CNC Machining Services: The Guide To Choosing Between Lathe And Mill For Your Project

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.What Are The Core Differences In Principle And Motion Between Lathes And Milling Machines? 3.How To Select Equipment Based On Part Geometry? 4.How Significant Is The Impact Of Equipment Selection On Costs At Different Batch Sizes? 5.What Are The Technical Advantages Of Turning And Milling In Terms Of Precision Control? 6.How To Evaluate The Impact Of Material Properties On Equipment Selection? 7.Under What Circumstances Do Complex Parts Require Turning And Milling Combined Machining? 8.How Does Equipment Selection Affect Project Delivery Timelines And Supply Chain Resilience? 9.LS Manufacturing Aerospace Division: Optimization Of Engine Mount Machining Solutions 10.How Can I Obtain Expert Advice On Equipment Selection And Accurate Machining Quotes? 11.Future Processing Tech Trends And Their Impact On Equipment Selection 12.FAQs 13.Summary 14.Disclaimer 15.LS Manufacturing Team

Gloria

Gloria

CNC Machining Services: A Guide To Drilling Tools Dor Precision, Efficiency, And Cost-Effectiveness

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.How To Choose The Most Suitable CNC Drilling Tool For Your Workpiece Material? 3.How To Set And Optimize The Core Technical Parameters For Precision Drilling? 4.How To Maximize Cost-Effectiveness Through Tool Management And Strategies? 5.Root Causes Of Five Common Drilling Defects And LS Manufacturing's Immediate Solutions 6.How To Choose The Most Reliable CNC Drilling Service Provider For Your Project? 7.LS Manufacturing Practical Case Study: Deep Hole Machining Of Inconel 718 Engine Casing In The Aerospace Industry 8.What Key Information Is Needed To Obtain An Accurate CNC Drilling Quote? 9.FAQs 10.Summary 11.Disclaimer 12.LS Manufacturing Team

Gloria

Gloria

CNC Machining Services: A Guide To Precision Drilling, Tool Selection, And Cost-Effective Production

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.How Can Precision CNC Drilling Services Achieve Hole Position Accuracy Control Of ±0.005mm? 3.CNC Tool Selection Guide: How To Choose The Optimal Drill Bit Based On Material Properties? 4.How Can CNC Drilling Services Improve Efficiency by 40% through parameter optimization? 5.How To Control Per-hole Cost And Ensure Quality In Precision Drilling? 6.What Are The Key Technologies And Solutions For Deep Hole Drilling? 7.How To Evaluate The Technical Strength And Service Capabilities Of A CNC Drilling Supplier? 8.What Are The Common Quality Defects And Preventive Measures In Precision Drilling? 9.What Are The Main Components And Optimization Strategies For Online CNC Drilling Quotes? 10.LS Manufacturing Aerospace Field: Precision Hole Machining Project For Engine Housings 11.Future Trends And Innovations In Precision Drilling Technology 12.FAQs 13.Summary 14.Disclaimer 15.LS Manufacturing Team

Gloria

Gloria

Online CNC Machining Services: Precision Hole Making From Drill Components To Results

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.How Can Online CNC Machining Services Achieve Stable Control Of Drilling Accuracy Of ±0.01mm? 3.What Are The Key Impacts Of Drill Bit Selection On Machining Quality In Precision Drilling? 4.How Can Online Drilling Improve Efficiency By 40% Via Parameter Optimization? 5.How To Prevent Excessive Burrs And Wall Roughness In CNC Drilling? 6.How To Select The Optimal Drilling Process Based On Material Properties? 7.What Are The Main Factors That Constitute An Online CNC Drilling Quote? 8.What Special Technical Guarantees Are Required For Deep Hole Drilling? 9.How To Evaluate The Technical Strength And Service Capabilities Of A CNC Drilling Supplier? 10.LS Manufacturing Aerospace: Precision Hole Machining Project For Engine Mounts 11.Future Development Trends And Innovation Directions Of Precision Drilling Technology 12.FAQs 13.Summary 14.Disclaimer 15.LS Manufacturing Team

Gloria

Gloria

Custom CNC Machining Services: Precision Metal Cutting For Maximum Efficiency & Value

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.How Can Customized CNC Machining Achieve 30% Cost-Efficiency Through Process Optimization? 3.How To Ensure Micron-Level Precision Stability In CNC Machining? 4.What Are Key Technical Sspects Of Metal CNC Machining For Diverse Materials? 5.How Can Cost Optimization Be Achieved For CNC Machined Parts Through Scientific DFM Analysis? 6.How To Select A Reliable CNC Machining Supplier To Ensure Project Success? 7.How To Control Deformation In Precision Metal Cutting Of Thin-Walled Parts? 8.What Are The Components And Optimization Strategies For CNC Machining Quotes? 9.How Can High-Volume CNC Machining Achieve Efficiency Breakthroughs Through Automation? 10.LS Manufacturing New Energy Vehicle Industry: Precision Machining Project For Motor Housings 11.Future Development Trends And Innovation Directions Of CNC Machining Technology 12.FAQs 13.Summary 14.Disclaimer 15.LS Manufacturing Team

