CNC machining materials is that conventional materials, even if they are not providing optimal results, are quite workable; when it comes to advanced materials, it creates doubt over machinability and skyrocketing prices with longer delivery times. It is really difficult for a technocrat like an engineer or a buyer to take these trade-offs between performance, price, and delivery times. While opting for the best material, one needs to have very deep knowledge regarding material properties.

The reason for this is based on the level of material knowledge that the supplier possesses. The following are some of the materials that will be assessed within this guide with the intention of comprehending the justification for selecting the specifications and cost-effectiveness of LS Manufacturing. There are five main types of materials that can be processed using the CNC machining technique.

Quick Reference Guide: Key CNC Machining Materials

| Material | Key Traits | Common Applications | Machinability Note |

| Stainless Steel | Resistant to corrosion, strong, durable. | Medical, food, marine parts. | Varies by grade; manage heat. |

| Titanium | Mechanical strength, resistance to light, and biocompatibility. | Plane, implants. | Challenging; needs expertise. |

| Bronze | Wear resistant, good bearing properties. | Bearings, bushes, and valves. | Good; avoid built-up edge. |

| Acrylic | Transparent, good optics, brittle. | Display screens, lenses. | Good; avoid cracks/scratches. |

| Ceramic | Hard, brittle, heat and corrosion resistant. | Electronics, medical, high-temp parts. | Difficult; specialized methods needed. |

Each material has its own characteristics, and for each material, there are some issues, which are issues associated with the material itself. One thing to have the desire to work with that material, and many other things associated with the professional. As your representative of LS Manufacturing, our team has expertise in the professional aspects associated with the material, as well as the proper use of the process, to ensure that your project becomes the very best of the very best, with characteristics associated with precision, power, and economy.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

For more than fifteen years, our company has been at work in the real world of hard materials with features that define closely tolerated specswith complex geometries. Along that line, it is not just that its body of knowledge on the material that we have. Rather, its body of knowledge about machined techniques that provides counsel on accuracy that provides optimal economy and was obtained out of our combined experiences within the aerospace, medical, and automotive industries that make up our markets.

We know about the deformation resistance within the standards for aluminum materials, as has been explained within the Aluminium Association(AAC) standards. However, being level-headed about the matter, we adhere within the standards for quality within our merchandise, within the established standards concerning the quality within the merchandise standards. This standards concerning the surface finishes are within the standards of the National Association for Surface Finishing(NASF) standards.

Our choice of material on our side understands that material choice is truly a functional process, and through the application that may be viewed in terms of the difference in the jet engine and even in the bio-implantable device itself. There’s definitely a difference because in the point that the implication of our process, in the meaning that the alignment of the process and procedure of the quality by the standards of the compatibility of the material to the process in the standards of National Association for Surface Finishing(NASF) that within our clientele, we understand that within our company, this means the same.

Figure 1: Machined acrylic parts, both transparent and opaque by LS Manufacturing

How To Maximize The Value Of CNC Machining Projects Through Material Selection And Process Optimization?

For a successful CNC project, you need to have the right combination, in the right formula, with the right materials, process, and supplier for professional CNC machining services. Many shops simply do the process that is defined for them by the drawing, with hidden problems left forlater. LS Manufacturing uses knowledge of materials combined with their advanced manufacturing capabilities, partnering for customized parts optimization, not simply for materials fabrication.

Strategic Material Selection Beyond Datasheets

It has absolutely nothing to do with a datasheet. It is the comparison of several properties like strength, weight, and resistance that it entitles. Our job is your support system during this critical selection phase. We can assist you in getting the right material with the capability that has not over-costed. This is the foundation of value-maximizing supplier collaboration.

Engineered Processes, Not Standard Parameters

Never can a high-performance CNC machining material with standard parameters offer a satisfactory result in the final product. We use our in-house database which has been established after thousands of successful projects, enabling us to engineer our machining process specifically to a type of material. By doing this, we guarantee the machining parameters, in combination with the cooling process depending on the type of material, will guarantee perfect parameters of finishing, size, and strength of a machining product, which defines our CNC machining services.

