5-axis CNC machining is the answer to the manufacturing of complex geometric parts. As long as the workpiece has complex curved surfaces, oblique holes, or multi-angle features, several clamping operations are needed with 3-axis equipment. The root cause lies in the limited degree of freedom of traditional 3-axis machine tools and fixed tool orientation.

This article will take a closer look at the definition, function, and different configurations of the A, B, and C axes in 5-axis machining and expound on the principles of their collaborative work. Meanwhile, combined with LS Manufacturing engineering practice, it illustrates how this technology solves difficult parts machining problems for customers and comprehensively improves the accuracy, efficiency, and profitability of customers. To save you time, here is a brief overview of the key findings.

5-Axis CNC Machining Core Points Quick Reference Table

| Module | Core Points |

| Challenges | 3-axis machining of complex parts requires multiple clamping operations, leading to issues in accuracy, efficiency, and cost. |

| Root Cause | 3-axis machine tools have fixed tool orientation without freedom of motion for handling spatial angles. |

| Technological Breakthrough |

Adding A, B, and C rotary axes allows the tool to approach the workpiece from all angles. |

| Core advantage |

Completing complex machinings in one setup with ensured accuracy, greatly improving efficiency. |

| Application Value | Offering customers high-efficiency solutions through practices such as LS Manufacturing. |

Equipped with two rotary axes, 5-axis CNC machining allows the tool to process the workpiece from any spatial angle. Its core value lies in achieving "one-time setup, complete machining" of complex parts. This fundamentally eliminates the cumulative error caused by many setups, completely ensures high accuracy in processing, and greatly reduces auxiliary time while simplifying production processes. It means the ultimate solution for the manufacturing of complicated parts in the required high quality, short cycle time, and at low cost.

