A wrong process choice may double your cost

You designed a perfect metal shell: smooth lines, delicate structure, and complete functions. The drawings were repeatedly scrutinized and the details were refined. However, when you submitted the design to the manufacturer with great expectations, the quotation you received was like a bucket of cold water poured on your head -far exceeding the budget! It may even be doubled!

Where is the problem?

Most likely, the problem is not the design itself, but a seemingly simple but crucial default choice: you default to "CNC machining", and your design may be a typical "sheet metal" part in essence.

"Sheet metal manufacturing" and "CNC machining" - both words represent "metal manufacturing", which sound like different paths to the same goal. But please understand:they are two completely different manufacturing philosophies, following completely different underlying logic.

The wrong choice is not just a deviation in the process path. It means waste of materials, soaring working hours, and misuse of molds, which ultimately directly translates into astonishing cost differences and uncontrollable production cycles. Understanding the core differences betweensheet metal manufacturingand CNC machining is not just a technical discussion on paper, but thefirst key step to effectively control costs and optimize delivery cyclesin the early stages of product development.

Sheet Metal Fabrication VS CNC Machining

| Features |

Sheet Metal Fabrication |

CNC Machining |

|---|---|---|

| Core principles | Deformation/connection dominated: cutting flat plate -> bending/forming -> connection (welding, riveting, etc.). | The essence is to "shape" thin plates. Subtractive dominated: cutting and removing materials from solid blanks (blocks, bars) to "carve" shapes. |

| Most suitable parts | Thin-walled, hollow, box-type: chassis, housings, brackets, panels, ventilation ducts, simple containers. | Solid, complex structure, high-precision features: molds, fixtures, engine parts, complex radiators, gears, precision bushings, parts with complex 3D surfaces. |

| Core advantages | Cost (large batches): Die stamping is extremely efficient. Material utilization: Usually high (flat blanking). Rapid prototyping: Laser cutting + bending is fast. Lightweight: Naturally thin walls. |

Design freedom: Almost unlimited geometry (deep cavities, complex curves, special-shaped holes, etc.). Ultra-high precision & surface quality: up to micron level. Material consistency: The entire part is made of a single solid material with uniform performance. |

| Core constraints | Geometric complexity: It is difficult to process closed cavities, self-intersecting surfaces, and thick solid features. Wall thickness consistency: It must be uniform (determined by the initial sheet thickness). Accuracy limitations: Multiple bending cumulative errors and welding deformation affect absolute accuracy. |

Cost (material & time): A lot of material waste (chips); long processing time for complex parts. Thin-walled parts are easy to deform: Cutting forces may cause thin walls to vibrate and deform, making processing difficult. Design constraints: Tool accessibility needs to be considered (such as deep cavities and narrow gaps). |

| Cost drivers | Batch: Small batches (laser/bending); large batches (mold stamping costs are diluted). Feature complexity: number of bends, special molds, welding volume. |

Material volume: blank size and material cost. Processing time: complexity, accuracy requirements, surface finish. Number of clamping times: Multiple clamping increases cost and error. |

| Typical material thickness | Thin plate: usually 0.5mm - 6mm (common in bending). Stamping can be slightly thicker, but it is still in the category of "plate". | No fixed restrictions: In theory, very thick blanks (tens of centimeters or even meters) can be processed, and thin walls can also be processed (but with great difficulty). |

This guide will start with the basic principles and deeply compare the differences between the two processes in terms of precision, cost, and speed. Through real cases and design guidelines, it will ultimately help you establish a clear decision-making framework.

Here’s What You’ll Learn:

- The core working principles of sheet metal and CNC:In-depth analysis of how two completely different manufacturing philosophies, “bendingand shaping” and “carving and removing”, can achieve part manufacturing.

- Key differences:Reveal the decisive differences and applicable scenarios between the two in core dimensions such as precision, cost, speed, geometric freedom, and material strength.

