CNC turning remains one of the most difficult industrial processes, since a great many manufacturers continue to experience delivery delays, dimensional inaccuracy, and cost overruns with the process. What explains this situation is the fact that conventional machining relies heavily on manual operation, with not enough digital process control.

We have achieved 24/7 operations and unparalleled precision at LS Manufacturing by automating robotic material handling and adding real-time sensor monitoring and compensation mechanisms. Such an approach ensures quality results are reliable, delivery schedules predictable, and production costs controllable.

Fundamentally, doing effective operations in modern manufacturing requires delving deep into the principles of operations underlying CNC turning. To save you time, here is a brief overview of the key findings.

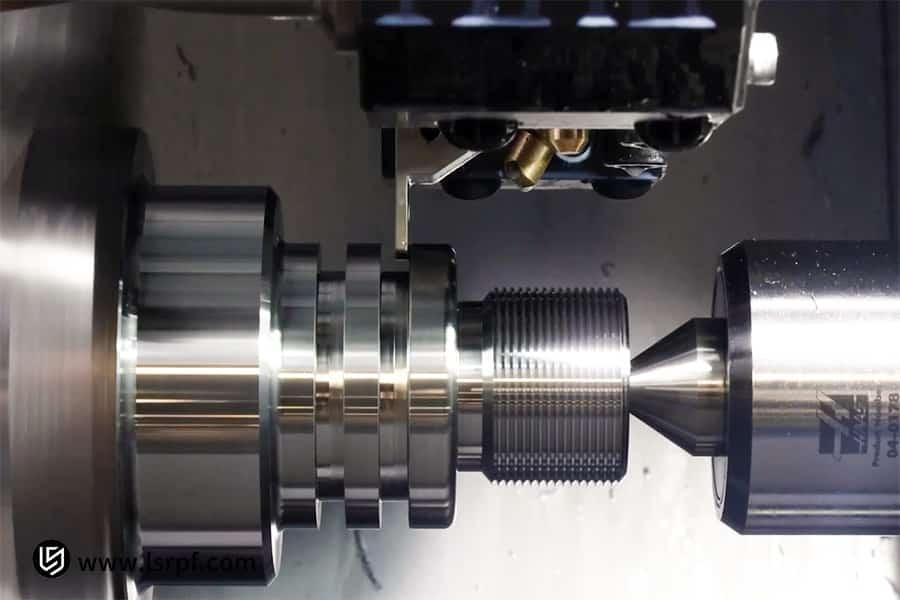

Figure 1: Precision CNC turning process for threaded shaft by LS Manufacturing

Quick Reference Table For CNC Turning

| Topic | Core Content | Key Points |

|

Definition |

Precision technology in manufacturing involving computer control, rotation of the workpiece, and cutting with tools. | Digitally driven, it is for parts of a rotational nature, such as shafts and sleeves. |

| Process Flow | The whole process from 3D modeling, generating the program, clamping to automated processing and inspection. | Precise programming and clamping are the cornerstones that ensure quality. |

| Advantages | It boasts extremely high precision, excellent batch consistency, high production efficiency, and the ability to process complex shapes. | Production uncertainty is converted into reliable output. |

| Application areas | Aerospace, automotive, and medical equipment that requires high precision for core components. | The fundamental processes of high-value manufacturing. |

| Key competencies | Optimize cutting parameters, use the right tool, reduce clamping times, ensure appropriate cooling. | It is the key to cost reduction and efficiency improvement, tapping the potential of the equipment. |

CNC turning ensures consistent quality with precision computer control. In a word, the deep integration of technology, management, and process experience is required to maximize its efficiency. Therefore, choosing CNC turning is much more than selecting a machining method; it means selection for a reliable, efficient, and predictable modern production model-a strategic decision for improving supply chain resilience and product competitiveness.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Why can you trust this guide? Because we present 15 years of practical wisdom by us in precision manufacturing. As your technical consultant, we have solved some complicated machining tasks, including high-temperature alloy components for aerospace, medical implants, and semiconductor device cavities.

Material cases handled in our smart workshop number more than 200 every year, with over 50,000 parts manufactured. Equipped with an online measuring system, each machine can form a unique process database. We can precisely optimize the cutting parameters, control deformation within 0.01mm for thin-walled parts, and realize multi-stage and one-time forming through composite machining.