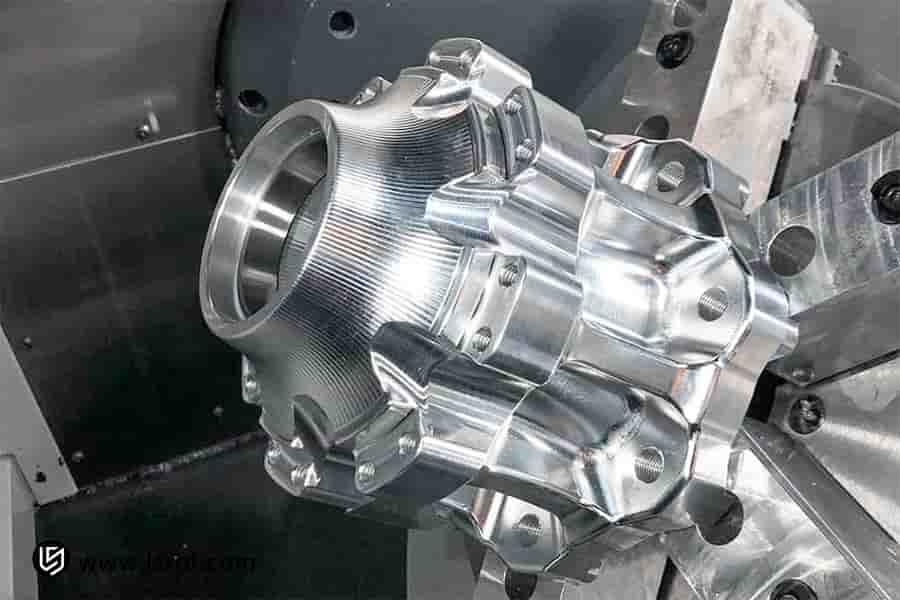

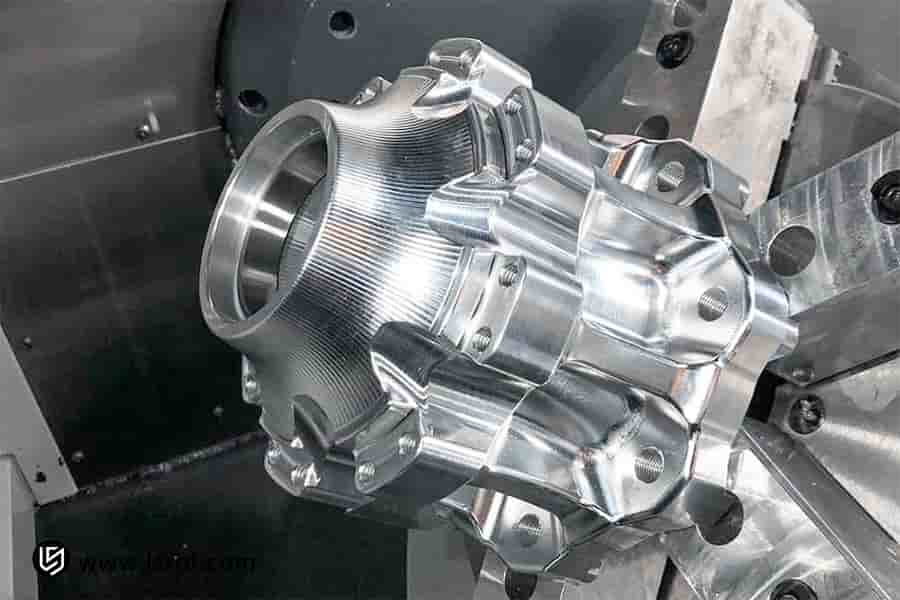

Figure 1: CNC system with full 5-axis contouring capability by LS Manufacturing

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

With the vast amount of information available on CNC machining, why should this discussion on 5-axis technology be worth a careful read? That is because we genuinely believe that true knowledge does not come from theoretical deduction but through repeated refinement at the production line. Our team, operating within the stringent frameworks of IATF 16949 and the International Aerospace Quality Group (IAQG), is always at the forefront, facing daily challenges brought in by high-hardness alloys, stringent tolerances, and complex geometries.

For more than ten years, we have successfully completed over 50,000 customized parts with 5-axis machining. Every breakthrough has given us valuable experience: how to optimize toolpath strategies according to various material properties, how to effectively control vibration and deformation in deep cavity machining, and how to scientifically plan production cycles within multitask orders.

This guide shares these practical insights, verified through testing with cuttings and coolants. Our purpose is clear: to systematically summarize our successful experiences and early lessons learned and help you avoid pitfalls that we had to face, directly addressing the core efficiency and quality bottlenecks in 5-axis machining.

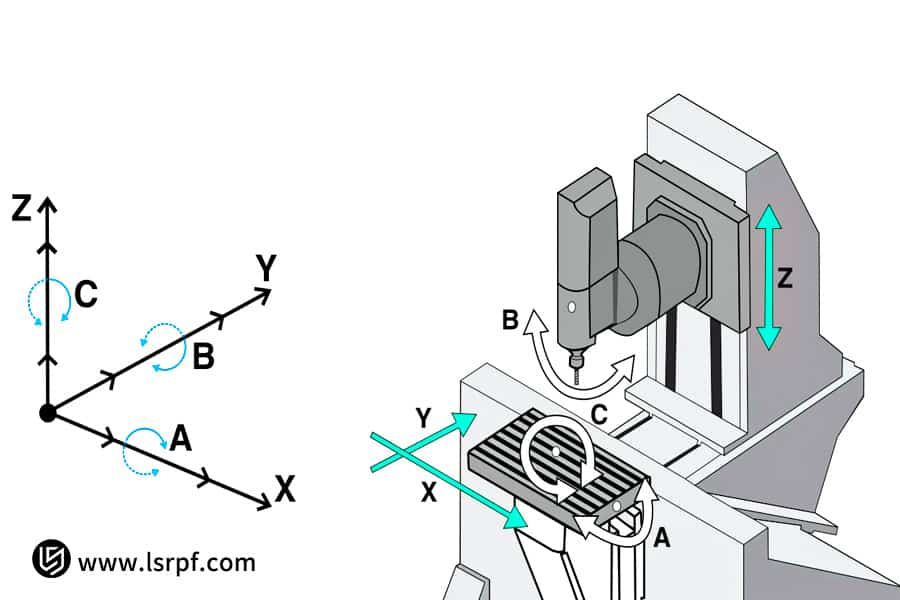

How Are The A, B, And C Axes Defined In 5-Axis CNC Machining?