- Design Optimization Guide for Engineers:Design guidelines designed particularly forsheet metal and CNCto help you stay away from pitfalls and leverage process advantages to reduce costs. drastically.

- Practical Cost Optimization Case:Reveal the true account of how we reduced the cost of producing an industrial controller housing by 75% through the replacement of process (sheet metalization).

The Smarts of Hybrid Manufacturing:Find out how to skillfully combine the advantages of sheet metal and CNC to achieve perfectly balanced cost-versus-precision on one part. - Expert Quick Questions and Answers (FAQ):Clarify misunderstandings (such as "Is sheet metal always cheaper?", "What is sheet metal processing?") and provide expert advice on material selection.

Now, let's take a deeper look at these two elementary processes that characterize today's manufacturing and gain the insights to take the best decision for your project.

Why Trust This Guide? LS's Manufacturing Philosophy

I deal with thousands of real parts a day at LS. What touched me most was to see so many "well-designed" but expensive parts. The root cause is typically very simple: for example, the designer was in the habit of using the "extrude" command in CAD, and voila, a part that might have been simply bent with sheet metal became an expensive, material-gobbbling machined part. This ability to see the "design-manufacturing" disconnect is the core of LS.

The uniqueness of our experience lies in the cross-process arena:from aerospaceprecision CNC partswith stringent tolerances to server sheet metal chassis requiring utmost cost-effectiveness, we are deeply involved. It is this global vision that gives us the power of optimization to "turn stone into gold".

A typical example:Customer had a part to be machined by expensivefive-axis CNC.We did not do it directly but asked ourselves:

Can it be achieved with a less complex and cheaper combination of processes? In the end, we dismantled it into several basic sheet metal components andweldedthem, saving customers up to 70% of costs without compromising on functions!

This is not a theory, but a practical solution that we have repeatedly verified in the roaring workshop.

The value of this guide is in this one.

It is not a theory book but the true knowledge seasoned withLS engineersby the real-life lessons and successful experiences of 10,000 parts a day.We are well aware of the original design purpose and have a better sense of the cost and feasibility of manufacturing.

Believe me, Gloria, experience working in the LS workshop tells me: This manual can help you avoid cost snares and create sound designs actually effective and economical. It shows our deep understanding and appreciation of craftsmanship.

Sheet metal manufacturing is far beyond "bending".It is a systematicmetal processingtechnology, which bends relativelythin sheetsof metal (such as steel, aluminum, stainless steel, copper, etc.) into three-dimensional parts or products with special functions and shapes by a series of exact processes. Its nature is material saving andrapid prototyping, especially suited for mass production of relatively simple-structure components.

Sheet Metal Fabrication In Depth: How It Works?Overview of the basic steps ofsheet metal processing

| Steps | Core equipment/technology | Key purpose and features |

|---|---|---|

| 1.Blanking | Laser cutting, plasma cutting, punching machine | Precisely separate the two-dimensional plane unfolded shape of the part from a large sheet of metal. |

| 2.Forming | Press Brake | Shape the two-dimensional flat plate into a three-dimensional structure through precision bending (V-shaped, U-shaped, air bending, etc.). |

| 3.Connection | Welding, riveting, screwing | Assemble and combine complex parts that cannot be formed by a single sheet into a whole. |

| 4. Post-processing | Grinding, spraying, anodizing, etc. | Improve the surface quality, corrosion resistance, aesthetics of parts or give them specific functions. |

1. Blanking: The first process of correct separation

Objective:To shear the desired two-dimensional unfolded part diagram (considering the subsequent bending deformation) from the enormousraw materialmetal plate properly and correctly.

Major technology and equipment:

- Laser cutting:Use a concentrated high-power laser beam to melt or vaporize the material. It owns extremely high accuracy (up to ±0.1mm), thin cutting seam, tiny heat-affected zone, and suitable for intricate shapes and fine parts. It is the mainstream high-precision blanking method currently.

