Against the context of continued growth of the global CNC machining sector, China, leveraging its end-to-end supply chain and production capabilities, has become a global force to be reckoned with in the industry. With its massive cost advantages and ever-increasing technology capabilities, Chinese CNC machining is attracting the attention of global manufacturers.

This article uses a data-driven research methodology to systematically undertake a cost-benefit analysis of CNC machining, providing an objective price comparison, quality, and lead times between indigenous and Chinese providers. The comparison will reveal the degree to which Chinese manufacturing can achieve cost savings of as much as 40% with precision quality.

As a supplier industry, LS Manufacturing, equipped with its own flexible manufacturing system and extensive engineering experience, can develop customized solutions for businesses of any size. This article will better inform readers about how to maximize supplier selection to balance cost savings with machining quality and supply chain reliability. To save you time, here’s a quick overview of the core conclusions.

Quick Reference Table Of Core Comparisons Between CNC Machining China And Local Suppliers

| Comparison Points | CNC Machining China | Local Suppliers |

| Main Advantages | Extremely high overall cost savings, extremely rapid technology updates | Geographical proximity, and convenient communication |

| Cost Structure | Huge cost savings (as much as 40%), highly competitive prices. | Unit costs are higher, resulting in huge overall cost pressure. |

| Quality and Technology | High precision (e.g., ±0.008mm), entire supply chain. | Consistent quality, and well-established technology. |

| Service and Flexibility | Flexible response with heavily customized solutions. | High threshold for customization, but normal service standards. |

| Appropriate Scenarios | Medium- and large-scale projects in quest of cost savings and which require flexible customization. | Small-volume, time-critical, or emergency projects. |

Chinese CNC machining (e.g., LS Manufacturing) has a lot to bring to the table in terms of cost savings, technical precision, and customized services, which brings specific value to budget-controlled projects and flexible solutions.

Using Chinese suppliers now forms the primary trend in optimization of supply chains of global manufacturing.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

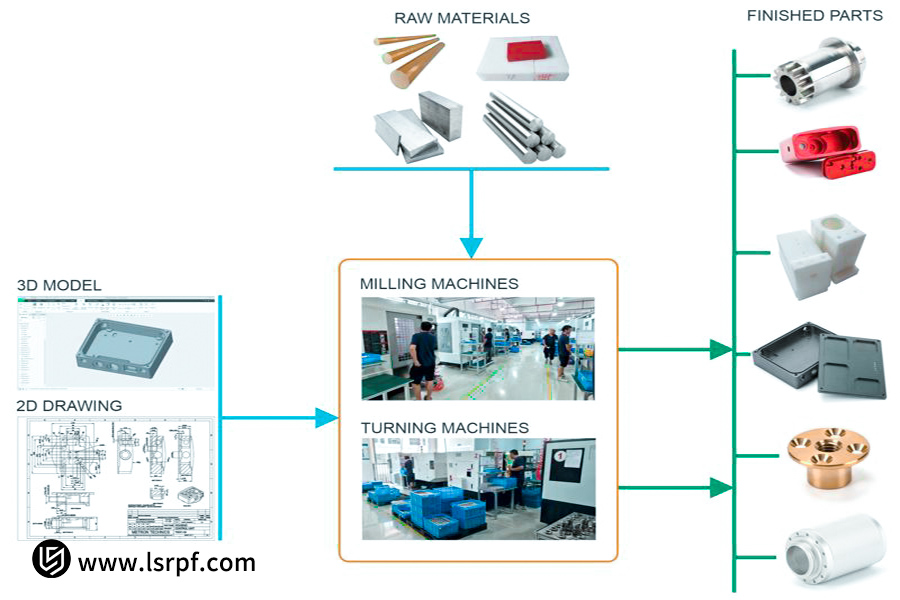

This manual is based on LS Manufacturing's twenty-year track record of CNC machining expertise. Not only do we have a complete lineup of state-of-the-art equipment, from five-axis milling machines to milling machines, but we also have extensive experience in how to realize up to 40% total cost savings for customers around the world through scientific supply chain management and optimized production processes.

