When Designs Go Beyond the Limits of Desktop Printers

Your carefully designed 1:1 car bumper, custom furniture component, or large architectural model is amazing, but it suddenly hits the cold reality:it is too big for your desktop printer. The excitement is immediately extinguished, replaced by a "cutting and splicing nightmare".

In order to print, you are forced to cut the complete model into dozens of small pieces. Then comes the long, error-prone gluing process. The result? The finished product is oftenstructurally fragileandfull of ugly seams, far from thesolid, one-piece workyou ideally wanted. Precious time is wasted on post-processing, and the integrity and strength of the work are greatly compromised.

But you can skip all this!There is a way to directly print your "giant" designcompletely, in one go, and get a truly solid, seamless finished product.

This is not fantasy, but the reality oflarge-scale industrial-grade3D printing services. With giant printing cabins and industrial-grade technology that far exceed desktop equipment, they are born to solve such "big" problems.

So, whichlarge 3D printingcompaniescan provide this "one-step" ability to print super-large, solid finished products? How to find the best partner for your project? This article will sort out the service providers worth paying attention to at home and abroad, helping you to easily turn your grand design into a complete masterpiece in reality.

Summary Of Key Roles In Large-Scale 3D Printing

| Company Type | Their Role | When would you engage with them? | Typical Representatives |

|---|---|---|---|

| Equipment Manufacturers | Create and sell large-scale 3D printers | When you want to purchase equipment, build or expand your own large-scale printing factory/capacity | Modix, BigRep, Massivit 3D, Builder 3D |

| Service Providers | Own and operate large-scale industrial 3D printers and provide on-demand printing services | When you need to outsource the printing of a large 3D printed part and do not want to invest in equipment yourself | LS, Xometry, Protolabs, Craftcloud |

This guide will first clarifywhatlarge-scale 3D printingis, and then take a deep dive into the two major players in this field: equipment manufacturers and service providers. We will use a real case to show how we printed a full-scalecar prototype, and finally teach you how to choose the best partner for you.

Here’s What You’ll Learn:

- Clearly define the boundaries of “big”:A practical size and application standard to help you quickly determine whether your project belongs to the category of “large-scale3D printing”.

- Identify the core player camp:Distinguish between technology founders (equipment manufacturers) and creative implementers (service providers), and accurately identify who is the key partner for your project.

- Master the mainstream “big Mac” technology:Understand the core technologies that drive large-scale printing (such aslarge-scale FDM, SLA, GDP, etc.) and their applicable scenarios.

- Insight into the market leader landscape:Get to know representative companies in the fields of large-scale equipment manufacturing (such as BigRep, Modix, Massivit) and professional printing services (such asLS,Xometry).

- From theory to practice:Througha real car bumper prototype case, reveal how large-scale integratedFDM printingsubverts traditional manufacturing, achieves 7-day delivery and 70% cost savings.

- Solve key decision-making problems:Authoritative answers to common questions (FAQs) such as "Who is the market leader?", "How to choose a service provider?", and "What is the price structure of large-scale printing?".

- Start your ambitious project:Learn how to take the first easy step to turn your big design ideas into a tangible reality.

Now, let’s take a closer look at the vast world of large-scale 3D printing, understand the landscape, and find the ideal partner for your project.

Why Should You Trust This Guide? Practical Experience From LS Large Format Printing Center

Hello everyone, I am Gloria, and I have been an engineer at the LS Large Dimension Printing Center for fifteen years. Every word in this guide can be said to be earned by our team's sweat and even the occasional "tuition" of scrap piles. Why should we believe it? Because "large size" has never been a beautiful picture in a brochure for us, but a hard bone to chew every day in the workshop.