- Plasma cutting:Use high-temperature and high-speed plasma arc to melt the metal, and high-speed air stream to quench the molten metal. Cutting speed is fast, especially good at medium and heavy plates (plate thickness for whichlaser cuttingis not economical), but accuracy and finish quality usually less good than laser cutting, with a larger heat-affected zone.

- Punch/stamping:Shear the plate using a die. Advantages: For a large number of parts with relatively standardized contours (large quantities of round holes, square holes, and prescribed outer shapes), the productivity is extremely high and one punching can complete several operations (punching, blanking, shallow drawing). Disadvantages: Expensive molds, low flexibility (long changeover time), and not for one-piece small lots or complicated contours.

Key points:

The edge quality and blanking accuracy influence directly the quality of downstream processes (more specifically positioningbending) and the final product. Choosing what technology to look at needs to consider material type, thickness, complexity of part, precision requirements, batch and cost of production.

2. Forming: The art of giving three-dimensional life

Purpose:To deform the flat blank into the required three-dimensional shape by plastic deformation. The most basic and most extensively used process in sheet metal forming is bending.

Essential equipment:Press Brake

Essential process:Bending

V-shaped bending:Most employed technique. The sheet is placed on the lower die with a V-shaped hole, and the top die (knife tip) is pressed downward into the V groove, folding the sheet along the predetermined line of bending. Thebending angleis precisely regulated by the depth of pressing of the top die.

U-shaped bending:Use a U-shaped lower die and matching punch to create a U-shaped form at one time. Generally requires more pressure.

Air bending:The top die tip does not hit the sheet downwards to the bottom to touch the bottom of the lower die V groove, nor hangs above the sheet by a finite gap. It is the pressing depth which determines the finished angle. Advantages:Good flexibility (a set of dies can bend in multiple angles), pressure needed is lesser, and rebound is easier to reverse. It is the current mainstream bending method.

Bottom bending/imprint bending:The top die pushes the sheet completely into the bottom V-groove of the lower die and presses more, with the material undergoing plastic deformation or even minor extrusion within the die cavity.Advantage:High precision and low springback.Disadvantage:Requires a larger tonnagemachine tool, causes greater wear to the die, and requires a specific V-groove for each angle/thickness.

Key considerations

- Springback:As soon as the bending force is removed, the metal will elastically spring back some of the angle. Compensation should be appropriately done during programming and design of the die.

- Bending sequence:For complexmulti-bendingcomponents, the bending sequence is extremely crucial, and interference should be avoided and accuracy should be ensured.

- Minimum bend radius:Depends on type of material, thickness, and heat treatment condition. A radius that's too small will result in too much stretching and cracking of the outside material.

- K factor/bending coefficient:A significant factor utilized to determine the location of the neutral layer in computing the unfolded length.

3. Connection: Building a complex whole

Purpose:Whenever the components are so complex that they can no longer be produced by bending a single sheet, or need to be constructed with other components, multiplesheet metal piecesor sheet metal pieces are regularly connected to other pieces.

Principal technologies:

- Welding:(MIG, TIG, spot welding,laser welding, etc.) The material is bonded by molten metal. Strengths: Strong and well-sealed (consecutive welding). Weaknesses: Thermal deformation is induced, subsequent processing is required, and the appearance is not necessarily gorgeous.

- Riveting:Connection is achieved by means of mechanical deformation of rivets. Merits: No thermal effect, employed in joining various materials, high reliability. Demerits: Pre-drilling is required, which increases the weight of the parts.

- Bolting/Screwing:Connection is achieved by means of the assistance of bolts, nuts, self-tapping screws, etc. Merits: Removable, simple to join, no thermal effect. Demerits: Pre-drilling or tapping is required, and the connection point is elevated.

- Snap/crimp:Use the elastic deformation of thesheet materialitself or a specially designed structure to create a fastener-free joint. Generally used on chassis covers, etc.

