Your future project is confronted with a crucial choice: opt for the tried, cost-effective 3-axis machining or pay for the efficiency and sophistication of 5-axis machining? The choice may save you thousands of dollars, but it might also result in time-consuming rework and delayed delivery. It's not just selecting an item of equipment here at LS Manufacturing, it's selecting the optimal technology path for your project. We're not just a supplier of machining services; we're your manufacturing strategy guide, working together to dissect each piece.

This article will outline the basic distinctions between 5-axis and 3-axis CNC machining, providing you with a concise guide to choosing CNC machining. Coupled with our years of experience, we would like to help you properly match project need with machining capability, in effect removing CNC machining errors and maximizing return on investment. To save you time, here’s a quick overview of the core conclusions.

3-Axis vs. 5-Axis CNC Machining Core Quick Reference

| Feature Dimensions | 3-Axis Machining | 5-Axis Machining |

| Core Motion | Motion of the tool along the three linear axes (X, Y, and Z). | Two rotating axes (A/C or B/C) are overlaid over the three linear axes. |

| Geometric Capabilities | Basically works on the geometric features in one direction; tough parts require multiple setups. | Tough curved surfaces, inclining features, and side surfaces can be machined in one setup. |

| Setup and Fixturing | Multi-setup parts are time consuming and prone to errors. | One setup completes most of the machining with minimal error accumulation. |

| Accuracy and Consistency | Multi-setup parts generate cumulative errors and relatively lower accuracy. | Fewer setups provide positional accuracy between features to achieve higher consistency. |

| Surface Finish | Tool change may be required in machining of detailed curved surfaces, affecting finish. | The tool acquires the optimum cutting conditions, resulting in better surface finish. |

| Cost and Efficiency | Lower equipment and programming cost, suited for straightforward parts. | Higher equipment and programming cost, but higher overall efficiency for detailed parts. |

| Optimum Applications | Plate and disc parts; straightforward molds; 2D contour machining. | Aerospace components; impellers and turbine parts; detailed molds; medical implants |

This table merely shows that the key to choosing the right part is part complexity and accuracy needs:

- Choosing 3-axis machining: If your project involves a great deal of 2D or simple 3D geometry and you're cheap, then 3-axis machining is cost-effective.

- Choosing 5-axis machining: In situations where components have complex curves, sloping features, or require tight position tolerances, the ability to perform the whole operation in a single setup eliminates errors caused by multiple setups, reduces overall labor hours, and basically eliminates rework and delay caused by incorrect processing.

For mid-project projects, expert partner consultation like that of LS Manufacturing is crucial. We can provide the lowest cost hybrid process solution based on your own material, design, and production volume, and help make the optimal decision.

Why Trust This Guide? Real-World Experience From LS Manufacturing Experts

The knowledge reflected herein is not theoretical; it is the practical know-how of the LS Manufacturing personnel via thousands of high-precision machining endeavors. We have solid manufacturing experience in aerospace, medical, and precision instrument applications, and are equipped with sophisticated multi-axis CNC machine tools. This allows us to guarantee that recommendations are supported by high-volume, high-demand production.

For example, LS Manufacturing needed to produce a complex aluminum alloy aerospace bracket prototype. The customer had initially considered using 3-axis machining in several setups in order to save on costs, but we determined the approach would not provide the all-important relative tolerances of the thin walls and sloped hole systems. We chose firmly a 5-axis, one-setup approach to the prototype production.

This approach not only met all the stringent accuracy requirements set forth in the drawings, but also cut out the three-axis machining distortion and secondary alignment mistakes. This reduced the client's project lead times by 35% by effectively trimming weeks of rework and verification time.

This is the value of LS Manufacturing: We don't just do the machining; we apply our expertise to anticipate issues and set the best course of action at the front end of the project, so you receive optimal value for your investment.

