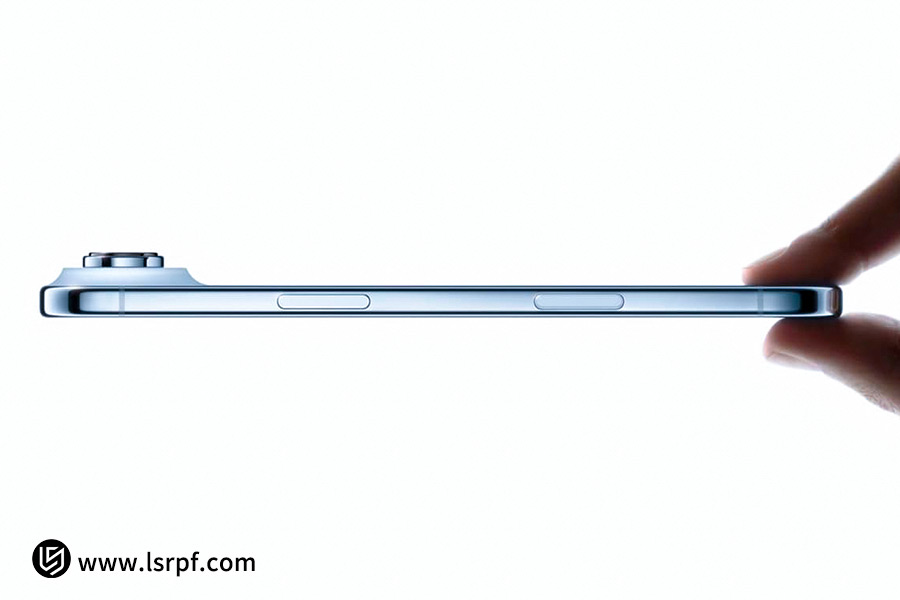

With a decade of phones that dreamed of being wafer thin and high-speed behind them, the introduction of the iPhone Air once more redefined "lightness." Underneath its breathtaking heft is another jaw-dropping materials science and precision engineering coup: grade 5 titanium.

Such a material, used by the aerospace and high-performance equipment sectors, is the key to achieving "thinness without toughness loss" in its strength-to-weight ratio and corrosion resistance. But how can this hard and challenge material be formed into one multicompartmented body and bulk-produced? That requires a chain of novel processing routes and structural geometries.

This piece will look at how grade 5 titanium has a role to play in why the iPhone Air is so incredibly light and expose the technical secrets of its high-precision production. To save you some time, here is a brief reference table summarizing the key findings.

Quick Reference: Choose Your Tap At A Glance

| Core Dimensions | Key Summary |

| Material Selection | Grade 5 Titanium (Ti-6Al-4V): An aerospace-grade alloy with an optimal strength-to-weight ratio and excellent corrosion resistance. Structural Processing: Titanium-aluminum composite design: Balancing weight, strength, and cost. |

| Precision CNC machining | Complex processes, high costs, and achieving unibody molding. |

| Advantages & Challenges |

|

| Partnership & Optimization | Collaborate with specialized suppliers (such as LS Precision) to optimize processes, improve yield, and jointly reduce cost |

iPhone Air is made incredibly light and durable by virtue of high-precision CNC machining in grade 5 titanium and an innovative titanium-aluminum composite design. The luxurious material, once out of reach due to prohibitively high costs, has been successfully mass-produced by partner manufacturing optimization with leading suppliers.

LS Precision has professional equipment and extensive experience in CNC machining. If you have any machining needs in this area, please feel free to contact us.

Why Trust This Guide? Practical Experience From LS Experts

Being a senior engineer in LS Precision, our company has been a long-time service partner for a top global consumer electronics brand and has been heavily engaged in the R&D and mass production of precision structural components for several generations of flagship products. LS Precision has had more than a decade of experience with high-end material CNC machining and has developed comprehensive technical capabilities, including materials analysis and prototype testing, to mass production optimization.

The grade 5 titanium case on the iPhone Air, the LS Precision group overcame a number of significant hurdles in CNC machining this metal:

- Because of its superior strength and superior thermal conductivity, regular cutters are quickly worn out. LS Precision achieved a 50% tool life extension using special super-hard coated cutters and optimal cutting conditions.