- Points to note:The choice of the method of jointing must consider in full strength needs, sealing needs, appearance needs, whether it is disassemblable, manufacturing efficiency, cost, and the impact on the parent material (e.g., the thermal distortion due to welding).

4. Post-processing: finishing and protection

Purpose:Improve the functionality, lifespan and aesthetics of the product.

Common processes:

- Deburring/grinding:Remove sharp edges and burrs from cutting and bending to offer safety and ease of assembly.

- Weld grinding/polishing:Polish the welding area and render it stunning.

- Surface cleaning:Remove oil, dust, and oxide coating (e.g., sandblasting, pickling).

- Painting (Painting/Powder Coating):Apply liquid paint or electrostatic powder coating which forms a protective decorative finish upon curing. Anti-corrosion, of various colors and texture, powder coating is long-lasting and environmentally friendly.

- Electroplating:(nickel plating, chrome plating, zinc plating, etc.) employs the electrolysis method to deposit a metal layer onto the surface, mainly for wear protection or anti-corrosion, or for decorative finish.

- Anodizing:(foraluminum alloys) forms a thin hard oxide surface coating. Increases corrosion resistance, wear resistance, insulation, and can be dyed to produce deep colors.

- Silk screen/laser marking:Add logos, text, and graphics.

Detailed Explanation Of CNC Machining: New Art Of "Carving" With Controlled Cutting

"Although the 'shaping' philosophy of metal sheeting by compression and retention of shape defines the end part geometry through the process of undoing material, CNC machining is a "carving" art whose essence is material removal under control."

It is much like a computer-age sculptor gradually stripping the rigid metal blank with step-by-step commands andcutting tools, and ultimately producing the complex form required by the drawing.

Before going through the nitty-gritty, let's overview the key steps and key contents of CNC machining from the following table:

| Core stage | Core tasks | Key input/tool | Key output/goal |

|---|---|---|---|

| 1.Programming | Convert design intent into machine instructions | CAD model, CAM software | G code (tool path instructions) |

| 2. Clamping | Ensure that the blank is stable and accurately positioned during processing | Solid metal billet (Billet), fixture, machine tool table | Firmly fixed and accurately positioned workpiece to be processed |

| 3. Cutting | Precisely remove excess material according to instructions to form the target shape | CNC machine tools (milling machines/lathes), high-speed rotating tools, coolants | Parts close to the final shape (rough machining/finishing) |

| 4. Post-processing | Improve the surface quality and performance of parts and conduct final verification | Deburring tools, sandblasting machines, anodizing tanks, measuring equipment | Finished parts that meet design requirements (size, surface, function) |

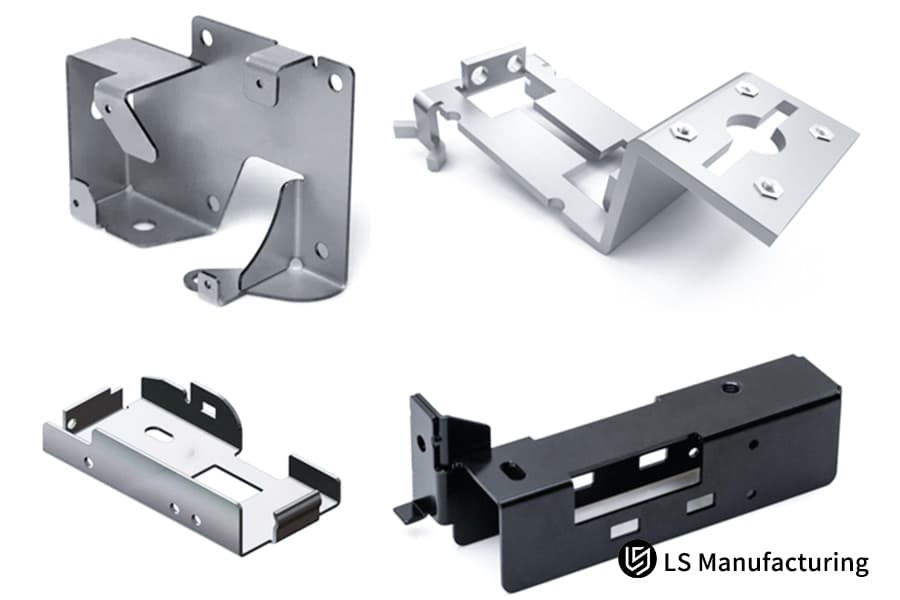

Figure 1: Tailored machined and formed metal components for exact applications by LS Manufacturing