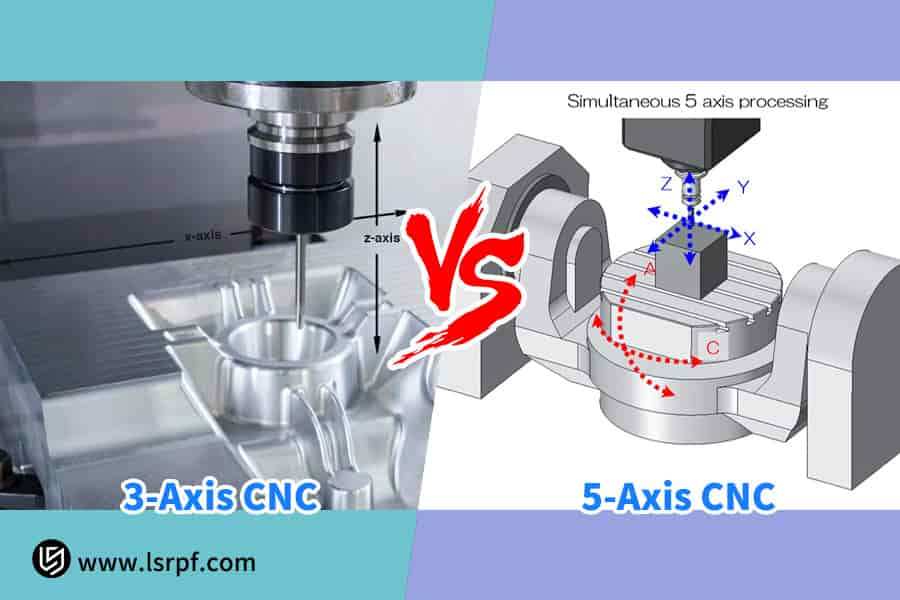

What Is The Core Difference Between 3-Axis And 5-Axis CNC?

Everybody's initial response is "number of axes," but this isn't what it's all about. The real difference goes far beyond this; it is a qualitative leap in motion capability, which directly motivates the types of parts you can machine and what precision is possible.The key to the difference between 5-axis and 3-axis CNC machining is understanding what the "positioning" and "synchronized" categories of five-axis machining entail. The leap in capability from "positioning" to "synchronized machining":

1. 3-Axis Machining:

It is only raked against the worktable and travels linearly up and down, side and side, and front to back (X, Y, Z) directions like the nib of a pen that will only travel straight up. If it strikes the side of the piece or a bevel with a built-in angle, the machine has to be shut down and re-clamped, a loss as well as being prone to compound errors.

2. 5-Axis "Positioning" Machining:

Two rotary axes first rotate and position the workpiece into its optimum position and clamp it, then the 3-axis linear machine completes the cutting. It is like hand-rotating a multi-bevel so it is directly facing the cutting tool. This allows for multiple sides of the part to be cut within a single clamping, greatly increasing accuracy and productivity.

3. 5-Axis "Linked" Machining:

This is truly the elegance of multi-axis machining. The 5 axes all move in unison and in concert with one another, thus keeping the tool in its optimal position with complex surfaces and being able to cut. Imagine the robot arm supporting the cutting tool and "wrapping" around the workpiece, gliding smoothly and cutting. This offers maximum processing of parts with long, complex curves, such as impellers and turbines, with a unique surface finish.

4. The Decisive Impact on Machining Capabilities:

This difference in capability in motion is, on its turn, directly translated to moving complex geometry. 5-axis machining never hesitates to move deep cavities, steep walls, and undercuts that three-axis machines may not be able to manage. Maintaining the optimum tool cutting position, it promotes quality and tool preservation.

The distinction between 5-axis and 3-axis CNC machining relies on the transition from "fixed-view" machining to "panoramic-view" machining. 5-axis machining not only eradicates the issue of location in "manufacturing multiple surfaces in a single clamping," but through linked machining, completes a qualitative leap in "manufacturing complex surfaces with the best position."

