With the highly competitive marketplace today, are your projects held up by exorbitant metal component fabrication costs and long production lead times? Confronted with complicated supply chains and rising costs, discovering a productive and trustworthy manufacturing partner has become essential to marketplace success. This is where LS Manufacturing can be of help.

Being a leading precision manufacturing services provider, LS Manufacturing is committed to removing efficiency and cost obstacles for its customers through its state-of-the-art CNC milling services. Through our professional services, companies are in a position to truly reduce costs throughout the entire process from raw material acquisition to production and processing, ultimately achieving extremely low-cost CNC milling services.

This artical will discuss how technology strengths of LS Manufacturing blended with its full-service strengths can reduce manufacturing costs by a significant amount and accelerate product delivery by a significant amount, enabling you to turn your concepts into competitive products quicker. To save you time, here’s a quick overview of the core conclusions.

LS Manufacturing CNC Milling Service Core Quick Reference

| Benefit Dimensions | Core Initiatives | Customer Benefits |

| Cost Reduction | Scaled Production and Optimized Materials | Integrated Supply Chain Bargaining Advantages Get Competitive, Low-Cost CNC Milling Services |

| Accelerated Delivery | Digital Processes and Smart Scheduling; Fast Die Changes and Efficient Multi-Axis Machining | Rapidly Reduces Production Cycles, Enabling Rapid Time to Market |

| End-to-End Quality | Monitoring for Quality Control; High-Precision Machines and Experienced Team | Acquire Consistent Parts with Low Risk and High Consistency |

LS Manufacturing CNC Milling Services offer customers complete solutions combining cost, efficiency, and quality through management and technology optimization, ideal for improving supply chain competitiveness.

Why Trust This Guide? Real-World Experience Of LS Manufacturing Experts

The suggestions in this guide are not theoretical solutions but come directly from more than two decades of experience of LS Manufacturing in precision manufacturing. We are not just a CNC milling services company; we are your partner dedicated to solving difficult engineering issues.

Our technicians and engineers are extremely experienced with the machining characteristics of numerous different materials, from titanium alloys to engineering plastics, and we always invest in technologies such as high-speed milling and multi-axis machining. This in-depth experience guarantees that all recommendations that we offer are tested and speak to your cost and efficiency issues in production.

The history of LS Manufacturing is rooted in thousands of successful projects. For example, we helped a medical device startup reduce unit costs by 22% and time to market by 30% by simplifying the fixture design and the machining paths of its core components without compromising micron-level precision. This clearly demonstrates the value of our CNC milling services.

LS Manufacturing excels at manufacturability analysis from the design stage, eliminating potential production problems and cost pitfalls before they occur. By choosing LS Manufacturing, you're putting your faith in a partner who gets the advantages of real-world expertise on your side.

How Does CNC Milling Help Companies Achieve Precision Manufacturing And Improve Efficiency?

