End the nightmare of "one cut and one waste"

Every manual lathe operator has had tense operating moments: holding their breath and staring at the dial,turningthe handwheel carefully, and worrying about cutting too much. Handwheel clearance, misreading of engraved lines, mental fatigue, and the slightest negligence may cause expensive workpieces to be scrapped. This is the lingering anxiety of lathe operators.

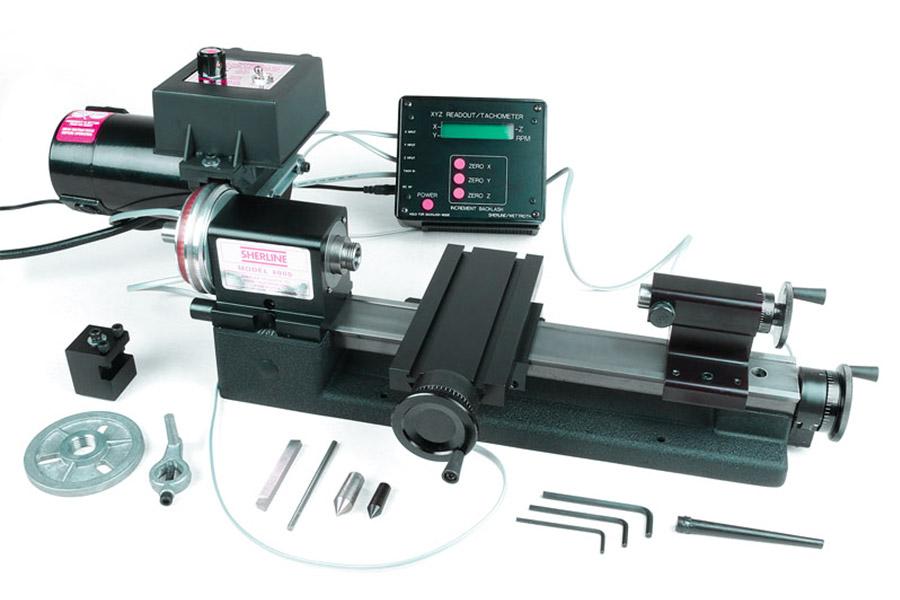

What if there is a technology that can clearly and intuitively display the exact position of the tool tip on the workpiece like looking at a digital watch? The answer is adigital readout device (DRO).

Simply put,DRO is the "smart eye" and "precision ruler" installed on the lathe. It measures the displacement of the lathe tool holder in real time through precision sensors and displays it on the screen in clear digital form (accurate to micron level).

The core value of DRO is to turn the originally "invisible" subtle displacement and error in lathe operation into "visible" digital information, ending the uncertainty of relying on naked eye estimation, fighting handwheel clearance, and repeated manual measurement, and bringingprecision machininginto the digital age. This is not only a tool upgrade, but also a revolution in operating concepts.

To save you time, here is a quick overview of the core conclusions about DRO on metal lathes.

DRO Core Answer Summary on Metal Lathe

| Comparison items | Traditional handwheel dial (Manual Dials) "Counting circles", "feeling by feeling" | Digital readout system (DRO) "Digital ruler", "GPS of lathe" |

|---|---|---|

| Positioning principle | Mechanical counting: Turn the handwheel number of times x theoretical feed per circle | Electronic sensor measures the actual displacement of the tool holder in real time |

| Core pain point | Tooth clearance/backlash (Backlash) Errors cannot be avoided: The gap needs to be "eaten" when moving in the reverse direction, which is very easy to cut too much | Completely eliminate the influence of tooth clearance error: It shows the actual position of the tool holder, which has nothing to do with the idling of the handwheel |

| Accuracy | Depends on the operator's experience, vision, and the wear and tear of the equipment, and errors are easy to accumulate | High and stable: usually up to 0.005mm - 0.01mm (0.0002" - 0.0004") |

| Efficiency | Slow: Frequent shutdown, tool retraction, measurement, trial cutting, and repeated corrections are required | Fast: Directly move the tool holder to the target size, greatly reducing the number of measurements, and basically no trial cutting is required |

| Accumulated error | Very easy to occur (multi-axis linkage, multiple reversing) | Automatically calculate and display the absolute position to eliminate cumulative errors |

| Complex operations | Difficult (such as tapers, arcs, coordinate drilling), requiring superb skills and calculations | Simple: built-in calculation function, easy to handle complex contours and coordinate positioning |