This book summarizes the practical methodologies distilled from both our successes and failures. You will be given production-proven process solutions that help your projects reach the best balance among efficiency, cost, and quality. We are committed to transforming complex problems into repeatable, verifiable, standardized solutions.

How Does CNC Turning Revolutionize The Conventional Ways Of Production?

The essence of CNC turning lies in shifting from reliance on "manual control" to being driven by "digital instructions." Understanding this transformation calls for us, first, to make something clear: what is CNC turning? To put it straightforwardly, it refers to automatic machining technology that precisely controls every movement of a lathe through pre-written CNC code. Compared with conventional lathes, the following are breakthrough advantages of CNC turning:

1. Predictability:

Conventional machining is dependent on the worker's experience and judgment. As a result, product quality and efficiency fluctuate greatly. In the case of CNC turning, however, because the machining can be regulated by programming, the machining time and finished product yield can be predicted with great precision, thus increasing the reliability of production plans.

2. Reproducibility:

Under the conventional model, even the same technician finds it very difficult to ensure consistency among batches of parts. CNC turning completely eliminates human interference with the execution of digital instructions, thus achieving precision and consistency at the micron level.

In a nutshell, CNC turning creates product quality and productivity based on a sound basis of calculability, predictability, and reproducibility by means of digital directions. It is this form of certainty that now substantially alters the logic of production in manufacturing and places its technological capability in a cornerstone position within modern manufacturing.

How Many Steps Are There In One Complete CNC Turning Process?

A complete CNC turning process is much more than clamping material onto the lathe; it's a complex, precisely controlled systems engineering process. The success of LS Manufacturing CNC turning emanates from meticulous control at every key step of this process. Essentially, it can be broken down as:

1. Drawing Analysis and Process Planning:

Quality starts here. Given drawings are carefully reviewed by the engineers to clearly state the requirement of tolerance and material properties, based on which a reasonable machining sequence, clamping scheme, and tool list will be planned to mitigate potential risks from the very beginning.

2. CAD/CAM Programming and Simulation:

Brain of precision: We prepare 3D models in CNC code efficiently with the help of advanced CAM software. Also, the whole machining process is simulated in advance by solid modeling. This will accurately predict and prevent any errors like tool interference and overcutting, ensuring a flawless program.

3. Precision clamping and tool setting:

Precision positioning and clamping are the basics of consistency. In this regard, all workpieces shall be positioned accurately and clamped securely with the use of high-precision fixtures, in strict adherence to standardized operating procedures. At the same time, a precision tool setter will set up accurate reference points for tools in order to create a foundation for micron-level machining.

4. Machining Process and First Article Inspection:

That is the essence: reliability means that during automatic machining, the status of every single piece of equipment will be monitored in real time by the operators. After the first article machining is completed, a full-dimensional check will be performed through a CMM; only if the data is fully qualified will the production of the whole batch begin, to avoid the risk of deviations.

5. Final Inspection and Shipment:

This is our pledge to the customer. After completion, the products undergo a final quality audit to ensure that all the technical requirements are met in full, and then cleaning, rust-proofing, and proper packing are carried out to ensure safe and timely delivery to the customer.

In a word, the rigid CNC turning process has sharpened our philosophy from LS Manufacturing: quality control in every procedure. From drawings to finished products, "high precision" and "high reliability" are inevitable results rather than goals with systematic and digital management, which makes sure that every part delivered to the customer is trustworthy.

