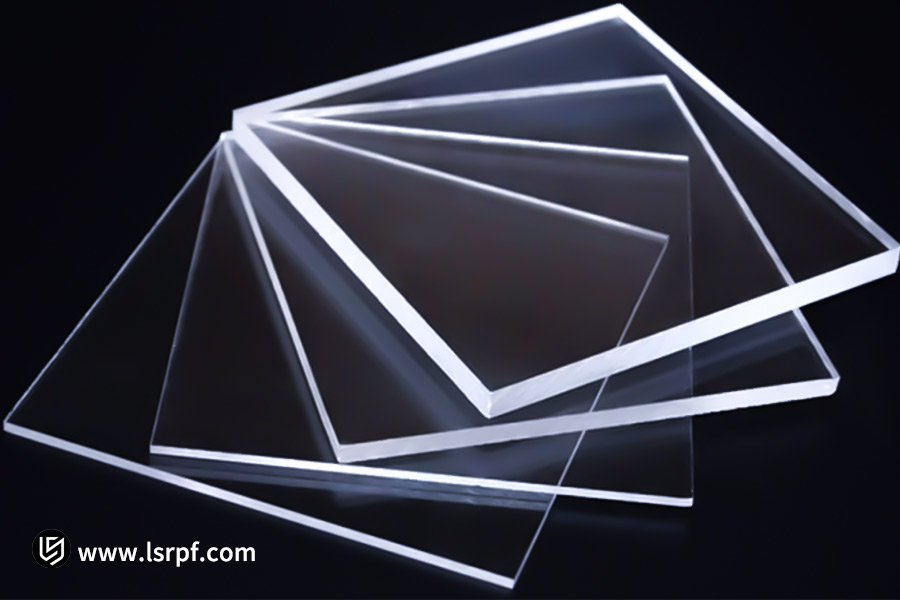

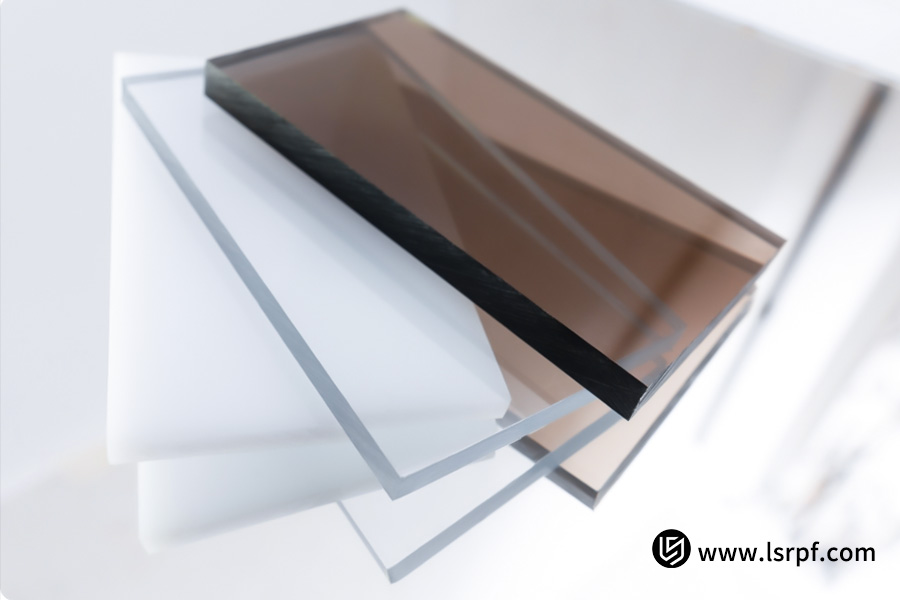

Mirror-bright, perfection—at least that's the impression at first glance, a seach clear acrylic (PMMA) sheet is an ideal clone-like sheet. There are, however, two fundamentally different fabrication methods hiding behind the smooth, even face:casting and extrusion. These two rudimentary fabrication methods provide the same material very different"personalities" and uses at the molecular level. The ugly reality is that such denial of natural differences is a highly perilous problem-having the wrong kind of acrylic is more than a less-than-perfect compromise in performance; It can lead to project failure, stupendous cost overrun, and even outright product failure or destruction in rigorous use.