Gloria

Gloria

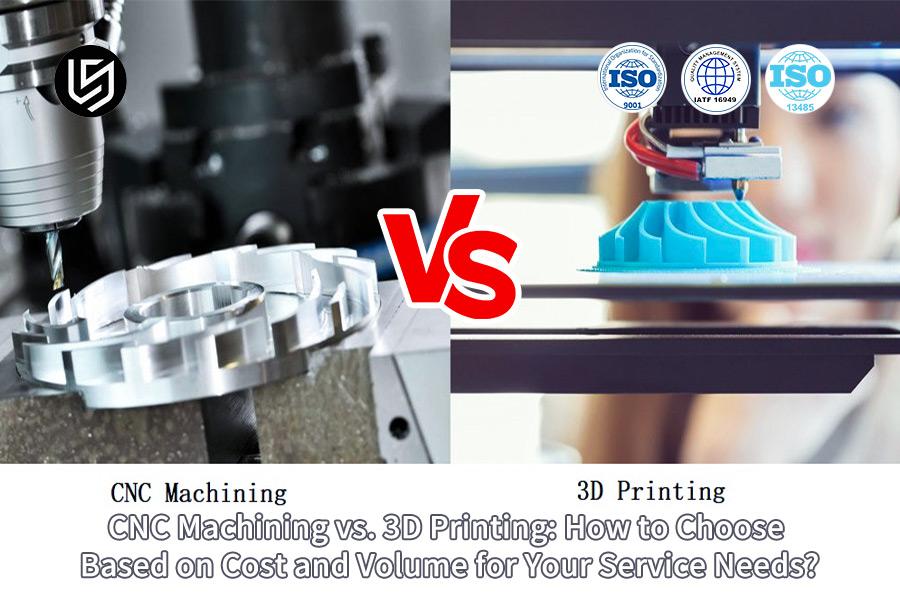

CNC Machining VS. 3D Printing: How To Choose Based On Cost And Volume For Your Service Needs?

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.What Are The Cost Structure Differences Between CNC And 3D Printing? 3.How To Scientifically Select The Optimal Manufacturing Process Based On Batch Size? 4.How Can The Cost-Effectiveness Of Different Materials In The Two Processes Be Quantitatively Compared? 5.How Does Part Complexity Affect The Economics Of Process Selection? 6.What Are The Key Impacts Of Accuracy Requirements On Process Selection? 7.How Should Process Selection Be Optimized When Delivery Deadlines Are Tight? 8.How To Balance Cost And Performance Via Hybrid Manufacturing? 9.How To Control Costs Through Process Optimization In Small-Batch Production? 10.LS Manufacturing: Optimizing Surgical Navigation Stent Production 11.How To Establish A Scientific Manufacturing Process Decision-Making Process? 12.FAQs 13.Summary 14.Disclaimer 15.LS Manufacturing Team

Gloria

Gloria

CNC Machining Services: A Technical Guide To Custom Reamer Tools And Precision Hole Finishing

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.What Are The Advantages Of Custom Reamers Compared To Standard Reamers? 3.How To Select The Optimal Reamer Type And Geometric Parameters Based On Material Properties? 4.How To Ensure Stable Hole Diameter Accuracy And Surface Quality During CNC Reaming? 5.Comparative Analysis Of Feasibility Of Hole Finishing Processes? 6.How Can Tool Geometry Optimization Address Machining Challenges For Specific Materials? 7.What Special Process Control Measures Are Required For High-Precision Reaming? 8.How Can The Cost-Effectiveness Of Custom-Made Reamers Be Quantitatively Evaluated? 9.How To Evaluate A CNC Machining Supplier's Precision Hole Machining Capabilities? 10.LS Manufacturing Medical Device Industry: Precision Hole Machining Project For Joint Implants 11.Future Development Trends And Innovation Directions In Precision Hole Machining Technology 12.FAQs 13.Summary 14.Disclaimer 15.LS Manufacturing Team

Gloria

Gloria

Selecting Gear Machining Services: A Guide To Applications, Technical Fit, And Accurate Pricing