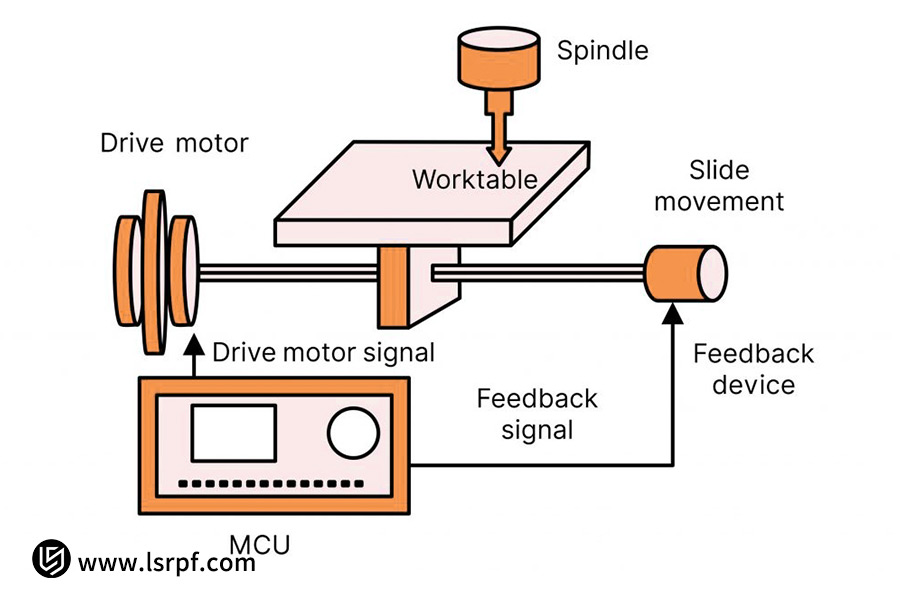

Accuracy and efficiency are core competitive advantages in modern manufacturing. CNC milling technology uses computer instructions to control machine tools, cutting raw materials into complex three-dimensional parts with precision. Its underlying principles are computerized control and high repeatability, which effectively preclude human error and deliver very stable product quality. As a leading precision CNC milling company, LS Manufacturing maximizes this technological advantage:

1. Unparalleled Precision Machining Capabilities:

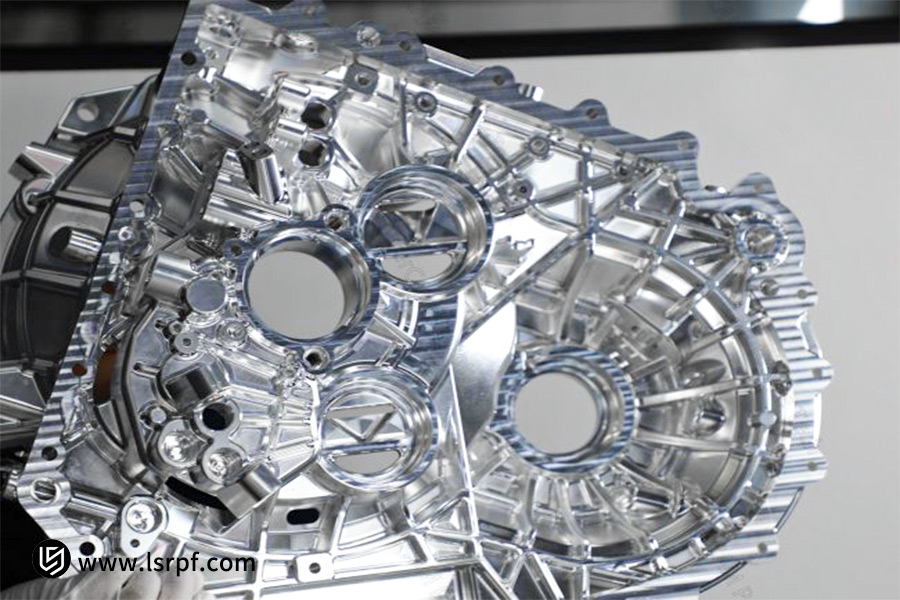

LS Manufacturing's five-axis milling centers can accomplish multi-faceted machining in a single operation, eliminating back-and-forth positioning mistakes and enabling the creation of such intricate forms as impellers and precision chambers, making the impossible possible.

2. Intelligent Optimization Drives Efficiency:

LS Manufacturing's engineers also apply high-end CAM software to maximize tool paths and cutting parameters for every CNC milling project. This not only reduces the time it takes to machine but also increases tool life as well as surface quality tenfold, striking a perfect balance between speed and accuracy.

3. Full-Process Stability Assurance:

From rigorous environmental control in our stable temperature workshops to online monitoring and automatic inspection throughout the entire process, we have established a reliable production system to ensure quality consistency from the first piece to the ten thousandth piece, significantly enhancing our customers' supply chain stability.

