DFM for CNC machining could be viewed as an approach that helps bridge the gap pertaining to the designing as well as the manufacturing aspect. This is because the manufacturers usually face issues like high machining complexity, cost overrun, and project delays, which could be considered as the major disadvantage for projects and, consequently, products in the market due to competition.

The challenge arises because production teams are not usually integrated into the designing process because of the absence of manufacturing knowledge in designing, and production teams usually join late when manufacturing optimization ideas cannot be incorporated before the flaws are identified in prototypes.

DFM For CNC Machining Quick Reference

| Category | Key Principles | Common Pitfalls to Avoid | Design Optimization Tips |

| Geometry & Features | Simplify 3D geometry; Design for standard tools; Do not have very vertical or thin facial features. | Highly slender walls to extreme degree; Small deep holes; Internal inaccessible voids. | Add Fillets at Internal Corners; All hole sizes must be standardized. Blind Hole Depth/Width Ratio should be controlled. |

| Tolerances & Finishes | Reasonable CNC machining tolerance levels; Call finish based on functional data. | Over tolerance (usually ±0.025mm); Irrelevant surface finish (e.g., Ra=0.4µm). | Default tolerance level usage, where possible; Critical surface selection only; Post-processing, whenever possible. |

| Material Selection | Based on machinability. | Very hard materials or gummy materials; Not taking into consideration the stock material availability. | Use 6061 or 304 stainless steel alloys. |

| Setup & Fixturing | Design for stable fixturing; Allow for tool access. | Parts that cannot be clamped securely; Features requiring many setups. | Include parallel clamping surfaces; Add tool access holes/channels; Minimize required orientations. |

DFM for CNC machining means and teaches this proactive approach-a team approach from the start. manufacturability needs to be focused on day one of the design phase by geometric simplification wherever and wherever possible,tolerancing, and design for good locations, and then the rewards can be significant regarding cost, time, and defective units. The goal of DFM is the development of probable problems in manufacturing into quality product.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

The literature is full of information on DFM, but ours is different in that we are speaking from the production floor. As a resource, we are the ones who are actually practicing what this guide is saying to do. We are acting on the level where the design meets the hard facts of production, the hard facts of the difficult alloys involved, the microns involved daily, rather than the theories involved. The lessons learned have been given the capability to make recommendations in this resource because of this process of manufacturing.

The success factor for us is our record for over 50,000 manufactured 5-axis machined parts, and every year we process a tremendous volume of orders, large and small, around the world, and we get sufficient experience with difficult material processes for alloys such as Inconel 718, and high speed milling for detailed features, and after that, we refine our tech methodologies according to the standards set by Metal Powder Industry Federation (MPIF), and we also leverage the usage of the accessible tech knowledge base such as Wikipedia.

They share principles of DFM hard-earned and proved in their most critical efforts in Aerospace, Medical, and Semiconductors: Advice that has been gained from experience that will save you money by avoiding expensive mistakes: know how that has been proved not in a lab but by precision, efficiency, and effective production of critical parts.