LS Manufacturing's experienced labor force has provided critical components to various industries, including aerospace, high-end consumer electronics, and industrial equipment. We have implemented a comprehensive quality control system to ensure that all products, from drawing through end-product, meet precision tolerance specifications of ±0.008mm.

LS Manufacturing previously assisted a European automotive parts supplier in redesigning the workpiece and streamlining its machining paths. Having identical mechanical properties, the supplier reduced the unit cost of a critical component by 35% and decreased cycle time in production by 20%.

This experience and data, as taken from actual projects, is the bedrock of all cost-benefit analysis in this guide. LS Manufacturing is convinced that only tried-and-tested solutions can serve as a solid basis for your supply chain decisions.

Why Is Chinese CNC Machining More Cost-Effective Than Local Suppliers?

In the age of manufacturing globalization, the adoption of Chinese CNC machining is a crucial approach for most corporations to optimize their supply chain and enhance their competitiveness. China has a gigantic cost advantage, not by intention, but by virtue of a sequence of structural factors that lead to the inherent strength of CNC machining in China. Specifically, these advantages are primarily reflected in the following three aspects:

1. Significant labor and operating cost savings:

China enjoys superior strengths both in specialized technical capabilities as well as general operating costs (e.g., energy and factory rent). This implies base quotes for machining services with comparable technical capabilities are considerably lower than their local counterparts in Europe and the United States, directly lowering the offshore CNC machining cost base.

2. Integrated materials and supply chain network:

China boasts the global leader's most industrial network, and it has low-cost and efficient raw material and component procurement pipelines. For example, with localized supply chain community and massive scale buying central, at LS Manufacturing, we get to reap highly competitive raw material pricing, savings which reach our customers.

3. High production efficiency driven by scale:

Chinese manufacturers excel in mass production efficiency and control of the process management. For example, LS Manufacturing, through scientific planning of manufacturing and automated sets of equipment (up to 50 sets of machining centers coordinated), optimized the utilization of equipment to over 85%, significantly reduced the fixed costs per unit and demonstrating phenomenal superiorities in cost-benefit analysis of CNC machining.

Chinese CNC machining that is low-cost, high-productivity, and rigorously quality-controlled cannot be beaten in overall value. For companies focused on highest return on investment, having a qualified Chinese supplier such as LS Manufacturing make for them is a number-tested, wise business strategy.

How To Choose A Reliable Chinese CNC Machining Supplier?

After the introduction of the cost benefits of Chinese CNC machining factories, the most crucial decision is how to rationally choose a CNC machining supplier. This is beyond price comparison and incorporates serious consideration of the overall capability of the supplier. In choosing a supplier, prioritize the following three primary dimensions:

1. Authoritative Certification and Quality System:

This is the crux of supplier reliability. First preference should be given to partners such as LS Manufacturing with proven international quality system certifications such as ISO 9001. This doesn't just refer to standardized production procedures but implies sustainable traceable quality control ability with assured product reliability and stability.

2. Comprehensive Technical Capabilities and Equipment:

A Chinese CNC machining centre will most likely offer high-capacity machining solutions ranging from three-axis to five-axis machining, milling, and other sophisticated operations and possess accuracy inspection machinery like coordinate measuring machines and laser scanners. They ought to be able to machine complex parts as well as conduct accurate quality checks for themselves so that drawings' tolerance specifications are achieved to perfection.

3. Professional Response Speed and Communication Support:

Good communication is necessary for professional offshore success. Inquire as to whether the supplier maintains a professional on-shore support organization capable of providing prompt quotations, transparent engineering response (e.g., Design for Manufacturing (DFM) checks), and simple bilingual communication. For example, LS Manufacturing promises providing an initial quote and technical review within 24 hours, significantly increasing the velocity and efficiency of first-stage project decision-making and momentum.

Selecting a successful CNC machining supplier is an integrated decision weighing hard capabilities and soft services. Based on the analysis of the above important factors, you can reasonably select a reliable partner such as LS Manufacturing, which possesses technical competence alongside a solid service-oriented culture.