This guide will get down to business and possess a thorough analysis of the basic differences between cast and extruded acrylic, putting you in a position where you can make the appropriate, intelligent, and simple decision for the precision needs of laser cutting, bending process sophistication, and a whole range of demanding applications. Familiarity with these differences is the initial necessity for a successful venture.

Cast Acrylic vs. Extruded Acrylic Core Feature Comparison Table

| Feature | Cast Acrylic | Extruded Acrylic |

|---|---|---|

| Manufacturing Process | Liquid monomer is filledinto a mold (e.g., between two glasspieces) and curedinto shape.(Like "baking a cake") | Molten resin pellets are continuously extruded through a die to form a mold. (Like "squeezing toothpaste") |

| Cost | High (lab-intensive, smallbatch production) | Low (continuous, automated, high efficiency) |

| Laser Engraving | Goodresults: Creates a matte, frosted white, high-contrast engraving. | The engraving comes out transparent, so the effect is less noticeable. |

| Laser Cutting | Minute burrs on cut edge and usually has to be post-worked (grounded or polished). | Better performance:Cut edge has natural, smooth, translucent "flame-polished" look. |

| Bending | Un reliable performance with increased burn control, and less reliable. |

Good performance: Low melting point, wide softening range, and stable,reliable bending. |

| Thickness tolerance | High (up to ±10%), with batch-to-batch or even within-one-sheet variation. | Very small, very uniform thickness. |

| Chemical resistance | Better, higher molecular weight, more chemical and scratch resistant. | Less so, more sensitive to certain solvents (e.g., alcohols and ketones). |

| Impact resistance | Better (higher molecular weight) | Slightly weaker. |

| Good Application Examples |

Applications requiring high optical quality,weather ability, chemical resistance, and good engraving: |

Applications requiring cost-effectiveness, good thermoformability, dimensional stability, and smooth cut edges: 1. Retail displays, shelving 2. Machine guards, safety partitions 3. Greenhouse glazing, skylights 4. Components requiring precise bending (face shields, sign housings) 5. Lighting diffusers |

Here’s What You’ll Learn:

- A clear “birth” metaphor instantly explains the fundamental differences between two types of acrylic.

- A stark comparison of laser processing (engraving and cutting) performance: Why choosing the wrong material can make a world of difference.

- The key fact behind hot bending: Why extruded acrylic is the definitive winner for accuracy bending(and why it's directional)

- The quiet battle of strength, hardness, and chemical resistance: From fish tanks to scratches at home, what's best for you?

- The cost and durability reality: How to make well-informed decisions for budget-friendly or precision build applications?

- A real-life DIY debacle: How the wrong material dismantled a display stand, and how professional solutions can rescue it to perfection.

- FAQ plies that baffle even seasoned hands, such as how to spot materials in an instant, why there's always casting needed in aquariums, and whether extrusion is actually"bad"or not.

- The ultimate guide for making the right choice: There is no "best" material, only the "mostappropriate"situation of application.

Finally, on to the all-so-important differences between cast and extruded acrylic to make an educated and precise material selection for your project!

Manufacturing Process: The Root of All Differences

Themost importantdifference between cast and extruded acrylic isin theirdiffering manufacturingprocesses.

| Features | Cast Acrylic | Extruded Acrylic |

|---|---|---|

| Manufacturing Process | Liquid monomer is poured between glass plates and slowly solidifies. | Solid pellets are melted and extruded, followed by rapid roll forming. |

| Molecular Structure | High molecular weight, long molecular chain, random cross-linking | Lower molecular weight, directional molecular chains. |

| Material Properties | Excellent chemical resistance, strong weather resistance, high hardness, good toughness, and a wide range of thicknesses | High dimensional stability, good thickness uniformity, low internal stress and high cost-effectiveness |

| Product Performance | Ideal for fine processing (such as cutting, engraving, and hot bending of thick plates), resulting in excellent optical properties. | Ideal for continuous processing (such as blister forming and hot bending of thin plates), resulting in highly predictable behavior. |

| Typical Applications | High-end aquariums, display cabinets, trophies, precision instrument panels, thick plate engraving, outdoor signs requiring excellent weather resistance | Light box panels, sign substrates, protective covers, display racks, blister products, general-purpose sheets |

Cast Acrylic

Process: liquid monomeric acrylic is poured between precision-finished glass molds and gradually heat-polymerizes and cures in a long-dwell oven.

