For the selection of a process for manufacturing metal parts, engineers are typically faced with a basic compromise: how to find the optimal balance between design freedom, efficiency, and cost? This is the basic difference between stamping and hydroforming, two traditional technologies. Stamping offers cost advantages in its high efficiency and high throughput, yet the expense of dedicated tooling renders it more suitable for large volume production.

Hydroforming, on the other hand, excels at flexibility, using liquid pressure to shape complex hollow or three-dimensionally curved parts with a single die. This reduces tooling investment and setup times, and therefore is aptly suited for small- to medium-volume, high-complexity uses. Understanding the fundamental differences between the two in terms of tooling cost, production efficiency, and complexity of parts is a valuable starting point for determining which technology is best for your project. To conserve time, the following is a concise summary of the key findings.

Hydroforming vs. Stamping Core Quick Reference Comparison Table

| Comparison Dimensions | Hydroforming | Stamping |

| Tooling Cost | Low. Typically, only half the die is required, and the die structure is relatively simple. | High. Requires a complete set of specialized precision cutting tools (punch, die, etc.), which is costly. |

| Production cycle | Slow . Single forming cycles are long, making it suitable for low to medium production volumes. | Extremely fast. Dozens of parts can be produced per minute, making it suitable for large-scale automated production. |

| Part complexity | High. Complex three-dimensional hollow structures and parts with variable cross-sections can be formed in a single pass, with strong integrity. | Medium. Hydroforming excels at manufacturing relatively simple sheet metal parts, while complex parts require multiple processes and molds. |

| Applicable materials | Suitable for a wide range of materials, especially pipes. The sheet metal forming range is narrower than stamping. | Extremely versatile. A wide range of sheet metal and strip materials can be processed, providing flexibility in material selection. |

| Surface quality | Good. Liquid force transmission minimizes friction damage between the material and the mold, resulting in minimal surface scratches. | It depends on the mold. High-speed stamping is prone to scratches, which usually require post-processing or a high-quality mold surface. |

The decision to hydroform or stamp is actually a question of sacrificing flexibility for efficiency:

- Choose stamping: When your project requires high-volume production (e.g., automotive panels or consumer electronics housings) and you are looking for very low unit costs and high production cycles, the high initial tooling cost is warranted.

- Choose hydroforming: When your project includes low- to medium-volume and complicated part geometries (for example, specially shaped tubes or aerospace components) and requires less welding, reduced weight, and improved structural integrity, then hydroforming is less costly tooling and shorter lead times.

Why Trust This Guide? Practical Experience from LS Experts

In the last twenty years, the LS Precision staff has been directly involved in more than a thousand metal forming projects, developing extensive experience in a broad variety of processes, ranging from conventional stamping to hydroforming.

LS Precision not only boasts of its state-of-the-art hydraulic presses and precision progressive stamping lines, but also of its specialty in exactly defining and implementing the optimal process solution based on a customer's specific product needs—whether cost budget, production volume requirements, or complexity in structure. Every comparison and recommendation in this guide is a product of LS Precision's years of on-field experience and deep industry knowledge.

LS Precision's experience practice has been effectively validated in a variety of principal industries:

- In the automotive field, we employ hydroforming to manufacture ultra-high-strength, lightweight A-pillar reinforcements for new energy automobile makers with 30% weight reduction.

- In the aerospace sector, we hydroform aircraft complex hollow titanium alloy tubes with stringently met requirements for both lightness and reliability.

- In consumer electronics, we utilize ultra-high-precision, micron-level stamping technology to mass-produce hundreds of millions of defect-free stainless steel components. These successes across industries demonstrate that our expertise isn't theoretical; it's practical, proven.

What Is Hydroforming? How Does It Fundamentally Differ From Traditional Stamping?