As a trusted precision CNC milling company, LS Manufacturing is leveraging a deep synergy of technology and know-how to help businesses in various industries overcome production bottlenecks and efficiently and accurately translate innovative concepts into competitive advantage.

Choosing expert CNC milling services ensures you not only the parts but also cutting-edge manufacturing processes and repeatable quality output.

Why Can LS Manufacturing's CNC Milling Services Significantly Reduce Production Costs?

In a competitive marketplace, controlling production cost is directly synonymous with a firm's profitability and competitiveness. LS Manufacturing's CNC milling operation provides a sound, low-cost answer, not by compromising levels of quality, but through the implementation of a lean cost control system throughout the complete production process. Our cost leverage is largely based on the following key strategies:

| Cost Control Dimensions | LS Manufacturing's Specific Practices |

| Material Optimization | Using computer-aided nesting software to plan cutting paths strategically, maximize sheet material utilization, and reduce material waste at the source. |

| Process Effectiveness | Cutting parameter optimization and multi-axis simultaneous machining technology save us significant single-piece processing time and lower unit labor costs. |

| Scale and Supply Chain | Mass procurement of raw materials centrally provides negotiating power, while stable production capacity provides timely delivery and spares customers from inventory charges and time. |

1. Intelligent Material Management:

LS Manufacturing utilizes the latest computer-aided manufacturing (CAM) software to optimize nesting on each CNC milling job and cleverly schedule tool paths, which results in maximum raw material utilization and minimal wastage from the very beginning.

2. Efficient Mass Production with Consistent Quality:

LS Manufacturing's volume production capability and automated lines significantly reduce the marginal cost of large orders. Moreover, consistent machining quality and extremely low scrap rates eliminate concealed costs such as rework and lost time due to defective parts.

3. Cross-Board Cost Savings with an Integrated Supply Chain:

Being a professional precision CNC milling company, we have developed extensive collaborations with the raw material suppliers upstream, with which we can assist our customers in purchasing better raw material prices. Such a cost saving is actually priced into our competitive quotations.

LS Manufacturing's value-for-money CNC milling services are the result of a scientific and systematic approach. By combined use of technology, management, and economies of scale, we have been successful in helping a large number of customers reduce production costs by up to 20% without affecting quality, achieving frankly first-class value for money.

How Can We Ensure Fast Delivery Without Compromising Quality Through CNC Milling Services?

In the quest for efficiency in the new age, the rate of delivery was a primary indicator of the value of CNC milling services. LS Manufacturing knows this. By process optimization and technological advancement, we have effectively achieved the optimal combination of speed and precision, keeping our unwavering commitment to fast CNC milling delivery. Our system of efficient delivery rests on three pillars:

1. Seamless Digital Assembly Line:

From online orders and automated coding to seamless data transfer, we've created an entirely digital process. This reduces substantial time in order processing and initial technical implementation, your needs serviced immediately and translated into production at rapid speed.

2. Intelligent Scheduling and Real-Time Monitoring:

Our advanced Manufacturing Execution System (MES) allows precise scheduling and real-time capacity monitoring of the workshop. Combined with our effective machining capacity of our five-axis machines and a preventative maintenance system, we effectively avoid bottlenecks in production as well as unplanned downtime, with the consistent output of vital assignments such as "48-hour prototype delivery."

3. Quality Behind Speed:

LS Manufacturing believes firmly that high quality and speedy delivery should go together. Every one of their machines is equipped with online inspection systems, providing real-time dimension feedback of critical importance in order to ensure consistent process control. What this means is that speedy CNC milling delivery does not occur at the expense of accuracy but due to more intelligence and automation.

LS Manufacturing's CNC milling capabilities combine cutting-edge manufacturing technology with lean process management to create a secure and effective delivery system. Our rapid CNC milling delivery concentration is geared towards delivering quality products and significantly shortening project cycles, giving you a competitive edge.