What 3 Factors Determine The Choice Between 3-Axis And 5-Axis Machining?

Selecting the appropriate CNC machining solution is many, many more than apples-to-apples equipment price comparison; it's top-to-bottom decision-making from the extremely specific project requirements. At LS Manufacturing, we guide customers through formal evaluation in three basic dimensions to realize optimal machining process efficiency and cost-effectiveness to the best.

1. Part Geometric Complexity:

That is the clincher. If your part consists primarily of 2D profiles or plane steps in 3D or linear holes, 3-axis machining is sufficient. But when the product is chock-full of inclines, deep cavities, undercuts, or free-form shapes, 5-axis technology is the only solution. It can slice out all the fine details in a single setup, in effect removing multiple positioning errors and ensuring precision and quality.

2. Production Volume and Efficiency Requirements:

Production quantity directly affects economic efficiency. In prototyping or low-volume production, 3-axis machining would normally be chosen due to its shorter setup time and programming costs. But when entering high-volume manufacturing, the efficiency advantages of 5-axis "single setup" are extremely valuable. It reduces setup time, human touch, and number of fixtures. While more expensive per hour, total cost per part may be less, and manufacturing cycle time can be significantly shortened.

3. Overall Budget (Including Fixtures and Labor):

Options need to consider the cost of ownership, and not just machine tool rate. 3-axis machining has less direct cost, but intricate parts may require expensive specialized fixtures, as well as high setup and inspection time. 5-axis machining is more expensive upfront, but by cutting or eliminating intricate fixtures, reducing setup time, and minimizing secondary operations, it generally offers tighter budgeting and avoids potential rework losses.

Simple parts, low volumes, and low budgets are ideal for 3-axis machining; complex shapes, high volumes, and tight cycle times are ideal for 5-axis machining.

Why Do "Seemingly Simple" Parts Require 5-Axis Machining?

Traditionally, 5-axis machining is reserved for complex curved parts. Many seemingly simple polyhedral parts are ideal candidates to demonstrate the advantages of multi-axis machining. Its strongest asset is in avoidance of CNC machining errors via process innovation.

1. Addressing the precision challenges of multi-angle features:

Take for instance, a box with multiple machining features on various faces. 3-axis machine tools require a number of re-clamping, with each introducing positioning errors and leading to misplaced holes. 5-axis technology allows all of the machining operations to be carried out in a single setup, effectively guaranteeing accurate positioning relationships between features.

2. Simplified Process and Reduced Human Risk:

3-axis machining of such a part often requires special fixturing, which is costly and highly operator skill-dependent, leading to batch scrap. 5-axis machining eliminates or reduces complex tooling, automates the process, and significantly reduces quality fluctuations because of setup inaccuracies.

3. The Inevitable Choice for Ensuring Tight Geometric Tolerances:

For those features needing high coaxiality or perpendicularity, "single-clamping" of five-axis machining guarantees that all machined features are defined using the same datum to avoid error accumulation. This is essential in those applications where high reliability is needed.

The implementation of 5-axis for "less complex" parts is generally a search for additional precision, efficiency, and dependability. It positively avoids CNC machining defects by optimizing the process, demonstrating that the advantages of multi-axis machining are truly a step towards better manufacturing thinking.

How Do 3-Axis And 5-Axis Machines Work Together To Enhance Efficiency In Automotive Mold Manufacturing?

In automobile mold manufacturing, LS Manufacturing does not simply choose between 3-axis and 5-axis machining. Instead, by way of scientific process planning, it synergizes both strengths, yielding a model of optimal machining. This synergy plays a critical role in achieving both high efficiency and high precision by striking a balance.

1. 3-Axis: Leveraging Stability and Economy

LS Manufacturing takes full advantage of 3-axis rigidity of machine tools and cost benefits, applying it to rough large-residue mold blanks and manufacturing general features such as common holes and flat surfaces. This positions the subsequent finishing process to be capable of doing rapid and stable machining in control, thus limiting total machining costs.

