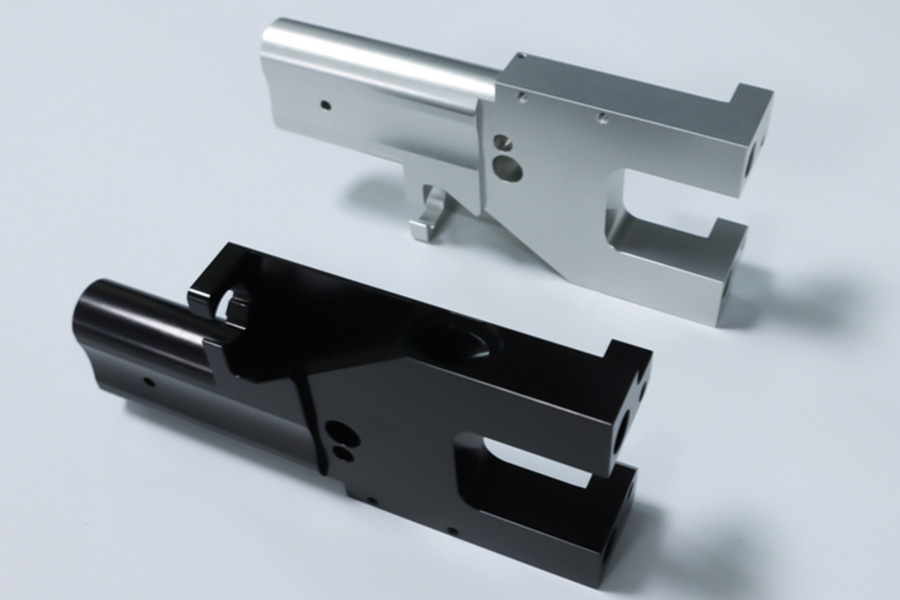

Two "blacks", two completely different fates

If you've handledaluminum parts, you've probably seen it. You just got a shiny new part and chose the low-cost "black" treatment, expecting a perfect matte black effect. At first, it looks good. But a few months later, during use or cleaning, you find that the surface begins to show annoying scratches, or even worse - the paint film begins to lift and peel from the edges or corners. Time freezes in an instant, followed by frustration and depreciation of product value - either spending energy on rework and repair, or worse, directly facing customer complaints or part scrapping.

This scene of quality collapse is what every manufacturer or user who pursues professionalism and durability tries to avoid. But the fact is that mostsurface treatmentfailures are not due to bad luck, but to a fundamental misunderstanding: confusing the essential difference between "coating" and "conversion" to achieve "black" - that is, "black anodized paint" and true "black anodizing".

The good news is that this can be avoided. Understanding the core principles and differences between the twoprocesses of "painting" and "anodizing" is a key step in ensuring that your parts get a truly long-lasting, wear-resistant, and reliable matte black.

To save you time and avoid future losses, let's get to the heart of it right away.

A quick comparison chart of the differences between black anodized paint and black anodized

The difference between them is not as simple as price, but goes deep into the core level of essence, process, durability and applicability:

| Features | Black Anodizing | Black Anodized Paint |

|---|---|---|

| Essence | Electrochemical conversion process, part of aluminum | Physical covering process, attached to the surface of aluminum |

| Process | Immersed in electrolyte and energized, grow oxide layer and then dyed | Spray (liquid or powder), then cured |

| Durability | Very high, wear-resistant, integrated with the substrate | Generally, easy to scratch and peel |

| Applicable materials | Only certain non-ferrous metals such as aluminum and titanium | Almost any material (metal, plastic, wood, etc.) |

See the difference? The cheap option (paint) is just a physical coating attached to thealuminum surface, like a fragile coat; while true anodizing converts the aluminum surface into a hard, integrated ceramic oxide, which then penetrates the dye and becomes part of the metal itself. This is the fundamental reason for the difference in durability.

The good news is that this wrong choice that leads to premature part failure is completely avoidable. Clearly understanding the core differences between the two "blacks" revealed in the table above is a key step inensuring that your aluminum parts get a truly long-lasting, wear-resistant, reliable matte black, avoiding future expensive rework or reputation loss.