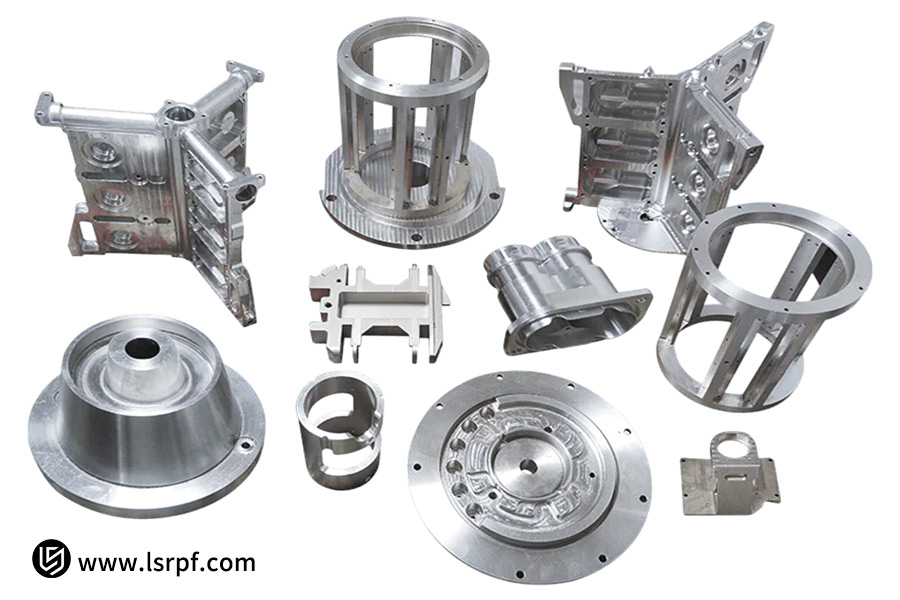

How Do Customized CNC Milled Parts Adapt To Diverse Industry Needs?

In modern industrial manufacturing, industrially produced parts fail to meet the idiosyncratic demands of a specific industry. This is precisely the advantage of custom CNC milled parts—they offer highly tailored solutions to meet the functional, material, and accuracy demands of specialized applications, finding their way easily into diverse needs from the automotive and aerospace sectors to medical devices. As a seasoned CNC milling parts manufacturer, LS Manufacturing implements such high flexibility with the following measures:

1. In-depth Requirements Analysis and Collaborative Design:

Designers at LS Manufacturing work with customers and collaborate in close association to create a comprehensive analysis of industry-specific requirements and obstacles unique to their market. Whether due to the medical requirement for biocompatible materials or aerospace requirement for strength with light weight, we can take your concepts and turn them into producible custom CNC milling part designs.

2. Seamless CAD/CAM Integration and Flexible Production:

Through the utilization of the advanced CAD/CAM software, we can quickly translate very complex design drawings into precise machine tool instructions. This computer flexible production enables us to change custom CNC milling part orders for diverse industries and specifications on a single production line so that we can respond promptly to small lots and high-variety production.

3. Expert Matching of Materials and Processes:

LS Manufacturing boasts several years of experience in machining a diverse range of materials from stainless steel and aluminum alloys through PEEK up to titanium alloys. Being your one-stop CNC milling parts supplier, we can recommend the most appropriate materials and surface finishes based on your industry application to ensure improved performance and longevity in the end-application environment.

The inherent superiority of custom CNC milled parts is their superior problem-solving potential and versatility. With its experienced technical staff and versatile system of production, LS Manufacturing ensures that every part shipped precisely fits the particular industry environment and application requirements, providing customers with additional value beyond the usual parts.

What Key Factors Should I Consider When Obtaining A CNC Milling Service Quote?

In the planning phase of a manufacturing project, obtaining an accurate and clear CNC milling service quote is critical. Not only does this impact budgeting, but also the direct impact on the feasibility of the project. As an experienced CNC milling service provider, we recommend the following points be noted when requesting a quote to be accurate and complete.

