Gear machining services are currently highly needed in finding solutions to the dilemma faced by engineers whenever they are designing gear systems related to material choice. The dilemma is normally encountered when faced with the challenge of selecting the material to be used in an effort to obtain the best requirements in terms of cost and resistance to wear. The wrong choice leads to the failure of the gear systems.

The biggest problem lies in the tradition of methods which still highly depend on empirical formulas and manuals. The methods did not take into systematic consideration some particular conditions of operation, therefore did not evaluate and weigh qualitative-quantitative factors by adjusting a balance according to effectiveness and costs. In this paper, a scientific method will be described concerning material selection of the gears, based on 20 years experience of the gear machining services offered by LS Manufacturing to help customers evaluate a suitable material in view of their special situation.

Gear Machining Service Quick Reference

| Section | Key Content |

| Introduction | Overcomes problems associated with material selection difficulties associated with conventional designs - wear/tear resistance versus strength versus cost. |

| Selection Framework | Scientific framework that balances cost and performance, distilled from 20 years of production experience. |

| Material Properties | Comparison of strength, hardness, wear resistance of steels, cast irons, bronzes, plastics. |

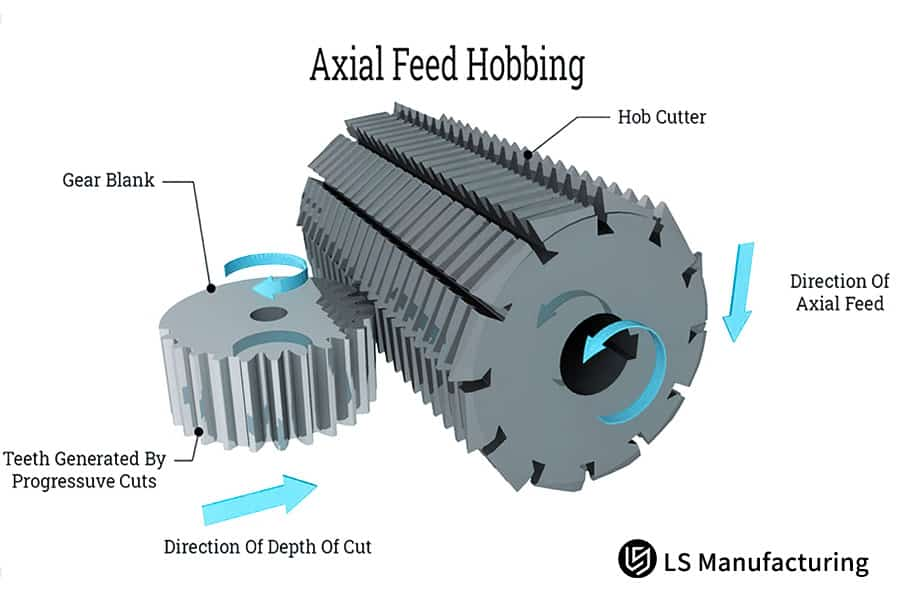

| Process & Heat Treatment | Links machining (hobbing & shaping) and heat treatment (carburizing or induction) to material, concluding with final gear performance. |

| Cost-Benefit Analysis | This analyzes the total cost implications related to gear material costs, processing costs, heat treatment, as well as lifespan in order to point out the most economical option. |

| Case Studies | Practical examples show how the framework provides the answer to questions of material choice for different sectors, such as the manufacture of cars and construction machinery. |

| Implementation Steps | Provide a step-by-step procedure that illustrates how an idea can be implemented by defining the requirements, selecting the material, and implementing the selected material. |

This handbook represents a comprehensive methodology for material selection in gears. The book goes beyond approximation into a well-rounded analysis pertaining to performance, processing, and cost. A blend of material science with material processing/machining and heat treatment expertise will lead the engineer to sound decisions.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

In the ocean of online data, how would you make this guide to gear machining services different? It is so because this is a guide from the front lines, not from the textbooks. Our knowledge isn't from the desk of a theoretical engineer; it is from the shop floor where each day, as also every day, the battles of quality-machined alloys, tight tolerance, and gear geometry are taken on.