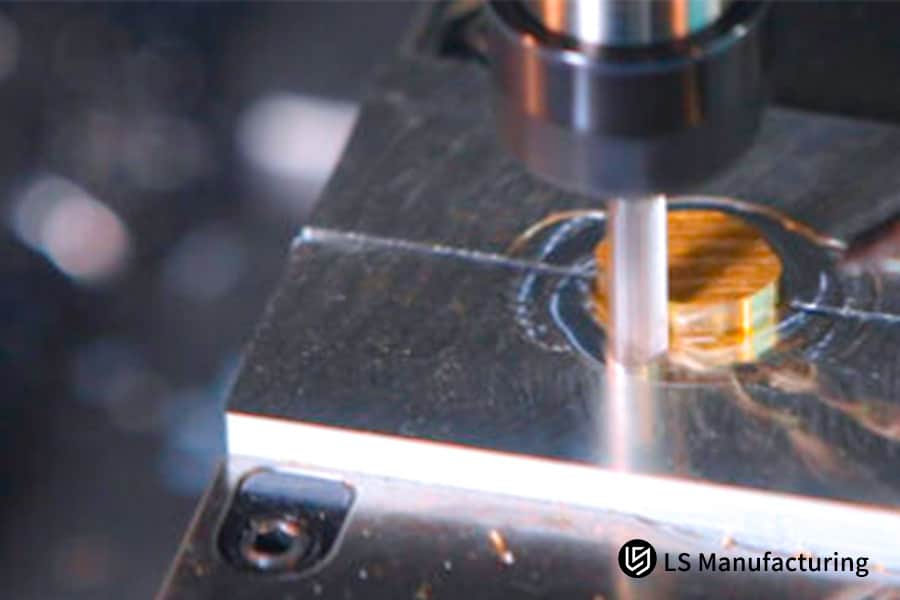

Figure 1: CNC machining of precision pockets and holes example by LS Manufacturing

Why Is DFM The Most Effective Way To Reduce CNC Machining Costs?

DFM, or Design for Manufacturability, is the most effective tool for achieving DFM cost savings and overall design and manufacturing cost control. It works by proactively integrating production knowledge into the design phase, targeting the root cause of expenses before any metal is cut. This strategic approach for DFM for CNC machining prevents costly problems that are difficult to fix later, making it a cornerstone of CNC machining optimization.

- Cuts Machining Time and Complexity: A crucial factor in the CNC machining optimization is the simplification of the part shape. The techniques described above aim at eliminating unnecessary complex surfaces in the part. Therefore, this will immediately reduce the major factor in the cost considered in the optimization problem.

- Enables Informed Selection of Materials and Processes: Cost-effective design and manufacturing cost control enable the informed selection of the appropriate material type. DFM analysis takes into consideration the availability and accessibility of stock sizes, as well as the machining properties of the chosen alloys. Moreover, DFM analysis considers the potential availability of more optimal production facilities for more than one process, with the aim of choosing the best process at the design level.

- Standardizes Components and Tools: Application of DFM for CNC machining process helps in the standardization of components and tools. Companies are able to standardize the end mill, drill bit, and type of threading. This reduces the cost involved in making specialized tools. Additionally, the standardization process of the same features in different parts helps in mass production.

In summary, DFM cost savings are profound because they are preventative, not corrective. By embedding principles of CNC machining optimization into the design itself, DFM for CNC machining smoothes out each step in production. This will result in superior design and manufacturing cost control, which decreases cycle times, reduces waste, and enables smarter material use-hence, a more competitive, manufacturable, and profitable product.

How To Perform Manufacturability Design Analysis For CNC Parts?

A calculated Design for manufacturability analysis is necessary in catering to the functionality of a product or idea designed by computer-aided designs to become cost-effective and dependable products or systems. In essence, this is all about the multi-dimensional analysis of the CNC part design evaluation by the DFM perspective. This is meant to proactively identify and resolve potential production issues well before machining actually takes place. This process relies on a structured review of key DFM check points to ensure the part is optimized for efficient and accurate manufacturing. The following table has been provided for a structured approach to this evaluation and also works as a practical CNC machining design guide:

| Dimension of Analysis | Key Considerations (DFM Check Points) |

| Geometry & Features | No sharp corners internally, radii must be used. Design Requirements; Wall thickness uniform and adequate; Standard hole sizes wherever possible; Design for tool access and tool clearance. |

| Tolerances & Finishes | Only use realistic values of tolerance; Do not specify surface finish to a greater degree than necessary; Clearly state critical measurements. |

| Material & Stock | To be selected could be done by capability of being machinable; Keep the standard size of stock material in consideration. Approximate cost of newly required materials. |

| Setup & Fixturing | Provides a solid base to clamp onto; Eliminate the number of set-ups; Ensure the features are accessible given chosen setup. |

An effective design for manufacturability analysis would essentially mean the systematic process based on the DFM check points. The engineers could then give feedback to the CNC part design evaluation based on a systematic analysis of check points for the DFM analysis varying from geometry to fixturing. This would ensure that the design done would not only be creative but also optimal for the predictable manufacture based on the CNC machining design guide.