Proactive Design for Manufacturing (DFM)

True value is often created before the first cut. Our engineers proactively analyze your design for potential manufacturability issues. We provide actionable DFM feedback to simplify geometry, improve rigidity, or suggest tweaks that dramatically reduce machining time and cost while enhancing part quality, a key pillar of customized parts optimization.

Predictable Outcomes Through Process Control

Even value can be attributed a predictability measure. This is because some of the variables that can be controlled by the company include tool wear, temperature, and fixturing. This rigorous process control minimizes scrap, prevents delays, and delivers the consistency required for assembly and performance, solidifying the value-maximizing supplier.

In fact, to fully optimize the CNC machining process, what you need, together with your capabilities, is a partner who can see beyond the print. This too shall address the seamless integration of material, process, and collaboration. What you need is a partner such as what the services of LS Manufacturing can offer, a partner who can offer more than what your machine shop can do.

Why Are There Such Large Differences In The Processing Costs Of Stainless Steel CNC Machining? What Are The Key Process Points?

Indeed, there is a fairly wide price range in the stainless steel CNC machining in a way that can more or less be attributed to machinability levels in different types of stainless steel. This begins with proper materials, and this ends in a cost-effective way by meeting their purpose in providing a solution to machinability problems. The supplier of proper materials must be competent in providing a solution to such properties in order to deliver their guarantee in relation to their pricing offer in cost effectiveness.

| Material Grade | Key Machining Traits | Primary Challenge | Cost Driver |

| 304 / 316 | Machinability is excellent, may work hard. | Heat & built-up edge. | Slower speeds, specific tool geometry. |

| 17-4PH | Strong, heat treatable. | Extreme tool wear. | Specialized tooling, post-processing. |

| 15-5PH | High strength, high toughness. | Similar to 17-4PH. | Carbide tools, controlled parameters. |

Ultimately, a precise LS Manufacturing machining quote for your project reflects this technical nuance. As experienced corrosion-resistant parts suppliers, we would not treat all of our clients the same way. This is because we have designed our parameters in-house in a way that meets work hardening requirements using the optimum path data of the cut in order to offer you the best processing cost per part at a relatively cheaper price by optimally processing.

How To Effectively Control Thermal Stress And Tool Wear During Titanium CNC Machining?

The concern in this titanium CNC machining is the low thermal conductivity. This directly proves that the material in question has a concern that results in the heating of the material during the machining process. In most cases, the titanium CNC machining process will cause the acceleration of the wear and tear of the tool being used to undertake the machining process.

| Challenge | Primary Consequence | Key Mitigation Strategy |

| Low Thermal Conductivity | Heat buildup in the tool/part. | High-pressure coolant, optimized chip evacuation. |

| Chemical Reactivity | Materials will weld to cutting tool. | Specialty coatings on cutting tools, speed/feed. |

| High Strength at Temperature | High forces. | Stiff setups, low radial engagement. |

In aerospace titanium alloy machining, any kind of compromise regarding any one of the above-listed factors will not be accepted. As a high-precision parts manufacturer, our firm adopts the 5-axis machining system for all operations, as the maximum possible involvement can be ensured through a dedicated set of machining parameters, which will be present in our database only. With cooperation from an experienced titanium alloy CNC machining supplier, any difficult to work with material will become a dependable one for us.

