than 50 different materials has been established to provide cost-performance optimization output.

Machinability of Materials and Tool Life

The machinability of different materials varies. This directly helps in determining the tool life as well as the machining time. Certain materials that are stronger in nature, like titanium or Inconel, would require specialized tools or lesser speeds. In this way, it can very easily be surmised that the database created in this project is a tremendous help in determining the point of intersection of requirements for the material.

Strength Properties versus Application Requirements

It is difficult in 5-axis material selection to ensure that a part has its functional requirements satisfied in terms of its strength, hardness, and heating demands. This can raise the cost of material supply by up to 30-50 percent if specification overload has occurred, and there is also a risk of component failure if the material cannot perform adequately.

Surface Finishing and Post Processing

There are some materials that have better surface finishes at the time of machining, and as such, polishing and coating processes are not required for them. This itself contributes a lot to the cost of the finished product since post-processing adds up to 20% to 40% of the cost of the finished product. Material selection based on our data avoids post processing.

Material availability and lead time

Generally speaking, the use of standard materials with better availability yields a price advantage over the use of custom alloys. The cost-performance optimization based on factors like availability of materials.

Thermal & Chemical Factors

Material selection would make more sense when the components are under high temperatures or strong chemical forces. This would call for better quality materials which are very expensive and more suitable for the purpose. One could also explore cheaper alternatives of the material through the database system that would also prove to be eco-friendly.

In 5-axis CNC machining, the material selection needs a proper combination of material properties and machinability along with cost variables. With our large database of materials and a cost-performance optimization, today, with the existing level of available technology, we can properly mix the need for 5-axis cost-performance with a goal of achieving a total savings of 15-25 percent.

How To Maximize The Benefits Of 5-Axis Machining Through Scientific Material Selection Guidelines?

In 5-axis CNC machining, it has been possible to describe that for optimal results, the systematic execution of the CNC material selection guide is to be followed. This also comprises the balancing act of satisfying the technology requirements with economical necessities for benefit maximization realization over the entire production chain.

Functional Requirements Analysis

The major requirement for any scientific evaluation is, of course, a complete understanding of functional factors applicable to a given component. These would typically encompass working loads, exposure to temperature, exposure to chemicals, life of design, and so on, and so forth. The quantification of each of these helps in making a material choice that can sustain accordingly without any unnecessary attributes adding more to its cost.

Machinability Index and Production Efficiency

In 5-axis machining, the challenge offered by each material is unique because the machining cycles, tool life, or resulting surfaces may vary greatly. In the CNC material selection guide, the machinability indexes recommended based on the cutting speed and tool life data are considered to provide the ability to estimate the cost of production precisely.

Cost Performance Optimization

The benefit maximization advantage has its importance only after the process of cost performance optimization has been completed. In reality, the truth lies in the context wherein the cost performance analysis pertaining to materials is but one part, whereas the whole cost analysis process involves processing time, cost of tools, secondary processing cost, as well as the scrap rate which might be involved.

Supply Chain and Availability Considerations

Material selection must account for lead times, availability, and supply chain stability. Standard materials with reliable supply chains often offer better pricing and shorter delivery times compared to exotic alloys. Our scientific evaluation process includes these factors to ensure project timelines and budgets remain manageable.

5-axis machining benefits can be maximized by only a properly implemented detailed CNC material selection guide. Indeed, scientific evaluation methods for material selection can go a long way in meeting functional needs while considering machinability, cost ratios, and supply chain considerations. This approach can ensure increased overall performance, minimized costs by as much as 15 to 25%, among others.

Figure 2: An in-depth overview of advanced 5-axis machining processes by LS Manufacturing

How To Optimize Cost In 5-Axis Machining Through Material Selection?

Cost-effective 5-axis machining will have some compromises regarding the expenditure of materials and production processes. By applying value engineering principles, it shall be possible to identify an optimum of diverse production factors for the manufacturer, which allows production of the component for a lowered total cost of production.

- Material Substitution Strategy: Cost-saving features will begin affecting the company in the following way in relation to making a substitution between the so-called higher alloys and lower ones based on standards: Using aluminum 6061 in place of aluminum 7075 will also result in saving 30-40% in terms of cost, which is applicable in non-critical areas.

- Machining and Efficiency of Production: The machining properties of materials can really matter for their importance in efficient 5-axis machining. Free machining steels & aluminum alloys are well suited for the rapid speed of machining as well as for the machining finish.

