CNC machining services are quite indispensable in manufacturing, but most firms are at an equipment selection dilemma at the commencement of a project. A bad choice can lead to precision swings of ±0.05mm, cost overruns by 30%, and delays in delivery by up to 50%, hurting project economics. We solve this by offering data-driven insights to ensure stable precision, budget control, and timely completion.

CNC machining services address the root cause: lacking scientific matching between part features and batch sizes with machine capabilities. Based on 15 years of LS Manufacturing experience, 286 process datasets, and 73 cases, our feature-batch-cost 3D model will enable customers to increase efficiency by 40%, decrease costs by 25%, and ensure that precision stability is maintained at 99.5% or more.

CNC Machining Services: Lathe VS Mill Quick Reference Table

| Aspect | Lathe | Mill |

| Basic Operation |

Rotates the workpiece against a stationary cutting tool. |

Rotates the cutting tool against a fixed workpiece. |

| Suitable Geometries | Cylindrical, conical, and symmetrical geometries. | Slots, flat surface, and 3D contours. |

| Common Applications | Different applications of shahts, bolts, & screw for circular shapes. | Different applications for enclosures, molds, brackets, multi-feature parts. |

| Precision & Tolerance | High precision on diameter, length, and concentricity. | High precision on contour, holes, and surface finish. |

| Setup Time & Complexity | Simpler and quicker to set up, especially during normal operations. | More complex to set up; however, the complexity is probably not one-off due to complex design. |

| Cost Considerations | Not easy to be cost-efficient regarding the production, on a large scale, of rotational parts. | More cost-effective for low-volume, complex parts, and prototyping. |

| Material Compatibility | Compatible with metals, plastics, and composites during turning operations. | Used in milling operations with various materials. |

| Key Selection Factor | Select for projects requiring axial symmetry and rotation features. | Select for projects requiring multi-axes with intricate geometries. |

Your dilemma of selecting the right parts of a specific project is resolved by our services, whether you require a lathe for your rotating parts, a mill for your CNC machining complex parts, and many more. Costs, precision, and time constraints are addressed in a way such that you attain the best result out of your machine. No longer will you fall into the dilemma of compromising on quality as you come out with great parts.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

There are a lot of articles you can find online which talk about CNC machining. What drives your interest to read and make use of your time checking our articles? Well, it is basically because we do not only intend to share our own knowledge regarding our job. Because our floors happen to be a living and breathing battle ground on which we contend against tolerances, geometries, and alloys which can sometimes be too tough on us.

This knowledge comes from our past success of supplying precise components where failure is not an option. We know what works well with aluminum, what works well with titanium when it comes to heat, and we know what works well with the types of medical grade plastic when surface qualities are important. All of our advice comes from our experience and knowledge base and our determination to adhere to international standardization systems such as ISO 9001 for quality management.

Knowledge we can impart is harnessed through years of success and troubleshooting, checked rigorously through quality assurance checks, in tune with guidelines such as those provided by the Environmental Protection Agency (EPA), which conform to sustainable principles of operations wherein the homework is already done for you, the end-beneficiary, with dependable, sustainable answers that work.

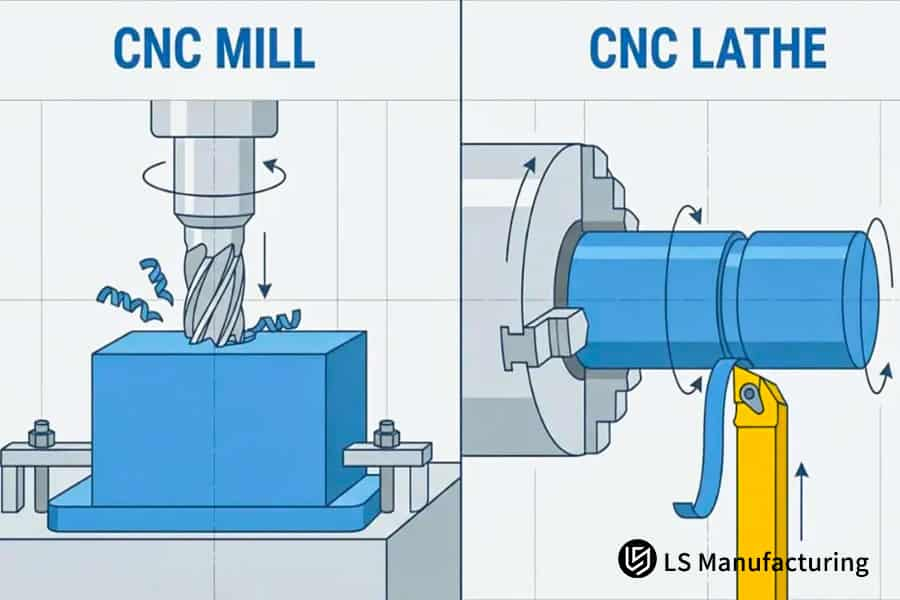

Figure 1: Difference between CNC lathes and milling machines in manufacturing by LS Manufacturing