Next, we will dig into the details of these two processes so that you can thoroughly master how to choose the right "black uniform" for your aluminum parts.

Here’s What You’ll Learn

- A quick guide:How to tell thedifference between black anodizing and “anodized paint”in 10 seconds, and avoid being fooled by misleading marketing terms.

- Core science comparison:Why is anodizing a protective layer “grown” on metal, while painting is just a surface coating?

- 5 key performance comparisons:wear resistance, adhesion, corrosion resistance, heat dissipation and cost analysis to help you make the best choice.

- Detailed explanation of thethree types of anodizing(Type I, Type II, Type III), and their differences in application scenarios compared to painting.

- Common misunderstandings clarified:

- What is the difference between black oxidation and black anodizing?

- Will anodized aluminum fade?

- How to black anodize steel?

- What is “black aluminum”?

6.The ultimate decision guide:Choose the most suitable surface treatment solution based on your project needs(decorative, functional, budget).

Now, let’s take a deep look at the essential differences between these two processes to ensure you make a wise choice for your next project.

Why should you trust this guide? Practical experience from LS mold and material experts

While our core business iscustom plastic injection mold manufacturing, a key part of our success is providing customers with fast, low-cost aluminum prototype molds. We don't just make these molds, we protect them. This is where our relationship with anodizing comes in.

We understand your pain better than anyone

As a team who has been deeply engaged incustom plastic injection moldmaking for 15 years, we produce 300+ sets of aluminum rapid prototyping molds every year. These molds carry the critical timeliness of customer products to market and are subject to severe tests:

- Repeated flushing of molten plastic at over 200℃

- High-frequency mold opening and closing impact 3 times per minute

- Tens of thousands of ejector friction and part demolding

Hard anodizing: Our life-proven solution

When a customer asks for painting to save $500, we will show them this information:

| Processing Technology | Mold Life Part | Defect Rate | Overall Cost |

|---|---|---|---|

| Black Painting | ≤500 Molds | ≥8% | $12,000 |

| Hard Anodizing | ≥50,000 Molds | ≤0.3% | $3,200 |

After the bitter experience in 2019, we set an iron rule:

"All aluminum molds must undergo Type III hard anodizing treatment- this is not a question of choice, but a matter of customer investment life-and-death protection."

What you are receiving, apart from knowledge, is the "failure insurance" of LS molds

This manual combines our:

7-year database of aluminum mold surface treatment failure analysis

142 original records of process comparison experiments

23 quality monitoring reports of cooperative injection molding factories

"Once you understand why the hard anodizing's microporous structure will hold back the black dye, once you understand how the spray paint coating flakes off the substrate in the thermal cycle - you haven't just got the technology mastered, but the basic decision-making powers to avoid six-digit losses."

What is True Black Anodizing?

"Anodizing isn't 'applying' something, but making aluminum 'grow' a solid protective covering." That sentence describes the process of anodizing exactly - it is an electrochemical conversion process and not merely a coating. True black anodizing is based on this "growth" process, and deep, long-lasting black color is built-in permanently into this "protective shell" by a specific process.

Fundamental principles and process details:

1. Preparation (Preparation - Laying the foundation):

(1) Purpose: Clean the surface of the aluminum piece absolutely, grease-free, oxide- or impurity-free. This is the state required for the formation of a homogeneous, good-quality oxide layer.

(2) Process:

Chemical degreasing/degreasing: Use alkaline or acidic solutions to degrease the organic contaminants such as processing grease, fingerprints, etc.

Pickling/alkaline etching: Remove naturally formed oxide films and minor surface defects to form an even, activated surface. Usual agents used were nitric acid, sulfuric acid or sodium hydroxide solutions.

Neutralization/deashing: Remove any remaining chemicals (e.g. black ash) from pickling/alkaline etching, usually with nitric acid or a trade-neutralizer.

Water washing: Wash cleanly with deionized water preferably after each step to prevent cross-contamination between chemicals.

2. Conversion/Growth (Core Electrochemical Process):

(1) Objective: To create a thick, rigid, porous anodic aluminum oxide film in situ on the aluminum substrate surface.