What Common DFM Errors Can Lead To Increased CNC Machining Costs?

It is amazing how the smallest oversights in design can balloon costs astronomically. Avoiding common DFM errors is key to successful manufacturing cost control. A few proactive reviews with a focus on CNC design optimization will save falling into these pitfalls, ensuring the design functions and can be made profitably. Many times it means lower costs and greater reliability. The following table summarizes some of the common mistakes and impacts that can occur:

| Common DFM Error | Consequence | Key Principle for Design Optimization Solutions |

| Unnecessary Tight Tolerances | Increases machining time, requires special tooling/inspection, raises part cost. | Specify tolerances based only on critical part function. |

| Ignoring Tool Access & Geometry | This increases time for machining, tool wear, and possibility of breaking the tools. | Minimise internal details. If this is really important, you may use assembled component. |

| Overly Complex Internal Features | Extends machining time, increases tool wear, risks tool breakage. | Simplify internal geometry; use assembled parts if needed. |

| Wrong Selection of Materials | Problems during machining, worn-out cutting tools, wastage of material. | While selecting the material, one has to be very cautious while taking functionality, cost, and machining into consideration. |

This is to say that effective manufacturing cost control of profitable products begins with the knowledge of common DFM errors. As a result of the integration of the design optimization solutions that focus on simplicity, standard tools, and tolerances, the designers will be able to achieve excellent performance with respect to CNC design optimization. This will eliminate costly errors common in the initial DFM processes.

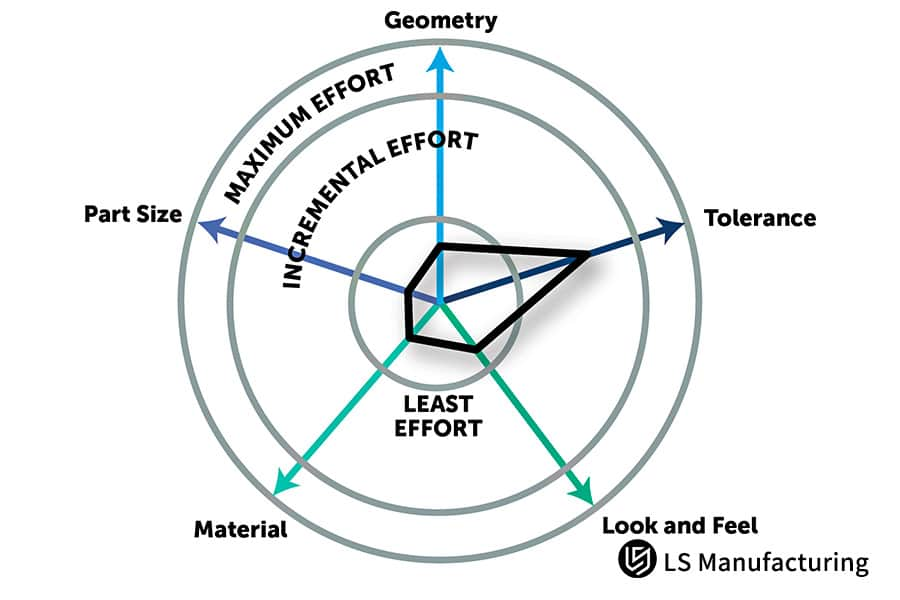

Figure 2: Factors influencing CNC machining effort: geometry, tolerance, material, and size by LS Manufacturing

How To Improve CNC Machining Efficiency Through Design Simplification?

One of the approaches to design simplification strategy is an extremely effective tool to carry out a great improved processing efficiency. The main point is that the most elementary form of CNC process optimization is designed to simplify the complexities of production at the root cause of the problem and will result in an increased level of reliability and cost-saving CNC machining with a reduced level of processing time and possible errors.