Clearly explaining the specific definitions of the 3 rotary axes gives a head start to mastering how to use the technology in 5-axis CNC machining. The three correspond to A-axis B-axis C-axis CNC, which are the rotational movements in correspondence to the machine tool linear coordinate axes. Specific definitions and functions include:

- A-axis: Rotation about the X-axis: A-axis motion refers to the rotation about the X-axis of the machine tool. You can therefore imagine the entire workpiece or tool swinging back and forth in a direction centered on the X-axis. Such motion is ideal for the machining of features that are inclined or for curved surfaces on the sides of workpieces.

- B-axis: Rotation about the Y-axis: The B-axis is the rotational motion around the Y-axis. It always appears in the form of left-right rotations of the worktable or spindle. Therefore, when machining, the B-axis will cooperate with other axes such that the tool tilts at an optimal angle, thus efficiently completing the milling of a complicated cavity or mold.

- C-axis: rotation about the Z-axis: The C-axis is the name given to the rotary motion through 360° around the Z-axis that is perpendicular to the work table. It is the most used in CNC rotary tables axis and acts much like a precision indexing head in that it can precisely rotate a workpiece through any circumferential position to machine all kinds of holes or contours distributed on the circumference.

In other words, the essence of 5-axis CNC rotary axis technology is the accurate definition and coordinated movement of the A, B, and C rotary axes. It is this logic of movement based on a Cartesian coordinate system that makes the A-axis B-axis, and C-axis CNC machining capable of machining complex spatial angles.

Why Does 5-Axis Machining Have To Count On These Rotary Axes?

The most important advantage of 5-axis machining is the possibility it provides for overcoming the spatial limitation of conventional 3-axis machine tools by means of rotary motion. These rotary axes are not just functional supplements; they are rather a cornerstone to efficiently and highly precisely machine complicated parts. Their core value is represented mainly in the following aspects:

Accurately achieve multi-angle positioning and complete the machining of complex geometries

The most fundamental function of these rotary axes is to make the tool approach the surface of a workpiece from any desired optimum angle through the oscillation of axes A, B, and C. Whether it is an inclined hole, complex curved surface, or deep cavity structure, the tool can always keep the best cutting posture to complete all processes in one setup, which is a core expression of 5-axis CNC fundamentals and constitutes a solid foundation for the technology.

Effectively avoids interference between tool, workpiece, and machine tool

When manufacturing deep cavities, concave sections, or compact structures, the tool shank or the spindle head usually collides with the workpiece. Spatial adjustment of the angle by means of the rotary axis allows for an interference-free path and thus makes areas safely accessible for the tool that would not have been accessible in this way with a conventional tool.

Ensuring overall accuracy, improving surface quality

All operations, ranging from datum positioning and side machining to the engraving of the surface, are done on the same coordinate system without repeatedly operating the work. Essentially, this avoids accumulation caused by repeated positioning. In addition, by adjusting the angle, the area where the linear velocity at the tip of the ball end mill is the largest can be used for cutting and engraving the workpiece, thus achieving a better surface quality.

In a nutshell, the power of 5-axis CNC fundamentals lies in the different degrees of freedom supplied by these CNC rotary table axes. For machining, they raise it from a 2-dimensional plane to 3-dimensional space in order to achieve "one clamp, complete machining". This is not only crucial to enhance efficiency but also a determining factor for ensuring the integral form and position tolerances and geometric accuracy of parts; thus, it is indispensable technology for manufacturing in high-tech fields such as aerospace and precision medicine.

What Are The Common Axis Configurations For 5-Axis Machine Tools?