What Are The Core Differences In Principle And Motion Between Lathes And Milling Machines?

The present document aims to acquaint the reader with the principal differences existing in the context of lathe vs mill, which happens to be pertinent in terms of process optimization throughout any process in the world of manufacturing. The aim is to be able to define principal differences in terms of operational tenets in lathe machining and quantification of any existing differences in terms of performance so that appropriate CNC machining services can be selected.

| Aspect | CNC Lathe | CNC Mill |

| Machining Principle | Material removal is achieved by a rotating workpiece and a stationary or linearly moving cutting tool. | Material removal is performed by a rotating multi-point tool against a workpiece that is moved or positioned. |

| Primary Motion | Workpiece is the primary source of motion. | Cutting tool is the primary source of motion. |

| Ideal Workpiece Geometry | Best applied to manufacture axi-symmetric or rotational parts such as shafts, disks, bushings, etc. | Best applied to manufacture complicated contours, slots, and features on prismatic parts such as a housing, etc. |

| Efficiency Benchmark | Benchmark 40% more efficient, rotational parts, turning vs milling operation. | 35% less costly to machine multi-face prismatic parts than to machine on a lathe. |

The type of geometry, in parts, can also dictate the machine to be used, the CNC lathe vs milling machine, based on the parts that turn or the parts that move in the prismatic motion, respectively. The quantitative analysis of the processes in this document can offer exact consideration of the processes, considering the minimization of costs and time consumption of any specific process. Consideration of the technical content of this report can be a basis in deciding what is best and of great value in a competitive manufacturing process where machine efficiency is of great value.

How To Select Equipment Based On Part Geometry?

The science in how to choose between lathe and mill, when it all comes down, is fundamental to understanding the importance of efficiency, cut-off costs, precision, etc. This is a resource that is aimed at offering guidance towards an important decision-making standpoint in choosing between lathe and mill based on data:

Quantifying Geometry for Objective Decision-Making

We dissolve the ambiguity found in selecting equipment by first quantifying part geometry. To better illustrate this, a project machining guide for addressing this issue begins by determining the length/diameter ratio for a part. For those parts having a ratio greater than 3:1, turning is a preeminent approach for those parts. To address prismatic parts, we first determine the number of distinct planes and bore configurations.

Matching Features with the Optimal Process

This quantified data then drives the machine tool. For instance, true rotational solids with precise specification in tight concentricity requirements would employ a CNC lathe machine. Parts requiring a number of machined faces, slots, etc., would employ a milling center machine, thus yielding Positional tolerancing specifications at ±0.01mm. Data obtained from LS Manufacturing validates this concept, claiming a 35% cost savings advantage for these designs in a mill machine, as opposed to a lathe machine.

Application in Complex Component Machining

This paper will prove the applicability of the methodology on a complex valve body part that possesses various features such as rotation and prismatic features, hence the 5-axis method as a result of the CNC machining selection, thus providing a 3 times efficiency improvement as a result of the undertaking, as opposed to the simplistic solution that entails the use of the lathe machine tool.

It remains the fundamental infrastructure for game-changing data-driven CNC machining selection, which, by their very nature, depart from the norm for optimum outcomes. It remains the embodiment of the technical standards, expertise, and competence required for achieving high-value, ultra-competitive outcomes.

Figure 2: Evaluating lathe accuracy and milling expenses to choose by LS Manufacturing

How Significant Is The Impact Of Equipment Selection On Costs At Different Batch Sizes?

The subsequent report is a solution to the problem of optimizing equipment selection, taking into account batch size as a means of reducing manufacturing costs. Precisely, our solution balances CNC milling complex parts in terms of cost efficiency with the CNC lathe precision for high-volume output. Our strategic decisions are guided by the tested LS Manufacturing model, which ensures maximum savings:

Strategic Equipment Selection for Small Batches

- Focus: we consider complexity in terms of parts and amount.