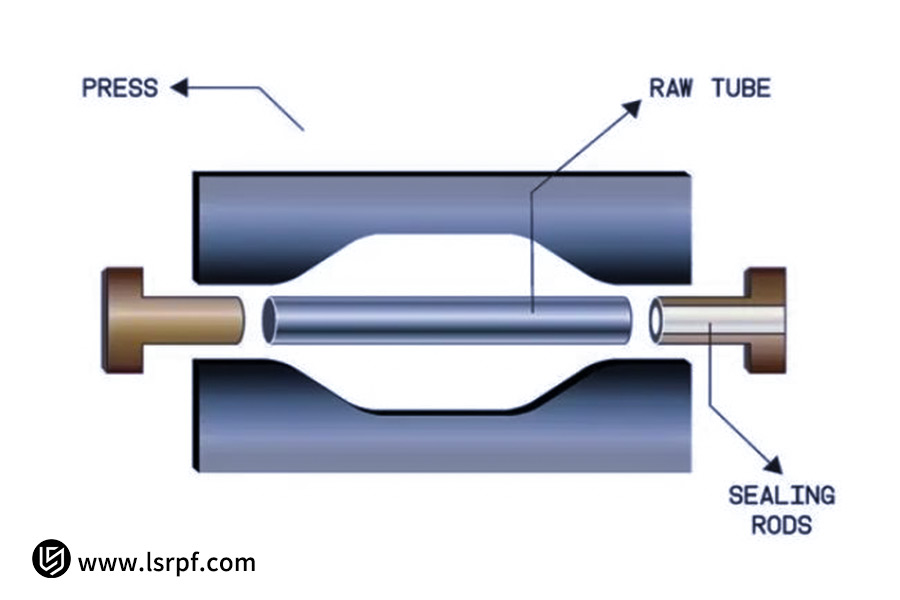

With the evolution of complex and lightweight metal parts manufacturing, hydroforming technology is increasingly becoming a core process. So, what exactly is hydroforming? Hydroforming is an advanced manufacturing technology that employs high-pressure fluid (usually water-based emulsion) as a force-transmission medium to inflate and form a metal blank (sheet or tube) in a mold cavity, thereby creating a complicated three-dimensional shape.

1.Hydroforming workflow:

Hydroforming process consists of three steps:

- Put the blank into the lower mold and close the mold;

- Pump high pressure fluid into the sealed blank, plastically deforming the blank to conform to the mold cavity;

- Release the pressure and remove the precisely formed part.

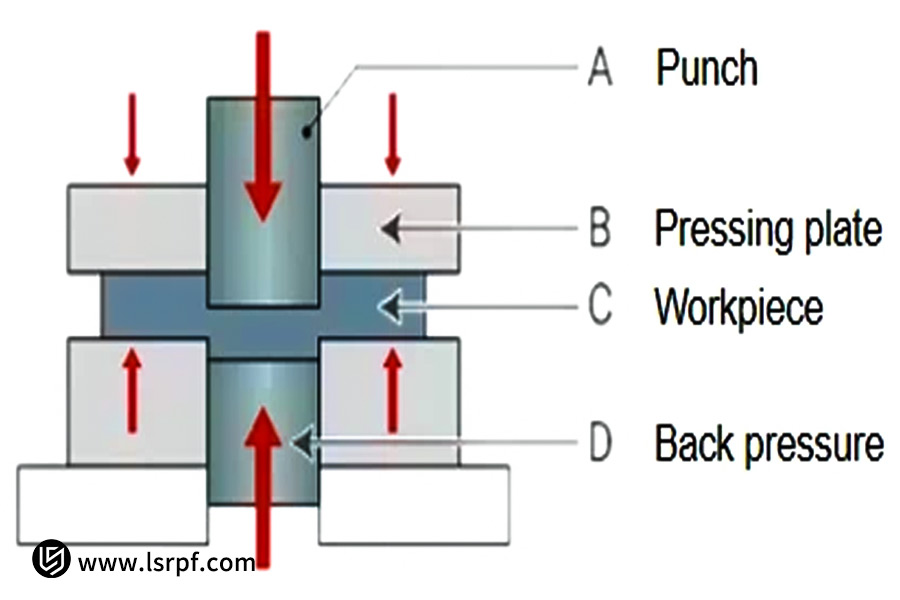

This is in direct contrast with traditional stamping, which applies mechanical pressure through solid punches and dies to cut or plastically deform the sheet through impact force.

2. Differences between hydroforming and stamping:

Hydroforming and stamping differ in three ways:

- From the perspective of forming methodologies, hydroforming is a "flexible" hydrostatic forming process, while stamping is a "rigid" mechanical stamping process.

- This has a direct implication in a tremendous tooling cost saving: hydroforming typically requires only half the tooling, significantly less than stamping requiring a complete set of precision tooling.

- In terms of production efficiency, stamping is suited to high-volume production since it is high-speed continuous production; while hydroforming has a slower cycle time and is better suited to small- to medium-volume, high-complexity production scenarios.

The main advantage of hydroforming is the creation of complicated shapes at lower tooling costs, while stamping offers high productivity in mass production. The choice of process depends on the general project requirements for part complexity, volume, and cost.