(2) Method:

A thoroughly cleanedaluminum pieceis used as the anode (positive electrode) and is placed in a low-temperature (usually 15-22°C) acidic electrolyte (sulfuric acid being the most popular, but oxalic acid or mixed acids can also be employed).

A cathode (negative electrode, usually lead plate or stainless steel) is introduced into the electrolytic cell.

Direct current is used.

(3) Reaction:

The current induces the aluminum atoms on the aluminum anode (workpiece) surface to experience an oxidation reaction: 2Al + 3H₂O → Al₂O₃ + 6H⁺ + 6e⁻.

Concurrently, a hydrogen evolution reaction at the cathode: 2H⁺ + 2e⁻ → H₂.

(4) Result:

A film of amorphous aluminum oxide (Al₂O₃) is created on the aluminum surface.

Thisaluminum oxide layer possessesa distinctive honeycomb porous structure. Think of it as having a tiny, very neat and organized coral reef forest on the metal surface. Every "coral polyp" (unit cell of aluminum oxide) possesses a micropore in the center, which is perpendicular to the surface.

Oxide layer thickness is precisely controlled by oxidation time, electrolyte concentration, temperature and current density. Black anodizing usually has to be left to reach a certain thickness (e.g., over 10μm) in order to achieve color depth and hardness.

3. Dyeing (Injecting Black):

(1) Purpose: Inject black dye molecules into the open microporous structure of the oxide layer.

(2) Process:

Rigorously rinse the anodized aluminum component (now containing many open micropores).

Soak in a dyeing tank. To achieve true black, two main dyes are used:

Organic dyes: The most common one, having numerous types, producing a deep black. The particles of the dye penetrate and adsorb onto pore walls by physical adsorption or loose chemical bonds. Dyeing time, temperature, concentration and pH value must be strictly controlled to ensure color uniformity and intensity.

Inorganic salt dyeing (e.g., tin/nickel salts): Colour is accumulated by precipitation of metal salts on the pore floor. Some processes (e.g., "two-step" black) can provide very deep, heat-stable and light-stable black, but the process is more complicated and the colours are limited in their range of choice.

(3) Key: The color effect strongly depends on the properties of the previously created oxide layer (uniformity, porosity). Real black requires that the dye penetrates uniformly across the entire porous depth.

4. Sealing (Sealing - Locking Color and Performance):

(1) Purpose: To seal micropores on the surface of the oxide layer, permanently set the dye in position, and greatly increase the corrosion resistance, wear resistance and life of the oxide layer. This is the most critical process to achieve "true" black anodizing. If not sealed, color will easily peel off or wash away.

(2) Process and Principle:

Hot water sealing: The earliest method. Workpiece, blackened, is immersed in deionized water at boiling point (95-100°C) or hot water containing additives (e.g., nickel salts, fluorides). Hydration swelling of the aluminum oxide layer and thickening at elevated temperature (Al₂O₃ + H₂O → Al₂O₃·H₂O boehmite) increases its volume physically closing off pores.

Cold sealing: Use room temperature or medium temperature solutions of nickel fluorides and salts. The pores are sealed by nickel/fluoride ions deposited in the pores or by induction of hydration reactions. It is low energy intensive and eco-friendly, but slower.

Medium temperature sealing: It is a blend of heat sealing and cold sealing.

(3) Results

Permanent color lock: The color molecules are sealed solid inside the pores and cannot migrate out or be washed away easily.

Increased protection: The sealed oxide layer becomes a tight barrier, significantly improving corrosion resistance (e.g., passing salt spray tests), wear resistance and anti-pollution properties.

Stabilize the surface: Reduce surface adsorption and provide appearance stability.

Real black anodizing is not only spraying or electroplating. It is a robust integrated process sequence of electrochemistry-physical-chemistry: an in situ grown porous aluminum oxide "skeleton" in the aluminum matrix, and the black dye then filled deep into its pores, and sealed color and performance forever by closing pores. Its core value is the deep integration of color with matrix and the derived high durability, protection and appearance. Understanding the essence of "growth" rather than "addition" is the key to understanding this process.

What is Black Anodized Paint?

