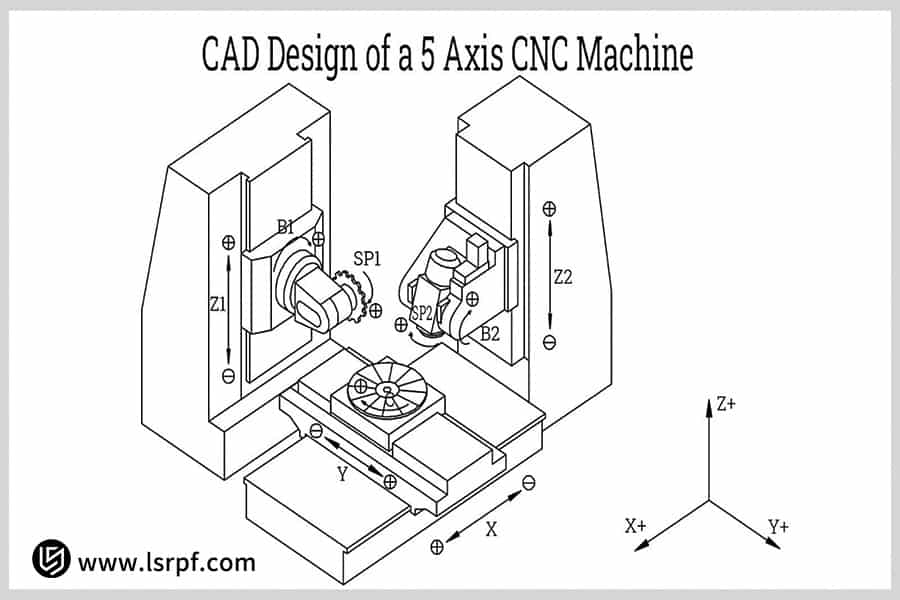

Traditional manufacturing methods usually fall into the trap of cumbersome procedures and inefficiencies when dealing with ultra-high precision, a part with complex curved surfaces, or an irregular shape. It is because of this challenge that five-axis CNC machining technology has been in development. Unlike the traditional three-axis devices, a five-axis machining center realizes coordinated movement of three linear axes X, Y, and Z, and two rotary axes that can machine five complicated surfaces of a workpiece in one setup.

LS Manufacturing has integrated advanced five-axis CNC equipment, professional process planning capability, and rich industry knowledge, dedicated to providing solutions in fields that have high demands on reliability and precision. Choosing LS Manufacturing means choosing a wiser and more reliable way to turn innovation into quality production; it helps drive the manufacturing standard of the industry to a new high together. To save you time, here’s a quick overview of the core conclusions.

Five-Axis CNC Machining Core Quick Reference Table

| Feature Category | Description |

| Basic definition | A three-axis system has two additional rotary axes that allow the tool to approach the workpiece from any spatial angle and perform its function to form a complex part with one-time clamping. |

| Main Benefits | It greatly reduces the number of clamping operations, improves precision and efficiency in machining by avoiding accumulation of errors. It is especially good for machining complicated curved surfaces and allows the use of shorter cutting tools in order to enhance rigidity within the system. |

| Common Types | Mainly divided into a rotary table type, which is applicable for small and medium-sized parts, an oscillating tool head type applicable for large parts, and a hybrid type which encompasses characteristics of both. |

| Typical Applications | Key technologies are utilized for the fabrication of high-precision parts, including engine blades in the aerospace industry, artificial joints in medical devices, and turbine impellers in the automotive sector. |

| Key Challenges | High equipment and software costs are involved; sophisticated CAM systems, as well as dedicated post-processors, are required for programming, and operator skill requirements are very high. |

Five-axis CNC machining technology can realize the optimal angle at which the tool approaches the workpiece through multi-degree-of-freedom spatial motion and is particularly suitable for high-precision complex part machining in aerospace, medicine, and other fields. In the application process, there are also significant challenges: large equipment investment, complex programming requirements, and specialized personnel training.