Our competitive advantage resides in the provision of basic parts for the difficult sectors. In the aerospace sector, the parts required to develop gear parts have to operate in highly stressful conditions, and a single error won't do. In the health sector, accuracy will always work in our favor. One of our major guidelines involves adhering to sector standards as set out by trustworthy agencies such as the Metal Powder Industry Federation (MPIF) and the needs of Additive Manufacturing (AM) Technology.

In the last two decades, the number of customized gears produced through LS Manufacturing, has been in the tens of thousands. Moreover, all these gears, whether it’s prototyping or manufacturing, have much to offer us in terms of what we can gain from these processes, such as: computer programming the path for the certain type of material used for the gear, processing the machining of the heat-treated gear, and shortest path to get a perfect gear.

Figure 1: Budget-friendly materials for high-accuracy gear production by LS Manufacturing

How Do Professional Gear Machining Services Match The Best Material Solution Based On Working Conditions?

The basis for reliable gear performance lies in the selection of materials for which the selection has to commence with an accurate assessment for its applications. Quality gear machining services not only involve mere fabrication but also consist of scientific gear material matching that considers key material matching such as load, rotation speed, lubrication, exposure, among others, whose objectives are geared towards avoiding unnecessary material failures.

- Comprehensive Analysis as the First Step: The first step to The process of determining the gears involves detailed analysis of working conditions. The engineers will consider factors such as torque variation, shock overload, working conditions, and potential exposure to corrosive materials. This information forms the basis of whether or not the material for the gears can be selected.

- Leverage the Vast Data of Materials: The instrument for this analysis in the context of LS Manufacturing includes a custom-built database which contains information about more than 200 types of material grades. This huge set of data includes different kinds of material alloys, the material condition post certain heat treatment processes, and material composites used for a comparison of material properties in the context of requirements for internal stresses.

- Simulation-Driven Validation: Even before the metal is machined in making the component, the use of the simulation software application enables the prediction of the metal’s behavior with respect to the stress patterns in the component even before the metal utilized in making the component is machined.

- Balancing Performance and Practicality: The aim here is to develop a solution that would provide directions for a material in which perfection is attained at balance. This proposed material satisfies the demands of technical performance as well as other requirements and takes into consideration the aspect of manufacturing.

In perfect summary, professional gear machining services ensures the following: material matching is optimized on the back of methodological interpretations on the working condition analysis result data captured in an approach to material selection with extensive databases that apply simulated material properties to provide the cost-performance engineered gears with the planned working life span.

How To Systematically Evaluate Gear Materials For Performance And Cost?

Informed gear material selection cannot be done without a holistic mindset for the technical specifications as well as manufacturability. A comprehensive processability assessment forms the foundation, evaluating how a material behaves during machining, heat treatment, and finishing operations. Data-driven analysis of this nature plays a highly important role in achieving the objective of cost-effectiveness analysis by validating that the material chosen is optimal from the cost perspective as well.

| Factor | Key Considerations | Typical Impact |

| Processability | Tool life, machinability, quality of surface finish. | Determines production efficiency, quality consistency, and direct manufacturing cost. |

| Heat Treatment | Hardness, dimensional stability, core material properties. | Extremely important for both durability and increased cost. |

| Service Performance | Resistance to wear and fatigue strength, and others. | Defines functional durability and ability during service. |

| Total Cost Analysis | Cost of material, processing, hardening, and finishing. | Total cost analysis of the component is determined from this information. |

This means that through this method of evaluation, it has become possible for a comparison to take place involving more than 20 different materials of gears. Given the consideration of the result assessment in the machining operation and the technical requirements, it can well be stated that what constitutes maximum economy and efficiency in the solution can currently be achieved. It must not be forgotten that our technique always enabled our clients to get a further saving of 15 to 30% along with meeting the total technical requirements.

What Are The Performance And Uses Of Common Gear Materials?