- Standardization and Supply Chain Optimization: The standardization of the materials used in the organization and which are easily available or at least should have a strong supply chain helps achieve the economies of scale purchasing discount, thereby helping in economic optimization and reducing material costs between 10-25% and also optimises project schedules.

- Design for Manufacturing Integration: Designing shall focus on geometry optimisation of parts to reduce material use and facilitate easy machining. Designing provides locations where material wastage can be brought down considerably. Less material wastage in the design will mean 5-axis machining usage at affordable costs.

Due to the profitable use of the cost-effective 5-axis machining process and the implementation of the value engineering principle, the realization of the cost of the economic optimization benefit can be realized through the use of the materials. The machinability of materials or the supply of materials stands amongst the biggest concerns in achieving economic optimization benefits up to 20-40%.

What Are The Key Factors To Consider When Selecting Materials For 5-Axis CNC Machining?

Understanding how to choose CNC machining material requires evaluating multiple key considerations that impact both manufacturing efficiency and final part performance. When selecting a component, there has to be a judicious combination of properties and cost associated with it, which would help in achieving the required outcome. This systematic approach involves analyzing various performance indicators to make informed decisions.

| Consideration Category | Key Factors | Impact on 5-Axis Machining |

| Mechanical Properties | Properties of strength, hardness, toughness | Measure of Effectiveness – It gives the standards of matter/Object. |

| Thermal Properties | Heat resistance, thermal expansion | Inter-relation of the latter to the former. |

| Chemical Resistance | Resists corrosion, resists chemicals | The application of chemical resistance has incredibly high value in contexts that define a hostile environment, as well as in health care. |

| Machinability | Tool life, speed, and surface finish | Affects processing costs and times. |

| Material Availability | Lead time, cost, reliability at the supply chain | Project planning, cost management |

The art of how to choose CNC machining material is a matter of evaluating the significance of aspects that occur within the mechanical, thermal, and chemical domains. Therefore, a deliberate evaluation of performance indicators analysis will allow selecting a material that optimizes functionality concerning cost efficiency regarding production efficiency during 5-axis CNC machining.

How Can High-Performance 5-Axis Machining Materials Meet Extreme Conditions?

The 5-axis machining performance materials should be able to bear such severe working conditions that have never been faced before by the materials used for machining in different technologies, namely, the fields of work, for example, power or medical industry, and so on. The materials used for machining are required to be able to function in highly heated or corrosive or loaded conditions. These machinable materials have their most specialized applications in the specific sectors where the component being substituted is not an option.

- Thermal Stability and Heat Resistance: Using composition of material Inconel or utilization of titanium alloys particularly, namely, would be for resisting higher temperatures above 1000° C. In respect to the matter regarding the design of turbine blades & exhaust portion, one significant matter to consider would be resistance to size despite existence for failure for normal materials.

- Corrosion and Chemical Resistance: For use in medical equipment, a chemical plant, or other harsh environment, usually corrosion-resistance against chlorine, hydrochloric acids, or other materials will be a necessity. Nevertheless, very few materials are used in a medical environment that have excellent corrosion-resisting properties, such as stainless steel, nickel, or paint.

- Mechanical Strength and Fatigue Resistance: High-performance machining materials offer superior strength-to-weight ratios and excellent fatigue properties, enabling lighter, more durable components. The characteristic of being light has therefore become a significant advantage of machining in aero & auto components.

- Wear Resistance and Surface Hardness: In cases involving friction/rubbing or impact force, the characteristics of hardness & anti-wear for materials can never be overlooked. This is used in machinery like cutting tools & bearings constituted of tool steels & carbides or surface-hardened alloys.

High-performance machining materials are made to function well in certain conditions where the use of other materials is not feasible. This is mainly because the specialized applications of high-performance CNC machining materials results in the best possible results concerning resistance to heating, resistance to corrosion, strength, and wear resistance. These properties enable the creation of products intended to operate in extreme conditions.

How To Optimize The Material Cost Ratio In A 5-Axis Machining Service Quote?

The material cost factors always account for 30-50% of the total 5-axis machining services quote. The region thus plays a very important part in material cost optimization. At LS Manufacturing, we always make use of different strategies that could help our clients save on costs significantly without compromising on the quality and performance of the parts.

| Optimization Strategy | Key Approach | Typical Savings |

| Bulk Material Purchasing | Leverage volume discounts | 10-25% |

| Material Substitution | Use cost-effective alternatives | 20-40% |

| Design Optimization | Reduce material waste | 15-30% |

| Process Efficiency | Optimize toolpaths | 15-60% faster |

Efficiency optimization of tool paths to have effective material cost optimization in the 5-axis machining services quote, there has to be a holistic approach. Be it bulk buying, material optimization, design optimization, or optimization through processes; there is ensured cost savings. The transparent pricing applied in our organization ensures that the client are informed about all the amounts incurred by them, which leads to no less than 20-40% cost-saving advantage.