Five-axis machining represents a development direction that cannot be ignored for modern manufacturing, and the trend is toward high precision, high efficiency, and high flexibility. Mastering this five-axis machining technology has strategic significance for enhancing the core competitiveness of enterprises and adapting them to meet the needs of the high-end manufacturing market.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

This guide is, first of all, authoritative due to the strong corporate strength of LS Manufacturing. We not only have an industry-leading cluster of five-axis CNC machining centers but also an integrated solution system that ranges from digital design to precision inspection. That is to say, what we share are mature methodologies that have been validated by high-end equipment worth millions and directly translated into high-quality products.

The engineering team of LS Manufacturing has long been deeply involved in high-end fields like aerospace and precision medicine, where "zero tolerance" for defects is crucial. They have solved countless core problems related to complex curved surface processing, thin-walled part deformation, and special material machining. What you see here is the most universally applicable essence of strategies and key pitfall avoidance guidelines extracted from these successful cases.

It embodies lessons learned and wisdom acquired through real project work of engineers to provide you with a proven path, effectively avoiding common pitfalls, improving efficiency and accuracy in your technical decisions.

How To Achieve Perfect Forming Of Complex Parts By Five-Axis CNC Machining?

The reason why five-axis CNC machining can realize the perfect forming of complex parts lies in its breakthrough in motion freedom. In the traditional three linear axes, X, Y, and Z, two rotary axes are added, like A and C axes, which make the tool approach the workpiece surface from any angle. The five-axis linkage machining method promotes the processing concept from "workpiece fixed, tool moving" to a new level of "tool and workpiece coordinating in space". Its advantages are reflected in the following three aspects:

1. Overcoming machining dead angles:

For those areas that three-axis machine tools cannot effectively reach, such as deep cavities and concave structures with negative angles, five-axis machining can turn the workpiece angle by rotating the worktable or tool head, ensuring that the tool is always in the best position for processing.

2. Ensuring Surface Accuracy:

Five-axis CNC machining can ensure that during the processing of some complicated curved surface parts like impellers or human joints, the tool side edge is in ideal contact with the surface. This is unlike a three-axis machining technique that can only perform tip milling. Therefore, it ensures a better surface quality, higher geometric accuracy, and uniform cutting forces.

3. Efficiency Improvement of Machining:

Because it allows the use of shorter tools by adjusting the angles, this greatly improves the rigidity of the system and allows bigger cutting parameters to be used, along with reduced finishing allowances, thus drastically improving the efficiency of machining complex jobs.

LS Manufacturing is based on the most advanced five-axis equipment, relying on its mature process database to guarantee product quality stability. In a nutshell, five-axis CNC machining increases the degree of freedom to solve the forming difficulties of complex parts, which is essentially the foundation technology for high-end manufacturing.

Figure 1: 5-axis CNC design diagram by LS Manufacturing

What Are The Types Of Five-Axis CNC Machine Tools And The Applicable Scenarios?

Five-axis CNC machine tools are primarily classified by their implementation method for the two rotary axes. Further, the different structures determine their performance characteristics and different scenarios that are applicable to them. Next, I will give you a systematic view of structural characteristics, differences in accuracy, and typical application scenarios of three mainstream types.

| Type | Structural Characteristics | Accuracy & Performance | Typical Application Scenarios |

| Swivel Head Type | The rotary axis (A/B axis) is integrated into the spindle head, while the worktable remains fixed. With fast dynamic response, it is ideal for machining complex curved surfaces. | Owing to the swiveling of the spindle head, however, the rigidity is a little weaker when heavy-load cutting is applied, and accuracy maintenance should be the focus. | This type is suitable for the processing of big, heavyweight, boxlike pieces such as mold processing in the automobile industry, engine casings, etc., without the need to rotate workpieces. |

| Rotary Table Type | The rotary axis (A/C axis in general) is integrated under the worktable, and the spindle head just performs the linear movement. | With the best structural rigidity, it has strong load-bearing capability and the highest precision of the rotary axis. Therefore, it is suitable for high-precision parts processing. | It can meet the demand for small and medium-sized precision parts that need multi-directional processing, including impellers, medical implants, and precision structure parts. |

| Hybrid Type | A combination of the two types mentioned above, generally with one rotary axis in the head and one in the worktable. | It has the highest flexibility, which can find the best machining angle within the stroke range to balance accuracy and flexibility. | For product development and small-batch and multi-variety production, such as the parts in the aerospace industry with a complex and irregular shape. |