- Moreover, to minimize the thermal deformation dimensional errors of titanium alloys, LS Precision came up with a multi-step cooling and dynamic calibration process and micron-level tolerance control.

These remarks are not scholarly but result from actual data and technical experience acquired during the mass production of more than tens of million pieces of titanium alloy.

Why Has Grade 5 Titanium Become The Preferred Choice For Lightweight High-End Consumer Electronics?

With mobile phones aiming to be thinner and lighter, material selection becomes crucial in defining the product. Here, grade 5 titanium (Ti-6Al-4V) has emerged as the material of choice for weight reduction for premium consumer electronic devices.

1. 5 Titanium's Core Advantages:

Its best advantage is its greater weight-to-strength ratio—it is lighter than aluminum but more resistant to deformation than steel. Grade 5 titanium is a few orders of magnitude stronger than traditional aluminum alloys, which enables it to give the same structural stiffness at a thinner gauge and thus achieve gigantic weight savings.

Compared to stainless steel, titanium components are 40% lighter but equally strong. Moreover, grade 5 titanium also has higher corrosion and creep strength and is also highly resistant to scratches and ordinary usage impacts.

2. Challenges of Grade 5 Titanium:

This phenomenal performance is very costly and difficult to produce. Grade 5 titanium, though costly, is also very strong and having low thermal conductance, making it very difficult for CNC machining, needing tools, experience, and precision control to the extreme. This therefore requires the services of the best precision machining experts.

With its disruptive traits of being "lighter than aluminum, stronger than steel," grade 5 titanium is the be-all and end-all solution to pinnacle lightness and strength in products.

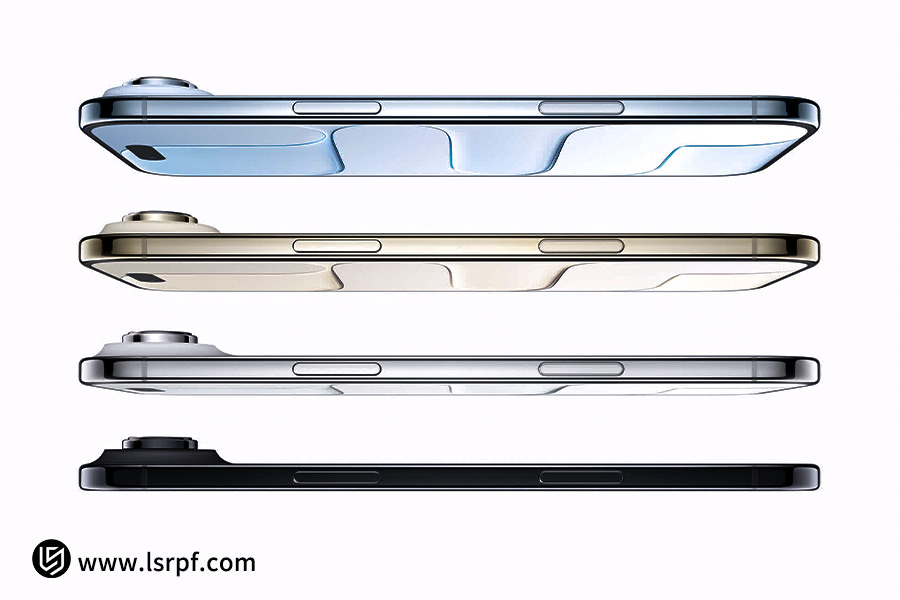

iPhone Air Ultralight Design: A Perfect Combination Of Titanium And Aluminum Inner Frame

Ultralightness of iPhone Air titanium version is achieved by an ingenious material combination technology: a titanium frame composite structure paired with an aluminum alloy inner frame. Such a construction achieves the optimal balance between the three most fundamental variables of strength, weight, and expense.

1. Ingenious Material Combination Innovation:

Outer titanium structure built from grade 5 titanium alloy (Ti-6Al-4V) to achieve higher strength-to-weight ratio and corrosion resistance, offering complete structural stiffness and high-quality touch feedback to the phone. Inner aluminum alloy structure leverages light weight, formability, and reduced cost of aluminum, offering support with minimal overall weight and fabrication cost.