DRO is not only a tool upgrade, but also a revolution in operating concepts. It bringsprecision turningfrom a field that is highly dependent on "feel" and "luck" to a digital era that is quantifiable, repeatable, safer and more efficient. This guide will clearly tell you what DRO means, reveal how it works, and use a real case to prove why, in many cases, you really need toinstall a DRO on your lathe.

Here’s What You’ll Learn

- DRO Secrets:How does the lathe's "GPS" return processing errors to zero?

- Three precision components work together:DRO's "eyes", "nerves" and "brain"

- Operational mechanism to solve the three core pain points of lathes:Why is DRO a must-have artifact?

- Overcoming the "orphan" rotor shaft repair:How doesDRO achieve zero errorin single-piece reverse engineering?

- Authoritative answers to 4 high-frequency questions:Practical FAQ about lathe DRO

- Ultimate conclusion:Why is DRO the most worthwhile investment for manual lathes?

Why trust this guide? Insights from LS CNC and precision machining experts

Hi, I’m Gloria, and I’ve been working in precision machining at LS for more than 15 years. Here, we’re not talking about “roughly” or “almost” work.Our daily work is a “close fight” with tolerances of one thousandth of an inch (0.025mm) or even smaller.What is the diameter of a hair? About 0.003 inches (0.076mm). The precision we deal with is often much more demanding than this. A tiny deviation can cause expensive parts to be scrapped, precision equipment to stop, and even affect the success or failure of the entire project.

The core of our LS is indeedCNC machining, and those highly automated precision machine tools are our main force. But many of our engineers and technicians have come step by step from the era of manually shaking the wheel and looking at the dial.We have a deep understanding of how precision machining technology has evolved step by step to today. This understanding makes us understand that technology is not an either-or elimination, but a layering and fusion. And DRO (digital readout device), in my opinion,is a crucial bridge in this evolution process.

This bridge brings the soul of CNC - "precise, real-time position feedback" - back to the manual machine tools we are familiar with.Why areCNC machine toolsso precise? One of the core reasons is that they know the exact position of their tools at any time. DRO gives manual equipment the same "eyes" and "perception ability". Imagine turning an axis on a manual lathe. In the past, you had to stop constantly and measure repeatedly with calipers and micrometers, which was not only inefficient but also prone to human errors. With DRO, you only need to look at the clear digital display to know in real time where the tool has gone and how far it is from the target size.This is not only convenient, but also a revolution that drives "guessing" and "estimation" out of precision machining.

Trust this guide because it comes from our practical experience of fighting "between millimeters" every day, from our deep insight into the evolution ofprecision machining technology, and from real stories of us relying on DRO to overcome dangers and achieve perfect precision countless times.

What is DRO on a metal lathe?

"DRO is a very intuitive abbreviation, which stands for Digital Readout." It is an indispensable key equipment in modernprecision machining workshops, especially lathes, milling machines, and grinders.

1. Core Concepts

(1) It is not a controller:

DRO does not automatically move the tool holder, worktable or spindle of the lathe.

It is essentially anextremely accurate measurement and display system. Its core task is to tell the operator the current precise position of the machine tool moving parts (such as the tool holder) relative to thereference point.

(2) It is the "GPS" of the lathe:

- Traditional lathe operation without DRO:Imagine driving in a city without maps and GPS. You can only estimate where you are by counting how many turns you have made (how many grids the handwheel dial has turned) and how long you have walked (feeling). This is very experience-dependent, error-prone, and it is impossible to know the exact coordinates in real time. When operating a lathe, you need to constantly check the scale ring on the handwheel (which may have a vernier scale) and manually count the number of turns and grids to estimate the position of the tool tip. This process is cumbersome and prone to accumulated errors.