Based on the experience of serving many industries, LS Manufacturing follows a complementary strategy in the configuration of equipment. It equips the large structural components for the aerospace industry with swivel-head machine tools, while high-precision rotary table machine tools are preferred for precision parts in medical devices. Professional equipment selection advice helps us match up the most suitable processing solution to the special needs of customers and strike an optimal balance between the two most important elements: efficiency and quality of processing.

In short, the selection of the five-axis CNC machine tool is not static; it should be done with the core based on comprehensive judgment about the size, material, precision requirement, and production volume required for the target workpiece.

What Are The Disruptive Advantages Of Five-Axis Machining Compared To Three-Axis Machining?

Five-axis machining has fundamental advantages over traditional three-axis technology in the field. The basic breakthrough achieved by adding two rotary axes is the flexible control of tool posture, realizing a disruptive improvement in precision, efficiency, and cost. This essentially speaks to a leap in manufacturing philosophy that compares five-axis with three-axis CNC. Specific disruptive advantages in five-axis machining are reflected in the following:

1. Leap in Precision:

Five-axis machining completes multi-faceted machining of the workpiece in one setup. It essentially avoids the repetitive positioning error caused by multiple setups and ensures extremely high geometrical tolerances and dimensional consistency of workpieces that cannot be reached by three-axis technology.

2. Double Efficiency:

It saves auxiliary time used for several setups, allowing high-speed cutting with short tools, which has considerably reduced the manufacturing cycle. Meanwhile, it can directly machine conventionally difficult-to-reach surfaces like deep cavities and negative angles without designing and manufacturing dedicated tooling fixtures.

3. Cost Optimization:

While the investment in equipment remains high, five-axis technology reduces the overall manufacturing cost of each part due to reduced fixtures and lower scrap rates; this is advantageous for shortening delivery cycles, especially in cases of small-batch, highly complex products.

The LS Manufacturing practice proves that an aerospace structural component that originally needs three three-axis machine tools and several setups can be formed on a five-axis machine tool in one step.

The machining cycle is reduced by 40%, and the precision is comprehensively improved. The advantages of five-axis machining lie not only in leading technical parameters but also in enhanced manufacturing certainty, therefore bringing customers a real competitive advantage.

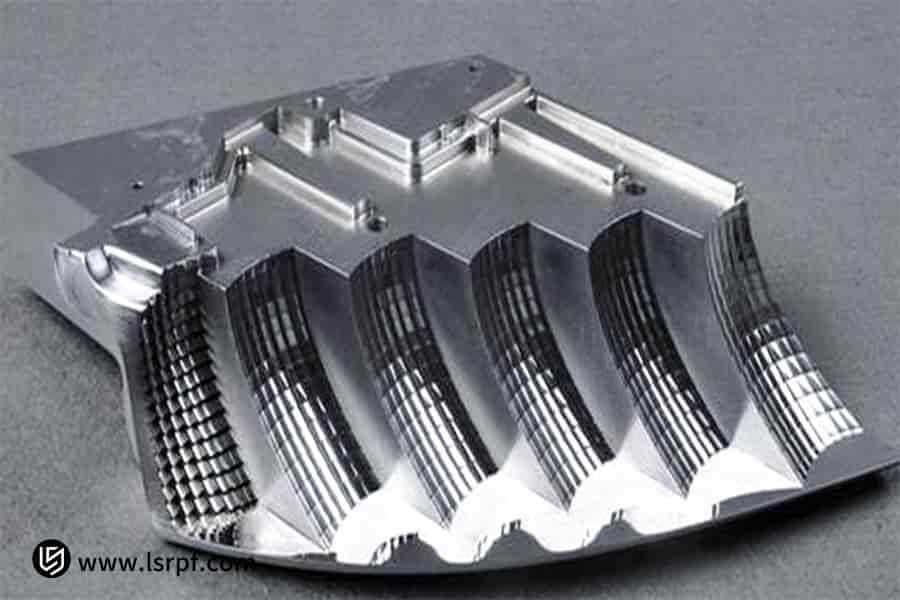

Figure 2: 5-Axis CNC Machining diagram by LS Manufacturing

How Does Five-Axis Machining Promote Part Accuracy Due To Single Clamping?