Structural Characteristics:slow curing yields dynamic structure with high molecular weight, highly extended chains, and random crosslinking.

Performance Advantages: Enhanced resistance to chemicals, weather and UV resistance (no yellowing or hardening on long-term use outdoors), increased surface hardness and shock resistance, and ability to formulate tra-thick sheets (several centimeters or more).

Applications and Processing: Due to its built-in strength, it is particularly suited for secondary processes such as deep engraving, precise cutting, and complex hot bending (especially for thick sheets). The final product has adequate transmittance of light and optical clarity and therefore sees extensive use in high-end applications with high levels of durability needs.

Extruded Acrylic

Core Process:Melted and heated solid acrylic particles are extruded continuously in sheet form through a slot die, similar to squeezing to othpaste. The sheets are subsequently rapidly flattened, molded, and cooled down by carefully controlled cooling rollers.

Structural Characteristics: Rapid molding produces in comparatively low molecular weight, which in turn assume the forms highly ordered molecular chains in the direction of extrusion.

Advantages: Extremely narrow sheet thickness tolerances, high dimensional stability (fewer warped), low internal stresses, good productivity, cost benefits.

Working and Applications: Molecular orientation creates more reproducible and homogeneous thermoforming behavior (e.g., blister forming, sheet bending) in a single direction (usually parallel to the direction of extrusion). Facilitates continuous roll production (sheet). Usually employed when economic issues of high production, good uniformity, and facility processing are required.

The character of the difference between extruded and cast acrylic is in how they are produced, and that consequently determines their physical properties, processing behavior, molecular structure, and consequently, their best application.

To those who process acrylic by laser, an awareness of the intrinsic difference in cutting and engraving capacity between extruded and cast acrylic is critical because this determines directly the quality and usability of the final product.

Cast Acrylic vs. Extruded Acrylic Laser Processing Performance Comparison Chart

| Processing Method | Cast Acrylic | Extruded Acrylic |

|---|---|---|

| Engraving | ✓ Excellent Results: Produces a beautiful, frosted-glass-like frosted-white effect. | ✗ Poor Results: The effect is barely noticeable, leaving only a faint melt mark. |

| Cutting | ✗ Rough Edge: Leaves a slightly rough, matte edge that requires additional polishing. | ✓ Smooth Edge: Natural "flame polishing" produces a smooth edge, requiring no post-processing. |

Extruded Acrylic vs. Cast Acrylic: Key Comparisons in Thermoforming

If accurate bending is necessary for your application, extruded acrylic is obviously the way to go. The table below summarizes the main differences between extruded acrylic and cast acrylic when thermoforming.

| Features | Extuded Acrylic | Cast Acrylic |

| Preditibility | Preditibility Since it possesses an even molecular composition and low melting point, extruded acrylic melts extensively and can easily be bent when heated. It has the ability to produce sharper and more accurate bends. | Irregular molecular structure results in in consistent flow upon heating, so precise bend sharder to obtain.More aggressive heat (180-220°C) needed and is apt to crack or spring backfrom stress within. |

| Directionality (Anisotropy in Bending) | Interestingly enough, extruded acrylic exhibits a directionality in bendability—simpler to bend in the direction of the extrusion than perpendicular to it. | Theoretically is otropic, but uneven stress distribution may result in random warping or distortion on bending. |

| Limitations of Cast Acrylic | Cast acrylic is more temperature-needed to be softened and its reaction is less consistent when curved and thus more susceptible to stress orcrack unless managed in professional environments. | |

Extruded Acrylic vs. Cast Acrylic: Strength, Hardness, and Aquarium Design Considerations

While both cast and extruded acrylic sheets have comparable impact resistance, they behave greatly differently in a host of key strengths areas with practicality dictating their usage in aquarium design and other harsh applications.

Surface Hardness and Scratch Resistance

Cast acrylic is surface hardened (more often 10-15% harder than extruded acrylic) and less susceptible to being scratched by cleaning equipment or marine life. This is particularly important for observation panels for aquariums, which are cleaned regularly. As durable, extruded acrylic is more susceptible to visible scratching and will require more frequent polishing in order to provide surface clarity for high wear applications.