2. Extremely High Assembly Precision Requirements:

It is extremely precise assembly of this composite state, and it must be accomplished. The difference in thermal expansion coefficients and physical properties of the two metals necessitates nanometer-scale joining technology; even minimal imperfection will compromise structural integrity. This is the most valuable to highest-level precision manufacturers – with strategic joining methods and close tolerance control, the two materials are brought together to produce the iPhone Air titanium model's reliability and lightness.

iPhone Air achieves ideal strength, lightness, and affordability through its cutting-edge incorporation of a titanium frame and aluminum alloy core. The realization of ultra-light design fully warrants the supreme significance of precision manufacturing to consumer electronics design.

How Does CNC Precision Machining Create A Top-Tier Titanium Alloy Frame?

Placing the solid block of grade 5 titanium into the impossibly resilient but brittle titanium case of the iPhone Air is the ultimate height of precision engineering. The CNC precision machining is a significant and pivotal role to the job of so doing. It is subtraction, computer controlled cutting an ingot of titanium into a precise intricate shape.

1. CNC Machining of Grade 5 Titanium:

Grade 5 titanium CNC turning is a combination of art and engineering.

- Turning of grade 5 titanium generates huge heat due to low thermal conductivity and high strength, leading to severe tool wear (tool wear rate is 8-10 times the machining rate of an aluminum alloy) and workpiece thermal deformation.

- To address this issue, under strictly controlled cutting speed, feed rate, and coolant conditions on a multi-axis CNC machine tool, and specifically diamond-coated cutting tool must be used.

2. CNC Machining Process:

The machining process can be broadly divided into three stages:

- Roughing removes the excess material at a fast pace;

- Semi-finishing initially defines the silhouette of the product;

- Fine machining involves micron-level control for precision as well as surface finishing.

Each operation demands different toolpaths and cutting parameters to guarantee the quality of the final surface and final product dimensions. For example, accurate features like the bezel's antenna slots and button holes demand five-axis machining center milling to a high precision to guarantee that all the features meet design specifications.

CNC precision grinding is a critical element of mass production on a grand scale of grade 5 titanium bezels. By surpassing the disadvantages of tool wear and heat warpage, it transforms hard titanium into bezel components with intricate structures and elegant appearances via a sequence of precise cutting processes. This proves the excellence of top-notch manufacturing technology and imparts the product with delicate structural strength and beautiful appearance.

Why Choose Grade 5 Titanium Over Other Materials?

Today in the electronics industry, with ultra performance and light weight being the largest mandates, material selection is most important when making product competitiveness decisions. Grade 5 titanium (Ti-6Al-4V) excels above all others in so far as it is a balanced representation in most of its most important performance features. A comparison of major materials is provided on a side-to-side basis:

| Features | Grade 5 Titanium | Aluminum Alloy | Stainless Steel | Carbon Fiber |

| Strength-to-Weight Ratio | Excellent (Aerospace Grade) | Good | Moderate | Excellent |

| Material Cost | Expensive | Economical | Moderate | Expensive |

| Processing | Difficulty | Extremely Easy | Moderate | Special Processing |

| Durability | Excellent (Corrosion and Scratch Resistance) | Good | Excellent | Fair (Easy to Delaminate) |

| Texture | High-End and Warm | Moderate | Refined | Technological |

A comparison between titanium and stainless steel, grade 5 titanium can gain a weight savings of as much as 40% while maintaining the same strength. Its lighter weight relative to aluminum is also demonstrated by: For the same strength requirements, titanium parts can be made thinner to achieve truly ultralight structures.

Carbon fiber lightweighting is excellent but is limited by anisotropy and poor impact resistance, which puts constraints on application in consumer products. Grade 5 titanium's unique value is its leading overall performance in the world: it offers superior strength-to-weight ratio, exceptional toughness, and superior appearance.

While machining can be challenging and costly, these challenges can be eliminated by having an alliance with LS Precision, an advanced machining supplier. LS Precision is extremely experienced with machining grade 5 titanium and can help brands eliminate machining problems and realize their design vision.