The central secret of the improvement in the precision of five-axis CNC machining lies in its revolutionary "single-clamping" technology. In traditional manufacturing, parts have to be transferred and re-fixed multiple times between different machine tools, with each clamping introducing new positioning errors. Five-axis technology integrates the machining process into a single machine and thus fundamentally eliminates the cause of error accumulation. In particular, its contribution is reflected in two aspects:

- Guaranteeing positional tolerances: When traditional methods are used for parts that contain complex angular features, such as a hole system with different directions in an engine block, several adjustments of the workpiece posture cannot guarantee the accuracy of the position among the holes. Five-axis machining adjusts the angle of the workpiece through the rotation axes, allowing the tool to complete the machining of all the features at one go, unifying all the references, and ensuring extremely high positional accuracy among the hole systems.

- Form and position tolerance preservation: Parts with complex curved surfaces, such as impellers, may be subjected to several clamping operations that could destroy the continuity of the entire contour, hence leading to deviations in form and position tolerances like coaxiality or profile. A single clamping operation can keep the datum unchanged throughout the whole process from blank to finished product; thus, it perfectly controls its macroscopic geometric accuracy.

LS Manufacturing translates this theoretical advantage into stable output with professional tooling design and process planning. We effectively control the cutting forces and thermal deformation with high-precision fixtures matched with optimized cutting parameters, ultimately achieving micron-level precision control for our customers.

To put it another way, single clamping is the foundation for the leap in quality and efficiency reached in five-axis CNC machining; it provides the ultimate solution for making high-precision and complex parts by eliminating datum transformation errors.

Which Industries Will Be In Urgent Need Of Five-Axis Machining Technology?

Five-axis machining technology has become a core technology in high-end manufacturing because it can better solve the problems of complex structures and the forming of high-precision and high-performance materials. Due to the advantages, five-axis machining of complex parts holds an irreplaceable position in many high-precision industries. In particular, its key industry applications are concentrated in:

1. Aerospace:

Parts in this field generally use integral structures with lightweight and difficult-to-machine materials. Five-axis technology can complete high-precision machining of multi-angle hole systems and complex curved surfaces in one clamping, ensuring the structural strength and aero performance of the parts. LS Manufacturing processed titanium alloy structural parts for an aerospace company, integrating traditional multi-process methods into a one-time molding process, where precision was fully met according to stringent standards.

2. Medical Devices:

Artificial joints and surgical robot components are examples of such products featuring complex shapes and highly demanding requirements for biocompatible surfaces. Five-axis machining can perfectly achieve bone-fitting curved surfaces and internal lightweight hole structures of implants, without the need for secondary surface treatment. Our cobalt-chromium alloy joint solution for a client achieved micron-level contour accuracy and a mirror finish.

3. High-Precision Automotive Manufacturing:

The five-axis technology can efficiently complete the machining of complex flow channels and cooling water circuits during the manufacturing of engine cylinder heads, turbocharger impellers, and high-performance molds, which greatly improve product performance and durability. In a word, such industries have one thing in common: the extremely high demands placed on the geometrical complexity, material properties, and reliability of parts.

Equipped with profound experience in these industry applications, LS Manufacturing has built up a rich process database and solutions, and thus can support customers all the way from design optimization to mass production, making it a reliable partner.