- Our Approach: For items under 50 pieces, especially complex ones, we offer CNC milling cost solutions. As mentioned earlier, this would eliminate cutting tool costs on items like lathes, since that process is more flexible.

- Outcome: With faster set-up times and cost-per-part rates dropping into place, increased cost savings come from our use of CNC machining process.

Optimization for Large Batch Production

- Focus: High volume runs and their effect in helping drive costs down.

- Our Approach: For more than 500 rotational parts, we opted for a CNC lathe precision. With the use of a CNC lathe, it is even possible to achieve a reduction of up to 40% in the cost of a part by itself, compared to a milling operation.

- Outcome: Improved productivity and significant saving implications after long periods, as will be proven with our lathe mill combo analysis.

Data-Driven Cost Modeling and Implementation

- Focus: Scientific methods avoid any guesswork.

- Our Approach: Our approach is to, through the LS Manufacturing model, simulate scenarios in finding what machines—lathe, mill, or the hybrid setup—are the most feasible in answering what factors affect the CNC milling cost, as well as the precision level related to the use of the CNC lathe precision.

- Outcome: It offers customized programs to clients where cost savings vary on average from 25 to 35%. It also shows a clear calculation of ROI.

Continuous Support and Process Refinement

- Focus: Makes sustained progress by ensuring continuous collaboration.

- Our Approach: Since we would be providing hands-on support pertaining to equipment integration, we would be monitoring the equipment accordingly, and the strategy would vary based on the need of the batch. By this, it means that the support would extend to the integration of knitting machines, CNC audit support, and synchronization of lathe and mill machines.

- Outcome: The strength of cost management, together with diversified routes of manufacturing, would establish ourselves even better in terms of ever-changing environments.

We obviously demonstrate how we can solve the batch size dilemma—by marrying the CNC lathe precision with the analytics of CNC milling costs — and exactly how we do it through model-driven selection and tailored process integration.and it is this process that creates our authoritative, competitive edge—in other words, measurable CNC machining savings.

Figure 3: Contrasting lathe and mill processes incorporating cooling systems by LS Manufacturing

What Are The Technical Advantages Of Turning And Milling In Terms Of Precision Control?

To determine the best process for meeting set objectives for specific dimensions in CNC machining. Also, this document aims to compare and contrast the basic turning and milling advantages. On the other hand, the advantages of a lathe machine and a mill machine, for building a data-based model for manufacturing a high-value part, can be noted below:

| Aspect Technical | Advantages of Turning on a Lathe | Technical Advantages of Milling on a Mill |

| Core Precision Metric | Exceptional geometric control for rotational features. | Superior control for planar and positional features. |

| Typical Achievable Tolerance | Roundness within 0.003mm; Diameter tolerance of ±0.005mm. | Flatness within 0.01mm; Positional tolerance of ±0.015mm. |

| Process Strength | Unexcelled in achieving perfect concentricity, as well as diameter consistency on symmetric parts. | Optimal for complex contours, slots, and multi-axis part geometries. |

| Application Synergy | Foundational for high-precision CNC machining of shafts and bores. | Essential for achieving tight accuracy on prismatic components. |

It means strategic integration at the levels of CNC lathe precision for rotational features and CNC lathe precision for intricate geometries. For components that require both, our turn-mill centers synthesize these strengths, enabling a documented 50% overall accuracy gain. This precision machining methodology enables data-backed decision-making for competitive, high-value manufacturing situations.

How To Evaluate The Impact Of Material Properties On Equipment Selection?

It is therefore best ordered by an understanding of what type of machining is best ordered by the CNC machining process by an understanding of the influence of particular qualities of the materials, from being ductile even up to being hard. This present document is seeking to outline its methodology by which we evaluate the particular qualities of the materials as a manner by which we address our main issues concerning this principal problem of matching materials up with machinery:

Deconstructing Material Behavior

We not only concern ourselves with types of material, we concern ourselves with how it acts to cutting forces. For metals such as ductile alloys of aluminum, we study shear zone creation and risk of built-up edges to optimize CNC lathe parameters. For composite or otherwise hard material types such as composites, we study fracture mechanics and thermal stability to justify a CNC mill strategy.