Reducing Setup and Operations

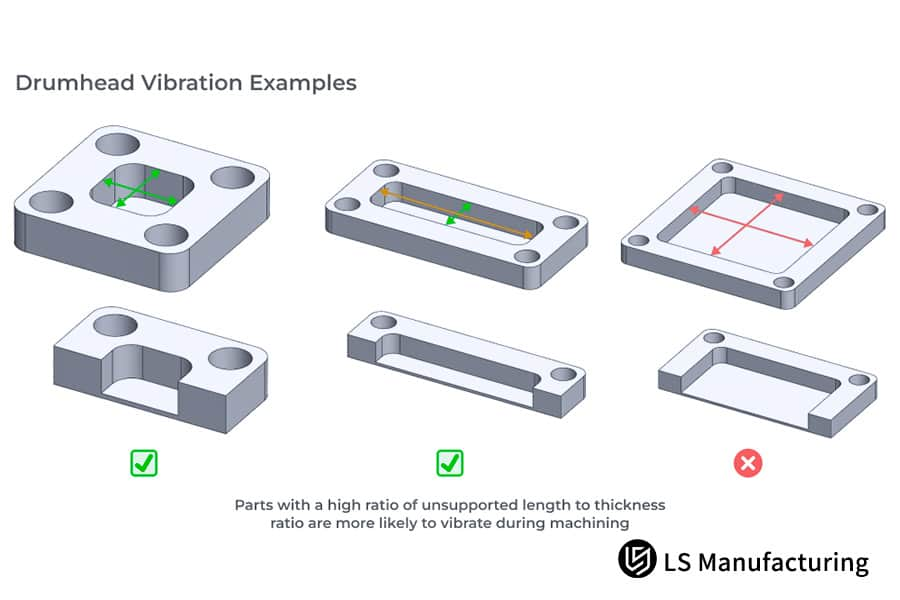

One of the most effective means toward improving processing efficiency is to design a part that can be machined with fewer setups. That means orienting all critical features so they are accessible from as few sides as possible. A part that can be set up once or twice instead of four times drastically cuts non-cutting time spent on fixture changes and realignment, directly contributing to cost-saving CNC machining and shorter lead times.

Standardization and Feature Combination

As a good design simplification strategy, it is firmly dominated that standardization of hole sizes, corner radii, and pocket sizes is necessary so that various features can be produced using only one tool to reduce the need for multiple tool changes. Conversely, combining smaller and autonomous parts into one, more complex machined part eliminates the processes related to the assembly of smaller parts together, apart from the prevention of inventory and the emergence of CNC process optimization.

Geometry Optimization for Smooth Tool Paths

Additionally, geometry optimization for smooth tool movement means that the design will be manufacturable, thereby ensuring fewer, smoother, and optimal tool paths. Thus, geometry optimization makes it possible to eliminate deep and narrow holes since optimal geometry yields higher feed rates, aggressive cuts, and reduced tool wear, which are all directly proportional to the optimization of the manufacturing process.

Prioritizing Function Over Unnecessary Precision

The CNC machining process optimization may involve consideration of the following: A substantial increase in machining time may be a result of non-justified precision in detail, which may result in thrice-the-time machining time. The standard machining tolerance may be the remedy for non-justified precision in detail in cost-saving CNC machining.

In conclusion, a deliberate design simplification strategy is fundamental to maximizing manufacturing productivity. By focusing on minimizing setups, standardizing features, and optimizing part geometry, engineers unlock significant improved processing efficiency. This holistic approach to CNC process optimization not only accelerates production but also enhances quality consistency, delivering on the promise of truly cost-saving CNC machining from the first design iteration.

How Does Tolerance Design Affect CNC Machining Costs And Quality?

Tolerance of the part and its cost are big forces behind quality and specification tolerance. Intelligent tolerance design optimization integrates the needs of function with the needs of manufacturing reality and is a vital instrument in machining cost control. Intelligent application, through complete DFM materials analysis, holds the solution to effective precision usage.