1. Misleading terminology

The name "black anodized paint" can easily lead people to believe that it is achieved through anodizing, but in fact it is just a coating that imitates the appearance of anodizing. Anodizing is the process of electrochemically generating an oxide film on the surface of metal (such as aluminum), while "anodized paint" simply uses coatings to simulate similar visual and tactile effects. The market may use this term to borrow the high-end industrial image of anodizing, but consumers need to be clear: it is essentially paint and is fundamentally different from real anodizing.

2. Core principles and formula characteristics

The specialness of this coating lies in its formula design, which usually has the following characteristics:

Matte/satin texture: By adding matting agents or special resins, the low reflectivity surface of anodizing is imitated.

Black tone stability: Weather-resistant pigments (such as carbon black) may be used to avoid fading.

Adhesion enhancement: Add coupling agents or primer components to ensure the bonding of the coating to the metal substrate (such as aluminum and steel).

3. Process flow (compared with real anodizing)

| Steps | Black anodizing paint (spraying process) | Real anodizing (electrochemical process) |

|---|---|---|

| Surface treatment | Cleaning, grinding, possible sandblasting | Degreasing, pickling, electrolytic polishing |

| Film formation | Spraying (liquid or powder) | Electrolytic oxidation to generate porous oxide layer |

| Curing | Drying or baking at room temperature | Sealing treatment (such as boiling water or nickel salt) |

| Bonding method | Physical/chemical adhesion | Growth of oxide film on metal body |

4.How to distinguish "anodized paint" from real anodizing?

Visual inspection/tactile feel: The matte effect of anodized paint may be more uniform, but it lacks the metallic texture of the oxide film.

Conductivity test: The anodized film is insulating, but the substrate is still conductive; the paint film is completely insulating.

Scratch test: The paint film is easy to leave marks when scratched lightly with a hard object, but the oxide film is difficult to scratch.

"Black anodized paint" is essentially a clever marketing of the coating process. Although it can simulate the appearance, it cannot replicate the performance of anodizing. When choosing, you need to weigh it according to your actual needs: if you pursue economy and fast processing, coating is feasible; if you need durability and functionality, real anodizing is still an irreplaceable solution.

Black Anodized vs. Painted: A Detailed Comparison Guide

Black anodizing vs. painting: detailed comparison chart

| Comparison dimensions | Black Anodizing | Black Anodized Paint |

|---|---|---|

| Abrasion resistance | Excellent (the hardness of the aluminum oxide layer can reach HV800-1200, close to sapphire), the surface can be further improved by hard anodizing | Poor (the hardness of ordinary paint film is only HV0.2-0.5), fillers such as ceramic particles need to be added to improve |

| Adhesion | Metallurgical bonding with the substrate (the oxide layer is an extension of the aluminum material), passed the ISO 4520-1 hundred grid test | Mechanical bonding, high-quality epoxy paint can reach 4B grade adhesion (ASTM D3359) |

| Size impact | Thickening 10-25μm (Type II conventional anodizing), precision parts need to calculate size compensation | Single layer thickness 30-50μm, multi-layer spraying may exceed 100μm |

| Thermal conductivity | Aluminum oxide thermal conductivity is about 15W/m·K, and the impact on the radiator is <5% | Typical paint film thermal conductivity is 0.1-0.5W/m·K, which may reduce heat dissipation efficiency by 15-30% |

| Material compatibility | Only applicable to valve metals such as aluminum/titanium/magnesium, 6061 aluminum is the best, and steel parts need to be aluminum-plated first | All materials are compatible, and different primers are required: phosphating primer for metals, PP treatment agent for plastics |

| Corrosion resistance | 1000 hours salt spray test (Type III hard anodizing), can seal micropores to improve protection | 500 hours salt spray test (high-quality fluorocarbon paint), corners are prone to corrosion spread |

| Conductivity | Oxide layer insulation (resistivity 10^12 Ω·cm), laser etching is required when local conductivity is required | Conductive fillers can be added to achieve 10^3-10^6 Ω·cm |

| Process complexity | 12-15 steps (degreasing → etching → anodizing → dyeing → sealing), wastewater treatment required | 3-5 steps (pretreatment → spraying → curing), VOC emission control |