If your part needs an above-normal strength-to-weight ratio and high-end look, grade 5 titanium is the solution, and LS Precision can help you overcome these machining challenges.

LS Case Study: Customizing Grade 5 Titanium Components For A Top Brand

As the consumer electronics sector sought ultralightweight, LS Precision Manufacturing, which had extensive experience in machining specialty materials, was in a position to help a leading world consumer electronics corporation make the breakthrough product innovation feasible. The following is an in-depth case study:

1. The challenge of the client:

A global consumer electronics industry giant was launching a revolutionary ultralightweight flagship product, and the essential structural components needed to be machined from grade 5 titanium. The customer had extremely high requirements:

- The material needs to be light in weight but of exceptional strength;

- The surface treatment needs to result in a perfect, mirror finish;

- In mass production in large quantities, a high yield of more than 99.8% was necessary.

This presented unprecedented challenges to machining stability and accuracy.

2. LS Precision's innovative solution:

To counter this challenge, LS Precision brought together a specialized technical team and created an integrated solution:

- The fifth-generation five-axis CNC precision machining center was employed to offer accurate, one-shot molding of intricate geometries.

- Special PCD (polycrystalline diamond)-coated tools were created to overcome the distinctive properties of grade 5 titanium in order to attain more than three times longer tool life.

- A new multi-stage cooling system was developed to manage thermal deformation in machining effectively.

- LS Precision created a precision fixture system for specialized purposes to achieve machining stability, and a general quality control system was implemented from raw material inspection to inspection of the finished products.

3. Outstanding project results:

Thanks to LS Precision's technical expertise and rigorous quality control, the project achieved outstanding results: the first 100,000 products were shipped as scheduled, with a 99.85% yield rate, exceeding expectations. The product was 45% lighter than the conventional design, and the strength was increased by 30%, exactly satisfying the customer's ultra-lightweight requirement. The project won the customer's applause and established a long-term strategic partnership.

LS Precision Manufacturing boasts of the seamless combination of state-of-the-art materials and state-of-the-art processes to provide customers with one-stop-shop solutions, from design optimization to mass production.

Choosing Titanium? Four Advantages And Challenges You Must Understand

When selecting grade 5 titanium as a material for your product, it is necessary to be aware of its properties fully. This aerospace-grade material is of the most benefit but also contains certain issues, and deciding on it should be done after weighing these two sides.

1. Four Core Advantages:

Titanium metal has four core advantages:

- Excellent Strength-to-Weight Ratio: Grade 5 titanium is stronger than steel and light like aluminum, making it ideal for ultra-lightweight designs.

- Exceptional Corrosion Resistance: Extremely resistant to corrosive media like sweat and seawater, its lifetime is much longer than that of stainless steel.

- Exceptional Biocompatibility: Non-toxic to the human body and non-allergic, ideal for wearable devices.

- Superior Texture and Aesthetics: Its characteristic metallic luster and soft touch confer superior quality and added value.

2. Four Real Challenges:

Similarly, titanium metal also faces four major practical challenges:

- High Material Cost: Grade 5 titanium is 10-15 times higher in cost than aluminum and 5-8 times higher than stainless steel.

- Complex Processing: Requires specialized equipment and tools and processing is 3-5 times longer than for aluminum.

- Difficulty in Controlling Manufacturing Yield: Thermal deformation and tool wear during processing have a direct influence on product yield.

- High Post-Processing Requirements: Surface treatment and coloring procedures are more complex than for conventional materials.

Comparisons to stainless steel also highlight its value:

At equal strength, titanium parts weigh more than 40% less than stainless steel and offer higher corrosion resistance. These processing challenges are precisely where LS Precision's expert partnerships are well worth it—we push through difficult manufacturing obstacles so that you can focus on product design and innovation in the market.

Collaborating with an experienced titanium-processing partner such as LS Precision not only overcomes these challenges but also achieves the maximum potential of this unique material, ultimately creating truly competitive, high-quality products.