In 5-axis CNC machining, the A, B, and C rotary axes can be assigned to either the worktable or the spindle head of the machine tool. This gives rise to a number of variations in CNC axis configurations, which directly influence the machining capabilities and applicability. Below is a comparison of several mainstream configurations:

| Configuration Type | Core Features and Applicable Scenarios |

| Dual Rotary Table | The worktable integrates both rotary axes, such as A and C axes. It is ideal for small to medium-sized complex and precision part machining. |

| Dual Swing Head | Both rotary axes, such as A and B axes, are mounted on the spindle head. It is suitable to deal with the large and heavy workpieces. |

| One Rotary and One Swing Head | For instance, one rotary axis may be on the worktable, such as the C-axis, and another on the spindle head, such as the B-axis for flexible machining. |

The first critical step in the successful implementation of the 5-axis CNC machining project is to choose an appropriate configuration of CNC axes. LS Manufacturing has an advanced machine tool cluster covering all the mainstream configurations above-mentioned, and its seasoned process team can match you with the most effective and economical solution from the source according to the specific dimensions and structural features and precision of the parts, for the best balance between processing capacity and cost-effectiveness.

Figure 2: Parts finished in a single setup using a rotary axis by LS Manufacturing

What Are The Essential Differences Between 3+2 Axis Positioning Machining And 5-Axis Linkage Machining?

The fundamental difference between the 3+2 axis and 5-axis machining is the state of motion of the rotary axes in the process of machining: it either involves step-by-step machining after fixing an angle or integrated machining, with all axes continuously linked. This distinction lies at the heart of 3+2 axis vs 5-axis machining and determines their respective technical levels and applicable scenarios. The following table compares, in detail, the essential differences between the two modes:

| Comparison Dimensions | 3+2 axis positioning machining (5-axis orientation) | 5-axis linkage machining (true 5-axis) |

| Working principle | Rotary axes are at a fixed angle and then locked. Further, only X/Y/Z axes perform the linear cutting. | The X, Y, and Z linear axes always move synchronously and continuously while performing the cut in coordination with two of the A/B/C axes. |

| Machining of Objects | It is suitable for the machining of box-shaped parts with discrete angular features, such as polyhedra and oblique holes. | Specially designed for complicated geometries with continuously changing shapes, like impellers, propellers, and sculptured surfaces with intricate detail. |

| Main advantages | Easy programming, high stability, more economical, and avoids multiple workpiece clamping. |

It is able to machine complex spatial surfaces in one time with excellent surface quality and contour accuracy. |

| Machine Tool Requirements | Dynamic performance that the CNC system and machine tool are required to provide is relatively low. | A high-performance CNC system is required with a high dynamic response to avoid motion errors. |

3+2 axes machining can perform a variety of tasks of 3-axis machining in stages and batches, making it an excellent way to work out a polyhedron. In true 5-axis linkage machining, all axes are moving at every instant of the cut, optimally keeping the tip of the tool in contact with the surface. This is the ultimate way of producing top-level complex parts in such fields as aerospace and energy.

How Do Different Rotary Axis Configurations Affect The Actual Machining Results?

The distribution of the rotating axis, namely the configuration of the CNC axis in 5-axis CNC machining, determines the working capability and precision of the machine tool and forms the core of 5-axis CNC axes explained. Different configuration schemes will bring drastically different machining results:

Impact on Machining Accuracy and Stability

In the case of small precision parts, such as titanium alloy implants for medical devices, a dual rotary table would be most effective, meaning the A and C axes are on the worktable. This setup can reach extremely high indexing accuracy and stability due to the light weight and low rotational inertia of the workpiece, resulting in clear contours of complex trabecular structures.

Impact on machining range and accessibility

When machining large impellers or automotive molds, a dual oscillating head configuration is more appropriate: both B and C axes are on the spindle. The workpiece can be fixed on the worktable without creating centrifugal force problems due to workpiece rotation. This permits the tool to approach any area of the big job from the best angle, solving interference and accessibility problems.