Figure 3: Advanced composite components using multi-axis precision fabrication by LS Manufacturing

Expert Materials Suggest How To Improve The Success Rate Of 5-Axis Machining Projects?

Expert CNC material advice is crucial for achieving project success in complex 5-axis machining applications. By leveraging deep industry knowledge and technical expertise, professional consultation helps manufacturers avoid costly mistakes and optimize material selection from the earliest design stages.

- Early Design Phase Integration: Early integration with material professionals during the design phase enables proactive problem recognition for the manufacturing process. Among the advantages of early professional consultation, there are: optimization of the geometrical part with regard to material, optimization of the manufacturing process with regard to machining, and material choice.

- Performance Simulation and Testing: This gives experts the ability to simulate the performance of the material based on actual working conditions using advanced material performance simulation software. This expert CNC material advice includes finite element analysis, thermal modeling, and fatigue testing to validate material choices before production begins.

- Application-Specific Recommendations: Though professional consultationg is done based on industry specifications recommendations, the properties required for components in the aerospace industry may not be the same for the healthcare or vehicle industries. Professional consulting plays an important role in ensuring the materials meet all the specifications.

- Risk Mitigation and Cost Control: Expert CNC material advice helps identify and mitigate risks associated with material selection, such as supply chain disruptions, material defects, or unexpected machining challenges. This proactive approach significantly improves project success rates and reduces overall project costs.

Expert CNC 5-axis material advice is very essential for a project success of 5-axis machining. While integrating, predicting, advising, and countering this process, experts in 5-axis machining make sure that all materials are well aligned to all requirements to be very economical while being extremely effective in this production process.

How To Balance Processing Cost And Performance Through Material Selection?

The optimize machining cost and performance is a very complex issue. Thus, a systematic approach is required. By utilizing the benefits of advanced analysis techniques, it will be possible to find the balanced solution for which requirements can be effectively met.

- Multi-Objective Optimization Framework: Our systematic approach uses mathematical models to evaluate trade-offs between material cost, machining time, tool wear, and part performance. This data-driven methodology identifies the optimal material selection that delivers the best value proposition for each specific application.

- Lifecycle Cost Analysis: Optimize machining cost and performance, and the initial cost of the material and the machining cost cannot be considered. For a lifecycle cost analysis, it means that we ensure the best lifecycle cost is the result of the selected material.

- Application-Specific Performance Criteria: Every project has some performance requirements that vary in each project, which need to be measured in terms of cost as well. Our systematic approach involves factors like strength, corrosion resistance, temperature stability, and fatigue life to check that the balanced solution meets all performance requirements.

- Material Database and Experience Integration: By integrating our material database and project experience, we can maximize our expert CNC material advice for customers on how to optimize 5-axis machining cost and performance. The knowledge bases include material substitutions, machining conditions, and design alterations that led to successful results.

Achieving the optimal balanced solution requires a systematic approach that optimize machining cost and performance through multi-objective optimization, lifecycle cost analysis, and application-specific criteria. The best materials for a certain purpose may be singled out when considering the whole situation and drawing from expert knowledge because they offer the best performance, reliability, and value for money.

Figure 4: Professional reference for material choices in advanced multi-axis machining by LS Manufacturing

LS Manufacturing: Aerospace Engine Blade 5-Axis Machining Material Optimization Project

LS Manufacturing has completed a material optimization project for one of the aerospace engine manufacturers, focusing on turbine blades made from high-temperature alloys. This project really showed how materials could be optimized in concert with 5-axis machining to lower the final cost.

Client Challenge

An aerospace engine company was facing critical production issues regarding their turbine blade product. The product, in its present form, has good characteristics since it is a high-temperature alloy; it is, however, not machinable. Additionally, the single-part costs are 40% over budget and do not meet the requirements concerning their fatigue life.

LS Manufacturing Solution

Our engineers undertook a detailed review of the materials and a series of machining tests to determine the best choice. We offered a new generation of nickel superalloy with improved material properties at high temperatures. In addition, the materials had improved machinability. Our solution entailed optimized heat treatment techniques for improved material structure. We developed new techniques for 5-axis simultaneous machining. This increased tool life by three times. Furthermore, machining time was also reduced.