Implementing the Match Logic

We utilize our material-equipment compatibility database, where material properties such as tensile strength, thermal conductivity, and abrasiveness are correlated against quantified machine outcomes. This is immediately applicable to the decision to use lathe or mill, and determine parameters such as lathe speed for stainless steel to mitigate work hardening, or milling climb and conventional milling for carbon fiber to guarantee the edges are clean.

Validating Through Prototype Testing

Prior to our actual process of full-scale production, we implement a test of the shortlisted equipment. If, for example, the workpiece material is titanium, then an appropriate test would consist of evaluating the surface quality and tool wear characteristics of both a high-precision lathe and mill. This step validates our earlier prediction and finalizes the selection of appropriate machines for efficient CNC machining of the material batch.

Our method, we explain below, eliminates the problem – material machine mismatch – with our proprietary, data-validated method. We describe below how we analyze, correlate, and validate the characteristics of the transforming material into machine-controlled inputs useful for precision machining. We believe this level of technical detail reinforces our position as the authority on delivering high-value, intricate machining projects.

Under What Circumstances Do Complex Parts Require Turning And Milling Combined Machining?

Determining when the complex component requires multi-axis CNC machining versus when separate machining operations are called for is critical to the efficiency of the system. This document identifies specific technological scenarios wherein the operations provide critical advantages, primarily due to the elimination of multiple setups. There are quantifiable gains of accuracy and efficiency on components of significant value:

Technical Scenario Analysis: Geometric Complexity

- Assessment Criteria: We assess part geometry with respect to coexisting critical features.

- Our Method: We identify parts combining CNC turning precision elements (e.g., bores, diameters) with CNC milling capability demands (e.g., flats, contours, off-center holes).

- Problem Solved: This analysis avoids the inefficiency and error pileup in the process that might result if the machinings were performed on separate lathe and mill.

Implementation of Single-Setup Strategy

- Core Action: We program and execute all operations in one chucking on the turn-mill center.

- Our Process: The part is produced via synchronized turning and milling tools.

- Result Achieved: This eliminates baseline and repositioning errors, directly reducing cumulative tolerances from 0.05mm to 0.015mm.

Validation and Efficiency Benchmarking

- Performance Measurement: We determine the benefits achieved with the help of the cycle time analysis/verification using CMM.

- Our Verification: We will compare our single machine's cycle time with a traditional multi-machine routing example to validate our predicted 60% efficiency increase.

- Final Outcome: Customer recieves completed part, knowledge of accuracy of precision machining metrics attained.

We address the challenge of integration by applying a strict geometric and tolerance-based decision framework. We show technical depth in how we analyze, program, and validate the production of turn-mill center by presenting a clear case for how to unlock superior accuracy and efficiency in competitive CNC machining projects.

How Does Equipment Selection Affect Project Delivery Timelines And Supply Chain Resilience?

This is influenced by the choice of the machinery, which, in turn affects the process on the lead time vulnerability within the CNC machining supply chain. While the 3 to 5 days could well be sufficient to accomplish the needed task for the more basic machinery like the CNC lathe or mill, the intricacies involved in some cases require time and can take up to 7 to 10 days, which may become a challenge. However, with the overall cluster of machinery and the help of the science of the process, it is possible to achieve the needed results within the required time as follows.

Strategic Equipment Clustering for Flow

Our floor is typically set up not around individual machines but rather clusters of those machines. In other words, placing CNC lathe capacity next to our milling stations and turn-mill centers. This is in an effort to eliminate delay time associated with queueing when a part needs to have several processes applied to it. A shaft can move meters, not minutes, as it's being converted from a bar stock in preparation for its keyway machining and turning processes.

Dynamic Scheduling & Process Compression

We have a patented scheduling algorithm to assigned jobs in a most effective way considering the live status of the component in a machine shop and its geometry as well. We have optimized the entire operation wherever possible and done a combined operation in a machine shop, which can be done in a multi-tasking machine. Thus, non-cut time has been minimized by over 60%. Further, in case of a critical project, it can be routed in a shortest possible time, i.e., within 24 hours in a most effective way.

Proactive Supply Chain Integration

This expands our upstream visibility and control by leveraging the equipment status of our primary material supplier. Having awareness of our CNC machining schedule and availability also gives us just-in-time material procurement. This leverages the raw materials we have stored on-site to make up our supply chain, taking our business out of the mercy of the supply chain and making sure the machine shop does not become unproductive due to supply chain issues.