- Operating a lathe equipped with DRO:It is like having a high-precision GPS navigator installed on your car. It tells you inreal time, continuously and accurately: "Your tool tip is now atX axis: +125.358 mm, Z axis: -50.127 mm". The operator no longer needs to count and do mental calculations, and can see the current position at a glance, greatly simplifying the positioning and dimensional control process.

2. Working principle:

The core of the DRO system consists of two parts:

(1) High-precision sensors (grating scales or magnetic scales)

These scale-shaped sensors are directly and firmly mounted on the key moving parts of the lathe. The most common ones are:

Z axis (saddle/longitudinal slide):Measures the movement of the tool holder along the spindle axis (length direction).

X-axis (cross slide/cross slide):Measures the movement of the tool holder perpendicular to the spindle axis (diameter/radial direction).

(For morecomplex machine tools, there may also be a Y-axis, etc.)

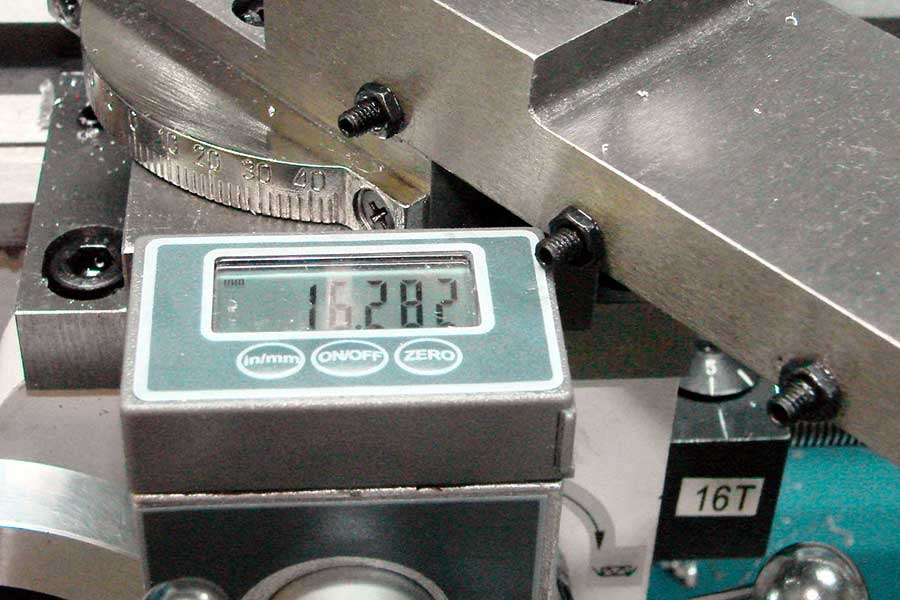

(2) Display unit (reading head/display):

The reading head mounted on the moving element (e.g., slide) senses the corresponding fixed sensor (magnetic scale/grating scale) in real time.

The reading head detects the small change of the scale or magnetic poles on the sensor and converts the physical displacement into an electrical signal.

These are transmitted to the display unit (which can be a box with buttons, mounted in a position convenient for the operator to view).

The processor within the display unit accurately computes the displacement and displays the present position coordinates (the usual X and Z values) in real time on the display screen in the form of distinct, readable digital numbers.

Core value:This process completely removes the traditional handwheel dial and the operator's manual counting/estimating, and provides direct high-accuracy and continuous position readout.

DRO does not replace the operator to automatically control the motion of the machine tool, but gives the operator a pair of "accurate electronic eyes" and a "real-time position dashboard". It reads the high-precision displacement sensor signal attached to the machine tool body directly, and indicates the physical location of the lathe tool holder in real time and with high precision. It basically solves the agony of traditional dials-and-counting-based lathe positioning. It is a groundbreaking software to boost processing efficiency, precision and simplicity of operation.

The three key components of the DRO system: eyes, nerves, and brain

Imagine installing a "smart assistant" on an old-fashioned lathe, so it can tell you the exact position of the tip of the tool in real time and help you with complex calculations. This is adigital display unit (DRO). It is founded on a human-type body system with three key units: "eyes", "nerves" and "brain", functioning together:

1. Measuring ruler - the system's "eyes" (see position)

What is it?It is the "eyes" of the system, i.e., to feel the movement of all the machine tool axes accurately. They are generally mounted in:

Z axis:Along the direction of the bed (from the spindle box to the tailstock).