- Precision Carries a Direct Cost Premium: Unnecessarily tight tolerances are a major expense driver. They demand slower speeds, multiple operations, specialized tooling, and rigorous inspection. A core goal of tolerance design optimization is to reserve such precision only for critical functional or mating features, thereby containing overall machining cost control effectively.

- Differentiated Tolerances Balance Performance and Economy: Optimization is selective. Therefore, a component may call for tight tolerance interfaces for CRTs and commercial tolerance interfaces elsewhere. This approach ensures proper function where needed while relaxing machining cost control pressures on non-critical areas, achieving the perfect balance between quality and cost.

- Material and Process Drive Feasibility: The relationship between the attainment of tolerance and material process is inevitable. DFM materials analysis is an extremely crucial part of DFM. Stronger material means higher cost when machined. There will also have to be consideration regarding the tolerance limit of the CNC machine. Ambitious tolerance levels will lead to higher expenditures.

- Standardization Ensures Predictable Outcomes: Now all parts have to have tolerances of standardization, and any variation will lead to additional costs later on. This practice is a straightforward yet powerful form of tolerance design optimization that supports effective machining cost control.

Thus, intelligence-based tolerance design strategy is required to attain the best manufacturability design. Furthermore, CNC machining tolerance design optimization with the help of effective tolerance strategy is an imperative as identified by the DFM materials analysis that instead of highest accuracy, the level of accuracy required is needed. Such designed strategy leads to ensured functionality of the part while getting optimal machining cost control.

Figure 3: CNC machining stability guide: part vibration examples by LS Manufacturing

How Can Material Selection Achieve Cost Optimization Through DFM Analysis?

The reason for the cost of a part and the manufacturability of a part is based on material selection. This is necessary for the standardization of DFM material analysis to redevelop the material selection optimization. This task considers the properties of material in relation to manufacturing feasibility, which directly affects the machining cost control in relation to design for manufacturability CNC.

Machinability Assessment for Direct Machining Efficiency

The central theme in material selection optimization is the selection of the material grade based on machinability. The DFM material analysis, for a material, is based on several material characteristics, including hardness, chip formation, and thermal resistance. Selecting a material grade based on machinability results in faster feed rates, longer tool life, and improved surface finish.

Maximize Usage of the Standard Stock to Eliminate Scrap

One of the most effortless ways to cut costs has to do with optimization, whereby the objective is to ensure maximum usage of the standard sizes for the stock pieces. The suggestion by the design for manufacturability CNC evaluation has concerns with certain size variations for the minimization of scraps and off-cuts.

Balancing Performance with Alternative Materials

There are multiple materials that can satisfy the performance requirements. An in-depth DFM material analysis investigates the alternatives available. For instance, selecting a pre-hardened steel material instead of an alloy, which needs heat treatment post-machining, will eliminate distortion and material selection optimization for a simpler process of production.

Cost of Ownership

The better material will provide the required property for the lowest cost of ownership. This approach might explain how, for example, a material which is relatively more costly but with simpler machining will eventually provide the lowest cost since the machining time is minimized and the value of tool wear is minimized too. This holistic view is central to strategic CNC machining cost control and intelligent material selection optimization.

In short, material selection is regarded as the most critical decision in the design for manufacturability CNC. The use of DFM material analysis helps the designer in making optimum utilization of the selection of materials. This approach helps to select the material, which is able to generate the part easily with minimum wastage.

How Can Early Supplier Involvement Improve The Effectiveness Of DFM Implementation?

Integrating production expertise at the start of the design process is crucial for optimal outcomes. Proactive supplier collaboration represents a powerful strategy for achieving a successful collaborative implementation of DFM. This approach, centered on early design involvement, allows manufacturing realities to directly inform and improve a design before it is finalized. Effective CNC machining supplier collaboration bridges the gap between concept and production floor.

