Gear machining is usually thought of as a separate manufacturing link, but it is actually a concentrated reflection of systemic transmission problems. When there are constant breakdowns on your machinery owing to premature failure of the gears, or transmission noise prevents the high-positioning of your products, this "mismatch" of the gear with other components in the system is often to blame.

The reason for this is that they ignore systemic factors such as a load spectrum, operating conditions, and installation accuracy. This guide tries to reveal how LS Manufacturing's "Design-Materials-Process" collaboratively engineering approach raises gears from an isolated part to a highly reliable component deeply integrated with the system to realize synchronization with equipment life.

To solve systemic issues, one needs a systemic perspective in the first place. Let's understand first what role gears really play in your equipment. To save you time, here is a brief overview of the key findings.

Figure 1: Gear manufacturing process employing indexable inserts by LS Manufacturing

Gear Machining Guide Full Text Quick Reference Table

| Partial Categories | Key Points Summary |

| Core concept | To break the isolated concept of gear manufacturing and establish a systemic collaborative engineering mindset. |

| Core Problem | The main cause of gear failure is the systemic "mismatch" with other transmission components, not the gear's own quality. |

| Solution | Employ the "collaborative design-materials-process" approach to ensure perfect gear-system matching. |

| Design Collaboration | Gear manufacturing and macroscopic profile design based on real load spectra and operating conditions. |

| Material Collaboration | Matching material properties and heat treatment processes to design loads and expected lifespans. |

| Process Collaboration | Production processes should yield the realization of the designed tooth profile and optimum material performance. |

| Installation and Validation | Strictly controlling the precision of housing and installation specification, and conducting system-level testing and validation. |

| Ultimate Goal | To turn gears from cost-intensive components into highly reliable parts that increase the competitive power of the machine. |

From a single manufacturing step, deep collaboration across design, materials, and processes guides how gear machining has moved from one single manufacturing process to a key engineering process that secures the reliability and performance of the whole transmission system. This basically addresses some of the main pain points, including unplanned downtime and noise, thereby maximizing the value across the lifecycle of the equipment.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

For a long time, our team has served leading companies in the automotive, industrial automation, and heavy machinery industries. Because of the meshing noise and transmission efficiency, the gears we machine for gearboxes directly affect the market competitiveness of the end product. The core gear pairs we provide determine the reliability level of the whole system through their lifespan and backlash.

In the past decade alone, we have successfully delivered over 50,000 custom gear parts. Each of these has deepened our understanding of the synergy between design, materials, and processes: what tool paths best utilize the performance of modified steel, what heat treatment and finishing sequence balances deformation and residual stress, and how to ensure consistency for every gear in mass production.

It is a guideline from which every opinion and solution has been repeatedly verified by countless chips, measurements, and rigorous customer acceptance tests in our workshop. We share the experience candidly to help you avoid the pitfalls we have encountered.

Core Myth: 90% Of Gear Failures Originate Prior To Design

A common but fatal misconception in the pursuit of superior gear machining quality is to consider gears as isolated precision parts. Many failures actually did not arise from manufacturing defects, but rather from inherent mismatches with real-world operating conditions established during the initial transmission system design phase. To fundamentally avoid such "inherent deficiencies," our approach concentrates on two steps before design:

1. Reverse Engineering of Design Inputs from System Operating Conditions:

Our engineering team initiates each project with a comprehensive analysis of your equipment's actual operating environment, meticulously evaluating factors ranging from transient impact loads and thermal deformation cycles to long-term lifespan targets. These critical system-level requirements are then precisely translated into definitive gear design parameters: including calculated safety factors, customized tooth profile modification schemes, and optimal material grade selection, ensuring the final design is robustly tailored to real-world application demands.

2. Pre-Verification Through Co-simulation:

Before any physical manufacturing takes place, the proposed gear model undergoes exhaustive co-simulation within a fully virtualized transmission system. This advanced digital prototyping integrates multi-body dynamics with finite element analysis to identify and fix potential failure points of localized high-stress concentrations, vibration modes, and acoustic noise, hence confirming seamless integration with bearings and housings for best system performance and durability.

It is the most scientific and reasonable transmission system design in the end, constituting a very important foundation for effective gear machining. In other words, gears can be considered dedicated "system servers," while a demand side driven reverse engineering and verification process guarantees their perfect fit with the requirements of the host system right from the beginning a guarantee of unparalleled performance and service life.

Precision VS Cost: How To Find The Optimal Balance?