The challenges of lead time and resilience can be met by engineering clusters of interconnected equipment, smart dynamic scheduling, and pro-activeness in supply chaining. This presents how we can achieve not only smart machines like CNC lathe and mill but achieve a state of technical certainty in terms of time in competitive high-value activities.

Figure 4: Selecting the right CNC machining process for production by LS Manufacturing

LS Manufacturing Aerospace Division: Optimization Of Engine Mount Machining Solutions

The case discusses how the experience of LS Manufacturing has been able to handle the key machining bottleneck for the aerospace industry with respect to machining the titanium engine bracket. Faced with unsustainable costs and lead times from conventional milling, we deployed advanced CNC machining and integrated turn-mill process innovation to deliver breakthrough efficiency and precision:

Client Challenge

The difficulty the client was experiencing revolved around machining of the Ti-6Al-4V material, specifically an engine mounting bracket. This process had consumed 4 hours of processing time in creating a single part of the product using the CNC milling process. This had increased the time of creating the product, thereby increasing the cost factor by 40%. This had affected the chances of successful rollout of the consignment at hand. The product required precise machining since its measurement of critical pilot diameters stands at 50mm ±0.01mm and the precise positioning of its faces at ±0.02mm.

LS Manufacturing Solution

Using our quick analysis replication method, whichs RAP stands for, we immediately understood that the pilot diameters, the feature, was related to the rotary nature of the piece, hence making the operation best performed on the high speed CNC turning on the lathe. Although this, we have managed to redesign the operation that first entails the turning all diameters on one chucking operation on a turn-mill center. Second, we have designed the operation that the intricate machining on the 5-axis machine will be performed, again on the same chucking position. Far fewer setups!

Results and Value

Cycle time dropped by 70%. New levels were set at 1.2 hours per part. Of course, there were some efficiencies in terms of costs, where the total cost dropped by 35%. More significantly, though, there were improvements in terms of positional accuracy, specifically in mounting face, where it was raised to 0.008mm. And of course, there was savings of 1.2 million RMB, allowing the production of the client to be expedited.

Yet again, our tech savoir-faire/familiarity may be evidenced in terms of breaking down the elementary part to be combined in a way which facilitates the hybridization of said process. Increased speeds, cost savings, and raised tolerances of the components of aerospace-grade CNC machining materials may be realized to the extent that turn-mill synergy may be of use to us.

Discover the power of turn-mill solutions for your aerospace machining.

How Can I Obtain Expert Advice On Equipment Selection And Accurate Machining Quotes?

As has already been mentioned, in order for us to speak of the success of our project with regards to acquiring suitable project results, it is imperative for us to acquire a scientific CNC machining quote. As has already been mentioned, this document has sought to throw light on how it is possible for us to acquire a most appropriate CNC machining plan from your part specification, as well as acquiring a clear and certain prediction with regards to costs:

Structured Data Intake for Foundational Clarity

- Submission Portal: We assist the client in the submission of the comprehensive package through the submission portal.

- Required Inputs: This includes 3D model (step/iges), material spec, critical GD & T callouts, batch volumes.

- Problem Solved: It eliminates the guessworks that are the bases of all the further work done, including the CNC machining development.

Technical Analysis and Process Simulation

- Dual-Analysis Method: Our team of engineers carries out a two-part analysis on the data submitted.

- Feature-Based Strategy: We would start by breaking down the part to map each of these features to an optimal process; for example, a CNC lathe vs CNC mill.

- Virtual Simulation: We digitally simulate setups and toolpaths in a virtual environment to verify that the cycle time works and lathe and mill compatibility, addressing issues before they happen in real life.

Customized Solution Tiers and Transparent Quoting

- Tiered Proposal: We do a tiered recommendation, from standard to optimized with clear cost benefit breakdown.

- Clear Rationale: Every proposal includes the equipment selection logic, justifying the recommended machine shop approach.

- Final Deliverable: The output is a fixed, line-item quote and a documented machining plan, within 2 hours, which allows for fast, informed decisions.

We’re able to give you scientific recommendations through the application of a gated analysis of your data, which we use to find out the best machine shop approach. This is not an estimate, but rather a fixed-cost plan, as we’re able to achieve this through simulated technology. This is an illustration of our depth as a firm.