Partnering With LS Precision: Optimizing Cost And Efficiency Of Titanium Parts

For decision-makers in a project that require improved product performance while keeping total cost in view, choosing grade 5 titanium is not always synonymous with suffering high production expenses. LS Precision uses innovative collaborative working plans to bring clients the practical solutions of cost reduction and efficiency improvement.

1. Early Project Stage:

As a technical partner, the value of LS Precision is evident at the beginning of a project. Expert DFM (Design for Manufacturability) consulting is what we provide, performing early in the design cycle. Leveraging our extensive experience with grade 5 titanium CNC precision machining, we make recommendations to customers:

- How to reduce complexity of machining by reducing deep holes and complex cavities;

- How to maximize wall thickness distribution to avoid deformation hazards;

- How to establish reasonable tolerance levels to avoid over-machining.

These plain-sounding recommendations can pay huge dividends in ultimate cost—a minor design refinement can reduce machining time by 30% or increase tool life by 50%.

2. Manufacturing:

LS Precision employs a sophisticated process database and optimized machining parameters in manufacturing to achieve the highest possible efficiency for each CNC machine. Our own in-house tooling and fixture systems also enhance machining stability and consistency with a yield rate of over 99.5% and a significantly reduced quality cost. We also utilize an optimal raw material utilization policy, where material waste is managed through intelligent scheduling and recycling of the scrap.

Through front-end design optimization and innovative manufacturing processes, LS Precision allows customers to utilize the superior performance of grade 5 titanium while controlling overall costs responsibly, achieving both increased product quality and economics.

FAQs

1. Is the cost of grade 5 titanium prohibitively expensive?

While raw material cost for grade 5 titanium is in fact higher than traditional materials, the reality that it offers a higher strength-to-weight ratio means less material can be utilized to achieve the same structural strength, offsetting this cost to a great extent. Of greater importance, working with an experienced manufacturer like LS Precision will do much to reduce total cost through part design, processing optimized for a given application and optimized material usage. Therefore, grade 5 titanium is not overly expensive but a cost-effective one to invest in.

2. Is the titanium bezel susceptible to scratching or discoloration?

Grade 5 titanium is naturally resistant to corrosion and scratches, and a dense oxide film forms on the surface, providing natural protection. LS Precision's advanced surface treatment technology (e.g., micro-arc oxidation, sandblast treatment, or PVD coating) can further enhance the surface hardness of products to above HV800, increasing wear resistance by 3-5 times. Besides enhancing durability, treatments also provide complete color options, ensuring long-lasting product appearance.

3. Can I enjoy professional titanium alloy CNC machining even for small orders?

LS Precision has numerous high-accuracy five-axis CNC machines, and we can scale from prototyping to small lots. We have the same quality service for both startups and large brands. With dedicated small-lot production lines and an on-call response team, we ensure that regardless of the order size, you receive the same technical assistance and quality warranty, allowing customers to validate their product designs at the optimal price.

4. Besides mobile phones, what other product applications are titanium alloys suitable for?

Grade 5 titanium alloy is widely used in medical devices (such as orthopedic implants and surgical tools), aerospace components, high-performance outdoor equipment, and intelligent wearables. LS Precision has abundant project experience in these markets and provides professional titanium alloy processing solutions to clients from diverse industries, helping them achieve the best combination of lightweighting, high strength, and high reliability.

Summary

Grade 5 titanium, with its excellent qualities of being "stronger than steel and lighter than aluminum," makes it the optimal choice for extreme lightweighting in high-end consumer devices. However, to transform the potential of this revolutionary material into a successful product requires a dedicated precision manufacturing partner.

LS Precision, possessing years of high-quality CNC machining experience, has surpassed the challenge of machining grade 5 titanium. Not only do we offer exact manufacturing capacity, but we also offer full-line solutions from initial material selection and structural design optimization through mass production and shipping that allow customers to maintain product quality with effective overall cost control.

Contact LS Precision for a complimentary technical consultation and quote! Supply us with your product requirements, and our engineers will get back to you with an initial solution in 24 hours! Let us work together to transform your innovative thoughts into market-leading, world-class products.

Upload your design drawings now and get an instant CNC machining quote ( CNC machining price), let LS be your strong backing in pursuit of ultimate CNC machining precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com