Programming: The Interpreter of Digital Design

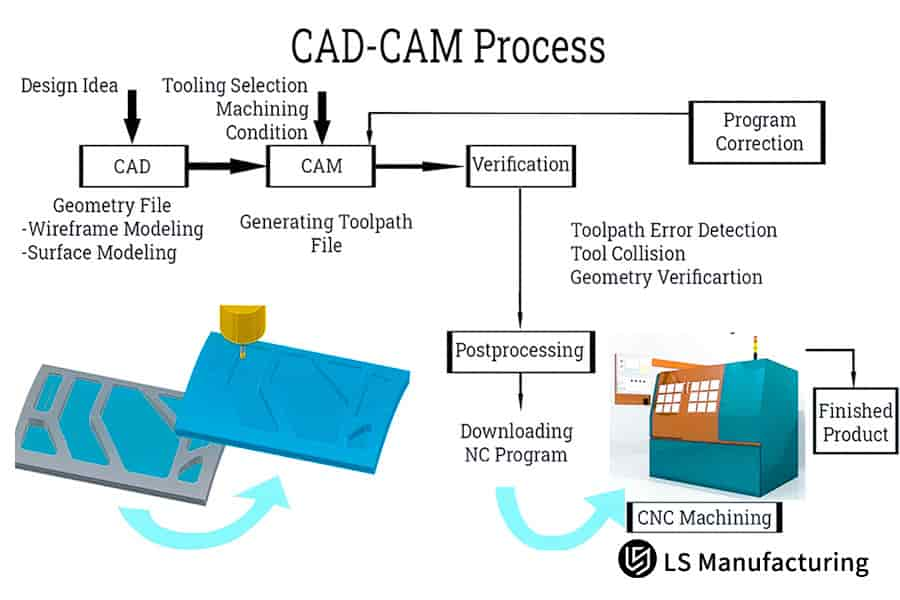

Process:It is the start and brain of the entire machining process. The engineers first design or get a specific3D modelof the part in computer-aided design (CAD) software. The one is then interpreted into computer-aided manufacturing (CAM) software. Tool paths, cutting conditions (speed, feed rate, depth of cut), tool choice, etc., are planned and programmed with care by the engineers based on material properties, required tolerance, surface finish, and machine tool capability. The main function of CAM software is to translate complicated 3D geometry and machinings into a series of precise instructions - G-code thatCNC machinescan use to perform the operations.

Importance:The quality of programming will directly affect the efficiency, accuracy and quality of the finished part. Good programming can save tool paths, eliminate wasted travel, eliminate collision, maximize material utilization, and achieve the tolerances and surface finishes of design.

Clamping: A Solid Foundation

Process:The operator then places the solid piece of metal material (e.g., a billet) on a table or chuck of aCNC machine(which most often is amilling machineor lathe). This will mean the use of special fixtures (e.g., chucks, vises, clamps, special jigs, etc.) to keep the billet secure and stable to keep the billet from vibrating or moving due to the shock or stress of high-speed cutting forces.

Key Points:Precise positioning and rigid clamping are both important. Even slight misplacement or looseness of clamping will directly cause the machining error or even wasted workpieces. The clamping system should be specifically designed to supply stiffness and enable tool accessibility to all the surfaces to be machined.

Cutting: "Precision 'Digital Sculpture'"

Process:This is the central link of CNC machining. The machine tool's control system reads and executes G-code instructions. The spindle spins the selected tool (e.g., end mills, drills, turning tools, etc.) at high speed.