Is Quality Control Reliable In Chinese CNC Machining?

For the best CNC machining companies in China, reliability and quality will typically be what most purchasers will want. In fact, leading companies like LS Manufacturing have achieved world-class precision and consistency via a strict quality control system and are therefore an efficient and dependable choice. Their dependability and quality are resting on three legs:

1. Full-Process Precision Inspection Technology:

LS Manufacturing also possesses the latest world-class accuracy measuring equipment such as coordinate measuring machines (CMMs), laser scanners, and roundness gauges. This means that every significant dimension is followed using objective facts rather than human experience to ensure consistent tolerances from first-piece to batch order. This precision fully satisfies the stringent needs of high-end segments such as aerospace and medical devices.

2. Data-Driven Process Monitoring:

LS Manufacturing maintains strict SPC (Statistical Process Control) throughout its whole process, collecting and comparing the machining data in real-time in order to anticipate and prevent any potential deviation. This quality control process with proactive approach keeps the defect rates to very low levels (e.g., below 0.1%), inherently ensuring product consistency and much better than the traditional model relying on last-check inspection.

3. A consistent quality culture:

From raw material receipt inspection to self-examination by production operators to final full-scale inspection (FAI), quality responsibility rests with every employee. Using the ISO 9001 format, we have a traceable and improvable closed-loop system of quality management in place such that every batch of products shipped to our customers is believable.

Quality control in the finest modern Chinese CNC machining factories has evolved from "experience-based" to "data-driven." When quality control supported by a rigorous system is combined with inherent cost advantages, the resultant CNC machining cost-benefit analysis leads to a highly competitive market.

How To Minimize The Risks Of Offshore CNC Machining?

While outsourcing CNC machining in China, companies are actually aware of the potential for issues like logistics and communications. However, through systematic management practices, these can be managed effectively and allow you to enjoy offshore CNC machining cost benefits while providing a stable supply chain as when you are running locally. LS Manufacturing's main risk mitigating practices are as follows:

1. Supply Chain and Logistics Transparency:

LS Manufacturing has created a platform of end-to-end visibility of the supply chain. Using international partners in logistics, customers can track their order status from factory to delivery destination in real time. We also typically recommend customers to establish safety stock or apply flexible shipping options through less-than-container load (LCL) and full-container load (FCL) to effectively meet offshore CNC machining costs and delivery timetables.

2. Professional Communication and Engineering Support:

To remove communication barriers, LS Manufacturing has on-the-ground support staff in North America and Europe, plus Chinese-speaking project managers who are completely fluent. This is so you can do technical clarifications within a local time zone and language, with our factory in China professionally handling the process with proper and effective communication – a significant advantage that is more than typical Chinese CNC machining services compared to local CNC machining.

3. Standardized Processes and Contractual Guarantees:

From our initial DFM (Design for Manufacturability) report, to our mid-term IPQC (In-Process Quality Control) report, to the eventual Full Dimension Inspection (FAI) report, we thoroughly record every step. Stringent contract terms precisely define requirements for quality, delivery commitments, and intellectual property protection, providing you with peace of mind in the legal arena.

The risks to the offshore partnership are not so large as to be insurmountable. The key is to choose a partner like LS Manufacturing that possesses an experienced management system and open processes.

How Does Data Demonstrate The Cost Savings Of CNC Machining In China?

To objectively analyze the advantages of China CNC machining, the most effective method is an offshore CNC machining cost-benefit analysis of real project information. LS Manufacturing uses data-based techniques to uncover hidden expense and clearly demonstrate the dramatic economic benefits of offshore collaboration. Following is a cost comparison analysis of a project producing 10,000 aluminum alloy cases annually:

| Cost Elements | Local North American Vendor | LS Manufacturing | Savings |

| Material Cost Per Unit | $18.5 | $14.2 | 23% |

| Processing Expenses Per Unit | $45.0 | $28.5 | 37% |

| Mold and Fixture Amortization | $12,000 | $8,500 | 29% |

| Total Annual Cost | $675,000 | $442,700 | 34.4% |

Apart from the direct costs in the table, our cost-effectiveness analysis of CNC machining reveals other advantages:

- Efficiency of Scale: Consolidating 50 machining centers into one production management system has increased our equipment utilization rate to over 85%, compared to the industry norm of 65%. This is the prime reason for a 37% reduction in per-unit machining costs.