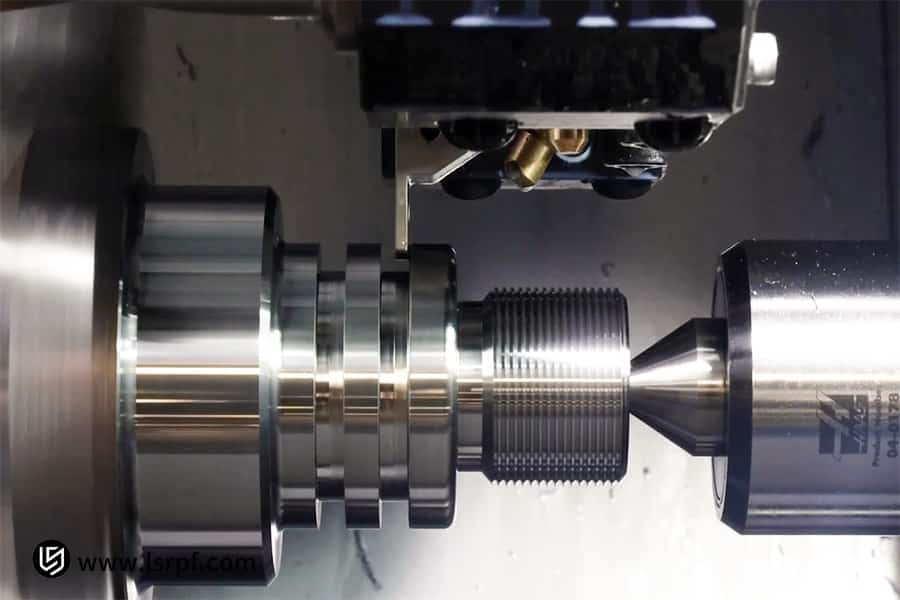

Figure 2: Various precision-made parts constructed from metal by LS Manufacturing

What Are The Main Benefits When Referring To CNC Turning Compared With Conventional Lathes?

Indeed, the benefits of CNC turning become revolutionary because it shifts the making of precision metal parts from an art dependent on human skill to a predictable science. This core value of precision turning with the use of CNC can be juxtaposed to that of conventional lathes based on the following table:

| Comparison Dimensions | Conventional Lathe | Precision CNC Turning |

| Precision and Consistency | Due to operator skill, dimensions are prone to fluctuation during mass production. | Program-controlled machining allows micron-level repeatability, so it guarantees consistency among batches of parts. |

| Machining Complexity | It can basically only turn simple cylindrical and conical surfaces. | It can easily process complex curved surfaces, irregular contours, and precision threads. |

| Efficiency in Production | Manual machining is less efficient and not suitable for mass production. | CNC machines allow unmanned operation 24/7 at high efficiency. |

| Human Factor Impact | Highly dependent on experience, prone to fatigue, and operational errors. | By programmed execution, it minimizes human error and thus assures quality stability. |

The critical benefit of CNC turning is its comprehensive leap in quality, efficiency, and reliability achieved by digital control. Precision CNC turning transforms "uncertainty" into "certainty": it directly brings customers higher product quality, shorter project lead times, better overall costs, and stronger design implementation capabilities.

What Industries And Products Does the technology Of CNC Turning Mainly Apply To?

The range of application of CNC turning is very wide. The high precision, high efficiency, and consistency in machining features make it an irreplaceable core process for many high-end manufacturing industries. The main areas and typical products it covers are:

- Automotive Industry: The materials are used in the core parts of the engine, such as pistons and shafts; gears in the transmission system; brake calipers; battery boxes and motor shafts of new energy vehicles, whose requirement for wear resistance, strength, and lightweight is particularly high.

- Medical Devices: This category of materials, mainly applied to forging precision rods for use in surgical instrumentation, implants, such as femoral heads for artificial joints, dental implants, and endoscopic metal parts, should have excellent biocompatibility and surface finish.

- Aerospace: The product portfolio focuses on machining key landing gear components, turbine engine blade tenons, and flight control system actuators, among others. The products have to meet very high strength-to-weight ratios and high reliability under extreme conditions.

- Communications and Electronics: Responsible for the fabrication of precision sleeves for fiber optic connectors, probes for chip test sockets, and heat sink housings featuring special minute dimensions, complex internal cavities, and electrical and thermal conductivity.

From speeding automobiles on land to aircraft in the sky, from life-saving operating tables to data centers which transmit information, its presence is everywhere. Supplying key components for so many leading industries fully proves our profound strength and exceptional reliability in materials science, process planning, and quality control, allowing us to serve top global clients.