Future Processing Tech Trends And Their Impact On Equipment Selection

Given the tremendous pace of evolution that allows for a new class of highly sophisticated CNC machining technologies, a new strategy is needed with respect to equipment selection. This is precisely addressed through the solutions provided by LS Manufacturing, which possess the expertise required in successfully tackling the convergence of precision, intelligence, and system solutions as it relates to machining centers:

Mastering Multi-Axis Synchronization for Monolithic Components

Complicated fact related to the complex CNC machining is that the precision level has to be within the micron level. Another complicated fact related to the machining process, if more than one direction of the machine moves, the precision within the micron level has to be considered. As discussed, the above problem is avoided by our own servo tune model. Another feature, which has to be considered, is tool loads, like the cutting process related to the turbine casing, this feature has to be considered, eliminating the vibration, resulting in the machine, which is related to the turn-mill center.

Implementing Adaptive Intelligence for Unmanned Production

In order to design the lights out machining, we first need to develop the autonomy, the answer to the question that will include the constant quality problem, as explained above. For instance, when we notice the signs of damage on one machine in our milling machine, the answer to the question will include the solution to the described above, and therefore, this will define our smart production line.

Engineering Seamless Process Integration via Digital Twins

Isolated lathe and mill machine work can create bottlenecks; therefore, our answer is to provide a digital thread of integration using a virtual twin of the total machine cell. This allows for simulation and optimization of work processes before actual implementation, eliminating integration problems and possible collision issues associated with multi-tasking operation of a CNC mill-turn machine.

Enabling Agile Reconfiguration with Modular Platform Design

One of the biggest challenges these days remains the rapid changeover of products. Our platforms apply standardized interfaces and open-control architectures. This is directly offering production agility needs where customers can take a CNC machining cell from a primary turning station to a mill-turn system in just hours by merely changing out modular units.

This presentation presents a course for solving hardcore engineering problems, all the way from algorithmic control to system integration. This is the depth of executable technical solutions using trends to turn them into reliable, operational reality-our competitive edge. We are the only ones offering a solution that guarantees complex manufacturing constraints.

FAQs

1. For simple shaft parts, is it more economical to use a lathe or a milling machine?

For shaft parts where the length to diameter >2, it is recommended to use a lathe, which offers 40% greater efficiency than a milling machine. For turning, LS Manufacturing's precision reaches an accuracy of ±0.005mm.

2. How to determine if a part requires combined turning and milling?

If a part contains a combination of both rotating elements and complicated surface configurations, it becomes possible to achieve a 0.015 mm accuracy with a mere single setup with a 60% increased efficiency.

3. Which equipment is more cost-effective for small-batch complex parts?

For complex components where the batch quantity is less than 50 pieces, a milling machine should be chosen to avoid investing specially designed tooling for lathes. LS Manufacturing helps in cost-effective milling operations.

4. How much does equipment selection affect machining accuracy?

Scientific selection selection accuracy may be improved by 50%, up to 0.003mm in terms of lathe roundness, and 0.01mm position accuracy milling machine. The accuracy level varies depending on part properties.

5. Which equipment is more suitable for difficult-to-machine materials?

LS Manufacturing has a professional tooling and process database. For composite material such as hardened steel, which is difficult to mill, it is preferred to use a milling machine.

6. How to obtain personalized equipment selection advice?

Please send us part drawings and requirements, and our LS Manufacturing engineers will perform a scientific selection analysis and provide an exact quotation in 2 hours.

7. How to choose the fastest equipment solution for urgent orders?

Choose standard material based on the characteristics of the parts. LS Manufacturing offers 24 hour delivery on urgent orders.

8. How to optimize equipment selection to reduce costs in large-scale production?

Professional selection for batch sizes >500 pieces can cut unit cost by 25 to 35%. LS Manufacturing has large-scale production optimizing solutions.

Summary

By using scientific equipment selection, taking into consideration the characteristics of parts, batch size, and accuracy requirements of workpieces, the most appropriate compromise of quality, efficiency, and machine tools costs can be realized. The highly developed scientific system and substantial experience of LS Manufacturing in project handling provide the best solutions for its clients.

To get scientific advice in selecting scientific machine equipment or precise quotations from machining companies, just feel free to contact LS Manufacturing now! Upload the drawings now to get professional analysis and optimization advice directly. And if more complicated machining requirements require more in-depth talks, we are glad to arrange a live one-on-one conversation with senior experts at your own convenient time. Just click here now to upload your drawings and receive your dedicated machining advice!

Get your expert guide to choosing the right CNC service between lathe and milling for your project!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.