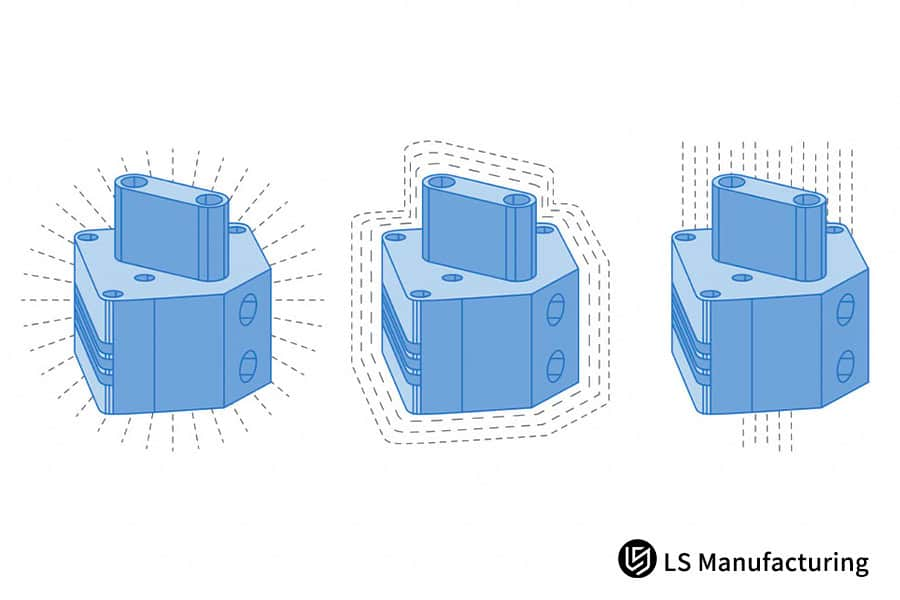

Figure 2: Multiple views of precision-machined CNC components by LS Manufacturing

How To Balance Wear Resistance And Economy In The Customization Of CNC Machining Bronze Bearings And Bushings?

CNC machining bronze for bearings & bushings has proven to be the best possible combination for self-lubrication, corrosion resistance, & durability. However, the biggest challenge that a wear-resistant parts supplier would encounter while machining such a material would be to retain the natural properties of the material and make such a process cost-effective. This would include several issues such as material buildup.

Optimized Tooling Strategy to Avoid Galling

One of the most common issues in CNC machining bronze material is galling. It can be understood as the sticking of material to the machining tool. We counter this effect through the aid of optimized tooling and other advanced tools that are specifically aimed at non-ferrous materials. This minimizes friction and adhesion, ensuring a clean cut, excellent surface finish, and extended tool life, which directly contributes to cost control.

Specialized Cooling for Dimensional Stability

The cooling of the bronze parts also plays a major role in the accuracy of the custom bronze bearing. If the bronze gets heated up too much during the machining process, it expands while cooling down, resulting in inaccuracies in the parts produced. The bronze machining at precision involves highly effective cooling methods that cool down the parts quickly in the machining zone. This ensures that the custom bronze bearings have accurate bore sizes.

Process Engineering for High Volume Efficiency

For large production volume scenarios, producing quality parts within competitively bulk machining pricing rates requires distinct process engineering. Here at MAKINO, we create specialized fixturing solutions that incorporate high-efficiency optimal tool path designs. Our distinctive manufacturing process combined with optimal material procurement helps deliver the economies of scale you demand while maintaining the high abrasion resistance that your application requires.

Alloy-Specific Machining Protocols

Not all bronzes are alike. We tailor our entire process—from speeds and feeds to tool selection—based on the specific alloy, whether it's phosphor bronze, aluminum bronze, or silicon bronze. This material-specific expertise ensures that the unique metallurgical properties of each alloy are preserved, resulting in a finished component that delivers optimal performance, longevity, and value as a reliable wear-resistant part.

The successful production of high-performance components in bronze is one highly complex equation, which includes profound knowledge of materials to preserve their wear resistance, combined with sophisticated machining technology to guarantee precision and economy. We can give as a value-added partner, or rather, we are very successful at taking raw CNC machining bronze stock and producing functional bearings or bushings that assure superior quality at optimal cost.