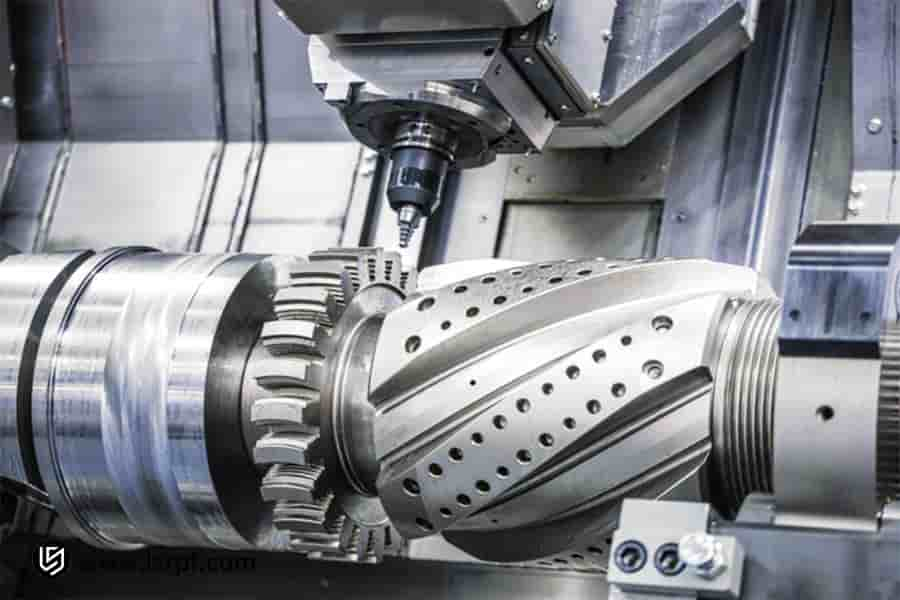

Figure 3: Metal cutting operation during CNC turning by LS Manufacturing

How To Considerably Reduce Costs With The Optimised Processes Of CNC Turning?

In today's fiercely competitive manufacturing, the real cost advantage does not come from lower prices but from inherent efficiency improvements through process innovation. At LS Manufacturing, significant cost optimization and value addition for customers is achieved through systematic optimization of the CNC turning process.

- Scientific Tool Life Management: We eliminate fixed tool change cycles by monitoring wear status in real time, based on cutting data, thus optimizing tool life without sacrificing accuracy, which directly impacts tool cost per unit of production.

- Dynamic Optimization of Cutting Parameters: Through extensive testing of various material properties, process engineers have created an optimal parameter library that is capable of ensuring quality and realizing maximum material removal rates, hence delivering a leap in production efficiency.

- Reduced clamping times through composite machining: With the use of mill-turning centers, all processes can be carried out within one clamping operation. This would avoid the occurrence of repetitive positioning errors and would enhance the precision of the product, save a lot of auxiliary time, and shorten the general manufacturing cycle.

- Value engineering-based scheduling strategy: Production planning is deeply integrated with process characteristics. For example, we group orders of similar materials and processes for scheduling to reduce downtime caused by machine tool changeover and debugging, ensuring the high utilization of equipment.

In summary, cost optimization in technology, management, and planning is an engineering project. It systematically eliminates waste in the production process by increasing production efficiency and conducting comprehensive value engineering analysis. Such profound optimization makes delivery speed faster and product quality more stable, thus giving the customers an overall competitive edge from beyond price.

What Are The Important Conditions For Realizing "Precision CNC Turning"?

Achieving "precision CNC turning" is by no means easy; it is a systematic engineering project. Behind the word "precision" lies the ultimate synergy of hardware, software, and environment. Our superior CNC turning performance is based on strict control over the following key conditions:

1. High-performance CNC system and high rigidity machine tool:

During the operation, it needs a precise control "brain" and a solid "body". Advanced CNC system offers high precision in instruction execution. The high rigidity of the bed and spindle can effectively repress the occurrence of cutting vibration, laying the foundation for achieving micron-level precision and excellent surface quality.

2. Precision fixtures and high-quality cutting tools:

"Stable mounting" is necessary for "precise operation." Workpiece positioning and reliable clamping are performed with dynamically balanced precision fixtures. While doing this, the company chooses brand-name coated cutting tools and enacts strict life management to keep the process of cutting stable and predictable in tool wear.

3. The temperature and environmental controls must be kept tightly controlled:

Because it is truly a "hidden killer" of precision, constant temperature and humidity are kept in our workshop. The temperature control to the key components, including a spindle and ball screw, will effectively avoid dimension drift caused by environmental heat and machining heat, thus assuring long-term stability of the machining accuracy.

LS Manufacturing CNC turning represents the comprehensive embodiment of technological prowess, relying on the deep integration of top-tier hardware, rigorous processes, and stable environmental controls. It is by continuously investing and conducting lean management in these fundamental elements that LS Manufacturing CNC turning builds technical parameters into tangible, high-precision, highly consistent products, establishing an unshakeable competitive advantage in the field of high-end manufacturing.