Precision gear machining normally holds the concept in the production process: "the higher the precision, the better." However, scientific cost optimization needs to break this mindset. The point is that the increased precision leads to exponentially increased costs, while the real needs of many applications can be much better fulfilled by combining "appropriate precision + system optimization."

1.Looking for the inflection point of precision cost:

with the improvement of each level, ISO precision grade will lead to a sharp increase in processing costs, time cost, and wear and tear cost of machine tools/tools. For example, upgrading from ISO 8 to 6 results in a manageable cost increase and a significant performance improvement, but pursuing 3 from 6 forcibly will lead to a sharp increase in cost, while its actual contribution to system performance may be negligible.

2. Use a "precision + profile modification" combination strategy:

For gears that require medium speeds and small impact loads, it is not the best route to chase ISO 3 gears blindly. Instead, use much cheaper ISO 6 gears but carry out precision tooth direction and profile modification on its given installation error and load deformation data. The combined approach gives higher transmission smoothness and lifetime than the isolated ISO 3 gear with lower overall cost.

In other words, the optimum method of precision gear machining is a precise match based on systems thinking. We are not after the highest precision at any cost but rather seek to derive the most cost-effective precision level through deep understanding of the working conditions, supplemented by such system compensation technologies as profile modification, thereby arriving at true cost optimization while ensuring reliability.

Figure 2: Industrial close-up of precision gear machining components by LS Manufacturing

Process Selection - How Does It Determine The Performance Ceiling?

In gear manufacturing, much more than a straightforward listing of machining operations is involved in the selection of a process route, which fundamentally sets the final performance ceiling and cost structure. In particular, choices amongst various gear manufacturing process, specifically the combination of key gear cutting process and heat treatment, directly influence the integrity of the tooth surface, microstructure, and residual stress state, hence defining the boundaries of load-carrying capacity, noise level, and fatigue life.

| Process Stage | Core Capabilities and Performance Impact | Typical Cost and Applicable Boundaries |

| Gear hobbing/shaping | The tooth surface is soft, with high forming efficiency but low load-bearing capacity and precision on the tooth surface. It is the basic method of machining soft-tooth-surface gears. | At the lowest cost, it's suitable for light-load and general-condition transmissions but with relatively low performance. |

| Post heat treatments, precision rolling/scraping | It will economically increase the precision and improve tooth surface quality in quenched gears, but to a limited degree. | Economical cost is a common compromise between cost and performance for medium-load applications. |

| Gears grinding | It ensures highest tooth profile accuracy and optimum tooth surface roughness, vastly increasing fatigue strength and lowering noise. | Highest cost, preferred process for heavy-duty applications associated with heavy loads, high speeds, and low noise. |

In other words, the basic selection of gear manufacturing process is to find the most economical route for the performance target. The clue to avoiding performance overkill/underkill or scientifically setting the performance ceiling for gears is in identifying the complete capability map from simple gear cutting process to finishing.

Materials Science: How To Increase Gear Life By 300%?

Selection and microscopic control of materials during the quest for super performance are prime levers that determine the ultimate service life of gears. It is not a question of just selecting a gear grade; the full durability potential of gears is tapped by an exact intervention at the material level. This is much more than just a material substitution; it is a precision "customization" aimed at certain failure modes:

- Precise alloy design and element ratios: The optimization of the ratios of some key alloying elements, such as chromium, molybdenum, and nickel, strengthens not only the matrix but also toughens the core in particular and raises the fatigue resistance of the tooth surface to offer a fundamental guarantee against impact loads and heavy stresses.

- Controllable Carburized Layer Gradient Technology: The perfect transition between surface and interior is the key to an extended life. We precisely control the carbon-concentration gradient and effective layer depth of the carburized layer so as to realize extremely high surface hardness while attaining a smooth bond with the strong core, thereby fundamentally preventing surface crushing or spalling.

- Quantitative Control of Residual Austenite: Residual austenite, which normally is undesirable, is held within an optimum range by a special process. The metastable structures transform to martensite under stress, developing compressive stress that effectively impedes the propagation of microcracks and greatly improves the gear's resistance to pitting and wear.

The scientific way to achieve several-fold increases in service life from gear materials is to fully exploit the potentials of such materials. We will optimize, through synergistic engineering, alloy composition, heat treatment layer depth, and microstructure to "customize" armor for your gears to resist specific failure modes, hence achieving a leap in reliability beyond conventional standards.