Imagine:when you stand facing a section as tall as a human, it is no longer just a computer model. It is a realphysical challenge.What I'm concerned about on a daily basis is: "How to prevent this more than 1 meter long thing from warp like a potato chip after printing and cooling?" (warp control), "This suspended structure, besides the weight of the material, will it collapse during the printing?" (Structural design load-bearing), "It's hard to print, such a big fellow, how to package it to make sure that it is safe and intact to the customer, instead of crumbling on the road?" (Safe packaging and transportation).These are "big" ones which are seldom encountered insmall-size printing.

I'll give you an example.Last year, we printed a1:1 scale wing leading edgesection for an aviation customer for wind tunnel testing. The model was constructed on our Modix Big-60 V3, which was nearly 2 meters in size. This was not just a model, it had to withstand actual airflow loads, and had extremely strict requirements on surface accuracy and structural strength. The entire printing process lasted more than 120 hours. During the five nights and days, my team and I traded gawking at the monitor screen. Why? For at hour 78, we discovered an extremely tiny thermal expansion anomaly along the Z axis, and trimmed the temperature control parameters just in time to avoid disastrous interlayer separation.Large-scale printing, however, can ruin tens of thousands of dollars of materials and hundreds of hours of machine time at once due to a small mistake, such as a few degrees of temperature deviation. A little bad filling structure design or the lack of support would be enough.Neither is this pressure and responsibility easy for those who have never worked on large-scale projects to thoroughly understand.

This guide is the result of the basic knowledge and hard-earned experiencewe have learned after going through the experience of overcoming countless such "giant" challenges and having endured tens of thousands of hours worth of experience in large-scale printing.

It's not a theoretical conclusion, but the essence of real workshops, real machines, real breakdowns and successful practices. We share it in hopes that you can benefit from the detours we've taken and tackle thechallenges of large-scale 3D printingmore boldly.

So use this handbook on faith, for behind it are the very roars in theLS factory, the late-night arguments of engineers, and the phenomenal giant creations that did stand up successfully in the end.

Defining The Playing Field: What Is "Large-scale 3D Printing" Exactly?

"Before we discuss who is the leader, we first have to normalize the standard: how large is 'large'?" Friends, this is where we can't help but diverge when we enter the domain ofbig-scale 3D printing. When we speak of "large scale", it's not just the magnification of physical size, it also refers to the leap in capability, use cases and value. Now, let me bring you to explain this significant concept.

Before we move to the specifics, let us first learn about thebasic definition levels of large-scale 3D printingthrough this table:

| Definition Dimension | Core Standards and Features | Typical Examples and Application Scenarios |

|---|---|---|

| Dimensional Definition | Breaking through conventional limitations: Single-side dimensions are usually >300mm (about 1 foot), far exceeding the one-time molding capabilities of desktop/standard industrial machines. Giant: In meters. | Car bumpers, large sculpture bases, architectural component models, hull sections |

| Application Definition | Beyond Prototype: Meet 1:1 functional verification, direct manufacturing tools, and production of end-use parts. Value Driven: Solve the pain points of traditional manufacturing in small batches, customization, and complex structures. | 1:1 car panel prototypes, aircraft interior fixtures, customized yacht hulls, large art installations |

| Mainstream Technology | Adapting to large sizes: The technology itself or after modification can efficiently and stably handle large-volume printing. Cost and speed balance: Seek the economy and feasibility of large-scale production. | FDM/FFF (king of cost-effectiveness), SLA (high-precision surface), unique technologies such as gel dispensing printing (GDP - extremely fast large-size hollow parts) |

Now, let's discuss each of these dimensions in detail:

Defining large-scale 3D printing in terms of size

- Baseline rule:Printing objectswith a single-side dimension over 300 mm (approximately 1 foot) and which cannot be fully formed in a single pass by conventional desktop and most professional-level printers is within the realm of large-scale 3D printing. This is an operational dividing point, where the printing need exceeds the default capability of common equipment.

- "Giant" field:Real "giant" printing is in meters, e.g., multi-meter-long car components, same-height statues, building-part or mold-scale architecture. This scale stretches the physical limits of the printer and demands extremely high standards for materials handling, structure, print time (potentially from days to weeks) and post-processing. Size is the easiest fundamental dimension to define "large-scale".