In What Ways Does Hydroforming Outperform Stamping?

In the choice of a metal forming process, hydroforming technology, through its unique capabilities, provides significant advantages over traditional stamping in a variety of important ways. These advantages make it an important choice for modern manufacturing, where lightweighting, complex designs, and high performance are necessities.

1.Part complexity and integrated forming:

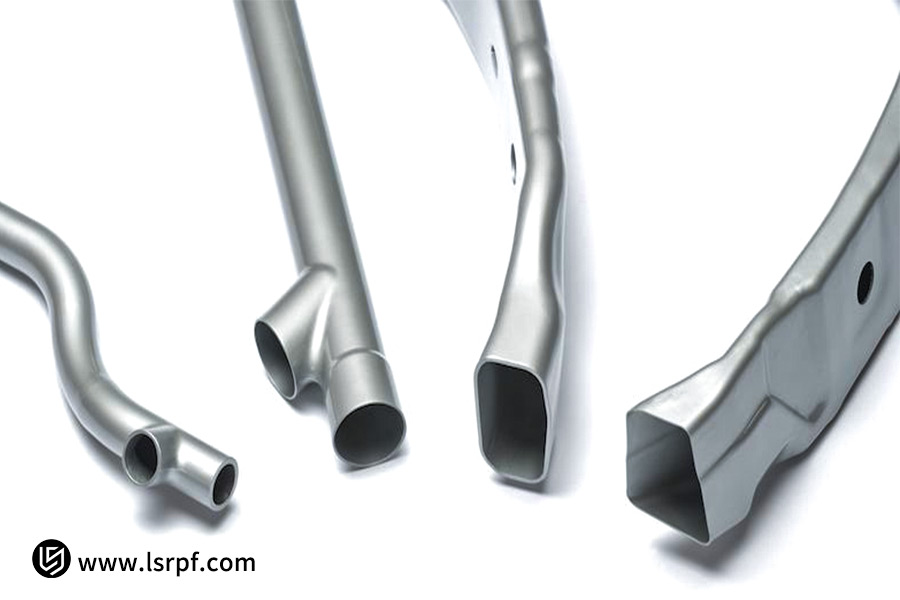

Metal hydroforming offers benefits in part complexity and integrated forming. It can transform a simple tube hydroformed into a hollow component with complex three-dimensional curvature, i.e., a variable-diameter tube or specially shaped branch, in a single process. This is difficult to achieve economically with stamping, where a number of dies and a number of operations are included, hence reducing welding and assembly.

2. Lightweighting and material utilization:

Hydroforming significantly improves part weight reduction and material utilization. By allowing control of material flow exactly, hydroforming enables the necessary strength and stiffness to be obtained with thinner walls, which reduces the part weight directly. Furthermore, the process generates virtually no waste (e.g., edge material from stamping), resulting in extremely high material utilization and lower total costs.

3. Strength properties and surface quality:

Hydroforming offers great advantages in strength and surface quality. Due to the effect of work hardening, hydroformed parts tend to be stronger than the original blank. Furthermore, the nature of liquid forming makes it easier to avoid scratching of the part surface by the die compared to stamping, resulting in improved surface quality and reduced secondary operations.

Hydroforming has overwhelming advantages compared to traditional stamping in producing complex hollow parts, light-weight design, material saving, and product strength and surface quality improvement. It is particularly well-suited to the demands of high value-added industries such as aerospace and automotive.

In What Scenarios Is Stamping Still A Better Choice?

Whereas technologies like hydroforming excel at creating complex parts, for the majority of applications, traditional stamping remains more efficient and cost-effective since it possesses certain special strengths. When ultimate production efficiency and unit cost are the project targets, the unmatched advantages of stamping are revealed.

High-volume production

In mass production, stamping boasts an unbeatable speed. It is a high-speed, continuous stamping with tens or even hundreds of strokes per minute and is highly suitable for parts that must be manufactured in millions of units, e.g., car bodies and electronic consumer product casings. This high efficiency cannot be achieved by hydroforming, which involves a longer production cycle.

Simple geometry

For parts with relatively simple geometries, stamping is the method of preference. For sheet metal parts, brackets, or shallow-drawn parts, stamping dies can form the parts quickly through simple blanking and bending operations. The process is stable and mature, without the unnecessary equipment and procedure expense of hydroforming.