The optimal selection of materials for gear machining requires a clear understanding of how different alloys and compounds behave under stress. Each category possesses distinct performance characteristics—strength, hardness, and wear resistance—that define its capabilities. Matching these properties to the right application scenarios is essential for designing durable, efficient gears that meet both operational demands and cost considerations.

| Material Type | Key Characteristics | Typical Applications |

| Alloy Steels | High strength, good hardness, and fatigue resistance. | Tranmissions designed for autos, industrial gearboxes, as well as other heavy machinery. |

| Cast Irons | High abrasion resistances and vibration dampings, low cost. | Heavy gear drives, agricultural machinery. |

| Copper Alloys | High corrosion resistance and low friction coefficient and machinability. | Marine gears, worm wheels, bushings, and corrosive environments. |

| Engineering Plastics | Lightweight, operates silently, and has strong resistance to chemicals. | Food processing equipment, low-power drives, noisy processes. |

In conclusion, the proper selection of materials for gear machining is always a balance among various performance characteristics combined with realistic requirements due to specific application scenarios. Comparisons based on data allow for informed decisions that achieve better gear life, lower maintenance costs, and avoid over-engineering.

Figure 2: Precision gear services and material choice flowchart by LS Manufacturing

How Can Custom Gears Meet Special Working Conditions Through Material Selection?

The custom gears are made to work properly even under adverse conditions. This is beyond the general use of the gear. The efficiency of the gear includes the material used to meet the challenge that comes with the special environment. This necessitates moving beyond conventional materials and adopting a knowledge-driven approach to deliver truly tailored solutions for durability and performance.

- Extreme Temperature Environment: In aerospace and the power industry, for example, the constant presence of high temperatures would be detrimental to conventional gears. However, Inconel features temperature strength retention and does not degrade due to oxidation. This constitutes a crucial tailored solution for the selection of custom gears.

- Resisting Corrosion and Chemical Exposure: In the case of marine or processing applications, the moisture as well as the chemicals involved can easily cause damage to the gear. The material used here would require resistance to corrosion. Using these materials creates custom gears that withstand harsh, corrosive special working conditions.

- Handling Heavy Loads and Shock: Intensive mining activities and heavy machinery create immense shock and abrasion for gears. The tailored solution would incorporate high toughness alloy steel, which would provide core strength with high fatigue resistance. This ensures that custom gears pass severe mechanical loading with ease.

- Special Requirements for Advanced Performance: Some gears, used in industries like robotics or medicine, may require special needs in terms of weight, sound levels, or other magnetic properties. Usage of advanced polymers or alloys without magnetic properties can meet the special gear requirements due to a particular functionality.

It can thus be concluded that custom gears are basically designed to offer solutions concerning special working conditions. This is achieved and realized, not through the use of ordinary materials, but rather by using knowledge to offer precise gear tailored solutions. In this regard, the decision to make use of the latest alloys and polymers with composite materials is aimed at ensuring efficiency of the gear to solve special problems.

How Can We Optimize The Cost Of Gear Processing While Ensuring Quality?

Cost-effective gear machining practices involve no sacrifices. The opportunities for weighing and measuring cost and quality appear to be the trademark of successful value engineering. The process linked with value engineering plays a crucial role in ensuring that all considerations provide enhancement of performance and life at an acceptable cost. All considerations related to quality assurance take a pivotal position.

- Material and Process Trade-offs: This is a holistic process. Factors affecting the cost of material include processability, necessity of heat treatment, and the life expected thereof. The value engineering process determines where the best quality material is required and at which point a cost-effective substitute is sufficient.

- Optimizing Manufacturing for Efficiency: In this strategy, the whole process from cutting to finish is observed. The strategy is directed at making the process simpler, accomplishing the task within less time, and using fewer tools. The whole process mentioned above is an integral part of an efficient cost-effective gear machining.

- Solution Offering the Greatest Economical Material Value Selected: Based upon the analysis of all relevant information, the material that offers the greatest material cost value is determined. Though these materials may not all be the least cost materials, the material needs and least cost of the materials are met. This precise matching delivers quality assurance for the intended application.

- Validation of the Performance and Durability: All recommendations proposed have been tested and run through various simulations. Furthermore, through this, it shall be guaranteed that it will save on production cost but shall still have the ability to meet such specifications and durability standards required. This final verification step is the capstone of our quality assurance commitment.

In conclusion, achieving sustainable cost-effective gear machining is the result of applying value engineering principles across the entire product lifecycle. By balancing material selection, process efficiency, and lifecycle performance, we deliver optimized solutions that reduce total cost by 20-35% while upholding the strictest quality assurance standards.