Defining large-scale 3D printing by use

Big-size 3D printingis not simply "printing large objects", but addressing the pain points of traditional manufacturing and achieving elusive goals. It excels in three areas:

- 1:1 prototype validation:In industries such asautomobiles, furniture, and consumer electronics, big-size 3D printing is applied to quickly and economically produce 1:1 functional or appearance prototypes for accelerating product development.

- Direct manufacturing of production tools:

It is used in industry to create large fixtures, fixtures, and molds that reduce the lead time and cost of traditional metal processing and increase design freedom. - Manufacturing of end-use parts:

It is the advent of age of mass3D printing technology, which is utilized for the manufacture of small batches of highly customized final-product parts, e.g., yacht parts, drone enclosure, etc. They are not easy to manufacture economically or at low cost with conventional manufacturing.

Mainstream large-scale printing technologies

Technology adaptation scale:Not all 3D printing technologies are suitable for mass production. The following are the mainstream ones:

FDM/FFF (fused deposition modeling):

The most accessible and low-cost technology for bulk printing. Thermoplastic filaments are deposited layer-by-layer, with low material and equipment expenses, wide material accessibility, and mature and stable processes. Although layer patterns exist and post-processing is high, it is perfect for bulk tooling, prototypes, and the majority of end parts. The bulkFDM systemsdominate the market.

SLA/DLP (photocuring - stereolithography/digital light processing):

SLA technology will manifest its merits when high accuracy, smooth surface and fine appearance are required for large models. Liquid photosensitive resin is used in UV curing molding, and surface finish and detail resolution better than FDM. It can be used on large display models, precision prototypes and some final parts. Yet, huge SLA machinery is expensive, materials available are limited and of high cost are required, secondary curing and washing post-printing must be done. Mechanical properties and long-term stability in resin parts are inferior to thermoplastics.

Innovative technologies:To address the needs of large-format printing, proprietary innovative technologies have recently been designed to meet its demands, including Massivit3D's GDP technology. Printing using specially light-cured gel-like materials, gigantic-sized print heads are extruded and stacked at high speed, high speeds of printing, and can directly print gigantic hollow structures with material and time savings. Though the material selection is single, it has distinct advantages in forming super-large visual mockups, props and light-weight structures quickly.

Thus, friends, when we refer to "large-scale 3D printing", we're talking about a sector that cuts across size breakthroughs, high-value uses and focused technical assistance. Not only "big", but also "strong" - able to produce 1:1 working models, replace expensive conventional tooling, and produce bespoke products on-demand. It is only by combining this definition that we can see who has dominance on more than one axis. This war has hardly begun.

Market Leaders Map: Meet The Industry Leaders

"To gain a good overview of the competitive landscape in the large-scale3D printing field, the key is to distinguish between the 'people who make guns' (equipment vendors) and the 'people who use guns' (service providers). The former offers the basis of technology, while the latter translates technology into actual value."

Quick reference table of large-scale 3D printing market core camps:

| Camp | Core role | Representative company (example) | Key advantages/features | Main market positioning |

|---|---|---|---|---|

| Equipment manufacturer | Technology founder | Modix | Cost-effective, modular, self-assembled large-scale FDM kit | Makers, education, small and medium-sized studios |

| Research and development and sales of large-scale 3D printing equipment | BigRep | Industrial-grade large-scale FDM reliability, German engineering quality | Industrial manufacturing,automobiles, aerospace prototypes | |

| Massivit 3D Printing Technologies Ltd | Proprietary GDP technology, ultra-high-speed printing, large-size single-piece output | Advertising, entertainment, large-scale displays, concept prototypes | ||

| Builder 3D | Industrial-grade FDM, highly customizable, emphasizing reliability and high-quality output | Professional industrial applications, customized needs | ||