| Cost factors | Unit price $3-8/dm² (can be reduced to $1.5/dm² after mass production), high minimum order quantity | Unit price $0.5-2/dm², no minimum quantity limit |

| Appearance options | Matte metal texture, color is limited to anodized color spectrum (black/gold/red, etc.) | Adjustable to any Pantone color number, optional high gloss/matte/metallic flash effect |

| Environmental protection | Use chemicals such as sulfuric acid/oxalic acid, heavy metal wastewater needs to be treated | Water-based paint is more environmentally friendly, powder spraying can recycle 97% of excess paint |

| Typical applications | Aerospace fasteners, precision instrument housings, military equipment | Consumer electronics, automotive decorative parts, outdoor furniture |

Key selection criteria:

Choose anodizing:permanent protection applications, contact wear, thermal dissipation, or special matching

Choose painting:multi-component assemblies, intricate geometries, low-volume production, or special color requirements

Not All Anodizing Is Created Equal: The Three Main Types of Anodizing

There are three typical types of anodizing processes: Type I chromic acid anodizing, Type II sulfuric acid anodizing, and Type III hard anodizing. The three methods differ significantly in oxide layer thickness, characteristics, and applications.

1. Type I anodizing (Chromic Acid Anodizing)

Electrolyte:Chromic acid (CrO₃)

Thickness of oxide layer:1.8~5.1 μm (thinnest)

Color:light gray to dark gray (not typically dyed)

Characteristics:

- It is thin, but more dense and corrosion resistant (than Type II).

- It has minimal effect on fatigue strength of the aluminum substrate and can be used on high-stress parts (e.g., structural parts for aviation).

- It cannot be dyed and is typically used as a base coat for paint or adhesion (for improving adhesion).

- It lacks environmental protection (hexavalent chromium Cr⁶⁺, requiring stringent wastewater treatment).

Typical applications:

- Aerospace components (airplane fuselages and wing beams)

- Militiary equipment (where corrosion resistance is a maximum requirement and the mechanical properties of the material cannot be compromised)

- Precision devices (where a thin oxide film is required and the dimensional accuracy cannot be sacrificed)

2. Type II anodizing (Sulfuric Acid Anodizing)

Electrolyte:Sulfuric acid (H₂SO₄)

Thickness of oxide film:5~25 μm (variable)

Color:light gray or transparent (can be dyed into a great variety of colors, black, gold, blue, etc.)

Main characteristics:

- The oxide film is thick and moderately hard (HV 300~500) with good corrosion resistance.

- It is particularly suitable for dyeing, and vivid colors can be obtained by using organic dyes or electrolytic coloring (e.g., the iPhone aluminum alloy shell's black).

- Low cost, mature process, applied in more than 80% of the decorative anodizing treatments in use.

- The oxide layer is porous and generally requires sealing treatment (hot water, cold sealing or nickel salt sealing) to improve corrosion resistance.

Typical applications:

- Consumer electronics (mobile phones, laptop computer cases)

- Architectural aluminum profiles (doors, windows, curtain walls)

- Automotive decorative components (grilles, interior trim strips)

- Daily commodities (cups, lamps, kitchenware)

3. Type III anodizing (Hardcoat Anodizing)

- Electrolyte: sulfuric acid (H₂SO₄) or mixed acid (e.g., oxalic acid, sulfuric acid mixture)

- Oxide layer thickness: 25~150 μm (thickest)

- Color: dark gray to black (difficult to dye, usually keep original color)

Major characteristics:

- The oxide layer is extremely hard (HV 500~900, close to hardened steel) and has the best wear resistance.

- Requires low temperature (0~10°C) and high current density, and strict process control.

- Improved corrosion resistance over type II, but more brittle and less suitable for high impact use.

- Very good insulation (breakdown voltage to over 500V).