1. Material selection is the foundation of cost:

Type of material of the part (steel, aluminum, or engineering plastic) has a direct impact on the cost of raw material and complexity in processing. Determining a material requirement is the first step towards a good CNC milling service quote.

2. Tolerance and Surface Finish Requirements:

Close dimension tolerance and special surface finishing (i.e., anodizing, electroplating) can add a lot of time and complexity to processing, and are major determinants of quote disparity. Bargain the lowest cost range of tolerance with your engineers to meet functionality.

3. Order Quantity and Optimization:

Unit cost is largely dependent on quantity size. Small quantity prototyping and large volume production utilize different price scales. Secondly, a quality CNC milling service company will proactively check your design and provide suggestions for optimization from the design for manufacturability (DFM) point of view, optimizing cost while maintaining function.

4. Choose a transparent pricing model:

Ensure the service provider provides an open cost structure, i.e., materials, machine time, post-processing, and all costs possible. LS Manufacturing provides open, no-hidden-cost CNC milling service quotes through our web-based RFQ tool and free technical consultation.

A truthful quote is the beginning to an effective partnership. By making the above clear, not only do you get a more credible CNC milling quote, but you also more effectively communicate with professional CNC milling service providers like us in a way that best co-designs solutions and maximizes cost-effectiveness and quality.

Why Choose LS Manufacturing As Your Precision Milling Partner?

When choosing a precision manufacturing collaborator, you need something more than a machine tool; you need a long-term partner who understands your needs and provides proven solutions. Being an ISO-certified precision CNC milling company, LS Manufacturing, with its extensive industry experience and technical expertise, has been the first preference for CNC milled parts supply to many leading companies. LS Manufacturing's primary strengths are:

1. Authoritative Certification and Professional Team:

LS Manufacturing has a strict ISO quality management system certification, whereby every process has international standards. Far more important, though, is the fact that we have a team of experienced engineers not only skilled in the process but also with comprehensive technical assistance from design optimization to mass production.

2. Exceeding Standards in Quality Control:

LS Manufacturing's commitment to quality is unparalleled. From the time raw materials are received to the time finished goods are shipped, every product goes through multiple precision inspection processes. This meticulous attention to detail ensures that every part we ship is of ultimate consistency and reliability.

3. Trustworthy, Long-Term Partnership Value:

LS Manufacturing realizes that a quality CNC milling parts supplier is a secure link in our customers' supply chain. We build enduring, respectful relationships with our customers through clear communication, on-time delivery, and constant cost savings, becoming an entity to be counted on behind their product success.

Choosing LS Manufacturing is choosing a partner which strongly integrates quality, expertise, and service. Not just your local precision CNC milling company, we are your strategic partner who will make product competitiveness and long-term growth possible. Let us utilize our expertise to make your next project a success.

What Innovative Applications Of CNC Milling Are There To Reduce Environmental Impact?

In today's manufacturing, better CNC milling services not only imply efficiency and accuracy but also responsibility for sustainable development. LS Manufacturing integrates environmental protection deeply into the manufacturing system, demonstrating that green manufacturing and low-cost CNC milling services are compatible with one another to create economic and environmental value for customers. Our green manufacturing practices are primarily reflected in three innovations:

1. Energy-Saving Equipment and Process Optimization:

LS Manufacturing invests in the latest generation of energy-efficient CNC machine tools and optimizes cutting parameters and machining paths. Its "green cutting" technology significantly reduces energy usage per unit of product, converting energy costs into direct customer savings and forming the foundation of our low-cost CNC milling services.

2. Material Recycling and Efficient Utilization:

LS Manufacturing is dedicated to raw materials that are eco-friendly and has an advanced metal chip recycling program. High-end CAM software enables intelligent nesting for maximizing sheet material, reducing waste at the source, and maximizing resource utilization.