| (Others: CEAD, Thermwood) | Large-scale composite material printing, five-axis machining integration, etc. | High-end industrial, aerospace composite materials | ||

| Service provider | Idea implementer | LS | Large-scale equipment capabilities + full-process engineering support (file repair, material consultation, post-processing) | Customization, high complexity, engineering-level needs |

| Operate large-scale equipment to provide printing services | Xometry, Protolabs, Hubs | A large manufacturing network integration, one-stop manufacturing platform, economies of scale | A wide range of industries, rapid manufacturing of standard parts | |

| Craftcloud | A price comparison platform that aggregates quotes from multiple service providers | Price-sensitive projects, simple inquiries |

Camp 1: Technology pioneers - makers of equipment

Main role:Equipment manufacturers are the pioneers ofhuge 3D printingtechnology. They design, produce and sell industrial orpseudo-industrial machinesthat can print truly enormous objects, and lead innovation in materials, processes and machine capability.

Typical companies:

- Modix:New business model of low-cost, modular large-formatFDM printerkits that customers can assemble themselves, lowering the entry barrier, popular among maker spaces, etc., with advantages of flexibility, scalability and cost control.

- BigRep:An engineering model from Germany and market leader in the industriallarge-scale FDM printing, the machine is particularly known for stability, reliability and well-quality prints. It specializes in providing production or high-demand prototype solutions to the automotive, aerospace and similar industries, emphasizing durability, repeatability and professional services.

- Massivit 3D:With its battery technology and gel dispensing printing (GDP) technology, it established market leadership in a first, with unparalleled printing speed, and can complete quick large single object printing, and leads in advertising signs, entertainment etc.

- Builder 3D:The industrial-grade large-scale FDM printing is its emphasis. The battery and equipment are strong and robust, with high output quality and high customizability to meet special or demanding industrial needs.

Other emphases

- CEAD:Combines large-scale 3D printing technology with five-axis machining and robotics to provide integrated additive manufacturing solutions for composite large structures.

- Thermwood:An experiencedCNC machinetool manufacturer. Its system of large-scale additive manufacturing combines large-scale extrusion printing with five-axis subtractive machining for molds, fixtures, etc.

Industry applicability:Equipment manufacturers are always extending technical limits and providing bare essentials of the enormous3D printing infrastructure. Their innovation determines the limits and scope of service providers' capabilities.

Camp 2: Service Providers - Implementers of Ideas

Core Role:Service providers serve as a bridge for leveraging large-scale 3D printing technology. They invest in and deploy large-scaleindustrial 3D printers,provide on-demand printing services to those who do not have the corresponding capabilities, and make complex technologies convenient services.

Representative companies:

- LS:Specialized3D printing experts, providing end-to-end engineering services for product design, such as document checking, material selection, process optimization, post-processing and engineering consulting. Target customers are those in need of quality, high-complexity customized solutions and value professional partners.

- Large-scale online manufacturing websites (e.g., Xometry, Protolabs, Hubs):"Amazon" of manufacture that integrates global manufacturing networks, providing one-stop on-demand manufacturing, covering a variety of processing and3D print technologies.They are able to respond rapidly to demand at a large scale through economies of scale and smooth processes. Their competences are in simple, rapid and large-scale manufacturing.

- Business-to-business price comparison websites (e.g., Craftcloud):Price comparison websites and aggregators. The site emails out quotations for comparison after models have been uploaded. The nature of the value is to provide price-conscious consumers with elementary needs with transparency and convenience, filling supply ends and demand ends.

Industry relevance:Service providers lower customers' thresholds for using large-scale3D printing facilities, accelerate popularization and innovation of technology, bear the expenses of equipment, and meet diversified demands through professional services and value-added services. LS's deep engineering services, the scale effect of platform companies, and price transparency of comparison platforms collectively form a rich and complementary service ecosystem.

Key difference in one sentence

Equipment suppliers offer "guns" (technical equipment) → Service providers are good at "firing guns" (value realization)

When choosing a partner: if you need technical equipment, go to camp one; if you need finished product services, go to camp two.