Figure 4: CNC machining of precision threaded metal shaft by LS Manufacturing

How To Choose The Best CNC Turning Material For Your Parts?

CNC Turning material selection probably represents the most critical first step in deciding on the final performance, reliability, and overall cost of parts. Optimal material selection balances mechanical properties, operating environment, and characteristics specific to the CNC turning process. Different materials will directly decide tool life, cutting parameters, and production efficiency. Following is a brief table comparing several common materials based on core characteristics and machining considerations:

| Material Category | Core Characteristics | Machining Considerations |

| Aluminum Alloy | Lightweight, good heat conductivity, moderate strength | Easy to machine, high surface quality; soft material which scratches easily |

| Stainless Steel | Resistant to Corrosion, high strength | The tool exhibits a strong tendency to work harden, requiring high wear resistance. |

| Titanium Alloy | High strength-to-weight ratio; good biocompatibility | Poor thermal conductivity; high cutting temperature; difficult to machine |

| Alloy Steel | High strength, good wear resistance | The cutting parameters should be modified according to the state of heat treatment |

Material selection is one of the most critical factors that decide the success of CNC turning. We can provide customers not only with machining services but also with professional consulting value based on materials science. We will analyze all functional requirements, working environment, and machining characteristics comprehensively to recommend the best solution to balance performance, durability, and economy, ensuring the ultimate success of your project.

How Does LS Manufacturing Help Solve The Challenges Of Its Clients With Respect To The problem Of Turning Precision Parts?

The core value of the CNC turning technology at LS Manufacturing lies in translating advanced technologies into practical CNC turning solutions that help in solving customers' pain points. Below is a case study showing how we help clients overcome their challenges:

1. Client's Problem:

One of the well-known industrial pump manufacturers had serious problems in the quality of its core product, namely, the impeller shaft. Conventionally manufactured impeller shafts have a very low dynamic balance pass rate, excessive vibration and noise during operation, which shortened the product life, resulting in constant high rates of customer complaints, thus seriously affecting the brand reputation.

2. LS Manufacturing Solution:

With this, our precision CNC turning team, without starting production of workpieces immediately, performed a detailed dynamic performance analysis of the workpiece. According to the analysis result, a dedicated precision hydraulic fixture was tailor-made for the customer to basically improve clamping accuracy. In this way, all critical components are machined in one setup through a five-axis precision turning center with optimized cutting path programming to guarantee impeller, journal, and other parts coaxiality is extremely high, thus laying a foundation for the dynamic balancing performance.

3. Results and Value:

After this upgrade of the CNC turning solution, the impeller shaft passed the G2.5 level dynamic balancing test once on the first try. The product defect rate was greatly reduced, from 15% to less than 0.5%, and the customer was able to eliminate vibration and noise, a core quality pain point. This greatly improved not only the reliability and service life of the water pump but also helped the customer solidify its market reputation and win a decisive competitive advantage in that process.

This case demonstrates that we provide not only machining services but also systemic problem-solving capability based on in-depth engineering analysis: through the innovative integration of technology and processes, we turn our customers' quality pain points into their market competitive advantages.

What Types Of Capabilities Should Be Emphasized When Using A CNC Turning Supplier?

The quality of any CNC turning supplier defines whether the project will be a success or not. The selection of the best is not solely based on comparing prices; it is rather a structured approach towards assessing the overall capability of the supplier, aiming to establish a long-term and stable partnership. In this regard, the core dimensions of focus ought to be:

1. Technical Equipment and Process Capabilities:

Pay attention to the precision of equipment provided by suppliers, including age and processing range. More importantly, their experience with complex materials should be reviewed-specialized technology and successful case studies in the processing of high-temperature alloys or thin-walled parts. This directly dictates their technological ceiling.

2. Quality Control System:

It is recognized that the prerequisite for quality stability is a strict quality control system. Confirm whether the supplier has international quality system certification such as ISO 9001 and learn their specific processes and standards all the way from incoming material inspection and process control to finished product inspection-including whether they are equipped with precision testing equipment, such as coordinate measuring machines.

3. Professionalism of the Engineering Support Team:

Reliable suppliers should provide engineering support upfront and not just manufacture from drawings. Find out if their team will engage in design optimization, value engineering analysis, and manufacturability recommendations; these can prevent any problems well in advance.