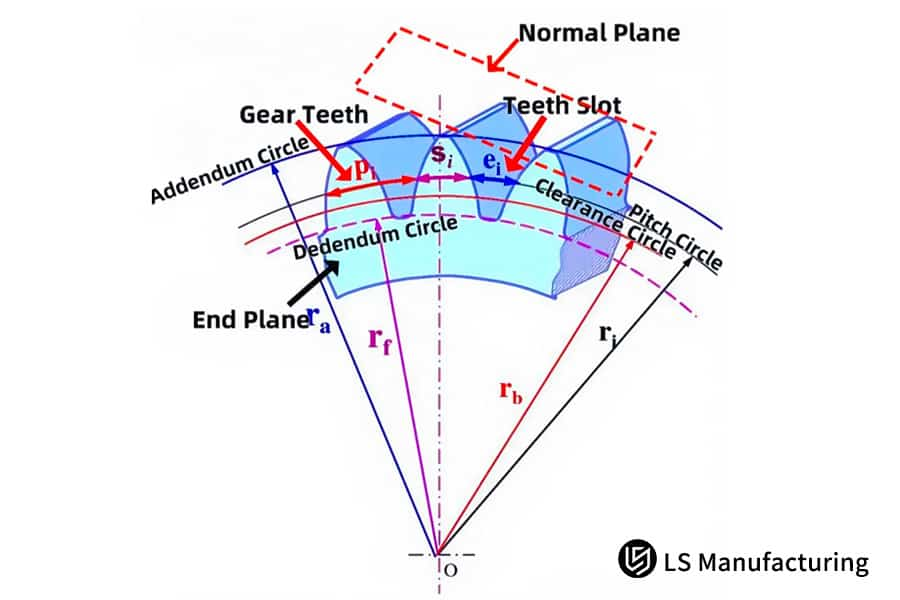

What Are The Special Requirements For Material Properties In High-Precision Gears?

Along with these performance considerations, precision gears are also expected to have a number of outstanding attributes, which ensure that the functionality of precision gears is maintained impeccably while performing its life service. Besides, precision gear materials are expected to be based on two primary notions: the first one is the notion of wear resistance, and the second one is the notion of dimensional stability. These ensure that precision gears are free from any sort of curvature or warpness.

Dimensional Stability Under Stress

While trying to achieve micron-level precision and keeping it intact, one has to take into account a material with least deformation properties. That is why tool-grade material, pre-hardened tool-grade material, and alloy steels are preferred with regard to dimensional stability during heat treatments.

Enhanced Wear Resistance

In high-precision gears, the delicate tooth surface, which would be on both flanks, would not be able to withstand any wear because wearing the surface would reduce its accuracy of transmission, hence increasing the noise. The precision gear materials are selected on the basis of their ability to create a wear resistance surface layer, such as that of the case-hardened steel material.

Minimizing Internal Stress and Homogeneity

Reducing internal stresses and ensuring homogeneity is essential here. Inclusions or segregation, as internal defects, should not be present in the material being used, nor should it have too high an amount of internal stresses to induce distortions during machining. This directly supports the dimensional stability of the final, intricate gear component.

Strict Certification and Process Controls

Each production batch is strictly certified for chemical composition and mechanical properties. Additionally, a strict control process is also exercised throughout the entire machining and heat treatment process. Hence, assurance of attainment to the stated wear resistance and the dimensional stability for the specified precision of at least like ISO grade 5 or better can be obtained.

In conclusion, for achieving accurate high-precision gears, it is an essential requirement to ensure the use of precision gear materials. The materials should be alloys which have dimensional stability as well as suitable wear resistance. Alternatively, proper handling of the materials can also ensure the desired level of gearing in terms of accuracy, efficiency, as well as acoustics.

Figure 3: Material selection handbook for custom gear production by LS Manufacturing

How Does Material Choice In Gear Manufacturing Affect Final Performance?

The selection of gear manufacturing materials can be regarded as a root or inherent choice that directly and irreversibly points the capability potential in a gear. Material selection can be seen as a first-order element in considering the performance impact, because it affects crucial characteristics, such as fatigue life, vibration, and carrying capacity, in a product. The link between material properties and performance implications for products is based on the fact that material properties must be understood in terms of their direct implications for the performance implications of the product.

Determining Fatigue Life and Durability

The metallurgical properties of materials, more so the core & hardenable properties, in effect determine the durability level in the cyclic loading process. Selecting gear manufacturing materials in the initial stages fixes the durability limit for the material, as the material is either durable enough to survive million cycles or it fails prematurely.