X axis:Along the direction of the cross slide (control the depth of the cut).

How is it done?

The ruler itself is highly accurate, inscribed with ultra-fine grating (or magnetic poles) that cannot be seen by the naked eye.

Types of general application:

Glass grating ruler:Like an ultra-precision glass rule, it utilizes the variations of light and dark introduced by the progression of light through the inscribed lines to "see" the position, to the utmost degree of accuracy, but relatively sensitive to the environment (oil spots, vibration).

Magnetic ruler:Just like a special "magnetic strip," it uses a magnetic head to sense the change of magnetic field to show the reading. It is resistant to heavy oil and dust, particularly well-suited for workshop environments, and has high accuracy. It is now the mainstream.

Simply put:Without this "pair of eyes," the system is "blind" and has no idea how far the tool holder has traveled.

2. Reading head - the "nerve" of the system (transmitting signals)

What is it doing?This component is like a "nerve ending" and "nerve fiber". It rides along with the tool holder (or slide) and skates over the "eye" (measurement ruler).

How is it done?While the tool holder is moving, the reading head "scans" or "feels" the precision scale on the measuring ruler's movement in real time. It has a very sensitive sensing device (optical or magnetic) inside, which is able to "click" and "count" the quantity of minimum scales traversed. It then transmits the change of position electrical signal directly to the display through the cable.

Short version:

It's an "intelligence agent" which properly and in real time sends the position information visible to the "eye" to the "brain". Without it, the signal is broken.

3. Display - system "brain" (computing and displaying)

What does it do?

This is the "intelligent brain" and "command center" with which operators interact day-to-day. It performs the following:

- Translation display:Accept the original electrical signal of the "nerve" (reading head), compute the actual position value at once, and display it in concise fashion on the screen. (Generally, thevalues of X-axis and Z-axis coordinates.)

Core control:Set the origin point, switch the coordinate mode, etc. through its buttons. - Smart calculation (such a useful feature!):It is the "spirit" of new DRO! It doesn't merely display numbers, but has a powerful calculator built within, and can help you calculate many pesky things which you had to look up the manual and tap the calculator before:

- One-click centering:Find the center point of the circular bar? Tap on it and the position will be calculated automatically, saving you time and effort!

- Metric/imperial unit conversion:Replace the unit of drawing. Click only and the number will be replaced automatically, no calculation error to fear.

- Absolute/incremental coordinate switching:See the absolute point or the displacement relative to a given point? Switch at will, more flexible handling.

- Bolt hole indexing calculation:Want todrill a circle of holesin the flange? Enter the number of holes and diameter, and it will automatically tell you the angle or location of each hole, saving you the inconvenience of the indexing head.

- Taper calculation assistance:Turning tapers? Enter the size and length of the big and small heads, and it will help you calculate the required angle or coordinate difference, which makes it a lot easier to adjust the tool holder.

Briefly:It transforms dull digital coordinates into user-friendly and intuitive information, and gives a "smart assistant" to greatly improve processing efficiency, accuracy and convenience. Operator's eyes and hands are free and they can focus more on operation per se.

Summary:

- Measurement ruler (eyes):Feel movement accurately.

- Reading head (nerve):Read and pass position signals in real time.

- Display (brain):Calculate and display coordinates, and provide powerful intelligent assistance functions.

These three elements work in concert together, like installing a "high-precision GPS + smart calculator" on the machine tool, making it easier and more accurate for experienced operators to work with, and also allowing beginners to begin working quicker. It is an excellent tool for improving the efficiency andaccuracy of lathe processing!

Why do we need DRO? How can it solve the fundamental pain points in lathe machining?

Thetraditional manual latheswith screw dial setting are plagued with pain points affecting process accuracy and efficiency. Digital readout display system (DRO) is designed to solve these problems and improve the operating experience.

Pain point 1: Eliminate "reverse clearance" error

- Cause of the problem:There is a "reverse clearance" between the nut and the screw of themanual lathe. On reversing, the screw needs to be immovable to eliminate the clearance and hence there is a difference between the dial reading and the actual tool holder travel and can quite easily result in newbiew size errors.