Case Study: Producing A 1:1 Scale Bumper Prototype for an Automotive Design Studio

"In the automotive business, a just designed bumper will be up for aggressive appearance inspection and wind tunnel testing before it is shipped off to expensive mold production. A high-fidelity 1:1 mock-up is the key to making the right choice."

Customer's pressing challenge: Full-size, high-strength prototypes, rapid and economical

Our customer is conceptualizing a new SUV and needs a 1:1 physical model of the front bumper (approximately 1.8m x 0.6m x 0.5m) before a high-stakes review session. The model will need to be durable to be put through follow-up low-speed wind tunnel testing for harsh appearance review and aerodynamic verification. The biggest challenge that faces them is:

Traditional techniques (CNC/Fiberglass) are too time-consuming and costly:

It is weeks and tens of thousands of dollars, and not possible to meet the stringent 10-day deadline.

Standard3D printing solutionsare inappropriate:Block printing and splicing will create structural flaws, cannot achieve the strength level necessary for wind tunnel testing, and post-processing is difficult.

LS's engineering solution: large-scale integrated FDM printing

Based on extensive analysis of the customers' requirements, we focused on three key areas: "single structural strength", "overall size" and "fast delivery". Our technical team designed a specific solution:

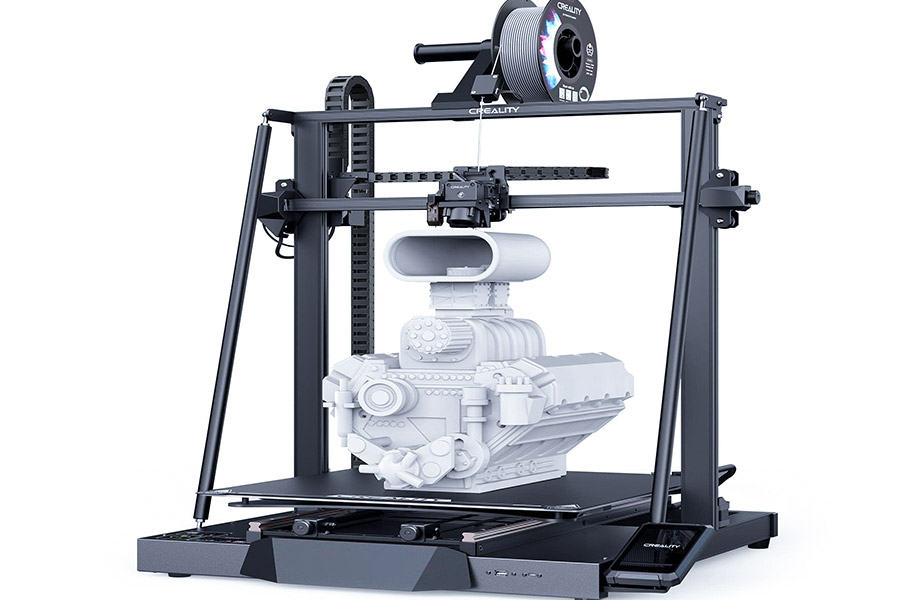

- Equipment advantages:We employed an industrial-grade FDM printer with a super-large molding size (>2 meters) in our workshop to ensure the entire part was printed simultaneously.

- Material Science:

We skillfully suggested and applied ASA material. ASA not only has better mechanical strength comparable to ABS, but its better UV stability and weather resistance make it ideal for appearance review and potential outdoor testing much further than normal PLA or typical ABS. - Precision process:

Printing strategy optimization:Our model was precisely made angle corrections during the slicing step to minimize support structures without compromising molding quality and surface finish of important surfaces (e.g., air inlets and crests).

Integral molding:The entire bumper was printed as a single operation, which consumed about 90 hours to preserve the integrity and inherent strength of the structure.