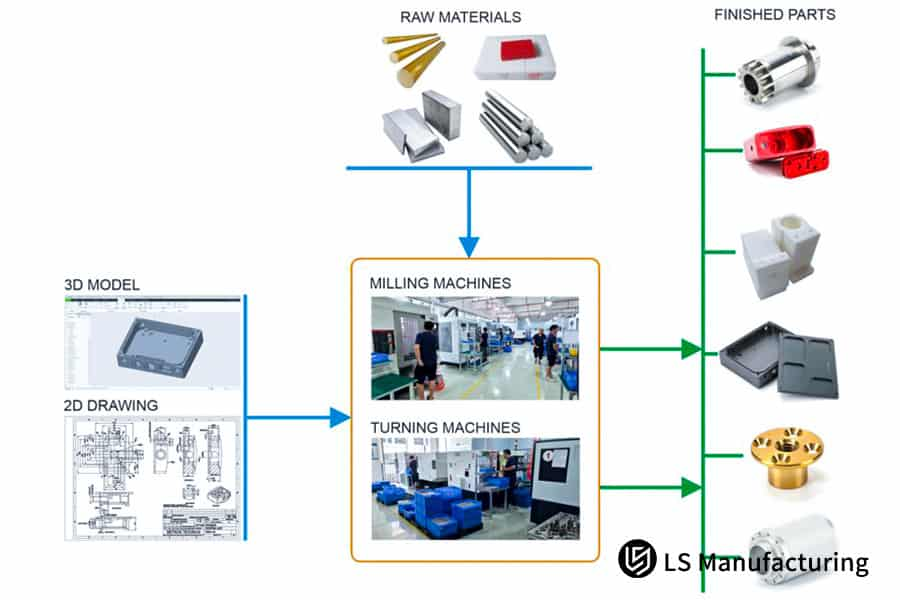

Figure 3: The CNC machining process for a range of metals and polymers by LS Manufacturing

What Is The Secret To Achieving Optical-Grade Cleanliness In Transparent Acrylic (Acrylic CNC Machining) Components?

The challenge presented by transparent acrylic CNC machining is rather unique. The material is not only brittle in nature but also soft, so it is quite prone to scratches, micro-cracks, and clouding. These features will simply annihilate the optical clarity that is required for the end product. Processing a raw material from scratch to a brand-new, crystal-clear piece is far from requiring the standard methods of machining, since it requires a systematic process which is holistic in approach, with stress reduction and prevention of surface damage being paramount.

- Surgical tools used for achieving the Flawless Cut: Standard equipment and drill bits would cause acrylic damage and melting as well. While performing our process, single flute drill bits that are sharp edged and have highly polished edges will be used to obtain a flawless cut without applying much pressure in order not to chip, melt, or build up edges and damage the acrylic surfaces. A flawless cut will ensure success in dealing with an optical-grade surface finish.

- Precise Parameters to Avoid Stress: The wrong speed, feed rate, and cut will produce heat and stress. These are the primary causes of crack and crazing internally. The key to our process can be summed up in two main ways: very high spindle speed and controlled feed rates. This produces sharp cuts that truly take away the material without creating the friction heat that can damage the molecular structure.

- Protective Workholding and Handling: Even a perfect machining process can be ruined by improper handling. We employ custom, non-marring vacuum fixtures and soft jaw systems that securely hold the workpiece without scratching the critical surfaces. Throughout the entire workflow, from machining to inspection, parts are handled with clean gloves and protected to ensure the pristine surface from the machine is delivered to the customer, a standard for a true custom plastic parts manufacturer.

- Integrated post-processing for perfection: Machining alone is not enough. To achieve optical perfection, it is considered that a controlled post-machining process, such as polishing or flame polishing, be done. Precision surface finishing occurs with the removal of microtool marks to obtain an optical finish without flaws. It is the integrated expertise in precision machining and surface finishing that defines acrylic CNC machining for optical applications.

In a nutshell, finessed attention to every aspect is necessary to realize lab-quality optical clarity in machined acrylic. There is a fine dance of specialized tooling, precise machine specifications, cautious handling, and finishing. What ensues is a thorough, obsessive attention to detail that ensures every clear part we supply as dedicated custom plastic parts manufacturer adheres to the highest level of optical excellence, rendering a functional part an imperfection in the visual aspect.

Can Precision Machining Of Ceramic CNC Parts Simultaneously Guarantee High Yield And Reasonable Price?

Ceramic CNC machining, in general, would be described as a very problematic process that aims to provide precision in the microns on a very hard and brittle workhorse. This makes it an extremely tough and hard workhorse that easily leads to chipping and cracking during the cutting process. The question that should be asked by a specialty material CNC manufacturer would be whether such complex components could be processed in production.

- Hybrid Process Integration for Optimal Outcomes: Besides the brittleness of ceramic material, it is not wise to exclusively depend on such a process. So, the strategy of process integration for optimal outcomes shall combine precision ceramic machining services with diamond grinding for initial processing, whereas laser processing should be used for complex cavities or stress-free cuts. This allows less mechanical stress to be applied onto the material, and hence, more complex geometries with an initially higher failure rate can be machined.