- DRO solution:DRO directly reads the tool holder's actual position with a high-precision linear grating ruler or magnetic grating ruler and displays it in real time. No measurement is dependent on the turning of the screw. The screen displays the true absolute position coordinates of the tool tip at all times, completely eliminating the positioning error due to the reverse clearance.

Pain point 2: "relative movement" to "absolute positioning"

- Cause of the problem:Conventional mechanical operation involves repetitive "relative movement" calculations. In the process of handling intricate workpieces in several processes, repetitive cumulative calculations are prone to produce inaccuracies and cause dimensional errors or rejections of workpieces.

- DRO solution:DRO supports the "absolute coordinate system" principle and can establish the "workpiece zero point". The absolute coordinate value of the tool tip from the zero point is displayed on the screen. The operator positions the tool tip to the target coordinate directly without cumulative calculation, with improved positioning reliability and ease of use.

Pain point 3: Improving processing efficiency and operator confidence

- Effects:The above pain points are resolved through a jump in processing effectiveness and increased operator confidence. Reduce the measurement frequency, no longer frequently interrupt to measure, calculate and correct; the operator can confidently feed, push the tool holder directly into a position close to the target size and take a "one-step" semi-finishing/roughing strategy to reduce the process cycle, shorten the finishing time and tool life; precise control of the tool tip position and removal of backlash errors minimize process uncertainty, smooth out the processing process and make it more controllable, and reduce psychological pressure.

If you find these problems troubling, or planning to upgrade your workshop processing capability, welcome to learn, I would be privileged to bring you there to experience the powerfulLS DRO system!

Hands-on case study: Re-winding the "orphan" rotor shaft of an out-of-date pump

When theoretic advantages are subjected to engagement with the extreme pressure of "no failure, only success", its value is actually blinding. It is a real maintenance situation that we have seen with our own eyes and was performed exactly in despairing conditions.

Customer Challenge:Repairing an essential "orphan", life-and-death sprint without drawings and spares

Project Background:One of the most critical imported pumps, the life of a chemical plant, suddenly failed. The cause was the severe degradation of its critical stepped rotor shaft. The pump is no longer produced after decades, its original drawings are lost, and spare parts are nowhere to be found. The entire production line ground to a halt, and every day of down-time spelled a staggering and enormous economic loss.

Difficulty in critical situations:The customer's only option for escape from the situation was to copy a new rotor shaft precisely. The structure of this shaft is complicated and sophisticated: five various stages of diameters, a high-accuracy bearing seat, and an extended precision taper (taper). Measuring is extremely awkward and complicated in the use of old-fashioned manual lathes. Any slight error in the step size (even aggregating to 0.01mm) leads to rejection of the expensive alloy steel bar on the spot, and pressure of cost and time increases manifold. It is not so much a technical problem, but also a high-stakes game of racing against time and cost.

