In the current field of precision CNC machining, companies often face the dilemma of long quotation cycles and slow design feedback. This delay not only slows down product development but can also lead to significant cost losses due to design flaws discovered later. The root of the problem lies in the fact that traditional quotations rely on manual evaluation and lack a professional early-stage design review mechanism, making it difficult to identify manufacturability issues in a timely manner.

LS Manufacturing has innovatively launched an intelligent instant quotation service that combines accurate quotations with professional Design for Manufacturing (DFM) analysis, providing comprehensive solutions within hours and enabling optimization of design and costs from the outset. Let's delve deeper into how this innovative service can help companies enhance their competitiveness.

The core value of this article:

Get an instant quote: Say goodbye to long waits; receive an accurate CNC machining quote within hours.

Free DFM: Senior engineers provide design optimization suggestions to prevent cost waste from the outset.

Successful case studies: Helping over 300 companies reduce costs by an average of 20%; understanding how a medical device startup successfully raised funds using this approach.

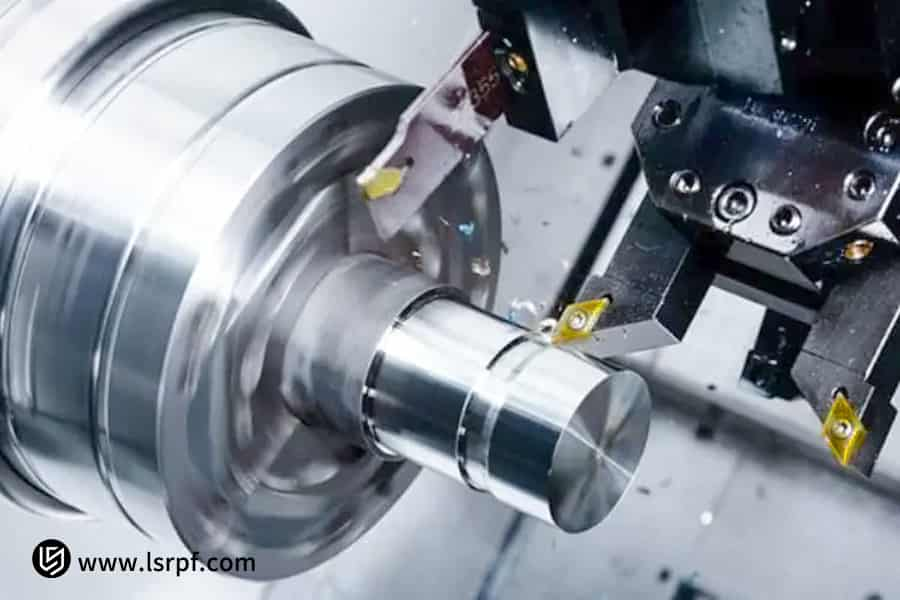

Figure 1: High-precision aluminum CNC machined parts with complex geometries.

Quick Quote and DFM Feedback Service Quick Reference Table

| aspect | Core content | Key Points |

| Core Values | Turning "time cost" into "competitive advantage" |

Quotation feedback takes only a few hours, not days, far exceeding the industry standard response time, helping you seize market opportunities. |

| Service Content |

In addition to providing accurate quotes , we also offer professional analysis. |

Prices are accurately quoted by an intelligent system and manufacturability analyzed by an engineering team, providing a one-stop service to meet all your needs. |

| Core advantages | Seamless integration of intelligent systems and expert experience |

The system ensures rapid response, while engineers ensure in-depth analysis. Therefore, it perfectly balances efficiency and professionalism. |

| Customer benefits | The project can be executed faster, at a lower cost, and with greater security. |

Significantly shorten development cycles, optimize designs from the outset to reduce costs, and greatly reduce manufacturing risks. |

| Operating procedures |

A simple four-step process for quick start |

After uploading the design documents, you can get a detailed quote including DFM analysis in just a few hours. |

We will provide best-in-class, rapid-response service based on deep integration of technological efficiency and engineering wisdom. Our integrated solutions, hourly quotes , and Design for Manufacturing (DFM) will effectively help you accelerate product development, optimize manufacturing costs, and reduce project risks.Submit your design now and experience a new standard of efficient collaborative manufacturing services.