Thin sheet metal processing

Stamping is the champion in the field of ultra-thin sheet metal and high-precision treatment. Stamping is extremely capable of treating thin sheet metal and can achieve very high micron-level accuracy through progressive dies, and the consistency is perfect in mass production.

Cost-Sensitive projects

For highly cost-conscious projects, stamping is the most suitable option. Once the high initial tooling expense is amortized, the cost per part is extremely low, and it remains a dominant choice for high-volume, low-margin businesses.

When your project requires high-volume, high-speed production of simple, thin sheet parts, and is highly cost-conscious, stamping remains the unmatched best choice due to its maturity, efficiency, and affordability.

Five Key Differences: How To Choose The Best Process For Your Project Needs?

When choosing a metal forming process for your project, deciding between stamping and hydroforming is critical. Both technologies differ significantly from their fundamental principles to their application contexts. Comparing the two on five significant dimensions will allow you to choose the most suitable method for your project.

1. Tooling Cost: Flexibility vs. Specialization

Hydraulic forming requires only half the die, offers relatively a simple die design, and reduces start-up investment. Stamping, on the other hand, requires a complete set of high-precision, special molds (punches and dies), which render the production cycle time-consuming and expensive, and therefore it is suited for large-scale production in order to recoup the investments.

2. Production Cycle: Different Batch Flexibility

Stamping enjoys an absolute speed advantage, with dozens of parts per minute being feasible, making it well-suited for high-volume mass production. Hydroforming takes a longer part cycle time, and although less productive, it is more suited to small and medium-volume production needs.

3. Part Complexity: Simple vs. Complex

Stamping excels at producing relatively simple sheet metal parts and shallow drawn parts. Hydroforming can produce complex three-dimensional hollow parts and parts with varying cross-sections in a single operation, with high integrity, and with fewer welds and assemblies.

4. Material Thickness: Numerous Applications

Stamping is best suited for processing thin sheet metal (typically 0.5-3mm) and is strong in processing super-thin sheets. Hydroforming can process thicker pipe and sheet material, and is excellent in structural parts with some wall thickness.

5. Surface Quality: Different Damage Levels

Hydraulic forming uses liquid as the force transmission medium, which lowers the contact with the mold to a certain degree, resulting in less surface scratch and better quality. Mechanical contact at high speed between material and die in stamping can very easily cause scratches, generally requiring post-processing.

Hydroforming or stamping is merely a matter of project requirements being accurately matched:

- Choose stamping when you need to produce simple, thin-sheet parts in large quantities and strive for the highest cost-per-part efficiency.

- Choose hydroforming when you need to produce small, complex geometries, reduce weight, and maximize material efficiency in a low-volume program.

These five primary distinctions will allow you to make the optimal process choice for your specific production volume, complexity, cost, and timeliness requirements.

What Types Of Materials And Products Are Particularly Suitable For Hydroforming?

The technology of hydroforming is not suitable for all materials, but it is quite suitable for forming certain metals. It is best suited for metals that possess good ductility. Next, I will give you an in-depth analysis from the aspects of material type, product form and practical application of the product.

Material types

Stainless steel, aluminum alloys, and carbon steel are the most widely used materials for hydroforming, while copper alloys and titanium alloys are used for specialty applications. The materials must possess sufficient plasticity to flow freely under high-pressure fluid and assume the form of the mold cavity, thus producing complex forms.

Product form

Based on product form, hydroforming is largely divided into two areas: sheet metal hydroforming and tube hydroforming. Sheet metal hydroforming is used primarily to manufacture medium-to-large shells with complex curves or shallowly drawn components. Tube hydroforming, on the other hand, is the fundamental application of the technology. Through internal pressure and axial feed, it is able to convert standard round tubes into structural components of varying custom cross-sections.

Product applications

Practically, the hydroforming tube process is best suited for the production of subframes, A-pillar/B-pillar reinforcements, and exhaust manifolds in the automotive industry; engine ducts and fuselage support components in the aircraft industry; and beautifully shaped chair frames and armrests in the furniture industry. The products share the common goal of achieving complex, hollow, lightweight, and integrated structures.

Hydroforming is a particularly well-suited process for the manipulation of ductile metal tubes and sheet, hence a ideal fit for component manufacturing use cases that demand light weight structures, integrity, and styling complexity.

How Does LS Precision Use Hydroforming TechnologyTo Address The Challenges Of Lightweight Automotive Manufacturing?