Chemical Resistance and Structural Integrity

The profile for chemical resistance reveals that cast acrylic should be used in water applications:

- Cast acrylic offers exceptional resistance to aquarium chemicals, saltwater, and adhesives (e.g., acetone-based cements)

- Extruded acrylic is more susceptible to stress cracking when it comes into contact with some cleaners or adhesives

- Cast material is less dimensionally unstable long-term when completely immersed at all times.

Stress Distribution and Load-Bearing Capacity

More uniform molecular structure of cast acrylic provides:

- Better transfer of mechanical stresses over extensive panels

- Reduced risk of stress fracture in joints

- Better performance for high aquarium structures(>1mtall) where water pressure is significant.

Fabrication Considerations for Aquariums

Even though both can be thermoformed:

- Cast acrylic offers the facility to finish the weld joints more accurately, critical to leak-free aquarium fabrication.

- Extruded forms can in curmicro-fractures in bonded joints with passing time.

- Cast acrylic optical quality maintains superiority after decades of immersion.

Design Recommendations forAquariums:

For residential, small-to-medium-size aquariums (<500L), extruded acrylic can be cost-effective with proper care. For commercial use, large sizes, or marine use, cast acrylic is the sole choice because it provides:

- A greater safety margin against failure in disasters.

- Improved maintenance of optical qualities.

- Improved durability in permanent in stallations.

Established aquarium producers always use cast acrylic even at its 20-30% higher price due to these performance advantages and reduced liability concerns. Cast acrylic is also weather resistant, appropriate for uses in seawater and freshwater environments where UV degradation is a concern.

Extruded Acrylic Costs and Tolerances:Budget Considerations for Project Factors

Cost Savings: Extruded Acrylic--A Cost-Effective Option

Extruded acrylic is much less expensive to make than cast acrylic, largely because its process manufacturing in continuous flow is less expensive. In contrast with batch manufacturing of casting, extrusion lines can produce sheets continuously,saving production cost by 10%-25%.The cost savings go directly in to the cost of the end product,and extruded acrylic is suitable for budget-conscious projects. Mass purchase and everyday use,on the other hand, appreciate extruded acrylic that is competitively priced but not overweight in performance.

Tolerances:Thickness Control Perfection

Acrylic extruded has unparalleled characteristics in terms of thickness control. Its manufacturing process utilizes the application of highly precise molds and online measuring systems that maintain each sheet's thickness tolerance at an incredibly tight tolerance (typically ±0.1mm). This almost-perfect uniformity is ideal for engineering applications where high-precision assembly is required, i.e., on instrument panels, optics, or multi-layer stacking. In the natural shrinking of cast acrylic during curing can cause small thickness tolerances (±0.5mm). This lack of precision will affect the accuracy and appearance of the finished product in assembly and appearance.

A Clever Solution for Engineering Applications

For cost savings and dimensional accurate use, extruded acrylic is the solution.

Its improved thickness consistency saves assembly time fitting issues, leading to material scrap and rework savings. Its high cost advantage allows designers to specify more challenging-to-machine forms or larger applications without exceeding budget and constraints. These advantages position extruded acrylic as a preferred material for usersrequiringhigh-precision machining such as electronic enclosures, signs, and display stands.

Case Study: From DIY Failure to Professional Retail Display

Challenge: : A skincare firm opened a new shop and needed 100 custom, fashionably shaped product displays. They purchased sheets of acrylic and attempted to bend them using a heat gun. The results included asymmetric bend angles, ugly stress marks, and cracking, with much wasted material and time consumed.

Problem: They likely used cast acrylic in error, which is more difficult to shape, and didn't have specialized heating and cooling equipment to track the molding process.

LS Solution: Their design was uploaded onto our website. Our engineers saw it right away and knew immediately what it was—a run-of-the-mill bending job and quality material—extruded acrylic. Linear heaters and special cooling fixtures industrial-grade were used to get exactly even bend radius and angle for each display.

Outcome: The customer received100 professional, perfect presentations within a period of time,beautiful enhancing their company image. They even saved money and did not have to go to the trouble of doing it themselves.

FAQs

1.How can I tell if I have extruded or cast acrylic?