Figure 3: 5-Axis CNC Machining parts by LS Manufacturing

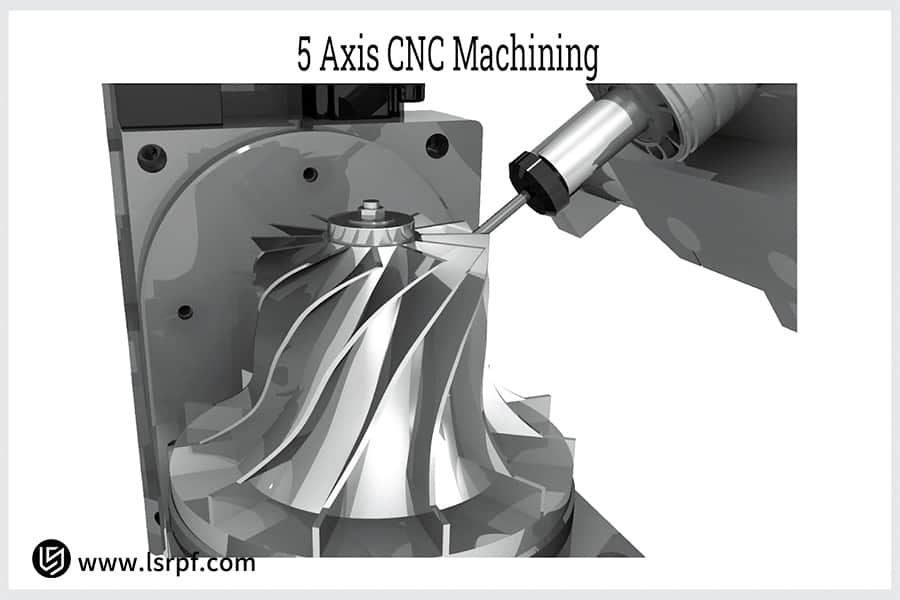

Case Study: How Does Five-Axis Machining Play A Key Role In Impeller Manufacturing?

Machining such complicated parts with high-end manufacturing and high aerodynamic requirements, such as impellers, has always posed a great challenge to traditional manufacturing methods in high-end manufacturing. The following case study shows how LS Manufacturing uses advanced five-axis machining technology to provide its customers with a superior solution.

1. Client Challenge:

During the machining of its core compressor impeller, aero-engine manufacturers used to use traditional three-axis machine tools. This meant numerous clamping and indexing operations had to be performed to process the base, back, and flow channel of the blade, which could lead to some serious deviations in the blade profile data, thus affecting the engine airflow efficiency. The qualified product rate was always around 70%, seriously affecting the new product certification and delivery.

2. LS Manufacturing Solution:

We developed a comprehensive process solution with a high-end five-axis machining center as the core. Professional CAM programming can achieve true five-axis simultaneous machining; the optimal tool side edge is in contact with complex curved surfaces. All the blades can be finished once without repetitive positioning errors. Meanwhile, it uses an online measuring system for real-time detection and on-machine compensation of key dimensions, ensuring the stability and reliability of machining.

3. Results and Value:

In the new solution, key impeller performance indicators were greatly improved: blade profile accuracy was always controlled within ±0.03mm, scrap rate reduced from 30% to below 3%, and the whole delivery cycle was shortened by 40%. This not only saved the customer much in costs but also helped their product pass stringent aerodynamic performance testing on the first attempt, setting a solid foundation for final model certification.

Five-axis simultaneous machining of very complicated parts, such as impellers, is more than a technology upgrade and the replacement of the traditional process to ensure the ultimate performance and reliability of such parts. LS Manufacturing, with profound process knowledge and rich experience in engineering, is committed to transforming equipment potential into customers' competitive edges.

Is The Investment In A Five-Axis CNC Machine Tool Worthwhile?

Whether or not to invest in a five-axis CNC machine tool, it should not be decided on by the higher initial purchase cost but should be analyzed based on its return on investment throughout its entire life cycle. Although five-axis CNC machine tools are much more expensive than traditional three-axis ones, the overall benefits provided often create value far beyond expectations. Specific analysis is as follows:

- Increased efficiency and reduced unit cost: five-axis machine tools complete five-sided machining in one setup, thus reducing several setup times, machine tool occupancy time, and tooling costs. For such complex parts, their machining efficiency can be increased several times, thereby quickly reducing their unit cost.

- Improvement in quality and reduction of quality loss: The extremely high machining precision and consistency can greatly reduce the rate of scrap and rework. For some high-value parts, saving even one scrap can save tens of thousands of yuan, which will be very important in areas such as aerospace and medical devices.