1.Client challenge:

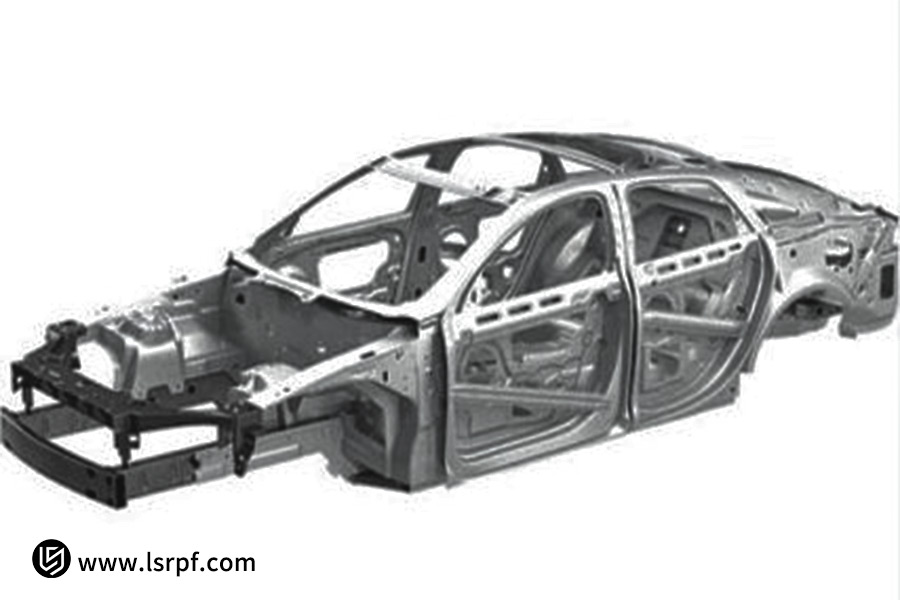

A new energy vehicle company was faced with an immense challenge in developing a new model. It had to reduce the weight of key parts of the main chassis by more than 25% without compromising safety. Traditional stamping and welding solutions not only weighed more than specifications, but also had risks of insufficient joint strength for multi-part assembly, making it difficult to meet the dual requirements of range and body rigidity for new energy vehicles.

2. LS Precision's innovative solution:

To rise to this challenge, LS Precision created an innovative metal hydroforming solution. LS company used topology optimization technology to re-engineer the chassis longitudinal beam, formerly comprising 12 stamped components welded together, into a single hollow structure that could be manufactured in a single process.

During the implementation process, LS Precision employed ultra-high-pressure metal hydroforming technology. Through the precise control of liquid pressure and feed rate by a computer, the high-strength aluminum alloy tube was perfectly formed into a complex three-dimensional shape in the mold.

3. Final results and value demonstrated:

This innovative solution achieved excellent results—weight saving by 30%, part count reduction by 80%, and overall stiffness improvement by 25%. Furthermore, the metal hydroforming process reduced the production cycle by 40% and achieved a material utilization rate of over 95%. This project not only solved the customer's lightweight problem but also significantly improved product safety and production efficiency through integrated molding technology, forming a successful model for new energy vehicle lightweight production.

What Key Factors Should Be Considered When Implementing A Hydroforming Project?

Carrying out a hydroforming project entails a comprehensive project that requires general consideration of a number of factors, including equipment capacity, mold design, material properties, and process control. These interacting factors concurrently determine the project feasibility, economic benefits, and final product quality.

Equipment investment

Equipment investment is the physical foundation of project realization. Corresponding to product size, forming pressure, and production capacity requirements, the appropriate tonnage and worktable size hydraulic equipment must be selected. Although more investment is required for larger-tonnage equipment, it can meet the forming requirements of more complex parts and achieve process flexibility. Investment in the supporting hydraulic system, control system, and auxiliary equipment should also be considered.

Mold design

Mold design is the most important technology. Though a hydroforming mold structure is simpler than a stamping mold, parting surface calculation, liquid channels, and venting system calculation still need to be accurate. CAE simulation software is used in simulating material flow and thickness distribution to predict wrinkling or cracking defects in order to optimize at the mold design phase. Mold material selection also directly affects mold life and part quality.

Material selection

Material selection directly affects process feasibility. Tubes or plates with better ductility and uniformity must be selected, such as high-quality materials such as stainless steel and aluminum alloy. The mechanical property of the material, anisotropy, and wall thickness uniformity should be strictly controlled. Otherwise, quality issues such as cracking or excessive thinning will inevitably occur in the hydroforming process.