Influencing Noise, Vibration, and Harshness (NVH)

The density, damping properties, and uniformity in microstructure of the material further contribute toward its noise-conducting properties. A softer material or one with the capability of being self-dampening would have the potential to eliminate or reduce the sound of gear whine. Therefore, the previously stated performance impact due to material selection also counts as important for the material's noise and smoothness properties. This is a vital element for the consumer and the industry at large.

Determination of the Load Carrying Capability & Strength

Primarily, the tensile strength, hardness, and contact fatigue resistance qualities of the chosen material would establish a basis on which the torques would be determined in the gear. This calls for a consideration of the gear manufacturing materials to the extent that the teeth in the gear would not bend, pit, or spall under the effect of loads, which plays a significant role in the performance impact as far as power transmission is concerned.

Enabling Accurate Performance Prediction

The gear manufacturing materials stage with respect to the proposed heat treatment process and machining operations make it possible to predict the performance. Thus, 'material process performance analysis' makes it possible for the output performance with respect to fatigue life, rate of wear, and deformation to be predicted.

That is, gear manufacturing materials selection has got to stop being a buying decision alone, with lasting effects, and must instead involve a profound technological process since, in fact, this is what has proven most decisive with regard to the underlying reliability properties a gear may have, namely fatigue life properties, among others. That is, a technically informed decision, based on prediction, will ensure that a product meets its intended requirements with regard to durability, among other properties.

How To Select The Most Suitable Gear Material Based On Specific Application Scenarios?

How to choose gear material is also related to the Success in some manner that can be obtained based on application-based selection considerations. Our intelligent system make this process simpler by translating complex parameters into easily comprehensible recommendations.

Define the Operating Profile First

This requires the analysis of the value of torque, speed, and other factors in an application. This operating profile provides a guide in establishing the operating requirement of an application based on the factors provided under the category of the hardness requirement.

Account for Environmental Conditions

Sometimes, the environment where the product has to work may assume importance equal to other factors cumulatively. The requirements differ as a function of the presence of the aggressive factors of the environment like temperature, water, chemicals, and abrasion to the product and are corrosion resistance, resistance to temperature, surfaces, etc.

Prioritize Performance Objectives

Based on the application requirement, generated criteria that tend to crop up are either related to optimizing life, weight minimization, elimination of noise, and cost optimization, among others. This particular stage, therefore, requires the process of prioritizing performance requirements with a focus of distinguishing those attributes that have all the potential of becoming a means of optimizing possibilities based on a particular material attribute, for instance, having a higher endurance limit and a higher damping factor.

Leverage Intelligent Analysis for Precision

The values of all these parameters would then be utilized as inputs for the intelligent system analysis. They would be capable of forming the difference or comparison in terms of an effective comparison of the data with the extensive material database. In this manner, the best options list would emerge along with all the details of the analysis.

In summary, a scientific method for how to choose gear material relies on application-based selection, systematically evaluating operational and environmental needs. Supported by an intelligent system, this approach delivers optimized, data-backed recommendations for superior gear performance and durability.

Figure 4: Custom component fabrication and material specification flowchart by LS Manufacturing

LS Manufacturing - Construction Machinery Industry: Heavy-Duty Gear Material Optimization Project

In this In heavy machinery, the material used determines the durability of the product. The LS Manufacturing case illustrates how scientific optimization can be used to successfully address the major technical problem in this way:

Customer Challenge

There were some patterns of pitting defects in the gear transmission system of engineering machinery. The material used, i.e., 20CrMnTi, was inadequate for heavy loading conditions. The life of a gear was below 3000 hours on an average. The occurrence of frequent pits hiked upthe cost of maintaining a gear system.

LS Manufacturing Solution

Based upon extensive evaluation of the properties of materials and simulation of conditions, the recommendation made by LS Manufacturing was that the material should be substituted with 18CrNiMo7-6 carburizing steel. The heat treatment procedure has also been optimized for hardness of HRC 60-62 on the surfaces. This further improves resistance to wear and resistance to load.

