Custom Gear Machining Services: A Complete Guide To Material Choices And Accurate Pricing

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.How Do Professional Gear Machining Services Match The Best Material Solutions To Specific Operating Conditions? 3.What Performance Indicators Should Be Given Priority Consideration When Scientifically Selecting Gear Materials? 4.How Does High-Precision Gear Manufacturing Ensure Dimensional Stability And Noise Control? 5.How To Build An Accurate Pricing Model For Gear Machining? 6.What Are The Strategies For Balancing The Hardness And Wear Resistance Of Gear Materials? 7.What Are The Key Factors Affecting Gear Manufacturing Costs? 8.How Do High-Durability Gear Materials Perform Under Extreme Operating Conditions? 9.What Are Some Key Factors Often Overlooked In Gear Material Selection? 10.LS Manufacturing: Custom Machining For Wind Power Gearbox Planetary Gears 11.Innovative Applications Of Advanced Gear Material Technology In High-Speed Transmissions 12.FAQs 13.Summary 14.Disclaim 15.LS Manufacturing Team

Gloria

Gloria

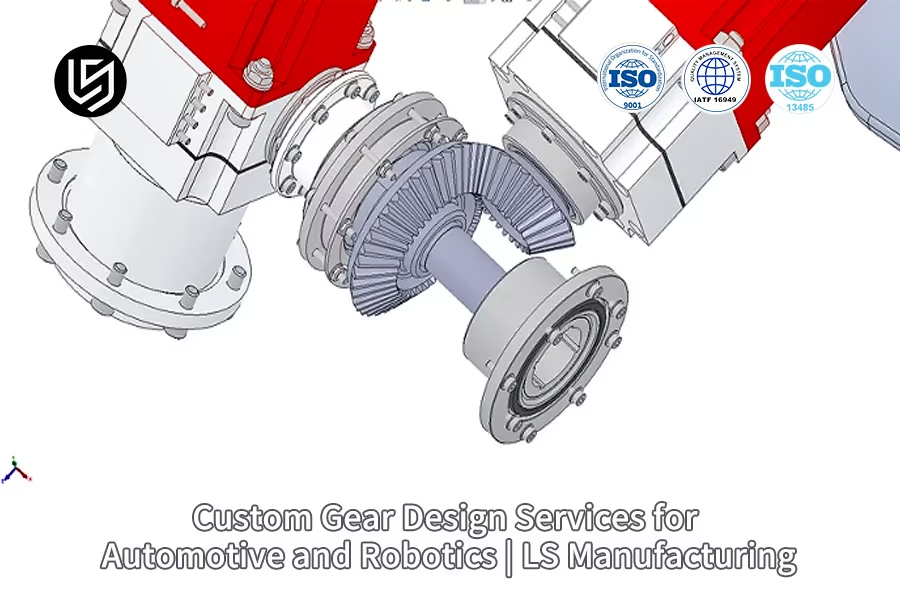

Custom Gear Design Services For Automotive And Robotics | LS Manufacturing

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.What Are The Core Principles That Should Be Followed In High-Quality Gear Design? 3.What Are The Design Differences Between Automotive Transmission Gears And Robot Joint Gears? 4.How To Improve Gear Performance Through Material Selection? 5.How Does The Gear Manufacturing Process Affect The Final Performance? 6.LS Manufacturing Industrial Robot Joint Gear Customization Case 7.How To Control The Cost Of Custom Gear Projects? 8.What Are The Key Points For Quality Control In Small-Batch Gear Production? 9.What Special Requirements Must Be met For The Gear Design Of Electric Vehicles? 10.How To Assess The Overall capabilities of a gear supplier? 11.FAQs 12.Conclusion 13.Disclaimer 14.LS Manufacturing Team

Gloria

Gloria