Results and Value

The project obtained excellent results in a number of performance measures. The fatigue life of the turbine blades was increased by 50%. The reduction in the costs for the single-piece process by 35% ensured the project was completed in the given budget with the highest level of quality. The project's cycle time was reduced by 30%, and this ensured a fast time-to-market for the engine project. The solution obtained complete certification in the field of quality from the customer and created a new standard for manufacturing the aerospace component with the highest level of quality and cost-effectiveness.

For instance, the aerospace engine blade project that they undertook is a testament to the capabilities of LS Manufacturing with their material and 5-axis machining. By leveraging their technological know-how, we managed to add value with regard to costs as well as time to complete, which has contributed to their success as a business partner with their aerospace customer.

Searching material on 5-Axis Machining? We have a instant quote ready for you.

Application Trends And Selection Strategies Of Advanced Materials In 5-Axis CNC Machining

In any case, however, the making use of such highly advanced materials in the processes involved in 5-axis CNC machining, like composite materials, function-gradient materials, or intelligent materials, has bright prospects for the future in areas involving aerospace, the medical industry, or the energy sector. Understanding application trends and developing effective selection strategy is crucial for manufacturers to stay competitive and capitalize on emerging opportunities.

Composite Materials Revolution

The usage of carbon fiber composites and others with a metal matrix is being done based on the strength-weight ratio properties and thermal stability. These advanced materials enable lighter, more durable components in aerospace and automotive applications, though they require specialized machining techniques and tooling to prevent delamination and ensure dimensional accuracy.

Functional Gradient Materials (FGMs)

FGMs are one of the main tendencies of considerable applications, where the material composition continuously changes from one point to another within the final product, featuring specific material properties depending on the region. Functional gradient materials are successfully applied to turbines, heat exchangers, and biomedical implants.

Additive Manufacturing Hybrids

Additive manufacturing processes can be combined with the 5-axis CNC machining method to produce complex geometries where the incorporated components are designed with additive manufacturing processes. This selection strategy combines the design freedom of 3D printing with the precision and surface finish of subtractive machining, opening new possibilities for customized components and reduced material waste.

Smart and Responsive Materials

Shape memory alloys, self-healing composite materials, and piezoelectric materials are part of a whole new class of advanced materials that can respond to environmental stimuli. Such materials have been used for the fabrication of intelligent structure, sensors, and actuators; properties unparalleled are offered by them. The same materials create some problems in their machining operations.

The 5-axis application trends in advanced materials are driving innovation across multiple industries. A comprehensive selection strategy must consider material properties, manufacturing requirements, and end-use performance to fully leverage these technological advancements. Being at the forefront of such innovations in the field of material science, while in possession of the needed machinists and facility to carry out such machining, puts the industry in a leading position to deliver.

FAQs

1. How does the difference in cost of machining different materials on 1.5 axes exist?

The differences of cost primarily exist in three areas, namely cost of materials, processing time, and cost of tool wear. We will be furnishing a cost analysis report as well.

2. How to check if a material meets a requirement for a specific working condition?

We issue a full suitability report after tests of material performance as well as a simulation of the working conditions.

3. Are professional services of material selection available for the small-batch producer?

We give our clients a free material selection consultation irrespective of the size of their order.

4. What special process preparations are required when machining special materials?

We also offer customized process solutions for special materials and a complete process, including tool selection and cutting parameters.

5. How to remedy a material selection error?

Services provided, which help in the loss minimization for our clients through material replacement and process engineering.

6. Do you provide material samples and test results?

We provide samples and the performance test result for easy verification and decision-making for our valued clients.

7. What are the benefits compared with conventional materials?

New materials possess a variety of key developments regarding performance, ease of handling, and lifespan, which will be further explained hereafter.

8. How to assess the impact of material changes on total project cost?

This is done to ensure viability by doing the life cycle cost analysis. We do full life cycle cost analysis.

Summary

Material selection using advanced methods and ample experience in 5-axis machining can now considerably enhance economic efficiency in machining. The company LS Manufacturing, owing to advanced technology integrated with a material system, stands out to be the best option for their clients to approach 5-axis machining.

Contact LS Manufacturing's experts now for free 5-axis machining material selection advice. We can provide you with the right material selection based on your application needs.

5-axis precision machining provides reliable assurance for critical testing components. Efficient and professional material solutions form the core support for your verification work.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.