- Predictive Process Design to Eliminate Defects: Success in ceramic processing has already been predetermined before the spindle starts to turn. A great deal of simulation work goes into accurately determining and countering the areas of stress within our engineering process. We have designed customized fixtures that distribute the clamping force uniformly and customized tool paths with minimal radial force in contact with the material. It is this proactive design philosophy that truly defines the core of our role as high yield supplier.

- Advanced Technology for Dimensional Control: Even for ceramics, where tolerances must be held within ±0.01mm, the process stability has to be very high. We utilize the latest CNC grinding machinery fitted with high-frequency spindles and thermal compensation to assure predictable material removal with high geometric accuracy, batch after batch, which is a must for high-quality parts within the semiconductor industry and medical industry.

- Cost Management Through Process Efficiency: For the right pricing, efficiency needs to be achieved to the fullest, with absolutely no compromise. Our know-how enables the optimization of the whole processing chain, starting with the nesting of components on the substrate and concludes with the reduction of unnecessary handling steps. Thus, our ceramic CNC machining service becomes a reality rather than a cost-prohibitive prototyping operation in cost-effective solutions in high-tech applications.

High-volume ceramic CNC machining can be both high-yielding and reasonably priced, thus competitive, but it is not a question of either-or; it is a matter of optimized expertise and technology. Our integration of advanced hybrid processes into our engineering capabilities with optimized workflows enables us to make one of the most difficult-to-work-with materials on the planet a reliable precision-part. Thereby allowing us to achieve these often-required production and pricing demands found within industry.

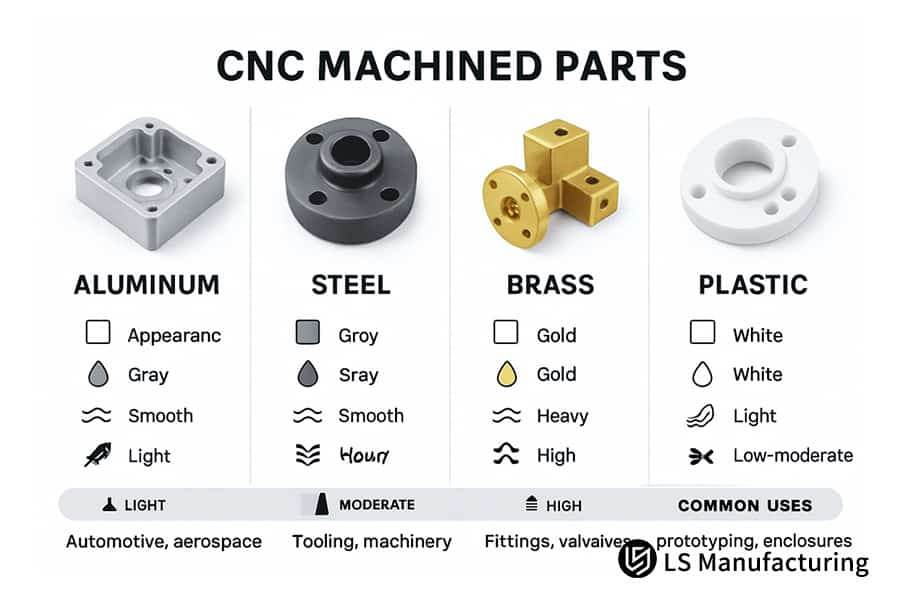

Figure 4: Five-material CNC components, including metals and polymers by LS Manufacturing

Customized Processing Of Titanium Alloy Bone Screw Trays In The Medical Device Field

The company, a major innovator in the field of medical devices, was faced with the major challenge of machining the complicated yet lightweight titanium alloy bone screw tray that provides the best possible accuracy of the finished tray so as to create a micro-tolerance fit and functionality as it was required, yet the tray was failing due to the machining distortion caused by the machining tools previously used by the companies.

Client Dilemma

This was deadlocked. The previous methods that were being used by the client with the two suppliers for the production of the trays were the production of the trays using warped trays. However, these could not be able to deliver the required tolerance. The geometrical accuracy required by the precision surgical tray made the process of its manufacture very sensitive. This titanium was also very sensitive.