- Capability leap, winning high-end orders: Capabilities for five-axis machining mean that companies can take on orders with higher technical requirements and higher added value. It is not only a direct increase in revenue but also a strategic investment to enhance market competitiveness and build brand image.

LS Manufacturing thoroughly understands that customers want advanced manufacturing capabilities but are under constant cost pressures. Therefore, we can provide flexible cooperation models in addition to the high-level five-axis machining service. We guarantee that you will enjoy a first-class five-axis machining capability without having to bear the high cost of purchasing and maintaining the equipment. This capability can turn fixed asset investment into controllable production cost, greatly reduce the technical threshold, and help you quickly acquire market competitiveness.

Five-axis machine tools are a typical "enabling" investment, and the real return value of them lies in the overall manufacturing capability upgrade and market opportunities which they can bring to an enterprise.

Figure 4: Complex part machining with 5-axis by LS Manufacturing

How To Choose A Reliable 5-Axis Machining Service Provider?

Manufacturing such high-precision and complicated parts requires the proper selection of a 5-axis machining service provider to ensure project success. This should be in conjunction with a professional evaluation system, instead of a decision based on price comparison alone. The core evaluation dimensions are as follows:

1. Capabilities of Equipment and Technological Advancement:

Know the brand, model, number, and age of the service provider's 5-axis machine tools. Advanced equipment is the essential foundation to ensure machining accuracy and efficiency; it can handle most materials, even titanium alloys and high-temperature alloys. LS Manufacturing does not only have many high-end 5-axis machining centers but also continuously invests in upgrading its equipment to keep ahead in technology.

2. Experience with Technical Team and Process:

Great equipment needs even better engineers to work on it. A good team will be able to offer solid CAD/CAM programming, strategies for toolpath optimization, and experience in solving process issues like vibration and deformation. The engineering team herein boasts extensive experience in aerospace, medical devices, and many other areas, thereby supporting your project at every stage, from design optimization through mass production.

3. Quality System and Traceability:

Reliable service providers should establish a complete quality control system, such as ISO 9001/AS9100, and be equipped with precision testing equipment like CMMs and laser trackers to guarantee data traceability. LS Manufacturing has established strict quality check procedures right from the very start to the whole process, ensuring that each delivered product meets the highest standards.

4. Project experience and reputation within the industry:

Whether a service provider has successful case studies of similar projects directly shows that it is capable of solving practical problems. Understanding reputation and customer reviews within the industry is another important means to verify the reliability of the services of an organization. In fact, the five-axis machining service you choose will soon understand your needs, solve your technical problems predictably, and turn out to be a long-term partner.

The reason can be found in making a prudent choice of supplier. It ensures not only the smooth delivery of current projects but also a solid manufacturing foundation for future technology upgrades and product innovation.

How To Get Professional Five-Axis Machining Solutions?

Getting a really professional and reliable five-axis machining solution is not an inquiry process, but an engineering collaboration from beginning to end. It starts with in-depth technical consultation to make sure the final solution will not only meet the drawing requirements but also optimize the cost while improving reliability and manufacturability. Our recommended collaboration process is as follows:

- Matching Requirements and Technical Consultation: This is the most important first step. Please provide product drawings, technical specifications, and expected goals. Our engineering team deeply communicates with customers in order to understand the function of a product, application scenarios, and core challenges. At this stage, LS Manufacturing provides free expert technical consultation to explore probable optimization opportunities together.

- Process Analysis and DFM Report: According to the results of communication, our process team will perform a detailed manufacturing feasibility analysis and do the DFM, present a preliminary machining strategy including workpiece clamping schemes, toolpath planning, and cutting parameter selection, and offer you a professional process analysis report for review.

- Preliminary Quotation and Timeline Confirmation: After the consensus on the process solution, a detailed quotation with a clear delivery timeline will be provided. All costs are clearly broken down; thus, there are no hidden costs.

A perfect five-axis machining solution is based on good interaction and co-creation between the manufacturer and the customer in the very early stages. LS Manufacturing dedicates expertise and experience to translating your ideas into the most cost-effective and efficient manufacturing blueprints through professional technical consulting and DFM analysis.