- Supply Chain Synergy: Strategic partnership of LS Manufacturing with aluminum suppliers maintains raw material prices 10-15% lower than the international market. The cost savings are transferred directly to the cost of material for the customer.

- Comprehensive Value Enhancement: In addition to achieving a total cost reduction of 34.4%, we also reduce the customer's product cycle time by 20% with optimized toolpaths and cooling solutions, also accelerating their cash flow.

These statistics clearly demonstrate the systematic and quantifiable cost saving of professional Chinese CNC machining. We invite you to send us your part drawings or technical specs, and we will provide you with a customized, detailed CNC machining cost-effectiveness analysis report to demonstrate the efficacy of our collaboration.

LS Manufacturing's CNC Machining Case Study: How To Achieve A 30% Cost Reduction?

A European-based industrial pump business was faced with a serious dilemma: its essential stainless steel impeller component, when locally produced, cost as much as $220 per unit, with delivery times of six weeks or longer, significantly diminishing its market competitiveness. This was their agony that made them re-evaluate their criteria for choosing CNC machining vendors and ultimately to choose to partner with LS Manufacturing.

1. Customer Pain Points:

- Old three-axis machine tools were inefficient in machining, and secondary clamping resulted in precision fluctuation.

- Raw material utilization rate was less than 60%, resulting in excessive waste.

- Longer cutting cycles reduced the capacity of the entire product line.

2. LS Manufacturing Solution:

As an experienced CNC machining center in China, LS Manufacturing established a professional engineering department and implemented the following innovative solutions:

- Process Innovation: Creation of complex curved surfaces in a single stroke with a five-axis machining center eliminates repeated clampings' errors.

- Material Optimization: Redesign of the blank through the use of nested layout software improved material usage to 85%.

- Tool Customization: Meeting the distinct needs of stainless steel. Special tooling improved cutting efficiency by 40% and doubled tool life.

3. Results and Value:

After three months of close collaboration, LS Manufacturing was able to attain satisfactory results:

- Significant cost reductions: Total cost per part reduced from $220 to $154, representing a reduction of 30%.

- Enhanced quality: Dynamic balancing accuracy increased to G2.5, and vibration and noise were reduced by 15%.

- Efficiency optimization in delivery: Production cycle shortened from 6 weeks to 2.5 weeks, while the customer's inventory turnover rate increased by 140%.

This case study clearly demonstrates that choosing a suitable CNC machining supplier is not just a question of cost; it's value creation too. As a Chinese CNC machining factory with decades of experience in the industry, LS Manufacturing leverages its technology expertise and process optimization capability to deliver end-to-end benefits much beyond expectations to customers.

What Are The Advantages Of Chinese CNC Machining In Complex Part Manufacturing?

Where the case of high-precision, intricate parts with tight tolerances and specialized material is concerned, China's best CNC machining services are unrivaled. Well-trained providers like LS Manufacturing leverage their technical know-how to translate China's CNC machining strengths into major competitive advantages for their customers' products. Where complex parts production is concerned, our main strengths are in the following three aspects:

1. Advanced Multi-Axis Machining Capabilities:

LS Manufacturing's five-axis machining centers enable the generation of complex curved surfaces in one operation, avoiding the cumulative errors that result from repeated clamping setups. For example, while machining the impeller parts employed in the aerospace industry, we are able to have a uniform accuracy of ±0.008 mm while reducing cycle time by 35%, which is not possible using traditional three-axis machines.

2. Comprehensive Process Solutions:

For complex parts made of hard-to-machine material such as titanium and Inconel, LS Manufacturing not only delivers precise processes like turning and milling and micro-drilling, but also offers skilled Design for Manufacturability (DFM) analysis for best part design from the start, maximizing manufacturability, strength, and reducing weight.