- Reducing the Need for High-Cost Redesign Loops: Often the most significant factor of early design involvement stage is the avoidance of changes at the end of the design process. If the supplier gets a glimpse into the design concepts, it would be easy for them to identify the regions where the material would not be machinable. This could be accomplished at no cost at this stage. Doing it later would be much too costly.

- Providing Specialized Process and Material Guidance: The knowledge of process capability and material performance that experienced suppliers possess can be very useful. Designers can thus tap into the advantage of recommendations for the best machining process, possible material tolerance, and substitute materials which are either more machinable or more cost-effective and still functional by supplier collaboration.

- Minimising the Costs and Lead Times Since Day One: A key goal of collaborative implementation of DFM is to design for efficiency. A CNC machining supplier collaboration enables the co-development of the involved parties to produce designs devoid of setup, shared tools, and simplified machining. Such efforts cater to the needs of minimizing, as much as possible, the primarily dominant factors responsible for cost and lead time right from the inception of the task.

- Building Alignment and Ensuring Manufacturability: The process of dialogue and dialogue continues to form an alignment and understanding of the goals and limitations. Thus, it aims at attaining innovation in design that is manufacturable. Therefore, the process of alignment reduces the risks of misalignments and the process of quoting and attaining manageable goals and advancing easily in the stage of production.

In conclusion, the power of early design involvement through supplier collaboration is transformative. It fundamentally shifts manufacturing input from a reactive constraint to a proactive design advantage. This collaborative implementation of DFM, especially with a specialized CNC machining supplier collaboration, is proven to accelerate development, reduce total cost, and dramatically increase the likelihood of launching a successful, high-quality product on time and on budget.

Figure 4: Optimized CNC part collaborative design for manufacturability analysis by LS Manufacturing

LS Manufacturing Medical Device Industry: DFM Optimization Of Titanium Alloy Components For Orthopedic Implants

A leading manufacturer of medical devices faced complexity in the production of a new orthopedic device. The titanium alloy parts machining was highly expensive and took so much time that it was jeopardizing the viability of the product. This case represented an area in the CNC machining design considerations that, if neglected, can undermine the success of the most innovative medical products. The need for professional intervention in the medical device DFM optimization became apparent.

Client Challenge

The implant had a lattice structure, which is difficult to produce, thus hard to machine, and the inclusion of screw holes to fix the implant also added to the complexity. Further, the surface finish requirements specified on the implant surfaces were unnecessarily tight, thus adding to the processing time, consequently the need for medical device DFM optimization.

LS Manufacturing Solution

The analysis carried out by the engineering group included a careful examination related to the type of titanium alloy parts machining. Recommendations were made related to the optimization of the lattice structure for retaining strength along with enhanced accessibility for machining tools, shaping the fixation hole for machining the components from different directions, and modifying the final surface finish specifications based on functional necessity. Each change was guided by practical CNC machining design considerations for biocompatible metals.

Results and Value

The collaborative medical device DFM optimization yielded exceptional results. The machining cost per unit was anticipated to decrease by 35%, and the machining time was anticipated to decrease by 40%. Moreover, the manufacturability increased because of the implementation, because of which the first pass yield increased to 99.5%. This LS Manufacturing success case successfully demonstrates the effectiveness of the design methodology on the ROI & ability within the workflow process, which pertains to the highly important function of medical devices.

This project stands as a definitive LS Manufacturing success case. It powerfully demonstrates that expert-driven medical device DFM optimization, which deeply understands the constraints and opportunities of titanium alloy parts machining, is not merely a cost-saving exercise. By applying practical CNC machining design considerations early, we transformed a challenging prototype into a reliable, high-quality, and commercially viable product, ensuring both clinical and business success.

Ready to have DFM done on your CNC machined parts taken to the next level? Click to optimize.

How To Establish An Effective DFM Collaboration Process With Suppliers?

Well-structured DFM collaborative processes could also allow transitions between designs and products, which could also be produced as a result of the manufacturing process itself. This should be conducted with a structured supplier management, which could promote design and manufacturing collaboration, using the same CNC machining engineering guide.