Results and Value

The lifetime of the gear increased above 8,000 hours, and the failure rate dropped by 70 percent. The economy value due to savings exceeded 500,000 yuan, which was solely attributed to a reduction in maintenance costs. In relation to a worldwide partnership for doing business, the material optimization project contributed to improving the position of LS Manufacturing as a trusted gear machining partner in the area of durable engineering machinery.

In the case of LS Manufacturing, the success story has been achieved through their knowledge and expertise in the analysis and optimization of the heat treatment process. The upgrade from their existing material, 20CrMnTi, to a better quality material, carburizing steel 18CrNiMo7-6, has helped them derive benefits in terms of gear life, cost savings, collaborations, and several others.

Upgrade gear material for durable performance? Click to match your heavy-duty requirements.

Application Trends And Value Analysis Of Advanced Materials Technology In Gear Manufacturing

The incorporation of advanced materials technology would identify the radical change that took place in the performance level and the life of the gear and the process of designing. The materials for gear machining technology would identify that the process of improvement would identify the technological trends, and that would in turn identify the beginning of one of the forces that make the process of gear machining unique.

- Advanced Performance on the Basis of Composite Materials: The development and enhancement of new high-strength composites and matrices based on metal materials has also emerged as another trend which has received emphasis. This is due to the fact that these advanced materials by a desirable strength-weight ratio as well as a higher ability to absorb vibration and are thus useful for airplanes and automobiles which easily require a reduction in their inertness and weight.

- Revolutionary Surface Engineering Techniques: Along with the raw material, many advanced surface treatments such as DLC Coatings, Plasma Nitriding, and Laser Cladding are also coming up. These have caused a remarkable rise in the hardness values of the surface of materials for gear machining, as well as friction and wear resistance.

- Flexibility in Design of Additive Manufactured Product: The metal used in the additive manufacturing process (3D printing) assists in designing complex/topology optimized designs, which are not possible in the cases of the subtractive manufactured product design. The technological trends enable lightweight, integrated structures and the use of novel, high-performance alloys, opening new frontiers in gear design and performance optimization.

- Smart and Functional Materials: Research into embedded sensors and self-lubricating or self-healing materials represents the future. These intelligent advanced materials could enable real-time health monitoring of gears, predict maintenance needs, and autonomously extend operational life, providing a profound long-term competitive advantage through increased reliability and reduced downtime.

In conclusion, staying abreast of technological trends in advanced materials and surface engineering is essential for modern gear manufacturing. By actively adopting and integrating these innovations into materials for gear machining, companies can achieve lighter, stronger, quieter, and more durable products. This proactive approach ultimately delivers a decisive competitive advantage in the marketplace.

FAQs

1. What are the variables affecting the variations of costs considering the gears made of different materials?

The variation in prices is mainly because of the material cost, difficulty of processing, and heat treatment process. We will give you recommendations on which is the better option of what to do next.

2. How can I determine that the material of the gear meets the service life requirement?

We have the ability to provide a precise account regarding the results of the life prediction tests since we have the capability to model the material fatigue tests as well as the operating conditions.

3. Can small batch production benefit from expert material selection advice?

For all our customers, we offer free material selection guidance regardless of the size of their orders.

4. Which techniques can help me ensure the quality of the information when working in special conditions?

In our laboratory, all the necessary equipment required for material tests is available. Accelerated life tests, on the other hand, may be carried out using simulated operating conditions.

5. How to solve the error problems with material selection?

In such cases, we can also help in material substitution or improve processing services so that the loss incurred by the client will be minimal.

6. Are the material samples and test reports ready?

The sample of material and performance test results are provided to the client by us.

7. Is the price for new material higher compared to conventional material price?

The new materials have been able to attain economically feasible prices by applying optimization and bulk purchasing technology.

8. How to assess the impact of material changes on overall costs?

We continue towards the cost evaluation of acquiring as well as processing, along with the charges involving maintenance.

Summary

Performance and lifespan of gear components can be enhanced by the application of scientific material selection and engineering knowledge. The firm possesses the highest technical ability and appropriate material systems to offer the most effective services for gear production to its consumers.

Reach out to the gear experts with LS Manufacturing today to get your free gear material selection analysis report! We will give you the expert recommendation on the best materials for your particular application requirements.

Let the perfect materials forge extraordinary gears. Get your personalized material selection analysis report now and usher in a new chapter of efficient and reliable transmission!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.