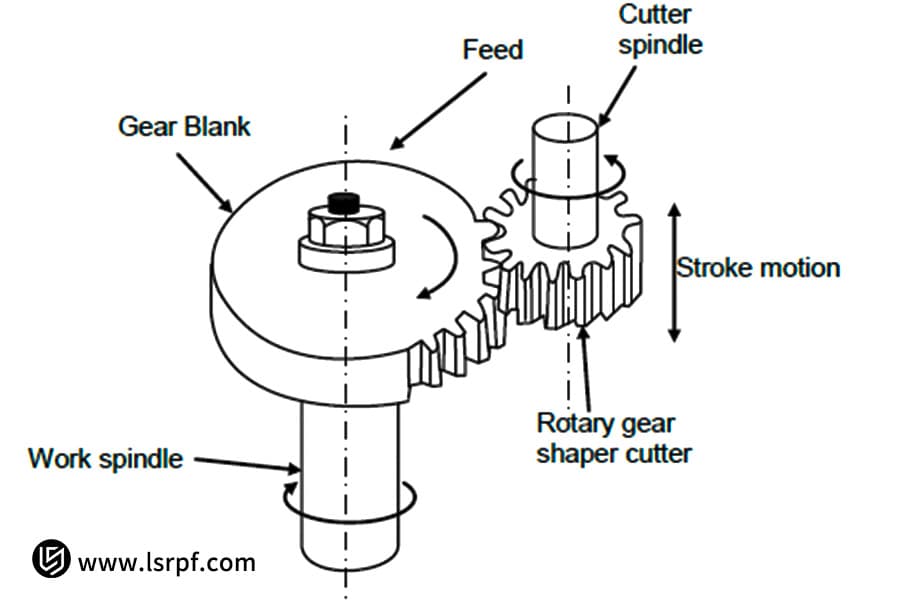

Figure 3: Internal configuration of a precision gear shaping tool and workpiece by LS Manufacturing

Gear Selection: Finding The "Best Partner" For Your Scenarios

In the design process for a transmission system, the appropriate selection of types of gears is actually the cornerstone for ensuring overall performance and cost-effectiveness. As a matter of fact, transmission efficiency, torque density, noise, and cost vary drastically across different application scenarios. It is only by comparing on the basis of "first principles" that we can find the true "best partner" for your equipment.

| Types of Gear | Core Characteristics and Advantages | Typical Application Scenarios and Considerations |

| Helical Gears | Smooth transmission, low noise, high load-carrying capacity, but generates axial force. | It was suitable for high speed, smooth, and quiet power transmission applications. Thus, it is used in automotive gearboxes and industrial reducers. |

| Bevel gears | It allows power transmission for intersecting shaft drives, enabling a change in direction and having a high torque capacity. | They enable applications of spatially intersecting shafts-for example, vehicle rear axle differentials and machine tool rotary drives. |

| Worm gear | It drives can realize high speed ratio in single-stage transmission, with smooth transmission and self-locking function, while the efficiency is relatively low. | The worm gear is made for medium- and low-speed transmission with a high reduction ratio and self-locking functions, such as lifting systems and conveying equipment. |

In other words, there is no best gear type; there is only the best application scenario. Therefore, the starting point for any selection lies in a thorough analysis of the equipment's core requirements. A successful selection comes from an accurate understanding of these needs - such as space layout, efficiency, noise, and cost - enabling the wisest decision between options.

Heat Treatment: The "Ultimate Amplifier" Of Gear Performance

Gear heat treatment is the central procedure of the whole gears manufacturing process that determines its service performance. It truly is a "performance amplifier." Excellent gear heat treatment is not just "quenching and hardening"; actually, it is a precision-controlled engineering process, performance improvement, targeted at obtaining an ideal balance of high surface hardness and high core toughness for a qualitative leap in component capabilitie

1. Controlled Atmosphere Heat Treatment Technology:

We use a heat treatment method in a controlled atmosphere with accurate carbon potential control to guarantee that the gear surface will have a constant and uniform carbon concentration during carburizing and an ideal effective layer depth, laying a basis for the formation of a high-hardness and high-wear-resistant martensitic structure without deleterious grain boundary oxidation to ensure the tooth surface is of good quality from the source.

2. Pre-deformation Compensation Technology:

Based on the deep understanding of the deformation laws of material heat treatment, reverse "pre-deformation" design is carried out in the cold working stage. Pre-correction of gear geometry and pre-compensation for the regular deformations that will happen during heat treatment can maintain high precision requirements without excessive grinding after heat treatment, preserve the optimal carburized layer, and reduce residual stress.