3. Full-Process Carbon Footprint Control:

LS Manufacturing uses localized supply chain coordination and process management to eliminate unnecessary logistics and paper consumption. This lean operation not only reduces our overall carbon footprint but also enhances operational efficiency, thus making environmental stewardship a natural consequence of our low-cost CNC milling services.

Choosing LS Manufacturing provides you with not only quality parts and economical CNC milling technologies, but with a strategic business ally that actively practices green manufacturing and can help you achieve your company's corporate social responsibility.

By incorporating sustainable innovation into every stage of CNC milling, LS Manufacturing has succeeded in transforming environmental stewardship into tangible operational benefits.

How Does LS Manufacturing Achieve Lightweight Housings And Reduce Costs For aerospace Clients?

In high-end manufacturing, aerospace customers often have to face the triple constraints of lightweighting, high precision, and cost. The following case presents how we create breakthrough value for customers with our custom CNC milling parts expertise.

1. Customer Dilemma:

An aerospace drone manufacturing firm was having difficulty building a new model. Structural intricacy of the primary aviation aluminum casing and close tolerances of ±0.02mm and lightness of weight requirement complicated it to do using traditional techniques. Ongoing prototype failure at unit prices of as much as $1,500 and lead times of as much as five weeks significantly hindered project progress.

2. LS Manufacturing's Solution:

With this challenge, we assembled a focused team to first conduct manufacturability analysis on the initial design, streamlining internal rib positioning and thin-walled construction. A five-axis CNC milling center then was used to machine everything in one setup. Combined with high-speed cutting technology, this provided effective, combined molding of complex surfaces and precise features, laying the foundation for rapid CNC milling delivery.

3. Results and Value:

By doing the processes with high precision, we were able to reduce the unit cost of housing by 30% to sub-$1,050, and significantly shortening the delivery cycle from 5 weeks to 15 days through process-improved production processes. This precision custom CNC machined part order not only assisted in the successful flight testing of the customer's product, but also positioned us as a dependable long-term strategic partner with our unmatched CNC milling quick delivery capability and consistent quality.

This case shows how expert custom CNC milling part solutions are able to transform manufacturing challenges into fundamental competitive advantages. Through technology integration and process streamlining, LS Manufacturing achieved significant lightweighting gains and cost savings for the customer while maintaining aerospace-grade quality.

Why Choose LS Manufacturing As Your CNC Milling Parts Supplier?

Choosing from multiple CNC milling parts suppliers means choosing a partner with a strong understanding of your business needs and one who can deliver long-term value. LS Manufacturing's CNC milling expertise stands out because we are end-to-end value beyond simply machining. Our strongest assets are rooted in three core areas:

1. End-to-End Service:

From design consultation and material selection to precision machining, surface finishing, and final quality inspection, LS Manufacturing offers a start-to-finish, vertically integrated service. This eliminates the communications cost and quality risk of dealing with multiple suppliers, offering a seamless project process.

2. Deeply Collaborative Expert Support:

LS Manufacturing's value doesn't stop at its cutting-edge equipment but also at its team of experienced engineers. They are pleased to visit your project, provide manufacturability analysis, and present process optimization recommendations. This technical support can avoid problems before they happen, save you time and make your process more efficient and cost-effective.

3. Efficient and Reliable Global Delivery Network:

LS Manufacturing's reliable logistics and supply chain infrastructure ensures that your orders, large or small, are delivered to your destination on schedule and with assurance. This confidence in delivery provides a good foundation for your production planning.

Choosing LS Manufacturing as your CNC milling parts supplier is not just obtaining a CNC milling service; you are also acquiring a strategic partner who is committed to your success and is willing to provide technical assistance and supply chain guarantee.

How To Start A Partnership With LS Manufacturing And Maximize Your Benefits?