- Define Clear Roles and Milestones Upfront: There should be clarity regarding roles, expectations, and milestones right from the onset of projects. Design and manufacturing collaboration can become very effective with a unified CNC machining engineering guide among all those who are involved.

- Standardization of Information Exchange through Templates: The process for exchanging information for design, feedback, and changes should be accomplished by using templates. This would remain one of the primary needs for efficient supplier management. The use of templates will ensure effective communication during the DFM collaborative processes.

- Creation of a Centralized Digital Platform: This includes the movement of the collaboration processes of the business to a centralized digital platform. It enables real-time design and manufacturing collaboration, creates a clear audit trail, and significantly enhances the efficiency of your DFM collaborative processes.

- Schedule Proactive, Early-Stage Reviews: Integrate formal DFM reviews at key design milestones, not as a final check. This proactive approach in supplier management allows issues to be resolved when changes are easy and inexpensive. It embeds manufacturability principles from the start.

Thus, a successful DFM collaborative processes has to establish strong grounds in the areas of structure, communication, and partnership. This strategic approach to supplier management transforms the relationship, ensuring design and manufacturing collaboration yields designs that are both innovative and optimally manufacturable.

FAQs

1. At what stage in this process is DFM analysis most helpful?

The process involved in the DFM analysis is most helpful during the concept and the detailed design stage. The idea is that the change in the design is not possible, and it can only be prevented when early intervention approaches are used. A company named LS Manufacturing advises its clients to first complete their preliminary design when they are required to perform the DFM analysis.

2. Would the functionality/performance of the final product be affected by the optimisation of DFM?

DFM optimization by professionals means that the optimization of manufacturing processes should be done without any compromise on function. Ensured by LS Manufacturing engineers, all the solutions for optimization produced do not impair functions.

3. Can the DFM analysis be used on small-batch manufacturing processes?

DFM analysis retains its own importance irrespective of the size of the end batch. In such a situation of small batches being produced, the use of DFM analysis can be helpful. LS Manufacturing offers solutions for DFM analysis in different projects depending on different sizes of end batches.

4. Which documents are generally utilized to execute the DFM analysis?

It should be mentioned that for the time of DFM analysis, complete models, drawings, technical specifications, and designs are required. According to the phase of the project, the data requirement list should be provided by the company known as LS Manufacturing.

5. What cost benefits could possibly be gained from using DFM optimization?

On average, the possible cost savings by optimizing DFM are sensitive to ranges between 20% and 40%. There is a cost savings breakdown for the respective cost items included with every project that is factored into the given cost/benefit analysis report by LS Manufacturing.

6. How to ensure effective implementation of DFM recommendations?

LS Manufacturing further assists in the implementation of recommendations made by the DFM in regard to processes for change management, in addition to the implementation services offered.

7. Are assemblability aspects considered in the DFM process?

Well, a detailed examination of DFM would entail its manufacturability and assemblability. The service component provided by DFM LS Manufacturing is the assurance of the ability to assemble or process the product that is being developed.

8. Can DFM Analysis be used to Optimize existing products?

For the existing products, the services include product redesign optimization. The cost optimization analysis, which is carried out through the DFM, assists in understanding where the cost optimization is achievable with respect to the existing products of the companies.

Summary

By the means of DFM analysis and optimization, companies can determine their cost leaders right from the conceptualization stages of the product. They can also increase the productivity of their manufacturing process and help projects to move ahead. Having years of expertise and professional knowledge in the field of engineering, the company, LS Manufacturing, assists clients with full service support in the means of DFM analysis to help the clients meet their aim of quality and cost-effectiveness.

Contact DFM expert today at LS Manufacturing to get a free initial analysis & optimization strategy recommendation! Let the success factor of expert knowledge work for you! Get a full analysis report today on a customized cost optimization strategy!

Optimize manufacturability design to achieve higher quality and efficiency at a lower cost. Get your customized production solution now.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.1