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.How Do Industry-Specific Gear Applications Dictate Manufacturing Requirements? 3.How To Evaluate The Core Technical Capabilities Of A Gear Manufacturing Service Provider? 4.What Are The Key Technical Indicators That Need To Be Met For High-Precision Gear Manufacturing? 5.How Do Customized Gear Solutions Meet The Requirements Of Specific Operating Conditions? 6.How To Build An Accurate Pricing Model For Gear Machining? 7.What Key Factors Should Be Considered When Evaluating Gear Manufacturing Service Providers? 8.What Are The Key Differences In The Manufacturing Processes For Gears Made Of Different Materials? 9.How To Ensure Consistent Quality In Large-Scale Gear Manufacturing? 10.LS Manufacturing Robotics Industry: Precision Gear Reducer Customization Project 11.How To Establish Long-Term Partnerships In Gear Manufacturing? 12.FAQs 13.Summary 14.Disclaimer 15.LS Manufacturing Team

Gloria

Gloria

CNC Machining Services: A Titanium vs. Tungsten Comparison for Performance and Cost

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.What Are The Core Differences Between Titanium Alloys And Tungsten Alloys In CNC Machining? 3.How To Choose Between Titanium And Tungsten For CNC Machining? 4.How Can CNC Machining Balance The Cost Of Titanium And Tungsten? 5.How Do The Key Performance Parameters Of Titanium And Tungsten Materials Affect Part Design? 6.What Special Process Technologies Are Required For CNC Machining Of Tungsten Alloys? 7.How To Overcome The Work Hardening Problem In Titanium Alloy CNC Machining? 8.How To Schieve The Optimal Cost-Performance Ratio When Selecting Titanium-Tungsten Materials? 9.What Key Cost Factors Need To Be Considered When Selecting Materials For CNC Machining? 10.LS Manufacturing Aerospace Division: Engine Turbine Blade Material Optimization Project 11.Analysis Of Application Trends Of Advanced Materials In High-End Manufacturing 12.FAQs 13.Summary 14.Disclaimer 15.LS Manufacturing Team

Gloria

Gloria

Online CNC Machining Services: A Supplier Guide From Instant Quote To Fast Delivery

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.How To Identify Truly Efficient Online CNC Machining Services? 3.How Does An Online Real-Time Quotation System Reflect A Supplier's Processing Capabilities? 4.In Order To Achieve Rapid Delivery, In Which Process Steps Should Suppliers Optimize? 5.How To Ensure The Quality Control Of Precision Parts In An Online Collaboration Mode? 6.How Does LS Manufacturing Customize High-Precision Titanium Alloy Brackets For Aerospace Customers? 7.What Key Points Should Be Considered When Comparing The Core Capabilities Of Online CNC Machining Service Providers? 8.What Are The Different Considerations Between Online CNC Prototyping And Mass Production? 9.FAQs 10.Summary 11.Disclaimer 12.LS Manufacturing Team

Gloria

Gloria

DFM For CNC Machining: A Cost-Saving Guide To Design Optimization And Supplier Collaboration

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.Why Is DFM The Most Effective Way To Reduce CNC Machining Costs? 3.How To Perform Manufacturability Design Analysis For CNC Parts? 4.What Common DFM Errors Can Lead To Increased CNC Machining Costs? 5.How To Improve CNC Machining Efficiency Through Design Simplification? 6.How Does Tolerance Design Affect CNC Machining Costs And Quality? 7.How Can Material Selection Achieve Cost Optimization Through DFM Analysis? 8.How Can Early Supplier Involvement Improve The Effectiveness Of DFM Implementation? 9.LS Manufacturing Medical Device Industry: DFM Optimization Of Titanium Alloy Components For Orthopedic Implants 10.How To Establish An Effective DFM Collaboration Process With Suppliers? 11.FAQs 12.Disclaimer 13.LS Manufacturing Team

Gloria

Gloria

CNC Machining Applications: Industry Case Studies And Custom Solutions

1.Why Trust This Guide? Practical Experience From LS Manufacturing Experts 2.How Does CNC Machining Achieve A Perfect Balance Between Lightweight And High Strength In The Aerospace Field? 3.How Can The Automotive Industry Meet Electrification Demands With CNC Precision? 4.What Special Biocompatibility Requirements Does Medical Device manufacturing impose on CNC machining? 5.How Can Electronic Devices Achieve Miniaturization With Precision Machining? 6.What Are The Unique Challenges In Processing Large Structural Components In Energy Equipment Manufacturing? 7.How Can Industrial Robots Improve Motion Accuracy Through Precision Machining? 8.LS Manufacturing Aerospace Field: Precision Machining Of Titanium Alloy Brackets For Satellites 9.Why Choose LS Manufacturing As Your Industry-Specific CNC Machining Partner? 10.How Do I Get Started On My Industry-Specific Processing Project And Get Customized Solutions? 11.FAQs 12.Summary 13.Disclaimer 14.LS Manufacturing Team

Gloria

Gloria