4. Capacity and Project Management Reliability:

Delivery capability is very crucial for the smooth progress of a project. One needs to understand the capacity load of the supplier, the production-scheduling logic, and flexibility on urgent orders. A well-defined project management process will ensure clarity and smooth communication.

In a word, choosing a CNC turning supplier involves comprehensive evaluation from three aspects: quality, cost, and risk. A truly reliable partner should be able to provide competitive prices while demonstrating strong technical capabilities, a rigorous quality culture, proactive engineering service awareness, and excellent operational management. Such comprehensive strength will be a solid guarantee for the long-term success of your project.

Figure 5: Detailed shot of precision component fabrication process by LS Manufacturing

FAQs

1. What are the minimum tolerances usually achievable in CNC turning?

Precision CNC turning at LS Manufacturing can commonly achieve tolerances of ±0.005mm (5 micrometers), but even tighter tolerances may be required in special structures and materials. Tolerances that are specific require a comprehensive review based on your part geometry, dimensions, and material properties. After checking your drawings, we will provide you with a clear and reliable technical commitment.

2. Is CNC turning suitable for machining small batches of prototype parts?

Excellent. Our flexible manufacturing system, together with effective CAM programming, supports quick responses for either small-batch or prototype orders. This model effectively controls your early R&D costs while drastically shortening the sample production cycle and providing strong support for accelerated product validation and market launch.

3. What materials do you mainly support for CNC turning?

We can undertake the machining of different metal materials such as stainless steel, aluminum alloy, titanium alloy, copper alloy, etc. Engineering plastics include PEEK and nylon. The process team will customize the optimal cutting parameters and tooling solutions for different material characteristics to ensure the best balance between machining efficiency and the quality of the finished product.

4. About how long does it take from the date of submitting drawings until you get a quotation?

We understand the urgency of project deadlines. We can, in most cases, provide a detailed quotation, including price, process, and delivery time within 8 working hours from the date we receive your complete technical data, thus helping our customers arrive at an efficient decision.

5. What surface finish is obtained by the CNC turning?

Generally, a surface finish of Ra 0.8μm can be stably achieved with the optimization of toolpaths, cutting parameters, and cooling technology. We can arrange the next steps in finishing procedures including polishing for high gloss requirements, like the finish of a mirror.

6. How do you ensure consistent quality during mass production?

We depend on the fully automatic CNC facility, SPC statistical process control in the whole process, and an all-around quality inspection system integrating first-piece, patrol, and final inspections. It is this systematic quality control that provides the core guarantee for the high consistency of our mass productions.

7. If my design is very complicated, does CNC turning allow one-step machining?

Most complicated designs can be machined in our milling and turning center in a single setup, such as parts with eccentric holes, radial features, or curved threads. This not only assures extremely high geometric tolerances but also avoids errors from multiple setups, greatly improving overall accuracy and efficiency.

8. What formats of drawings can you provide?

We support nearly all mainstream 2D/3D formats, including STEP, IGES, SLDPRT, DWG, and PDF. All your design data will be smoothly integrated into our production system to guarantee the accuracy and efficiency of information transmission.

Summary

CNC turning technology has become the first choice for manufacturing precision parts unparalleled in precision, efficiency, and consistency. LS Manufacturing fully understands this and continues to create value for customers beyond their expectations through state-of-the-art equipment, a team of seasoned engineers, and a rigorous quality system.

If you need a professional and reliable partner for your turnings, reach out to LS Manufacturing today for a custom solution and competitive quotation for your project! Let us work together in the development of your precision designs into perfect real-world products.

📞Phone: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website: https://lsrpf.com/

Disclaimer

The content on this page is for informational purposes only. LS Manufacturing makes no representations or warranties, express or implied, regarding the accuracy, completeness, or validity of the information. It should not be inferred that third-party suppliers or manufacturers will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type, or processes through the LS Manufacturing network. The buyer is solely responsible for this information. For parts quotations, please specify the exact requirements for these parts. Please contact us for more information .

LS Manufacturing Team

LS Manufacturing is an industry-leading company specializing in customized manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precision CNC machining , sheet metal fabrication , 3D printing , injection molding , metal stamping , and other one-stop manufacturing services.

Our factory boasts over 100 state-of-the-art five-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries and regions worldwide. Whether it's small-batch production or mass customization, we can meet your needs within 24 hours. Choosing LS Manufacturing means choosing efficiency, quality, and professionalism.

For more information, please visit our website: www.lsrpf.com .