An open and efficient process is essential to the development of a successful partnership. Our collaboration with LS Manufacturing is designed specifically to allow you to have your project in operation quickly and to reap the entire advantage of our professional CNC milling services right away. Simply follow these brief steps to initiate your partnership easily:

1. Requirements Communication and Document Submission:

Forward your design schematics (e.g., STEP, IGES format) and technical details through our site or directly converse with LS Manufacturing engineers. This step is the secret to receiving an accurate CNC milling service quotation as well as the beginning of our manufacturability study.

2. Design Optimization and Solution Confirmation:

LS Manufacturing's engineers will take a look at your design right away and provide a complete proposal, including a CNC milling service quote, within one business day. We often recommend professional optimization concepts to improve performance or reduce cost, so you can get the most out of your value.

3. Order Confirmation and Production Start:

After you've approved your quotation and proposal, your order will be automatically loaded into our sophisticated scheduling system. You will receive a personal project tracking window, which will keep you informed about the production progress. This is an open process in which you are fully in charge of the whole CNC milling process.

4. Strict Quality Inspection and On-Time Delivery:

After production, the component is forwarded for a critical quality inspection and is forwarded with a complete quality inspection report. LS Manufacturing will organize the logistics for timely and undamaged delivery of the product.

Working with us, you benefit not just with the parts but with an end-to-end system of service designed to make you a success. Make your inquiry today and obtain a competitive quote for CNC milling service and observe how LS Manufacturing can deliver fast and reliable returns on your project utilizing reliable CNC milling services.

FAQs

1. What materials are suitable for CNC milling?

CNC milling is materials flexible to a great extent, cutting metal and non-metallic material. Aluminum alloys (6061 and 7075), stainless steel (304 and 316), tool steel, and titanium alloys are some common metals used; non-metallic materials are engineering plastics (PEEK and nylon) and composites. The strength, weight, corrosion resistance, and machinability rating varies with varying materials.

2. How do we ensure the dimensional accuracy of CNC milled parts?

LS Manufacturing offers dimension accuracy from a combination of equipment, process, and experience. We possess ultra-high-accuracy five-axis CNC machinery to offer machining capability from the very beginning. We practice rigorous quality control throughout the entire process, using equipment such as coordinate measuring machines and optical profilometers for multi-step inspection at manufacture to achieve a consistent tolerance of ±0.01mm.

3. What is the typical lead time for CNC milling services?

LS Manufacturing's lead time is variable and efficient, with the ability to customize project needs. Low-medium complexity prototypes are completed within only 3-5 business days. Smalls-medium quantities can be produced in 2-4 weeks, contingent on order volume and process complexity. LS Manufacturing offers an expedited service track, with high priority given to priority orders so that you free your time, and you are able to accelerate product development as well as time to market. We also have online progress tracking.

4. What information do I need to obtain a CNC milling quote?

To receive a fast, accurate quote, we recommend that you provide us with three easy items of information: an accurate part drawing in STEP or IGES format with label critical dimensions and tolerances exactly stated; any special conditions such as material grade and surface finish; and the production quantity of your choice. LS Manufacturing will reply with a clean, itemized quote with no hidden cost within 24 hours on this basis.

Summary

With rich experience in CNC milling services, LS Manufacturing has built a solid manufacturing platform with low-cost CNC milling services, quick shipping, and high-quality services. Not only do we possess advanced 5-axis machining centers and a strict quality control system, but also offer one-stop service from design optimization to batch production for customers.

No matter if you're facing high-cost concerns, aggressive time-to-market pressures, or tight customization requirements, choosing LS Manufacturing assures you an experienced manufacturing partner who can turn your concepts into reality as high-quality products on time and with precision.

Contact LS Manufacturing now! Request a free, personalized CNC milling service quote from us, or post your project inquiry directly on our website. Let the experts from LS Manufacturing deliver efficient and reliable manufacturing solutions in 24 hours to accelerate your success together! Upload your design drawings now and get an instant CNC milling quote ( CNC milling price), let LS Manufacturing be your strong backing in pursuit of ultimate CNC milling precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.