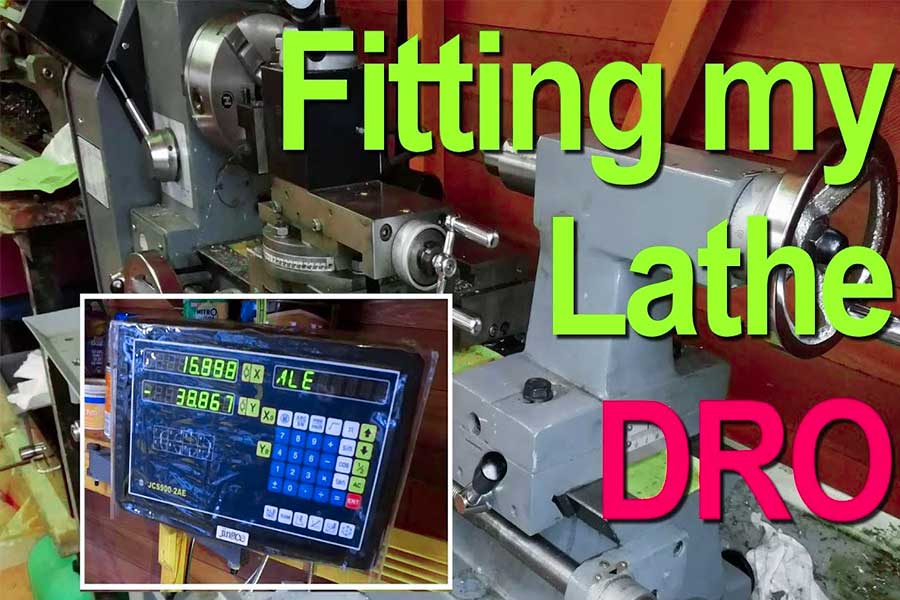

LS Breakthrough: DRO + hand lathe, reverse attack low-cost and high-precision

Key insight:Difficulty of this battle is not the lack of cuttability, but ensuring the accuracy of the dimension chain and the risk of manual calculation and implementation of complex tapers.Employing expensive CNC straightaway is accurate, but for a single repair, its cost and lead time (programming, tooling) are many times more than the customer's tolerance level.

Innovative solution:We abandoned the inertial "either purely manual or CNC" mentality and chose the third efficient means: installing a high-performance digital readout display system (DRO) on an accurate manual lathe. This is similar to providing the skilled "veteran" with accurate "digital eyes" and "smart brain".

Precision reverse engineering:

- Gently clamp the old worn shaft onto the lathe.

- Use the dial indicator with the coordinate capture feature of the DRO to accurately measure and record each of the main positions on the worn shaft: starting position (Z), finish position (Z) coordinates and diameter (X) of every step. The DRO displays the absolute coordinate value directly, and the information is objective and dependable.

Absolute coordinate processing, error zeroing

- When machining a new shaft, accurately position the Z axis zero point on the bar end face.

- The operator is no longer relying on the dial and estimation, but is shifting the tool holder wholly directly to the target (X, Z) position of each turn step based purely on the absolute coordinate value displayed by the DRO. The risk of cumulative errors difficult to avoid in traditional methods is completely removed.

DRO intelligent taper attack

For the most difficult extra-long tapers, the built-in taper calculation function of the DRO becomes the key to success.

Simply input the coordinates and diameter values of the taper initiation point (X1, Z1) and termination point (X2, Z2), and DRO will instantly and automatically determine the precise angle in which the tool holder needs to be turned.

The operator can modify the tool holder precisely according to this angle in order to achieve smooth andprecise taper turningand substantially reduce the likelihood of errors in calculation manually and unstable operation.

Results and Value: One Time Success, Turning the Tide

Ideal Delivery: The newly manufactured rotor shaft passed the demanding three-coordinate measuring machine (CMM) full-size test on the first run. Tolerances of all the key dimensions and the original design (after wear rehabilitation) are maintained strictly within 0.015mm, perfect in accordance with the equipment requirements.

Quantified Benefits:

Zero Scrap: One-run successful processing, no utilization ofprecious alloy steel bars, and maximum utilization of processing time.

Lightning Delivery:2 days from acquisition to delivery! It is extremely, extremely quick compared to looking for a secondary pump source orCNC customizing, which can take weeks or even months.

Stop loss and establish benefits:The customer's production line could start producing again at a super high pace, basically avoiding potential losses of millions of yuan from repeated production halts, which is priceless.

Key Takeaway:

This case deeply comprehends the worth of "applying the right technology in the right situation". Faced with high-value, single-piece/small-lot, reverse engineering or non-drawing repair projects, DRO technology is far from a "digital dial". It essentially converts the abilities of manual lathes:

From "experience-based" to "data-based":Operators are freed from excessive dependence on "feel" and complex mental arithmetic, and decisions and actions are governed by precise digital coordinates.

Approaching near-high accuracy at low cost:Its processing accuracy and credibility are significantly improved with the help of absolute coordinate positioning and intelligent auxiliary calculations (such as taper), to infinitely get close to theCNC level,and the cost is a fraction of the latter.

Empowering legacy equipment:It revives the old widespread manual lathes which experienced personnel are accustomed to and turns into an elastic, low-cost and trustworthy way of addressing high-end single-piece precision tasks. In today's age wherein flexibility of manufacturing and cost saving and efficiency maximization are the priority, this theory of "low-cost intelligent transformation" is of tremendous practical significance and promotional significance.