At the same time, the machine tool's servo motor accurately drives the tool and/or table to move along the X, Y, Z and other axes, following the programmed path. The sharp tool edge contacts the metal blank, cutting layer by layer, continuously removing unwanted material. Coolant is usually used to flush the chips, reduce the temperature of the cutting area and lubricate the tool, extending tool life and improving surface quality.

Multi-axis machining:

3-axis:The most basic form, the tool can move on three linear axes, X, Y, and Z. Suitable for machining parts with relatively simple shapes and main features located on the top and sides (such as plate parts, simple cavities).

4-axis:A rotation axis is added on the basis of 3 axes (usually rotating around the X-axis or Y-axis, called A-axis or B-axis). Allowing the workpiece to rotate, so that the tool can process the side and part of the non-vertical surface of the workpiece, reducing the number of clamping times (such as machining special-shaped grooves and lettering on cylinders).

5-axis: Two rotation axes are added on the basis of 3 linear axes (X, Y, Z) (common ones are A-axis around the X-axis and B-axis around the Y-axis, or C-axis around the Z-axis plus a swing axis). The tool can approach the workpiece surface from any direction, and extremely complex curved surfaces, deep cavities, and undercut features (such as impellers, engine cylinder heads, and precision mold cavities) can be processed in one clamping, greatly improving the processing capacity and accuracy of complex parts.

Figure 2: Process diagram for quoting specialized machined component production by LS Manufacturing

Post-processing: finishing and quality assurance

Process:The parts after cutting (usually called "machined parts") are usually not the final products. It may have sharp burrs (burrs), specific tool marks, or require specific surface properties and protection.

Common operations:

- Deburring:Manually or automatically remove sharp burrs generated by cutting edges to ensure safety and subsequent assembly.

- Sandblasting/polishing:Improve surface finish and obtain a uniform matte or bright effect.

- Anodizing(mainly for aluminum parts):Form a hard, corrosion-resistant oxide film on the surface, and can be dyed to enhance aesthetics and wear resistance. Other surface treatments include electroplating, spraying, etc.

- Measuring and Inspection:Using tools such as calipers, micrometers, height gauges, coordinate measuring machines (CMMs), etc., we strictly check the critical dimensions, geometric tolerances (such as flatness, roundness, position) and surface roughness of parts to ensure that they fully comply with the design drawings and technical specifications. This is the final stage of quality control.

What Is The Difference Between Sheet Metal Fabrication And CNC Machining?

Now that we understand how both processes work, let’s compare them directly on the dimensions that engineers care most about.

| Comparison Dimension | Sheet Metal Fabrication | CNC Machining | Expert Comments |

|---|---|---|---|

| Precision tolerance | Generally ±0.2mm or higher. Significantly affected by material rebound, mold wear, welding deformation, etc., high precision requires complex tooling or secondary processing. | Usually ±0.025mm or higher (micrometer level). The equipment has high precision and can stably achieve precision machining of complex features. | "Bearing fit, precision assembly, complex surface tolerance requirements? CNC is a reliable choice. Sheet metal requires additional processes to ensure accuracy." |

| Cost structure | Low raw material cost and high material utilization rate (less waste). Single piece/small batch: High mold/tooling cost, high unit cost after amortization. Large batch: The mold cost is diluted, and the unit cost is very competitive. | High raw material cost (whole piece of material), low material utilization rate (waste chips). Single piece/small batch: Relatively low startup cost (programming is enough), no mold fee is required. Large batch: The cost increases linearly with processing time, and there is a lack of economies of scale. | "Prototype/small batch? CNC is more flexible and economical. Large batch of simple parts? Sheet metal costs are overwhelming. Complex parts in large batches require comprehensive evaluation." |