3. Unparalleled Cost-Effectiveness:

Offshoring CNC machining of complex parts to China offers more than price. By integrating strengths along the entire supply chain from raw material procurement to high-precision machining, LS Manufacturing has the potential to save customers up to 40% in total cost while offering delivery quality at least as good as or even better than that of domestic providers. Therefore, CNC machining outsource to specialist Chinese factories has become more and more engineers' number one choice for challenging and complex parts projects.

With its technical expertise and cost advantage, LS Manufacturing can help your most complex design concepts become excellent physical parts, becoming your trusted manufacturing partner.

How To Evaluate The Overall Return On Investment Of CNC Machining Outsourcing?

A determination of the true value of outsourcing is more than just a comparison of unit costs in bids. A complete CNC machining cost-benefit analysis must be conducted to ascertain the total return on investment (ROI), including undocumented costs. A mature offshore CNC machining cost model can uncover significant economic value in a long-term partnership. ROI analysis mandates serious consideration of the following three basic components:

1. Explicit Cost Savings:

This is the most direct ROI. Compared to employing LS Manufacturing over local suppliers when it comes to raw material purchasing, unit processing fees, and molds amortization, customers typically end up with a 30%-40% reduction in direct costs, which provides the basis for calculating ROI.

2. Improved Operational Efficiency:

The indirect returns from outsourcing are equally significant. LS Manufacturing's case histories demonstrate that by automating manufacturing operations and shortening lead times, customers are able to increase inventory turns by more than 40%, unlocking significant levels of tied-up capital and enhancing time to market. All of these must be factored into a complete ROI calculation.

3. Quality and Risk Cost:

A cost-benefit analysis of expert CNC machining would include quality considerations. LS Manufacturing's high-tech quality control system keeps rates of defective parts below 0.1%. This directly reduces potential risks and rework, production downtime, and customer after-sales issues costs, adding stability to the supply chain. Hence, an ROI analysis based on science demonstrates that the value of outsourcing to LS Manufacturing is optimizing the entire supply chain from manufacturing and procurement to inventory.

LS Manufacturing recommends not only taking into account the up-front unit cost but also quantifying the foreign CNC machining's total cost and benefits. Contacr our consultants for a comprehensive, customized ROI analysis report to demonstrate the value of this with facts.

How Flexible Is The Chinese CNC Machining Supply Chain?

With increased volatility of the world market, supply chain responsiveness and flexibility have become core to the overall competitiveness of a company. Chinese CNC machining, when compared to local suppliers, displays impeccable strengths in supply chain flexibility that even influence a company's decision regarding which CNC machining suppliers to use. LS Manufacturing's flexibility predominantly appears in three ways:

1. Rapidly Responding Local Support:

LS Manufacturing has local support staff in major international markets, providing engineering input and price quotations in 24 hours. This enables customers to experience the cost advantages of Chinese production with the same responsiveness as local suppliers, effectively removing the response lag that is typical of traditional offshore arrangements.

2. Flexible Production Resource Allocation:

LS Manufacturing owns a machining fleet of over 50 multi-axis CNC machines, enabling flexible capacity adjustment based on order patterns. We are able to initiate production within 48 hours when customers have pressing orders or modify designs, and small-batch prototypes can be finalized in 72 hours. This is difficult for most local manufacturers with established production capacity to achieve.

3. Deeply Collaborative Supply Chain Network:

By entering strategic partnerships with raw material suppliers, LS Manufacturing maintains a steady inventory of generic materials such as aluminum alloy, stainless steel, and engineering plastics. Not only does this decrease raw material ordering cycles by 60%, but it also enables resources to be mobilized immediately when customers need to have materials in seconds, instead of waiting and risking delivery delays.

By creating an agile response mechanism and flexible manufacturing system, LS Manufacturing is able to successfully merge the benefits of Chinese CNC machining with those of local CNC machining, offering customers a perfect solution that balances cost competitiveness with optimum flexibility. In today's volatile market, this flexibility is exactly the competitive edge you require.