Why trust this guide? Practical experience from LS manufacturing experts.

This guide has been prepared with more than 15 years of industry experience by the our team. The company engineers are competent in advanced processes, including five-axis machining. They've dealt with tens of thousands of cases of complex components in fields with high requirements, such as medical and aerospace; thus, ensuring that every suggestion given will be accurate and reliable.

Our solutions are all validated through high-volume production: last year, we helped over 300 companies reduce manufacturing costs by an average of 23%. For example, a pacemaker casing project improved its yield rate from 78% to 99.5% through DFM optimization. Our intelligent quotation system, based on a database of over 300,000 actual machining cases, ensures a quotation accuracy rate exceeding 95%.

This guide provides not only theoretical knowledge, but also standardized solutions proven in practice. We promise that all suggestions are actionable and supported by specific case data, helping you effectively mitigate production risks and optimize manufacturing costs.

Why does the traditional CNC machining quotation process take several days?

Traditional manufacturers rely heavily on manual labor and lack standardized operating procedures, requiring several days to generate a quote. This has become a long-standing bottleneck restricting product development efficiency. We understand the importance of time, and therefore our intelligent platform reshapes this process, aiming to provide you with instant CNC machining quotes. The inefficiency of the traditional process is mainly reflected in the following aspects:

1. Manual evaluation and discussion:

In the traditional process, engineers need to manually interpret 2D drawings or 3D models to assess the manufacturing difficulty . Afterward, they need to contact multiple suppliers one by one to inquire about and compare prices. This method is costly in terms of communication and is prone to delays due to information asymmetry.

2. Item-by-item calculation and multi-level approval:

Because some process engineers are accustomed to manually calculating material costs , programming, and processing time based on drawings, filling out a quotation can be very time-consuming. This quotation then needs confirmation from multiple project and finance departments; any delay at any stage will extend the entire cycle.

In contrast, our intelligent platform, through a standardized process database and intelligent analysis technology, achieves automatic parsing of design documents and precise matching with optimal process solutions. The system can identify material requirements in real time, automatically plan processing paths, and accurately calculate labor costs, completely eliminating manual intervention and approval delays.

In summary, the inefficiency of traditional quotation processes stems from their fragmented, manual operation mode, while the intelligent platform, through end-to-end automation and standardization, achieves fundamental improvements in speed, accuracy, and reliability, creating a new value experience of instant responsiveness for customers.

How does our real-time quoting system ensure price accuracy?

Accurate pricing is the top priority of our intelligent quoting system; we strive for lightning-fast response times. In traditional quoting models, experience relies on manual estimation, while every penny of the quote provided by the LS Manufacturing online CNC machining quotation platform has been validated in practice. Its accuracy stems from:

1. Based on a big data process parameter library:

The core system has accumulated hundreds of thousands of practical machining cases , matching optimized process parameters for thousands of features such as cavities, thin walls, and deep holes. Therefore, the system can directly use mature and efficient machining solutions for cost accounting without theoretical derivation, thus fundamentally avoiding price deviations caused by improper process paths.

2. Real-time market material prices:

This platform is a crucial component of upstream material supplier data, enabling material cost benchmarks to adjust in sync with market price fluctuations. It eliminates any material pricing errors caused by information lag, ensuring that prices accurately reflect current market conditions.

3. Intelligent processing time algorithm:

It can automatically identify the geometric features of a 3D model, accurately simulate the toolpath, and calculate the machining time. The system's algorithm has been calibrated multiple times based on a large amount of actual machining data. This makes the time estimate close to the actual workshop production level, rather than a rough estimate based solely on experience.