2. 5-Axis: Focusing on Complex Surfaces and Deep Cavities

5-axis machining is a necessity for the finishing operation. 5-axis simultaneous machining provides the ability to achieve best cutting posture to finish steep sidewalls, deep cavities, and complicated curved surface details common on molds such as bumpers and instrument panels. One-pass high-quality finishing, smooth surface finish tool mark-free, and undercuts excellently addressed which are difficult to reach with 3-axis machines are some of the benefits.

3. Collaboration: Achieving a Perfect Closed Loop of Efficiency and Precision

LS Manufacturing engineers develop precise process planning to enable the 3-axis and 5-axis machining processes to perform their respective individual specialized tasks. 3-axis performs the "physical work" efficiently, and five-axis performs the "fine work" efficiently. This not only cuts mold delivery cycles dramatically but effectively ensures positional accuracy between mold surfaces and structural elements by minimizing multiple clampings.

The key to effective 3-axis and 5-axis automobile mold machining is cooperation, not compromise. LS Manufacturing utilizes this hybrid process method of science to provide optimized machining processes in reality, and customers benefit from reduced cycle time, improved quality, and decreased overall cost of manufacturing.

What Are The Hidden Costs Associated With Underestimating 5-Axis Investment?

In contemplating 5-axis CNC machining, most companies will only take into account the external expense of the actual equipment and not the numerous concealed costs involved with it. Failure to manage these concealed costs can not only deplete expected profits but can also cause additional problems by a lack of preparedness, debilitating the entire purpose of avoiding CNC machining mistakes.

| Hidden Cost Dimensions | Core Challenges | The Value of LS Manufacturing |

| Labour and Programming | Post-processing and programming by highly skilled programming professionals and technicians is complicated and time-consuming. | Working with a veteran group of professionals and well-organized processes as a routine for efficiency purposes enhances productivity without increased costs. |

| Software and Hardware Investment | There is a large investment needed for customized post-processors and higher-level simulation software to avoid costly collision risks. | The use of tried-and-tested simulation and post-processing software ensures program reliability and integrity. |

| Tooling and Verification | Repeated machining of complex angles requires accurate fixtures and longer program verification. | We provide optimized tooling solutions and process-based verification to ensure first-time success. |

These covert costs are a part of 5-axis CNC machining capacity and have to be managed. The worth of LS Manufacturing is in our proven methods and experience to effectively handle and streamline these costs so that your investment is safely and effectively converted into excellent products. This really stops business from CNC machining mistakes and value maximization.

Case Study: How LS Manufacturing Optimized Impeller Machining For An Aerospace Client?

The correct process in precision manufacturing is the key to success in a project. One of our clients, a developer of drone engines, faced the following critical problem: multi-setup machining of an aluminum alloy impeller on a three-axis machine tool caused enormous blade profile errors, dynamic balancing issues, and up to 15% scrap rate, significantly slowing down project development.

1. Customer's Dilemma:

Traditional 3-axis machining is unable to machine all those complex curved surfaces in one setup. Repositioning repeatedly inevitably results in cumulative error, the cause of non-uniform blade wall thickness and poor dynamic performance.

2. LS Manufacturing's Solution:

LS Manufacturing created a tailored machining process optimization solution that was particularly adapted to the structural characteristics of this impeller. In a single setup on a high-speed 5-axis machining center, we accurately machined all the curved surfaces, flow passages, and hubs. Using a special impeller programming module, we tightly controlled the tool path axis, offering maximum cutting forces and stability, demonstrating the outstanding contribution of 5-axis CNC machining in complex part manufacturing.