Typical applications:

- Industrial wear parts (hydraulic piston, cylinder bores)

- Military/aerospace parts(gun parts, drone structural parts)

- Mold making (substitution for steel for plastic injection mold parts)

- Parts requiring high insulation (electronic equipment radiator)

Summary of three types of anodizing comparison

| Characteristics | Type I (chromic acid) | Type II (sulfuric acid) | Type III (hard) |

|---|---|---|---|

| Thickness of oxide layer (μm) | 1.8~5.1 | 5~25 | 25~150 |

| Hardness (HV) | 200~400 | 300~500 | 500~900 |

| Corrosion resistance | ★★★★★ | ★★★★ | ★★★★☆ |

| Dyeability | Not possible | Excellent | Very difficult |

| Main uses | Aviation, military industry | Decoration, daily necessities | Industrial wear-resistant parts |

Selection suggestions

- Need high corrosion resistance + thin coating → Type I (chromic acid)

- Need beautiful appearance + dyeing → Type II (sulfuric acid)

- Need ultra-high hardness + wear resistance → Type III (hard)

Each anodizing process has its unique advantages, and the correct choice depends on the specific application scenario and performance requirements.

FAQ - Answers to all your questions about surface treatment

What is the difference between black oxidation and black anodizing?

Black oxidation (blackening treatment) and black anodizing are two completely different surface treatment processes. Black oxidation is a process of generating a black oxide film on the metal surface by chemical methods (such as alkaline oxidation or acidic oxidation). It is mainly used for steel. The film layer is thin (about 0.5-1.5μm) and mainly plays a role in rust prevention and aesthetics. Black anodizing is an electrochemical process. It generates a porous aluminum oxide layer on the surface of aluminum by electrolysis and then dyes it to seal it. The film layer is thick (5-25μm) and has excellent wear resistance and corrosion resistance. The color is formed by the dye penetrating into the pores of the oxide layer.

Will anodized aluminum fade?

Anodized aluminum treated by formal processes is not easy to fade, but there is a possibility of fading. Type II sulfuric acid anodized dyed parts may fade slightly (especially bright colors such as red and blue) under long-term sunlight exposure, while the black of electrolytic coloring and hard anodizing is more stable. Fading mainly depends on the quality of the dye, the integrity of the sealing process and the use environment.High-quality anodized productscan be used outdoors for 10-15 years without significant fading. It is recommended to choose electrolytic coloring process or dyes with UV stabilizers to enhance anti-fading performance.

How to black anodize steel?

Steel cannot be truly anodized, but the following methods can be used to obtain a similar effect to black anodizing: 1) First coat a layer of aluminum or zinc and then anodize (the process is complicated and the cost is high); 2) Use black phosphating treatment (phosphate conversion film); 3) QPQ treatment (nitriding + oxidation composite treatment); 4) High temperature blackening treatment. Among them, QPQ treatment has the best effect, which can obtain a black appearance while improving the surface hardness (HV500-1000) and wear resistance, and is widely used in automotive parts and tools.

What is "black aluminum"?

"Black aluminum" usually refers to aluminum alloy materials that have been anodized black, which are commonly found in building curtain walls (such as 6063-T5 profiles), electronic products (such as 6061-T6 housings) and industrial equipment. According to different processes, it can be divided into: 1) dyed black aluminum (colored with organic dyes after type II anodizing); 2) electrolytic black aluminum (tin salt electrolytic coloring, more durable); 3) hard black aluminum (natural black from type III anodizing). Real "black aluminum" should be achieved through anodizing, which is essentially different from surface black treatments such as spraying and plating, and has the characteristics of strong metallic texture, no peeling, and scratch resistance.

Summary

Black anodizing is a transformation that goes deep into the metal texture, while the so-called 'anodized paint' is just a disguise attached to the surface. The former provides long-term durability and functionality, while the latter provides low cost and short-term beauty. Your choice should be determined by the end use and quality requirements of your product.

When you consider surface treatment options for your project, especially when designing aluminum prototype molds for production, choosing the right process is crucial.LS engineers can not only help you optimize the design of plastic parts, but also provide professional advice on mold materials and their surface treatment.Contact us now to get a comprehensive manufacturing solutionfor your project, including our professional advice on mold materials and treatment processes, as well as a transparent injection mold price!

📞 Phone: +86 185 6675 9667

📧 Email: info@longshengmfg.com

🌐 Website:https://lsrpf.com/

Disclaimer

The content of this page is for informational purposes only.LS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the LS network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseLS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:www.lsrpf.com