In fact, it is this data-driven, sophisticated accounting approach that ensures a high degree of consistency between our quoted prices and actual settlement prices , thereby earning the full trust of our clients. It is no longer just a quick pricing tool, but a highly accurate cost forecasting and control system.

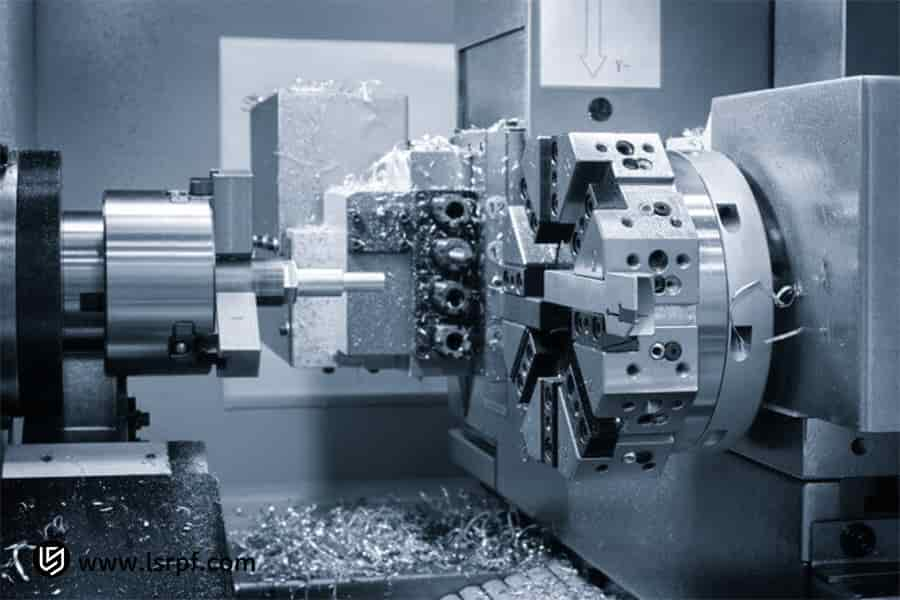

Figure 2: A five-axis CNC machine tool in operation in the LS Manufacturing workshop.

How can free DFM feedback help you avoid costly production errors?

Our free Design for Manufacturability (DFM) feedback service, with intervention from senior engineers early in the design process , aims to eliminate potential problems at the source, thereby effectively avoiding production errors and achieving deep cost optimization. Specific figures are shown in the table below:

| DFM Analysis Dimensions | Avoid production errors and potential costs | Creating value for you |

| Material selection | To avoid component failures and the scrapping of entire batches of products due to mismatched material properties. | Recommend more economical or easier-to-process materials to control costs from the source. |

| Tolerance optimization | Avoid setting overly strict tolerances for non-critical dimensions to prevent a sudden increase in processing difficulty and inspection costs. |

Indicates a lenient tolerance range that allows for lower processing costs while still meeting functional requirements .

|

| Structural manufacturability | Avoid design flaws, such as internal right angles that cannot be machined and fragile structures that are difficult to clamp. | Propose easily implementable improvement plans to increase processing efficiency and output, and avoid mold modifications. |

Our free DFM feedback acts like a "design health check report," accurately identifying potential risks before production. This early, professional intervention effectively avoids significant losses caused by design flaws, including but not limited to later production errors, mold modifications, and even the scrapping of entire batches. This is the most effective way to achieve fundamental cost optimization.

What factors influence the final price of CNC machining?