In short, the heat treatment of gears today has overcome the limits of conventional heat treatment: with controllable processes and proactive compensation for deformation to the maximum, it gives full play to the potential of materials. Precision control technology is the key to obtaining high strength, a long lifespan, and high reliability in gears and represents the ultimate guarantee to realize the goal of performance improvement.

Figure 4: Industrial close-up of machined gears and drive parts by LS Manufacturing

Case Study: Breaking The "Precision Decay" Curse Of Robot Gears

This case study details the systematic, collaborative engineering approach we employed to resolve the long-term reliability challenges of core transmission components for a leading collaborative robot manufacturer. By moving beyond a conventional supplier relationship to establish a deeply integrated partnership, we focused on the root causes of wear and failure. The solution centered on materially and geometrically optimizing the LS manufacturing gears, thereby dramatically extending their precision life under continuous dynamic loads.

1. Customer Challenges

Running for about six months under high speed and high dynamic loads, the customer's core joint gears suffered an irreversible, micron-level decline in positioning accuracy, which resulted in ultra-low repeatability in robot positioning and a decrease in product yield, with customer complaints continuing to grow, seriously affecting their market expansion.

2. LS Manufacturing's Collaborative Engineering Solution

Precise testing and simulation analysis revealed that it was the result of a combination of microscopic material defects and residual stresses developed by the heat treatment. Thus, our engineering team has come up with a multi-dimensional solution:

- Material Upgrade: The adoption of specialized vacuum melting steel enabled precise control over detrimental inclusions like oxides and sulfides, maintaining them at exceptionally low levels. This resulted in a significant enhancement of material purity from the source, directly contributing to superior fatigue strength and extended component service life under high-cycle loading conditions.

- Process Innovation: The integrated heat treatment methodology combining precise carbon potential control with deep cryogenic treatment was implemented to stabilize the metallographic structure and maximize the elimination of residual stresses. This innovation fundamentally addressed the root causes of later-stage dimensional instability, ensuring long-term geometric accuracy.

- Design Optimization: Through targeted gear fillet optimization and sophisticated local modification of the tooth surface profile, stress concentrations were effectively mitigated. These design enhancements promoted a more uniform distribution of operational loads across the tooth flank, significantly increasing load capacity and reducing the risk of fatigue failure.

3. Results and Value

- Precision Lifespan: The precision retention life for the custom-engineered gear pairs was critically extended from an initial 6 months to surpass 5 years of continuous operation. This breakthrough not only resolves the chronic failure issue but also perfectly synchronizes with the robot's overall design life, eliminating unplanned downtime and ensuring long-term positional accuracy: a fundamental achievement for reliable automation.

- Commercial Value: The exceptional reliability stemming from this enhancement served as a key competitive advantage, enabling our client to pass stringent certification and successfully enter several high-precision automotive final assembly and powertrain lines. This strategic market entry has generated a direct and sustained commercial value growth, adding over 30 million RMB in annual contract value.

The success of LS manufacturing gear comes from the deep synergy of three elements: materials science, heat treatment processes, and gear design. They achieved a leap in precision life by innovating from microstructure and residual stress control to macroscopic tooth profile optimization and thus created tremendous technological and commercial values for customers.

Figure 5: High-precision fabrication process for metal gears by LS Manufacturing

Quality Closed Loop : Making Inspection Data A "Process Navigator"

In today's manufacturing, gear inspection covers much more compared to assessing only final conformance. We're committed to building it into a dynamic quality control closed-loop system in which every piece of inspection data is a "navigator" that optimizes manufacturing processes and continuously improves the quality of the gears. The goal of such a closed-loop system is achieved in two main steps:

1. From Judgment to Analysis:

We utilize a high-precision gear measurement center for comprehensive data acquisition: tooth profile, tooth direction, pitch error. Moving beyond simple "pass/fail" judgments, we employ SPC methods to conduct in-depth trend analysis of this data, observing minute deviations and possible variation in the machining process in real time.

2. Analysis to optimization:

If, through data analysis, there are regular errors, such as accelerated tool wear or machine tool thermal deformation, the system will immediately trigger a feedback mechanism. These will be directly translated into specific process parameter adjustment instructions, such as optimization of cutting speed, compensation for toolpath errors, or adjustment of cutting fluid parameters, hence proactive intervention and correction of deviations before they lead to scrap.