LS Manufacturing Solution

Even prior to the commencement of manufacturing, a collaboratory DFM analysis has been done by our group. The redesign process, starting from the fixture layout, has been accomplished in a way that generates least stresses because of clamping forces. The machining operation that reduced stresses through a multi-step process has been designed.

Results and Value

The outcome was transformative. The final titanium medical component achieved a 25% weight reduction while all critical features held a stable tolerance within ±0.015mm. It is the effect that this specific part has resulted in, where the setup time for the end-user has been reduced by 15%, that is so crucial for emphasizing the delivery of the impossible to the possible: Technical partners who turn the impossible into the possible.

This is an exceptional instance where it has been realized that machining of advanced materials is not only the process of material removal, but it also involves an innovative technical foresight procedure where? It has been considered that we, for making an effective attempt at collaborative participation within the provisions of prime factors for the purposes of manufacturability, have formulated an improved item within unexpected surgeries pecified requirements.

If you are interested in learning how to use titanium alloy surgical trays to solve problems you encounter in CNC machining, we have provided the following link.

FAQs

1. What details would I have to give in order to be quoted on their CNC machine services offer by the company named LS Manufacturing?

Whether the specific and direct quote may be possible will depend on whether there are 3D views of the STEP/IGS file and what might need to be used, as mentioned above. The very specific quote, known as the ‘no hidden charge quote,’ will, however, definitely be able to be completed in 24 hours.

2. How long does normal delivery take? Can the shipment be expedited?

The time used in completing the task will take an average of 2-4 weeks, based on our CNC machining standard process. Not to mention the fact that we are flexible. Based on the time you need in your urgency in the project. We can make a commitment to you based on the time frame pertaining to your urgency required for your project.

3. What is the minimum order quantity (MOQ)? Do you support prototyping?

We favor high flexibility regarding customizability. The minimum order quantity should at least comprise 1 piece. Specifically, we would like to propose cooperation regarding the production of prototypes together with our firm. This will aid in the optimal development of the production process of future mass production with the best possible start.

4. How can I guarantee that the quality of the parts I receive will meet my expectations?

We also have the ISO certification, making use of the ISO 9001 quality management system, and the CMM equipment capable of inspecting the quality of the items in full. We shall also provide you with the quality inspection report of the items being shipped, ensuring your full specification is completely satisfied by the items being shipped to you.

5. How is my design intellectual property (IP) protected?

First and foremost, our top concerns lie in the protection of your intellectual property. We consider the intellectual property protection aspect of our association as the lifeline of the association itself. A robust confidentiality agreement may be established even before the execution of the current project. We hereby intend to maintain the confidentiality of your designs.

6. Do you provide Design for Manufacturability (DFM) feedback?

Of course! Our DFM analysis service is provided free of charge to all of our esteemed valued clients. First and foremost, our primary goal in this process is to assist in improving your designs. Eventually, we hope you would be in a position to reduce your manufacturing costs. The manufacturing process would also be accelerated. You may submit your designs.

7. Besides the materials mentioned above, what other special materials do you process?

In addition to common materials, we are also skilled in processing a variety of high-performance special materials, including but not limited to Inconel series high-temperature alloys, magnesium alloys, PEEK, and ULTEM high-grade engineering plastics. We welcome your inquiries to learn about our comprehensive material processing capabilities.

8. What about after-sales service if there are problems with the parts upon arrival?

We are also offering after-sales technical services. Just in case you notice that the required specifications of the different components that come with the package are not being met, you are free to reach out to the members of your project team immediately. We shall handle your inquiry accordingly to ensure that your project is operating in the right manner.

Summary

In order for you to successfully accomplish your task, you have to make the right decision. Most importantly, you have to make the right decision concerning your partner. When you have already considered the best material for you and your partner, you already possess the resources needed for the task of accomplishing your project. A valuable experience for LS Manufacturing concerning the processing of specialty material is enough to assure readiness in support concerning the manufacture department within your company.

Certainly, you would also need professional advice concerning your project. This you can undertake with effective immediate actions merely by clicking "Get Your Personal Quote and Free DFM Analysis" when you would also like to submit your designs to us. On the other hand, you can click "Download Our CNC Material Processing Manual" when you would also like to obtain more information concerning the services We Offer for you.

Get a personalized quote now and unlock the manufacturing potential of your products. Click to contact us!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.