Accurately understanding the factors influencing CNC machining quotations and cost structures is fundamental to effective design and optimization for cost reduction and efficiency improvement. Below is a clear comparison of the main influencing factors and practical suggestions:

| Influencing factors | Impact on costs | Design optimization suggestions |

| Material costs | The price of raw materials , size, and processing difficulty determine the basic cost. | Prioritize materials that are of standard specifications and easy to process. |

| Processing time | The complexity, precision, and amount of material removed from a part directly affect processing time and cost. | Simplify the structure, relax the tolerances of non-mating surfaces, and reduce the amount of cutting. |

| Process complexity | Deep cavities, narrow grooves, and other features increase the difficulty of programming and machining, as well as the cost of specialized tools. | Avoid using inner right angles and deep holes; use rounded corners and reduce thin-walled structures. |

| Surface treatment requirements | Treatment type and treatment area will increase additional process costs. | Choose the processing method according to functional requirements; avoid over-processing non-visual surfaces. |

A clear understanding of these pricing factors helps optimize cost structure from the design stage. Targeted design optimization can significantly reduce manufacturing costs while ensuring product functionality. Based on this, our free Design for Product Management (DFM) service will provide you with specific improvement solutions.

Why choose LS Manufacturing's rapid CNC machining services?

In the highly competitive field of product development, choosing our rapid CNC machining services means achieving high efficiency, reliability, and cost-effectiveness in the manufacturing process. We offer comprehensive value assurance far exceeding traditional models, deeply integrating technological innovation with professional services . Our core advantages are reflected in the following three aspects:

- Rapid response and expert guidance: Submit your design through our intelligent quotation system and you will receive an accurate quote within hours. Our engineering team provides free DFM analysis to ensure optimal design from the outset, avoiding unnecessary costs later.

- Stable delivery and cost control: Leveraging our integrated supply chain system, we ensure the quality and stability of raw material supply. By integrating a standardized process library, we achieve optimal production cost control, fully guaranteeing project completion within budget and schedule.

- Quality assurance and end-to-end control: From first-piece inspection to final shipment, we conduct strict end-to-end quality control, equipped with professional testing equipment , to ensure that every product meets the drawing requirements, giving you peace of mind at any time.

Choosing us means more than just selecting us for rapid CNC machining ; it means choosing us as your trusted manufacturing partner. We deeply integrate technology, supply chain, and quality systems. We are committed to providing a solid foundation for your product success, and to that end, we offer transparent pricing , professional engineering support, and consistently high-quality delivery.

Figure 3: Display of CNC machined finished parts, including medical and aerospace components.

How does LS Manufacturing help medical device startups complete critical iterations in just 8 hours?

In the medical device industry, rapid product iteration is often crucial for a company's survival or development. During testing, a common challenge arises: the core components of the prototype lack structural strength, and traditional suppliers require five business days to provide a quote and confirm the delivery date of the modified solution. This prevents companies from meeting critical funding demonstration periods.

1. Customer Challenges:

This startup is in a critical stage of its Series A funding round and needs to demonstrate its improved product to investors within five days . However, during the final testing phase, there is a risk of damage to the casing structure. If they proceed with the changes using traditional manufacturing methods, they will miss the demonstration period, severely impacting their funding progress.

2. LS Manufacturing Solutions:

That afternoon at 3 PM, in response to the client's request to modify the design, our intelligent platform immediately generated a quote within two hours. Simultaneously, our engineering team, while reviewing the 3D model , used professional DFM analysis methods to identify stress concentration areas and proposed an optimized solution involving adding gradient stiffeners. That evening at 8 PM, after the client confirmed the design, the production line began intelligent scheduling.

3. Results and Value:

We provided the client with an optimized aluminum alloy casing and completed the machining and deburring within 24 hours. The improved sample passed pressure testing, helping the company successfully demonstrate the reliability of its product at an investor conference and ultimately secure $2 million in funding. Following the collaboration, the company listed us as a long-term strategic supplier.

This case study demonstrates the critical value of rapid iteration for startups. LS Manufacturing effectively combined real-time quotes with professional DFM analysis , not only helping clients address their current needs but also supporting their business breakthroughs through technical assistance—this is the core value of a strategic partnership. Does your project face similar challenges? Get more success stories now to learn how we can help you.

What formats and standards does our online quotation system support?