If you have an acrylic sheet but do not know the grade, a simple machining test will tell you. Look for a concealed corner and drill a hole with an electric drill or a hand drill with a 3-5 mm drill bit. While you are drilling, watch the chips that appear:If the chips are continuous, filamentous, and coiled around the drill bit like wire, the acrylic sheet is extruded. If the chips are brown, brittle, powdery, or crumbled, the acrylic sheet is cast. This is because the cross-linked molecular structure formed during casting makes the material hard and brittle but susceptible to mechanical stress.

2. Why is cast acrylicrequiredfor large aquariums?

When constructing large aquariums, the choice of material itself impacts the stability as well as safety of the whole construction. Cast acrylic is unparalleled due to its superior chemical welding properties, a factor in being essential to the upkeep of safe and long-term aquarium operation. Take the case of a huge aquarium containing hundreds of thousands of liters of water. Its sides are exposed to terribly high hydrostatic pressure that acts upon all the joints all the time. The molecular structure of acrylic makes "molecular fusion" possible during solvent welding. When two sheets are brought in contact with a special adhesive solvent, their contacting surfaces fuse together and form a weld zone that is far stronger than the material itself.

3. Is extruded acrylic really inferior to cast acrylic?

Not at all. They simply differ. Extruded acrylic is a "better" option where there is the need for exact thickness, cost-effectiveness, and specifically heat-bend ability.

If there is a requirement for a certain thickness, affordability, and certain heat-bending properties, then extruded acrylic is a "better" option. "Good" and "bad" in terms of material selection aren't absolutes. Extruded acrylic is not in any way a "cheap alternative" to cast acrylic; instead, it's a niche material that is expertly optimized to suit particular applications. Like a screwdriver and a wrench, each has their advantage; the problem is in applying them.

For display props and signage that require complex bends, extruded acrylic's "memory effect" makes it an especially good choice. Thermoformed, it will retain a stable shape for many years without the stress-rebound characteristics of cast materials. This, combined with its improved process ability, allows the designer great freedom of design, unfettered by the inbuilt limitations of the material. Therefore, when these two materials are placed side by side, the question to ask is not "which is best," but "what is best In applications where thermoforming, high-precision machining, and cost economics are critical, extruded acrylic is the true "best performer." These qualities confer upon it its unique and inimitable role in modern manufacturing systems.

4. Can I glue extruded acrylic?

Yes, but you will need to use a glue specifically designed for extruded acrylic and take greater precautions against stress cracking. While extruded acrylic may be bonded using glue, it's a delicate process requiring utmost attention. In contrast to cast acrylic, its molecular structure makes it even more susceptible to being impacted by both types of glue as well as methods of application. Key Considerations: The Need for Specialized Glues. It is essential to use adhesives specifically labeled "extruded acrylic suitable." Such adhesives often incorporate modified chemistry with slow solvents, which effectively reduce internal stress in the material. The harsh solvents contained in common acrylic adhesives will cause "stress whitening" or even surface micro cracking.The Typical Problem Solution: If surface micro cracking in the bonded area is observed, cease use immediately and use a local annealing treatment with a heat gun at around 80°C. Mechanical joining and adhesive bonding can be combined together on load-bearing components. Keep in mind, the success of extruded acrylic bonding is 30% dependent on the glue used and 70% dependent on application methods. By adhering to these professional guidelines, you will be able to obtain satisfactory results from bonding and take full advantage of the material's economical and easy-to-process benefits.

Summary

Use the Right Tool for Your Application.Finally, there is no hard "better" between cast and extruded acrylic; there is only "better fit."

Select cast acrylic,if your project is high-end, needs fine engraving, or needs maximum hardness(trophies or artwork).

Choose extruded acrylic, if your project is affordable, requires specific thickness, or—most critically—is any type of heat bending.

Don't let poor material ruin your master full design. When your project requires precision curves, professional bending services are necessary. Upload your design today and receive a complete quote that not only covers the price of bending but expert material suggestions as well!

In the face of these higher challenges, LS'sCNC turning serviceis your indispensable ultimate "tool". It represents industrial-grade precision, unparalleled repeatability and efficient productivity, allowing your design ideas to be perfectly, consistently and efficiently realized.Choosing LSis to inject industrial-grade precision power into your extraordinary craftsmanship.

Upload your design drawings now and get an instantCNC turning quote(cnc turning price), let LS be your strong backing in pursuit of ultimate woodworking precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com