In a nutshell, we elevate gear inspection from a passive, post-manufacturing inspection to an active and preventive quality control core. Based on a real-time flow of "inspection-analysis-feedback-optimization" data, we ensure not only the quality of single gears but also the high consistency of each product in mass production, basically enhancing the intelligence and reliability of manufacturing.

The Secret To Custom Success: 5 Details That Determine Project Success Or Failure

- Front-End Manufacturability Review: Our engineering team engages in comprehensive manufacturability analysis during the initial design phase, proactively identifying and optimizing design features that would otherwise increase manufacturing costs, compromise final performance, or present significant machining challenges, thereby ensuring design for excellence and efficiency.

- Special Tooling and Fixture Design: Custom precision tooling and fixtures are specifically engineered for non-standard tooth profiles and complex geometric structures. This foundational step is critical to guaranteeing accurate part positioning and stability throughout machining, while effectively suppressing deformation caused by cutting forces and residual stresses.

- Process Precision Control Point Setting: Rigorous inspection points are established before and after each critical process, especially heat treatment, to monitor deformation trends in real time. The collected data provides a factual basis for precise allowance compensation in subsequent finishing operations, ensuring final dimensional accuracy.

- Clearly defined supply chain collaboration criteria: Explicit acceptance standards for outsourced processes (such as specialized coatings) and strict data transmission protocols are mandated. This ensures seamless quality consistency and traceability across the entire supply chain, safeguarding the integrity of critical manufacturing specifications.

- Ready-to-use guidance documentation: Comprehensive documentation is provided, including detailed installation alignment procedures, precise preload recommendations, and system-specific running-in specifications. This empowers customers to achieve optimal gear performance and longevity within their final application with minimal setup time.

The successful case in the custom gear manufacturing is the project done in an orderly way; it requires suppliers to be qualified in gear products, more importantly, transform professional experience into all-round detail control so as to ensure the success of complex projects and create value.

FAQs

1. Why are unit prices for small batches of custom gears relatively high?

You have really touched a very important point. The only real cost drivers concerning small batch production are process development and verification, such as activities like programming, tooling, and first-article inspection. Our advantages are: 1) A strong process database allows us to identify the best solution quickly and thus minimize expensive trial-and-error work; 2) In-depth collaboration in design at an early stage saves you from costly late-stage design changes and means a more economical total investment for you.

2. How to evaluate the technical strength of a gear supplier?

The main thing is whether they can get rid of the "processing according to the drawings" concept and actively discuss the operating logic at the gear level, like maximum impact load and lubrication conditions, propose preventive designs based on failure modes. That is the real depth of engineering.

3. How long does it take from drawings to receipt of the first samples?

Standard gears take 2-3 weeks, including complete process planning and quality planning. We have a fast-track sample channel. For urgent needs, we can deliver functional prototypes in as little as 7 working days while guaranteeing core quality.

4. How do you ensure the gear batch consistency?

We depend on standardized operating procedures, statistical process control, and a complete quality traceability system. Such a concept makes sure that the fluctuation of key parameters between different batches is far below industry standards, thus achieving excellent batch consistency.

Summary

Excellent gears come from the deep integration of systems thinking, material science, precision manufacturing, and rigorous quality control. At LS Manufacturing, we commit ourselves to being your reliable engineering partner for drive systems, fulfilling the needs with gear solutions based on deep understanding.

If you want a fundamental solution to technical gear problems, then do not hesitate but immediately contact us a team of gear experts to schedule an in-depth technical exchange! Allow us to serve as the very foundation of your equipment reliability through our systematic approach in gear engineering.

📞Phone: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website: https://lsrpf.com/

Disclaimer

The content on this page is for informational purposes only. LS Manufacturing makes no representations or warranties, express or implied, regarding the accuracy, completeness, or validity of the information. It should not be inferred that third-party suppliers or manufacturers will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type, or processes through the LS Manufacturing network. The buyer is solely responsible for this information. For parts quotations, please specify the exact requirements for these parts. Please contact us for more information .

LS Manufacturing Team

LS Manufacturing is an industry-leading company specializing in customized manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precision CNC machining , sheet metal fabrication , 3D printing , injection molding , metal stamping , and other one-stop manufacturing services.

Our factory boasts over 100 state-of-the-art five-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries and regions worldwide. Whether it's small-batch production or mass customization, we can meet your needs within 24 hours. Choosing LS Manufacturing means choosing efficiency, quality, and professionalism.

For more information, please visit our website: www.lsrpf.com .