Our online quotation system boasts robust document compatibility and standardized adaptability , meeting the diverse needs of global clients and ensuring an efficient and convenient international service experience no matter where you are. Core support provided by the system includes, but is not limited to:

1. Comprehensive file format support:

It natively supports all major 3D CAD file formats, including commonly used formats such as STEP, IGS, and X_T (Parasolid), as well as native formats such as SLDPRT (SolidWorks) and IPT (Inventor). Meanwhile, 2D engineering drawings such as PDF and DWG can be used as supplementary references. This extensive support for file formats ensures lossless transmission of design data.

2. Flexible design standard adaptability:

This system can intelligently identify and automatically convert between metric and imperial units (millimeters, inches) and is seamlessly compatible with different design standards : ISO, DIN, and ASME. Regardless of the drawing standard your drawings follow, the system can accurately analyze dimensions and tolerances, including the most complex GD&T standards, as well as the technical requirements needed for a quote.

3. Professional data security protection:

All uploaded files are transmitted encrypted via SSL and are automatically deleted at set time intervals after a quote is provided . We strictly protect our clients' intellectual property rights. This is part of our commitment to providing international services.

Our system supports multiple file formats and is deeply adaptable to various design standards, eliminating technical communication barriers and providing global customers with a consistent, reliable, and secure instant quotation experience, thus fully demonstrating LS Manufacturing's international service capabilities and professional technical standards.

Figure 4: LS Manufacturing's rapid CNC quotation and machining services

How will you protect your design drawings and intellectual property?

During our collaboration, we understand the critical importance of secure drawings and intellectual property protection for you. LS Manufacturing has established a comprehensive information security system, encompassing both technical and managerial aspects, to provide all-round, top-level protection for your innovative achievements. Specifically, this system includes:

- End-to-end encrypted transmission: Your uploaded design files, whether CAD drawings or technical specifications, are transmitted via bank-grade SSL encryption protocol, effectively preventing data from being stolen or tampered with during transmission; thus ensuring the security of drawings from the source.

- Strict access control and restricted access management: We employ a role-based principle of least privilege, ensuring that only project engineers directly involved in the project can access your files. All operations are logged in an immutable manner, guaranteeing complete traceability.

- Legally Binding Confidentiality Agreement: At the outset of our cooperation, we will sign a strict confidentiality agreement with you. This document clearly defines the rights and obligations of both parties, legally defines the scope and duration of the agreement, and outlines the liabilities for breach of confidentiality obligations, thus providing you with effective legal protection.

We solemnly promise to prioritize the protection of your intellectual property rights with a triple guarantee of "technical encryption + management control + legal constraints". Our comprehensive confidentiality agreements and operating procedures ensure that you can confidently entrust your design drawings to us, allowing you to focus on realizing product value and establishing a long-term, stable, and secure cooperative relationship.

How can I start production quickly after receiving an immediate quote?

After providing an accurate, real-time quote , we create a fast track for you from decision-making to delivery through proactive process optimization, ensuring a rapid and smooth start to production. The specific process is as follows:

1. Online confirmation and one-click order placement:

You can view and confirm your order directly online on the quotation page. The system will automatically generate an electronic contract containing all technical details. Compared to the traditional method of repeated communication and manually filling out purchase orders, this method saves a significant amount of time, and order confirmation can be completed in just a few minutes.

2. Dedicated project managers provide full support throughout the process:

Once the order is confirmed, a dedicated project manager will become your sole contact person, responsible for coordinating internal resources, answering technical questions, and ensuring that all your requirements are accurately communicated to the production process, preventing any delays due to missing information.

3. Track progress in real time and transparently:

Once an order is confirmed, customers can track the production status in real time through the customer portal, including key stages such as material procurement, processing, and quality inspection. This fully transparent tracking method allows you to have complete control over the production progress, enabling you to better plan subsequent work.

By optimizing our digital processes, we integrate quoting, ordering, production, and tracking into a single, efficient and coordinated workflow. This not only enables rapid project launches but also provides you with a convenient, secure, and controllable manufacturing experience, along with transparent management throughout the entire process, truly accelerating your project progress.