When making a choice of a CNC machining supplier, not only their geographical location but also the responsiveness of their entire supply chain need to be considered.

Why Is LS Manufacturing An Ideal Partner For CNC Machining In China?

In case China is outsourced to conduct CNC machining, the partner's overall technical capability will directly decide whether the project fails or succeeds. LS Manufacturing's standalone technical strengths and service system have made it a trusted partner for first-class Chinese CNC machining to numerous global buyers. Our key competitive strengths are located in the following three aspects:

1. Leading Technical Capabilities and a Comprehensive Quality System:

LS Manufacturing possesses a global-level machine shop with five-axis machining and mill-turn machining supported by a huge test laboratory (with coordinate measuring machines and optical spectrometers). This assures mission-critical parts have ±0.008mm precision stability from first piece to mass production, much beyond industry standards.

2. Data-Driven Cost Optimization:

LS Manufacturing not only provides competitive pricing but also offers clients 30%-40% overall cost savings through expert examination (such as Design for Manufacturing or DFM) and efficient production processes, releasing the full potential of China's world-class CNC machining.

3. Customer-Centric Partnership:

LS Manufacturing established local support personnel and project management procedure to facilitate effective communication and quick response. Prototype to high-volume production, we offer flexible and custom solutions, an extension of your supply chain. With LS Manufacturing, you're not buying just a supplier, but more the strategic business partner who is focused on your success.

We're ready to show you, with our technical ability and performance history, that outsourcing CNC machining in China is the best choice for both our growth.

FAQs

1. Is the quality of CNC machining in China reliable?

Completely reliable. In the case of LS Manufacturing, we adhere strictly to the ISO 9001 quality system and possess precision measuring tools such as coordinate measuring machines with critical dimension accuracy of ±0.008mm. Through process-equal monitoring and SPC statistical process control, we turn each batch of products international standard with high precision and consistency, and even exceeding customers' expectation.

2. Is offshore CNC machining a communications issue?

Absolutely not. LS Manufacturing has established a serious worldwide service organization, including English-Chinese bilingual customer support and 24-hour response system. By means of our designated project managers, on-line project management system, and ongoing project progress reports, we give you smooth communication, transparency, and control during the project process as simple a stress-free experience as working with a domestic supplier.

3. How do I calculate the total cost of outsourcing CNC machining?

LS Manufacturing adopts a cost model driven by data to properly calculate direct costs such as material procurement, production time, equipment depreciation, and administrative costs, and indirectly calculate costs such as logistics and customs fees. Through scientific CNC machining cost-benefit analysis, we provide customers with certain, detailed breakdown of costs so they can properly estimate aggregate costs and maximize opportunity.

4. Is Chinese CNC machining suitable for small-batch production?

Yes. LS Manufacturing boasts its dynamic, flexible manufacturing system ideally matched with the quick-response service of small batches of orders. With intelligent scheduling and modular process planning, we enable flexible production with a minimum order quantity of 10 pieces. Cost-effective, we promise each product to be in the same high-level quality standard, suitable for R&D, trial production, and custom demands.

Summary

Through this scientific cost-benefit comparison of CNC machining, facts clearly show that the use of Chinese CNC machining services, and more specifically conducting business with a trustworthy partner like LS Manufacturing, can result in 30%-50% overall cost savings for businesses, with assurance added or even improvement and consistency in product quality.

Not only does LS Manufacturing have state-of-the-art multi-axis machining facility and end-to-end quality management system, it also utilizes data-driven intelligent solutions to provide quantifiable value to our customers across every aspect, including process optimisation and supply chain management as well as delivery efficiency.

Contact LS Manufacturing today. Challenge us to turn these data insights into true competitive advantages at your company. Contact LS Manufacturing's industry veterans today for a free cost analysis report on your project. Let us demonstrate through hard facts and professional solutions that it's the wise strategic move to outsource manufacturing in China in an effort to maximize profitability and fuel growth.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.