Impact on Machining Efficiency and Flexibility

A hybrid configuration, such as one rotary head with one oscillating head, like a B-axis oscillating head combined with a C-axis rotary table, offers flexibility. In our practice , during the machining of communication cavity filters containing side features and top oblique holes, the B-axis oscillation is able to optimize the side milling angle, followed by fast indexing and machining of the top via C-axis rotation; it greatly increases efficiency compared to several clamping operations.

In other words, the different combinations of CNC rotary table axes are directly related to the final quality, efficiency, and economy in machining-not just mechanical differences. With a deep understanding of the 5-axis CNC axes explained and a rich collection of machine tools, LS Manufacturing is able to conduct precise process planning and select appropriate CNC axes based on your part characteristics at the very beginning of a project to ensure the best machining solutions right from the start.

Figure 3: Complex contours produced via ABC-axis kinematics by LS Manufacturing

What Is The Challenge With Multi-Axis CNC Programming? How To Solve?

Multi-axis CNC programming is the primary factor that would eventually unlock 5-axis machining capability. The challenge at the core of the technology is how to transform complex 3D models into correct motion commands that the machine tool can perform safely and efficiently. The major difficulties involved in this area are reflected in the following aspects:

- Precise planning of spatial toolpaths: 5-axis programming should be able to guarantee the positioning and attitude control of the tool in 3-D space. If the planning of the path is wrong, it will easily lead to sudden changes in cutting angles, material residue, or overcutting. We use advanced algorithms through CAM software to accurately fit the tool path to the workpiece surface and maintain a continuous and stable state during the cut.

- Comprehensive Collision Avoidance during Machining: The introduction of rotary axes significantly enlarges the possibility of interference between the spindle, tool holder, workpiece, and fixture. In this paper, we apply a virtual simulation system with a full machine tool model to the programming stage for the detection of kinematic chain collision and perform attitude adjustment or generate the avoidance paths automatically to ensure safety during machining.

- Precise matching and optimization by the post-processor: It is the post-processor's job to take these generic toolpath files and to translate them into code the specific machine tool can understand. For each machine, we write a custom post-processor matching the characteristics of the machine tool's kinematics and control system so that the program will exploit the full performance of the machine.

Faced with the systemic challenges associated with multi-axis CNC programming, we develops standardized solutions from experience gained in over 4,000 complicated projects. Our database of processes includes optimized parameters for various materials, tools, and features, combined with production-proven post-processor templates that enable us to provide safe, efficient, highly optimized machining programs for customers, effectively improving machining quality and efficiency.

How Does LS Manufacturing's 5-Axis Technology Solve The Machining Challenges For Customers?

The LS Manufacturing 5-axis Machining Case Study fully demonstrates how we translate the most advanced technologies into real value for our customers. Faced with a bottleneck, the manufacture of a complex titanium alloy component for an aerospace company was greatly improved by a systematic solution.

Customer Challenge

A certain aerospace company had a certain complicated spatially curved surface and deep cavity structure titanium alloy engine nacelle component that had to be machined. Conventional 3-axis machine tool segmented machining requires multiple clamping operations, leading to the accumulation of errors. It also causes tool chattering in the machining operation of the inclined surface and deep cavities, leading to unstable part accuracy. It resulted in an initial production scrap rate as high as 40%, severely impacting project schedules.

LS Manufacturing Solution

We came up with a 5-axis machining solution of a professional nature. Adopting the B-axis function of the machine tool with a 5-axis linkage machining center allows for a large angle of workpiece tilting and a continuous C-axis rotation, which allows the end mill to be always in contact with the workpiece surface in the best condition of cutting angle, thereby completing high-precision milling of all complex surfaces in one clamping process, effectively avoiding repeated positioning error and significantly improving the condition of cutting.