FAQ - Answers to your questions about lathe processing

1. Why is DRO used?

DRO is short for Digital Read Out. It is mainly used to show the tool or workpiece position coordinates in real-time accurately in the process of lathe processing. It replaces the traditional manual crank scale with a digital one to make it convenient for operators to reduce human errors, improve processing accuracy and efficiency, and be particularly suitable for complicated contour or high-precision part processing.

2. What does it mean to taper on a metal lathe?

Definition: Tapering on a metal lathe is the process of cutting a conical surface (e.g., taper shank or taper hole) by changing the tailstock offset of the lathe, using a taper attachment or a CNC program, so that the tool feeds at a specified angle when rotating the workpiece. It is widely used in the manufacturing of products with matching or the transmission of torque.

3. Do I buy a lathe or a milling machine first?

Choosing between buying a lathe and a milling machine first depends on your particular needs, budget, and skill level: a lathe is best for machining rotationally symmetrical components (shafts and sleeves). It is easy to handle and cheap, so it is ideal for beginners or those who work primarily with cylindrical parts. A milling machine is a good choice for cutting planes, slots, or complex three-dimensional curves. It is feature-rich but expensive. If you prefer versatility or have several parts to machine, you can choose a milling machine as your first option. It is smart to make a decision after thoughtfully examining common project types and long-term goals.

Summary

DRO is a brilliant innovation in the history of manual lathes. Although not revolutionizing the cutting nature of lathes, DRO redefines the means of interaction between machines and operators with precision in digital form, so that success or failure in processing is no longer "a question of experience and luck", but of "data and certainty".

DRO-equipped manual lathes are far superior in one-off and small-batch production. But when the project requires higher demands on efficiency, repeatability and complex contour machining, theCNC machining services are the best bet. In LS, we deeply integrate the idea of precision of DRO into everyhigh-level automatic CNC machine. If you are eager to obtain flawless parts and wish to get the processed product urgently and at an affordable price, please upload your design files now to receive an instantCNC machining quote!

📞 Phone: +86 185 6675 9667

📧 Email: info@longshengmfg.com

🌐 Website:https://lsrpf.com/

Disclaimer

The content of this page is for informational purposes only.LS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the LS network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

LS Team

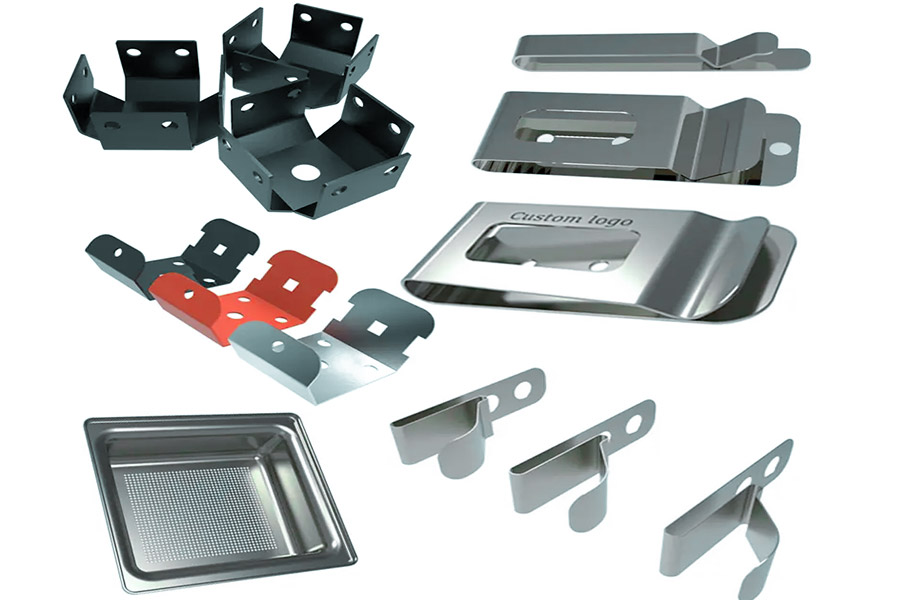

LS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseLS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:www.lsrpf.com