We invite you to take the first step in our cooperation: just contact us and give us your initial concept, and we will develop the remaining technological aspects while working with you to bring your design into a high-quality, real-world product.

Figure 5: Simultaneous 5-axis machining by LS Manufacturing

FAQs

1. Which materials are ideal for 5-axis machining?

5-axis machining is commonly used in high-hardness, high-value, and difficult-to-machine material processing. Besides common aluminum alloy and stainless steel, LS Manufacturing's high-performance machine tools and comprehensive process database have also managed to process many other materials efficiently, which are commonly used in aero and medical devices, including titanium alloy and high-temperature nickel-based alloy, to effectively guarantee the machining efficiency and surface integrity of complex curved parts.

2. What is the minimum batch size for 5-axis machining?

LS Manufacturing has a very flexible service model and is not restricted by any batch size. 5-axis machining is especially suitable for small batches, multi-variety, and high complexity in manufacturing. Whether for single-piece prototype verification or small-to-medium-sized batch production, we provide customers with cost-effective solutions to achieve fast iteration and low-cost prototyping.

3. What kind of accuracy is possible with 5-axis machining?

With our strict quality control system, 5-axis machining can also achieve precisions up to ±0.025mm or more. We make sure that the geometric tolerances and dimensional stability of such complicated parts can be met by adopting one-time clamping technology, online measurement compensation, and a temperature-controlled workshop environment for assured product quality.

4. Does 5-axis machining support a variety of CAD/CAM file formats?

We support all mainstream 3D CAD file formats, including but not limited to STEP, IGES, X_T, and PARASOLID. Our seasoned CAM engineering team can process your design data efficiently and carry out precise toolpath programming in regard to the characteristics of 5-axis machining to ensure a perfect transformation of complex geometries.

5. What is the typical time from design to delivery in general?

From confirmation of the data to delivery of the first piece, it usually takes 2-4 weeks with LS Manufacturing for parts of ordinary complexity. Besides, there is also a fast-response channel that optimizes production scheduling according to project urgency and can fully satisfy customers' urgent needs in R&D or production, therefore shortening waiting times.

6. How is collision protection ensured during 5-axis machining?

We ensure safety by triple protection: it first executes full-path virtual simulation in the CAM stage, is equipped with an advanced anti-collision system in the machine tool, and finally performs strict no-load run verification before formal machining. This ensures that there is a greatly minimized chance of damage to either the equipment or workpieces.

7. Do you provide supporting services beyond 5-axis machining?

Yes, we offer a true one-stop service. Apart from core 5-axis machining, our services also cover precision CMM inspection and various surface finishing processes such as anodizing, sandblasting, and passivation to ensure that customers get complete finished parts and simplify the management of their supply chain.

8. How to get an accurate 5-axis machining quote?

Please provide us with a detailed 3D model, technical specifications (material, heat treatment, precision requirements, etc.), and target quantity. Our professional team will evaluate the process within 24 hours to provide you with a transparent and detailed quotation, including manufacturability analysis recommendations.

Summary

The five-axis CNC machining technology, with the unique merit of five-axis linkage, possesses prominent advantages in precision, efficiency, and flexibility for the manufacturing of complex curved surfaces, deep cavity structures, and other high-precision parts. It is not only an upgrading of equipment but a leap from "manufacturability" to "lean manufacturing."

More than just the best high-performance five-axis machine tools, LS Manufacturing offers in-depth technical support for everything from design optimization and process planning to precision manufacturing with the help of our seasoned engineering team. We promise that ceaseless technological innovation will transform your ideas into competitive and high-value-added quality products, hence creating core value for your projects.

The next innovative design deserves state-of-the-art manufacturing solutions. Please submit your design drawings or technical challenges and act immediately. Contact LS Manufacturing to get a free professional DFM manufacturability analysis and quote in detail. Allow our team of five-axis machining experts to help with a one-stop solution from technical consultation to mass production delivery. Let's work together, surmount the manufacturing challenges, and speed up launching into the market.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.