| Production speed (delivery time) | Simple parts (such as flat plates, single bends): Extremely fast (minutes), especially when there are ready-made molds. Complex parts/welding and assembly required: Many processes (cutting, punching, folding, welding, surfacing), and the total cycle time is significantly extended. | The processing time is usually longer (hours or even days/piece). Complex 3D shapes, deep cavities, and fine features significantly increase processing time. Multi-axis equipment can improve efficiency but is still slower than simple sheet metal. | "1,000 simple brackets? Sheet metal can be done in one day. A complex box/shell? CNC may take several days. Speed requirements are the core consideration!" |

| Geometric degrees of freedom | Limited. Mainly relies on 2D contour + bending/forming + welding/connection. It is difficult to make complex surfaces, deep cavities, closed cavities or integrated fine 3D features. | Very high. Almost any designable 3D shape can be made, including complex surfaces, deep cavities, hollow structures, fine textures and integrated parts (no connection points). | "Design like origami or assembly? Sheet metal is feasible. Design like sculpture or with complex internal structure? CNC is the only solution." |

| Material strength and characteristics | There is work hardening at the corners, and the local strength may be improved, but residual stress may also be introduced. Welding/connection points are potential weak links, affecting the overall strength and sealing. The material thickness is relatively uniform. | The parts are processed from a whole piece of material, maintaining the original, uniform lattice structure and performance (strength, toughness, thermal conductivity, etc.) of the material. Good integrity, no weak connection area, suitable for high integrity requirements. |

"High stress, high fatigue, high sealing or strict integrity requirements? CNC one-piece molded parts are usually more reliable. Sheet metal needs to be handled carefully at the connection points." |

| Typical application scenarios | Chassis, cabinets, brackets, shells, chassis, ventilation ducts, sheet metal covers, simple structural parts. | Precision parts, molds, fixtures, engine/transmission parts, complex shells, medical device parts, prototypes, artworks. | "Function determines form, and form determines process. Clarifying the core requirements of parts is the first step in choosing a process!" |

Expert comments:

- CNC is the best choice for precision: CNC is the first choice when there are rigid requirements for micron-level tolerances and complex precision matching.

- Cost efficiency depends on batch size:

- Small batch/prototype:CNC starts quickly, has no mold fees, and is usually more cost-effective.

- Large batch of simple parts:Sheet metal has a huge cost advantage due to its extremely high material utilization and fast stamping/bending.

- Large batch of complex parts:Detailed cost accounting is required (CNC processingtime vs. sheet metal multiple processes + mold costs).

- Speed demand determines the outcome:

- Massive simple parts:Sheet metal (especially stamping) speed is unmatched.

- Complex single piece/small batch:CNC is relatively fast (compared to waiting for mold opening), but the processing itself is time-consuming.

- Geometric complexity is the watershed:Complex 3D shapes, deep cavities, and integrated structures are the absolute domain of CNC; sheet metal is good at "expandable" geometries composed of planes + bends.

- Structural integrity considerations:CNC one-piece moldingprovides more reliable protection for key load-bearing parts with high requirements for overall strength, fatigue life, and leak-free sealing; sheet metal requires special attention to the design and quality of connection points.

- Start with demand:The core of process selection is always the functional requirements, performance requirements (precision/strength), geometric complexity, budget and quantity of parts. This table provides the key basis for making wise decisions in these dimensions.

This table clearly highlights the essential differences and respective advantages of the two processes in several core dimensions that engineers are most concerned about (cost, speed, precision, capability, strength), and is supplemented by expert comments to indicate the key considerations for selection.

Practical Case Analysis: A Journey To Cost Optimization For An Industrial Controller Housing

Customer background and needs:A leading automation company designed a new industrial PLC controller that required rugged protection. The original plan was to use a whole piece of 6061 aluminum alloy (CNC machining) to manufacture the housing, and asked LS for a quote.

Initial challenge:According to the customer's design (milling of a whole piece of aluminum), we estimated theCNC machining costto be $180/piece. Although it met the requirements, we realized that this was not the most cost-effective solution.