Process parameter optimization

Process parameter optimization is the most significant aspect in ensuring product quality. Process parameters such as liquid pressure, feed rate, clamping force, and dwell time must be precisely controlled, and the optimal set of parameters must be established by performing a number of process trials. The majority of the recent hydroforming machines are equipped with intelligent control systems, which monitor the process parameters constantly and adjust them online to ensure stability and consistency during the forming process.

It is only through thorough technical feasibility study and process confirmation at the start of a hydroforming project that one can effectively implement the project and realize the complete advantages of hydroforming technology in the manufacture of complicated hollow parts.

How To Evaluate The Overall Manufacturing Costs Of The Two Processes?

A comparison of the total cost of hydroforming and stamping requires an overall analytical framework that, besides the initial investment, considers the total costs throughout the product life cycle. The following comparative analysis identifies the key cost factors:

| Cost Structure | Hydroforming Process | Stamping Process |

| Mold Cost | Low (Single Mold) | High (Multiple Precision Molds) |

| Material Utilization | High (90%-95%) | Medium (70%-85%) |

| Production Efficiency | Medium (Suitable for small and medium batches) | High (Suitable for large batches) |

| Equipment Investment | High | Medium to High |

| Post-Processing Cost | Low (Good Surface Quality) | High (Trimming May Be Required) |

- Mold costs: they are amortized based on production volume. While stamping is more expensive per mold, the per-part cost is extremely low in very large batches.

- Material cost: hydroforming's high utilization rate offers a tremendous advantage for precious metal projects.

- Equipment efficiency: directly influences labor and energy costs, and stamping enjoys significant advantages in mass production.

- The post-processing cost: secondary operations and surface treatment are included in the post-processing cost, and hydroforming's integral molding proves to be advantageous in this respect.

Generally, hydroforming is more economical for small batches and complex parts, while stamping offers a cheaper way of mass-producing simple parts. A sound decision should be made by precise calculation based on the real production volume, material grade, and product quality requirements.

FAQs

1. Are hydroformed parts stronger than stamped parts?

Hydroformed parts generally have improved strength characteristics. It is largely due to their uniform material distribution and work-hardening effects. The material deforms plastically and work-hardens when exposed to high-pressure fluid, significantly increasing yield strength. Furthermore, the single-piece forming operation eliminates weld heat-affected zones, maintaining improved structural integrity and fatigue strength, making it highly suitable for safety-critical applications.

2. Is hydroforming suitable for small-batch production?

Hydroforming is particularly well adapted to small-series production. It has a 40%-60% lower tooling cost than stamping tools, and its production lead time is short. LS Precison offers flexible production solutions from 100 to 10,000 pieces, which allows us to quickly modify production processes to meet customer specifications, helping customers achieve high-quality hollow, complex structural parts at controlled cost.

3.What are the differences in surface quality between the two processes?

Hydroforming delivers valuable surface quality advantages. Because it uses liquid as the force transmission medium, there is no mechanical contact between the tooling and the workpiece, and the surface is smooth and free of scratches. In comparison, stamped parts typically require additional surface treatment operations such as grinding and polishing. The difference is particularly apparent in exterior automotive parts and high-visibility consumer goods, where appearance requirements are exacting.

4. How to choose the most appropriate molding process for a specific project?

LS Precision provides professional technical consultancy service, suggesting the most suitable process solution through a four-step procedure: first analyzing the product structure and production volume requirements, then the material characteristics, followed by mold and manufacturing cost calculation, and finally sample trials and confirmation. Our engineers possess 20 years of industry experience and can provide you with the most cost-effective molding solution.

Summary

Hydraulic forming and stamping processes respectively have their own advantages in mold cost, production efficiency, part complexity, as well as the applications they can be used in. Hydroforming has an advantage in integral molding of complex hollow parts with the merits of low mold cost and excellent lightweighting. Stamping is advantageous in the aspects of efficiency and economy in the high-volume production of simple parts. A process should be selected according to the comprehensive consideration of product characteristics, production quantity, and quality requirements.

If you are seeking the optimal molding process for your project, contact LS Precision Manufacturing for consultation by an expert. We offer free process review services, in which our staff of seasoned engineers reviews the optimal solution for you, reducing cost and improving product performance. Contact LS Precision today to learn about the most cost-effective molding solution for your needs.

Upload your design drawings now and get an instant stamping quote (stamping price), let LS be your strong backing in pursuit of ultimate stamping precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com