3. Results and Value:

This solution completely solved the pain points of the customer. Dynamic balancing quality of the impeller was enhanced to G2.5 significantly, and qualification rate of the product rose from 85% to 99%. Moreover, by eliminating repeat adjustment and multiple setups, the overall machining cycle was reduced by 60%, allowing for on-schedule flight test of the customer's engine reliably.

This 5-axis machining case study in full demonstrates the advantages of five-axis machining. For high-value, advanced, and critical components like impellers, investment in proven 5-axis CNC machining technology is not only a way to recover quality issues but also the optimal method for maximizing total project efficiency and reducing overall cost.

How Can We Prevent Machining Errors At The Source Through DFM?

The root cause of the majority of machining faults and cost overruns is already during the part design. LS Manufacturing encourages preemptive cooperation, working with the clients to optimize machining processes from design phase to manufacturability analysis for design. This is the most effective method to avoid CNC machining faults.

1. Optimizing Geometric Features to Match Process Capabilities:

LS Manufacturing engineers verify significant features such as internal fillet radius and aspect ratio. For example, internal fillets to nominal tool sizes or preventing too deep cavities can significantly increase the 3-axis machining feasibility and efficiency. If 5-axis machining becomes inevitable, we optimize surface curvature to be smoother and more stable toolpaths.

2. Simplifying Structures and Reducing Fixturing:

One of the central goals of DFM is to minimize the amount of fixtures needed in machining. LS Manufacturing will recommend that parts with different angled holes be designed such that the angles are optimized to be machined using a single fixture. This has a direct effect on minimizing accuracy and reducing fixture complexity and operating time.

3. Selecting More Cost-Effective Alternatives:

LS Manufacturing frequently experiences that a subtle change in design can result in extensive savings. For instance, redesigning a complex surface to be machined using 5-axis simultaneous machining as a set of multiple simpler surfaces positionable on three axes can dramatically decrease programming and machining complexity and expense with little effect on functionality.

DFM is a proactive, data-driven decision-making technique in which your design is optimized before being shipped to manufacturing. Not only does this naturally eliminate CNC machining errors, but it lays the foundation for successfully achieving project cost and cycle time objectives through early stage machining process optimization.

How Can We Ensure We Always Use The Most Cost-Effective Solution When Working With LS Manufacturing?

We understand that the key to earning your long-term trust is being honest and equitable in all our partnerships. LS Manufacturing adopts a methodical strategy to ensure that every CNC machining choice we make on your behalf is based on data and the optimal solution for your project success, rather than our machine configuration.

1. Transparent Collaborative Evaluation Process:

At the start of a project, our process engineers will sit down with you and review part drawings, materials, and performance requirements. Our open process allows LS Manufacturing to determine exactly why a feature can be machined on 3-axis and another must be machined on 5-axis, so you are fully informed of the technical reasons and drivers of cost.

2. Data-Driven Process Simulation and Costing:

LS Manufacturing ensures to conduct in-depth process simulation and costing on all suggested solutions. That is, we simulate the complete three-axis and five-axis CNC machining processes together, accurately determining and analyzing their respective machining time, required fixtures, tool life, and programming cost, providing you with fact-based, unbiased comparison reports.

3. Principles Focused on Your Success:

We never over-recommend five-axis machining. What we think at LS Manufacturing is this: if an operation can be accomplished with three axes effectively and efficiently, we never recommend upgrading. We recommend only five-axis technology when it offers significant advantages in overall cycle time, accuracy, or cost.

With LS Manufacturing, the best CNC machining solution is fueled by rigorous analysis and unyielding integrity. We aim to be your trusted manufacturing navigator. Through open processes and data-driven decision-making, we assist in ensuring that each solution you choose yields the optimal performance-cost ratio, allowing you to derive maximum return on investment.

What Support Can I Receive From LS Manufacturing Before Starting A Project?

Before a final decision on CNC machining, the best action is to have your project assessed with professional judgment. We extend a genuine invitation for you to take advantage of LS Manufacturing's "Free Process Assessment" and let us help you translate theoretical knowledge into real, actionable solutions for your project.