Results and Value

After the implementation of the new solution, the machining quality of this component made a qualitative leap: the product qualification rate increased dramatically from 60% to over 98%. Due to process centralization, the delivery cycle was shortened by 50%. It has reduced tooling and fixture investment and secondary handling time, thereby significantly saving the overall cost for customers and ensuring the smooth delivery of critical projects.

This LS Manufacturing 5-axis machining case study shows that the key value of 5-axis technology lies in eliminating at its source those factors leading to precision loss through process innovation of "one-time clamping, complete machining." Confronting the high-end field manufacturing challenge presented by complex parts, LS Manufacturing not only provides advanced equipment but offers overall solutions with deep process knowledge, like a cutting parameter library for titanium alloys.

How To Choose The Appropriate 5-Axis Configuration Based On My Part Characteristics?

Essentially, correctly choosing the CNC axis configuration means closely matching the capability of the machine tool with that of the part needs, and that directly relates to efficient machining, accuracy, and benefits. For example, the following is a practical selection guide based on the characteristics of the part:

Part Size and Weight

According to the structure of the machine tool, large and heavy parts, like machine tool beds or large molds, have to be equipped with a gantry-type 5-axis due to high stability and great load-carrying capacity. The small and medium-sized precision parts like impellers and medical devices are best produced on the cradle-type (double-table) 5-axis machining center, in compact structure and with extremely high dynamic accuracy.

Geometrical Complexity and Technical Requirements

Axis Configuration: Cradle-type or composite 5-axis machining center for complex curved surface, deep cavity, and/or inclined hole workparts such as aerospace structural and injection mold parts. The cradle-type allows workpieces to be manufactured for multiple faces in a single setup. This configuration minimizes workpiece clamping times, ensures positional accuracy, and reduces cycle time.

Production Volume and Automation Requirements

Affecting Return on Investment: In high-volume production, 5-axis CNC machining centers should be equipped with an APS to realize 24/7 uninterruptible production, while in small-batch, multi-variety, flexible production, the demand for rapid setup and versatility is greater than that for pure high speed.

In short, the optimal CNC axis configuration comes with a deep understanding of how your part is being manufactured. Our engineers will provide the most economic and efficient 5-axis CNC machining solution for your needs while making sure everything you invest in is worth it. You can, at any time, reach out for an in-depth analysis report.

Figure 4: A and C axes industrial CNC machining center by LS Manufacturing

What Are Some Common Incorrect Uses Of Rotary Axes In 5-Axis Machining?

Incorrect usage of rotary axes in 5-axis machining bears the highest risk for equipment failure and part scrap. The 5-axis rotary axes principles need to be understood rather well, and the operation should be standardized. Here are a few common misconceptions:

- Ignoring physical limits, which results in collisions: Different 5-axis machine tool configurations selection have specific rotation angle limitations and interference zones. If these are not considered during the programming and operation, collisions between the spindle, tool, workpiece, or fixtures can occur easily. The key to prevention is a complete machine tool motion simulation before operating the machine.

- Programming Deviation from 5-Axis Rotary Axis Principles: The core of 5-axis machining is tool tip tracking (TCP) and coordinate transformation. Incorrectly setting the rotation center or programming zero point will result in incorrect tool posture and defective products. This means that process engineers should have a deep understanding of the principles of kinematics and ensure that post-processing files for multi-axis CNC programming are absolutely accurate.

- Confusion in the management of the coordinate system can also lead to a loss of precision: In continuous motion, the workpiece coordinate system needs to be offset accurately with rotation. If this depends on manual calculations or if this is not supported by the post-processing, the tool tip will deviate from its theoretical position. A professional CAM system will automatically handle coordinate rotation.

In short, avoiding these errors requires rigor throughout the entire chain, from equipment selection to process programming. LS Manufacturing, while providing solutions, ensures not only the rationality of the 5-axis machine tool configuration selection but also in-depth training based on the 5-axis rotary axes principles and multi-axis CNC programming support. With our professional rigor, we safeguard your complex machining processes.