LS's proactive value creation:With our deep experience in metal manufacturing processes, we proactively contacted the customer to discuss design optimization. We made a key suggestion: transform the design from "whole CNC machining" to "sheet metal process" solutions.

Core of the new solution:Select 3mm 5052 aluminum alloy sheet.

Manufacturing process:Laser cutting precision blanking → precision bending forming → welding reinforcement of key parts → necessary weld grinding.

Achievements and value:The customer gladly adopted our sheet metal proposal. The optimized solution quote was only $45/piece.

Core benefits:Cost reduction of 75%! Significant cost savings were achieved while ensuring the required strength, protection level and function of the product.

LS's value proposition:This case clearly demonstrates the core advantages of LS: We are not only your reliable manufacturing executor, but also your trusted manufacturing process consultant and cost optimization partner. We actively use our professional knowledge to review the design (Design for Manufacturing, DFM) and find more efficient and economical process paths (such as replacing CNC with sheet metal in this case), ultimately bringing real competitive advantages to customers.

Choosing LS, you get not only a supplier, but also a strategic partner who is committed to using professional manufacturing knowledge to actively reduce costs and increase efficiency for you. We look forward to using the same professional perspective to create value for your next project!

Figure 3: Custom CNC machined parts on display for online services by LS Manufacturing

FAQ- Quick Questions And Answers About Sheet Metal And Machining

1. Is sheet metal always cheaper than CNC machining?

Not necessarily. Sheet metal is usually cheaper when it is thin-walled (<6mm), simple in structure, and can be stamped/bent because of its high material utilization and fast production speed. However, CNC machining parts may be more economical when it comes to complex three-dimensional shapes, thick materials (>10mm) or high-precision cavities. The final cost depends on the complexity of the design, batch size, material thickness and tolerance requirements, and needs to be evaluated on a case-by-case basis.

2. What is "sheet metal machining"? Is this term problematic?

"Sheet metal machining" is a common industry term that refers to cold forming processes such as cutting, punching, bending, and welding of metal sheets (usually 0.5-6mm thick). Although "machining" broadly includes CNC, it specifically refers to the process of plastic deformation of sheets, which is essentially different from mechanical processing (cutting to remove material). Although the term is not absolutely rigorous, it can accurately distinguish it from casting, forging or machining.

3. How do I choose the right material for my design?

First, clarify the functional requirements: choose high-strength steel (such as SPCC) for load-bearing, stainless steel (304/316) or aluminum (5052) for corrosion resistance, and aluminum (6061) or magnesium alloy for lightweight. Secondly, look at the process: complex bending requires materials with good ductility (avoid hard aluminum), and welding prefers low-carbon steel/stainless steel. Finally, evaluate the cost and environment: use cold-rolled steel for ordinary parts, and galvanized steel for outdoor parts, balancing budget and life requirements.

Summary

The key difference between sheet metal manufacturing and CNC machininglies in their core process objects and target forms: sheet metal manufacturing focuses on cutting, bending, stamping, connecting and other operations on metal sheets. The core is to efficiently produce thin-walled, box-shaped and shell-like parts through deformation; while CNC machining (mainly milling andturning) uses rotating tools to cut and remove solid block materials (metal, plastic, etc.), and is good at manufacturing three-dimensional parts with complex three-dimensional shapes, precision features and high dimensional accuracy. Although the two are often used in conjunction, they are essentially complementary processes. The choice depends on the geometric characteristics,material thicknessand production requirements of the required parts - sheet metal is preferred for thin-walled structures, while three-dimensional complex precision parts rely on CNC machining.

"Are you still hesitating about whether your parts should be sheet metal or CNC machined? Don't guess anymore.At LS, we have top-notch equipment and senior engineers for both processes.Upload yourCAD filenow, our online platform will not only provide you with instantCNC machining quotes, but our engineers will also proactively evaluate the possibility of using sheet metal processes for you to find the most economical and efficient manufacturing path for you!"

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.