4.Post-processing Efficiency:Upon printing, we carefully removed the supports and performed necessary lightsurface treatment(e.g., sanding) to meet the customer's original appearance review requirements.

Outcome: Disruptive Efficiency and Cost Savings

With LS's solution, we were able to achieve the following successfully:

- Extremely rapid delivery:Within 7 working days from receipt of data to providing the completed prototype, far more quickly than the usual 3-4 weeks, and with the customer able to keep pace with the principal review.

- Significant cost reduction:The overall cost of the project was reduced by about 70% compared totraditional CNC machining, saving the customer tens of thousands of dollars in R&D expense.

- Fully functional model:

The delivery is one-piece molded, high-strength model which can directly be used for:

Design team conducts real touch testing and appearance inspection.

Test aerodynamic performance using low-speed wind tunnel test.

Customer feedback: Physical model helped them identify two design details difficult to catch in the digital model and made efficient optimizations, which was of great value.

Key Takeaway:

This is a successful example that shows us thatthe value of large-scale 3D printing is far higher than having large machines.The secret lies in theengineering abilityof the service provider - accurately understanding the requirements, scientifically selecting materials (such as ASA), optimizing printing techniques (such as reducing supports and ensuring the quality of crucial surfaces), and finally delivering areliable physical partthat can offer solutions to real-world problems. At LS, we rely on this deep engineering know-how to help clients have breakthroughs and save a great deal of money in tight time frames.

FAQ - Your Recent Questions About Large-scale Print Answered

1. Who are the leaders of the 3D printing market?

The leaders in themarket for 3D printingare not a single company, but are highly fragmented. In industrial polymer printing, Stratasys (as they developed PolyJet technology) and 3D Systems are the traditional giants that hold sway; metal printing is controlled by EOS and GE Additive; and for large-scale printing, the market enjoys a vibrant ecosystem comprising new entrants such as BigRep, Modix and Massivit, and professional service providers. These clients drive industry innovation with leading-edge technologies and customized solutions, reflecting the fragmentation and competitive dynamics of the market.

2. How do I choose a massive scale 3D printing solution provider?

If you are choosing a large-scale 3D printing service provider, you need to pay attention to five important factors in order to make your project a success: Equipment capability comes first, and you should decide whether its maximum print size is suitable for your needs; Material selection is also crucial, and you need to see if they have engineering-grade materials such as high-temperature resistant or high-strength polymers; Case studies can verify the experience of the service provider and judge its reliability through successful cases of similar projects; Engineering support services such as document inspection, optimization guidance and design consultation can improve efficiency and quality; Logistics capabilities cannot be ignored, and you must understand how they package, transport and deliver huge parts to avoid extra risks or expenses, in order to make a comprehensive and intelligent decision.

3. What is the cost of large-scale 3D printing?

The cost of large-scale 3D printing is mainly based on three fundamental parameters: Printing time is the biggest cost factor, since big machines have long operating times and great power expenses; Material usage will indirectly affect costs and needs to be calculated based on part volume and density; Labor and post-processing are involved in operations such as surface grinding, painting or assembly. Also included in the cost is logistics and packaging, which forms a considerable percentage. Owing to the big size of the parts, shipment and protection need to be professionally handled, which can lead to extra charges. To be able to get an estimated quotation, it is advisable to upload your 3D model to the service provider to be able to have a personalized assessment based on certain parameters to have proper budget control.

Summary

Withmassive 3D printing, both "equipment manufacturers" who have expertise in manufacturing equipment and "service providers" who install ideas in practice are precious. To companies that need massive projects, choosing a good service provider is obviously the most cost-saving and straightforward way to success.

Don't let your creativity be limited by print size. LS is great at making big ideas happen. With leading-edge large-scale printing equipment and a talented engineering staff, we can accurately translate your design from computer file to actual work of art.Adopt your largeCAD filetoday and get afree instant quote!Our engineers will contact you to work together to bring your "big" ideas to "big" life.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com