Figure 5: Schematic of the rotary axes in a 5-axis CNC machine by LS Manufacturing

FAQs

1. Does 5-axis machining have to involve simultaneous movement of all 5 axes?

Not necessarily. Common "3+2" positioning machining, in which the rotary axis is positioned to the optimal angle first, then cuts in 3-axis mode, is suitable for machining at specific anglesIn contrast, 5-axis linkage means all 5 axes move simultaneously and is used for the processing of complicated curved surfaces. We will precisely recommend the most effective and economical machining solution according to your part geometry.

2. Does 5-axis machining place a higher demand on programmers?

Yes, by a big margin. A programmer needs to have deep knowledge in 5-axis kinematics, tool attitude control, and collision avoidance strategies. Using an experienced process team and highly advanced CAM systems, we can deliver precise multi-axis CNC programs with safety and accuracy assured in the flawless machining process.

3. How is the accuracy of 5-axis machine tool guaranteed?

Because we value accuracy, we make sure it's guaranteed by multiple technologies: before shipment, a laser interferometer is used to precisely calibrate the rotary axes and embed dynamic accuracy compensation parameters into the CNC system for real-time errors. Meanwhile, every product has to undergo a strict quality control process to ensure it meets the requirements of the drawing.

4. Is 5-axis machining suitable for small-batch production?

Very suitable, the 5-axis machining of small-batch parts with complex structures can be done in one setup, saving the expense and time needed to prepare multiple-positioning toolings; accordingly, it provides a rapid response. Such a requirement was tailor-made for the flexible production services offered by LS Manufacturing.

5. Could the 5-axis machining process oversize parts?

Absolutely, we have several kinds of 5-axis machines, including gantry-type 5-axis machine tools with large working strokes for oversized parts. Besides, we can effectively solve machining challenges through professional process optimization strategies, such as area-based machining.

6. What file format does 5-axis programming require?

We recommend a universal format with complete 3D model information, such as STEP, IGES, X_T, or PARASOLID. All the above-mentioned formats maintain model data intact and can be directly imported into our CAM system for multi-axis CNC programming with high efficiency and accuracy.

7. How much more expensive is 5-axis machining than 3-axis machining?

The prices vary. Compared to simple parts, 5-axis machining involves higher depreciation costs; however, for complicated parts, 5-axis machining can reduce clamping times, merge processes, and improve efficiency, thus lowering the overall manufacturing cost, hence more economical.

8. How do I get a 5-axis machining solution for my part?

It's quite a simple procedure: just provide 3D drawings and specifications, then our engineering team will make a detailed evaluation within 24 hours and finally provide you with a complete solution containing an overall process plan, time estimation, and transparent quotation.

Summary

The A, B, and C axes are the core of 5-axis CNC machining to achieve efficiency and precision in making complicated work pieces. Proper comprehension and application of these rotary axes are of the most importance in creating competitiveness. With an accumulation of many years of experience in 5-axis machining and a professional team, LS Manufacturing has become a reliable partner for many leading companies within various industries.

If your project requires complex part machining, please do not hesitate to contact us for a free technical evaluation and quotation. Let us add value to your project by applying our professional 5-axis machining technology!

📞Phone: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website: https://lsrpf.com/

Disclaimer

The content on this page is for informational purposes only. LS Manufacturing makes no representations or warranties, express or implied, regarding the accuracy, completeness, or validity of the information. It should not be inferred that third-party suppliers or manufacturers will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type, or processes through the LS Manufacturing network. The buyer is solely responsible for this information. For parts quotations, please specify the exact requirements for these parts. Please contact us for more information .

LS Manufacturing Team

LS Manufacturing is an industry-leading company specializing in customized manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precision CNC machining , sheet metal fabrication , 3D printing , injection molding , metal stamping , and other one-stop manufacturing services.

Our factory boasts over 100 state-of-the-art five-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries and regions worldwide. Whether it's small-batch production or mass customization, we can meet your needs within 24 hours. Choosing LS Manufacturing means choosing efficiency, quality, and professionalism.

For more information, please visit our website: www.lsrpf.com .