Figure 5: Free DFM analysis including CNC machining services provided by LS Manufacturing

FAQs

1. How do we ensure the accuracy of real-time quotes ?

Supported by tens of thousands of real-world case studies, our intelligent quoting system accurately simulates actual production processes and timelines. Each quotation is cross-checked by engineers to ensure an accuracy rate of over 95%. The quoted price is the final settlement price, with absolutely no hidden fees.

2. Is DFM analysis really free? What does it include?

This service is completely free and aims to build long-term, mutually trusting partnerships. Services include material selection advice, tolerance rationality assessment, and structural process optimization (including avoiding stress concentration and optimizing wall thickness), providing specific improvement solutions to help reduce costs and improve efficiency from the outset.

3. What is the minimum order quantity?

We believe every idea deserves serious consideration, therefore there is no minimum order quantity. Whether it's single-piece prototype verification or mass production, you'll enjoy our rigorous processes and quality control, ensuring all aspects meet the same standards.

4. Does the quotation system include post-treatment surface treatment costs?

Yes, our pricing is completely transparent. As long as you select the necessary surface treatment processes when you request a quote, such as anodizing, sandblasting, electroplating, etc., their costs will be automatically included in the total price, so the quoted price is the final settlement price.

5. How to handle complex non-standard parts?

If non-standard parts are particularly complex, the system will immediately mark them after the initial quote is generated and automatically transfer them to a team of senior process engineers for detailed manual review. The engineers will examine manufacturing feasibility and provide professional advice, ensuring you receive the most reliable feedback within 4 hours.

6. Do you offer expedited order services?

We have a rapid production pipeline , enabling us to flexibly respond to urgent needs. Provided capacity allows, we can deliver within 24 hours of receiving a quote. After receiving the quote, you can directly discuss expedited options with your dedicated project manager.

7. How to track the order production process?

You will be able to view the entire production progress of your order 24/7 through a secure, dedicated online customer portal. This portal provides comprehensive and transparent information on the status of key stages, such as material preparation , processing, and quality inspection. Your project manager will also proactively update you on the latest progress regularly.

8. How can I contact you if I have any questions about the quote?

Each quotation includes the contact information of a designated technical sales engineer, whom you can contact directly by phone, email, or online chat. They will explain the quotation details, help you choose the appropriate process, and answer any questions you may have, ensuring you fully understand everything.

Summary

LS Manufacturing reduces traditional wait times from days to hours by using intelligent, real-time quoting and professional DFM analysis . This is how we optimize solutions and mitigate risk from the design stage.

LS Manufacturing redefines the standard for precision manufacturing services, helping you transform your ideas into high-quality products faster and more efficiently. Upload your 3D files now and experience the revolutionary changes in CNC quoting services ! Get an accurate quote and free DFM analysis within hours. Our expertise accelerates project progress; contact us to bring your ideas to market faster and gain a competitive edge!

📞Phone: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website: https://lsrpf.com/

Disclaimer

The content on this page is for informational purposes only. LS Manufacturing Service Disclaimer: No representations or warranties, express or implied, are made regarding the accuracy, completeness, or validity of the information. It should not be assumed that third-party suppliers or manufacturers will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type, or workmanship through the LS Manufacturing network. Buyers are responsible for verifying these details themselves. For parts quotations, please specify the specific requirements for these parts. Please contact us for more information .

LS Manufacturing Team

LS Manufacturing is an industry-leading company specializing in customized manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precision CNC machining , sheet metal fabrication , 3D printing , injection molding , metal stamping , and other one-stop manufacturing services.

Our factory boasts over 100 state-of-the-art five-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries and regions worldwide. Whether it's small-batch production or mass customization, we can meet your needs within 24 hours. Choosing LS Manufacturing means choosing efficiency, quality, and professionalism.

For more information, please visit our website: www.lsrpf.com .