1. Clear Technical Route and Process Planning:

You just need to send in your part drawing or 3D model, and LS Manufacturing's engineers will perform a detailed analysis. We will clearly let you know if your project is economically more suitable for three-axis machining or requires the convenience of 5-axis CNC machining. Technical support will also be provided in detail to assist you in making a decision.

2. Data-Driven Preliminary Cost and Cycle Analysis:

LS Manufacturing never gives quoted prices with no details. According to assessment results, we will present an initial process plan and cost-benefit analysis with proper knowledge regarding the machining cycle and budget incurred for different technical routes (3-axis or 5-axis), through which you can plan internally correctly.

3. Forward-Looking Potential Risk Warnings:

Capitalizing on our depth of experience in the manufacture of complex parts, LS Manufacturing is able to predict potential manufacturing risks in your design (i.e., accessibility, deformation, and tolerance issue) and recommend improvement recommendations to get your design in the best possible condition before production.

Contact LS Manufacturing today and send us your prints. You'll receive more than a quote; you'll receive collaborative planning with experienced manufacturing consultants.

FAQs

1. Is 5-axis machining necessarily more precise than 3-axis machining?

Not necessarily. The accuracy of machining is primarily governed by the machine tool positioning accuracy and stability. With the usual geometric features like planes and cavities, high-accuracy 3-axis machines are as accurate as microns, and with a simpler structure, more stable. 5-axis machining may be useful in preventing clamping mistakes of numerous times when cutting intricate curved surface. LS Manufacturing will select the solution that most offers precision and stability based on your specific needs and never unfairly recommend a best-of-the-breed setup.

2. How much does programming difficulty increase when upgrading from 3 to 5 axes?

Programming risk and complexity will increase considerably. 5-axis programming poses new challenges such as the control of tool rotation center, singularity avoidance, and collision and interference checking requiring extremely high levels of CAM software and engineer skills. This is the LS Manufacturing key to success—we possess a professional five-axis programming staff and a good process parameter library. Due to standardized operations and real-time simulation, we ensure safe and stable programs, which allow customers to safely sail through technical difficulties.

3. Is 5-axis machining necessary for small-batch prototyping?

If the prototype needs complex surface or assembly relationship validation, it is not discretionary. 5-axis machining's "one-step clamping" eliminates cumulative error from repeated positioning moves and makes the prototype a more accurate representation of the design intent. Though the machining rate per unit is greater, by not using special fixtures and time saved for assembly adjustment, R&D cycle and cost as a whole can be reduced with a more accurate design basis for future mass production.

4. How to determine whether a supplier has true 5-axis machining capabilities?

Three critical points to mention: First, confirm that it is really a 5-axis machine tool and not an indexing head; second, demonstrate a true 5-axis CAM programming system and simulation inspection process; and finally, ensure to inspect the actual complex parts they have machined. LS Manufacturing is open and encourages customers to visit our equipment setups, process documentation library, and representative workpieces to demonstrate our technical competency using actual examples of machining.

Summary

The choice between 5-axis and 3-axis CNC milling is not a question of comparing the cost of equipment; it is a question of technical option with immediate impact on project budget, productivity, and ultimately, success. As this article proves, the best solution usually results from an accurate compromise between part features, batch size, and overall cost.

LS Manufacturing wants to be your most stable and best strategic ally. By utilizing our extensive technical know-how, objective review of process procedures, and customer-focused philosophy in service, we are committed to giving you data-driven, best-of-class solutions. We are not a machining services firm; we are your trusted manufacturing advisor, such that each dollar of your investment counts.

Contact LS Manufacturing today and click "Get a Free Process Plan." Share your part drawing, and our LS Manufacturing experts will present to you a comprehensive, customized "3-Axis/5-Axis Machining Selection and Optimization Proposal" in 24 hours. A prompt CNC machining quote will be given.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.