CNC turning services represents the core of modern precision manufacturing, and thus, it is crucial to the stability and output of your entire production line. But this very critical nature also implies great risk because any failure in delivery by one supplier of such a crucial component can stop the work of your whole assembly line. This kind of disruption would invariably snowball into critical defaults on customer orders, with potentially huge economic losses.

This often exposes several weaknesses among traditional suppliers regarding production planning, passivity in risk management, and a lack of effective mechanisms for "on-time delivery" accountability. LS Manufacturing offers top-quality, high-precision CNC turning services and pioneered the legally binding commitment of "delay compensation" in the industry.

How do we make "on-time delivery" more than a slogan, but an uncompromising pledge? To save you time, here is a brief overview of the key findings.

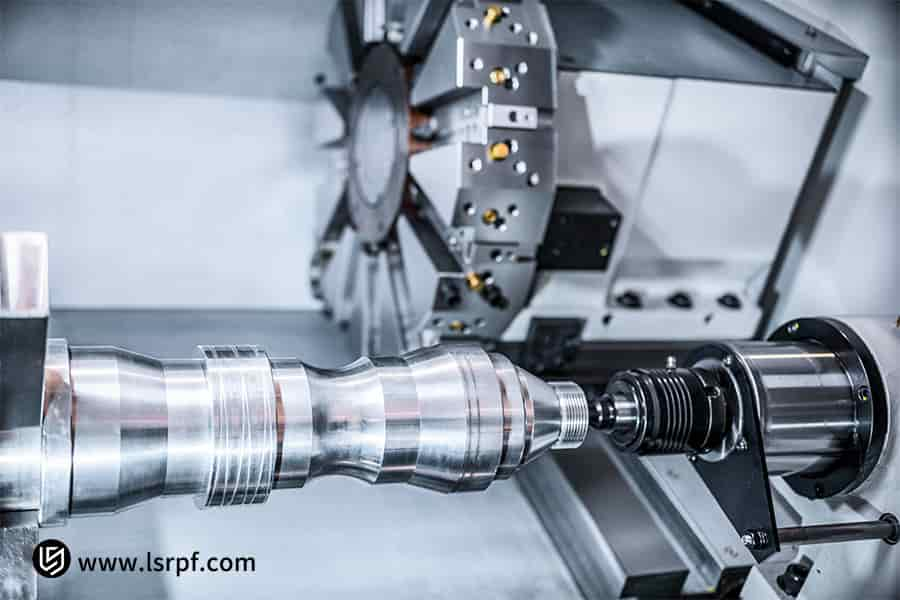

Figure 1: A trusted partner for a wide array of precision turned parts by LS Manufacturing

Quick Reference Table For CNC Turning Service

| Module | Key Points | Specific Content |

| Industry Pain Points | Supply Chain Disruption Risk | Delays by suppliers are the direct cause of shutdowns on the production lines and huge losses. |

| Root Causes | Misalignment of Responsibility and Risk | Inherent deficiencies in planning, risk control, and accountability among traditional suppliers. |

| Solution | Guaranteed Service Commitment. | We offer precision CNC turning services with a "delay compensation" clause. |

| Core Guarantee | Smart Manufacturing Management | With a transparent data-driven system, we guarantee on-time delivery 100% of the time. |

| Customer Value | Lock in Benefits | Above all, secure stability in your production plans and security in your supply chain. |

Below is the table showing how LS Manufacturing has turned "on-time delivery" from a slogan into an inviolable golden rule. We systematize critical pain points for the industry, root cause analysis, and provide you with the core value of absolute supply chain certainty through our legally binding contractual solutions and a sophisticated intelligent guarantee system, ensuring full accountability and trust.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

We aren't armchair strategists speculating on strategies but hands-on, value-added experience in precision manufacturing, which puts very demanding requirements on tough-to-machine materials such as titanium alloys and stainless steel at micron-level tolerances. We make critical parts for the aerospace, medical device, and high-performance automobile business where every thread's precision directly impacts flight safety, patient lives, and reliability under extreme conditions. Our processes are built to meet the rigorous demands of standards like ASME Y14.5 for dimensional tolerancing and ISO 9001for quality management systems.

In the past decade, we've manufactured over 50,000 custom parts with precision threads, giving us hands-on experience in selecting the best tap for a wide range of applications, from common steels to exotic superalloys. We have learned how to set exacting parameters for the best possible performance when tapping the most difficult materials like titanium alloys and have perfected the delicate balance between ultra-high efficiency and top quality in high-volume mass production environments.

This is a direct compilation of the invaluable lessons learned from both our successes and our failures. Each of the suggestions within these pages was born from rigorous, real-world testing on the shop floor; each pitfall and challenge navigated has been distilled into proven shortcuts that we offer you. There is no abstract textbook theory here, just reliable, battle-tested solutions verified not in a laboratory but with the evidence of machine oil and metal chips.

Why Is "On-Time Delivery" So Rare In The CNC Turning Industry?

Many companies in precision manufacturing have faced this frustrating scenario: a supplier repeatedly confirms a delivery date for on-time delivery CNC machining, yet the order is perpetually delayed, severely disrupting their production schedule. This predicament, where promised deadlines for CNC machined parts are consistently missed, points not merely to a supplier's oversight, but to a deep-seated, systemic flaw inherent in many traditional CNC turning services that fundamentally lack the robust processes required to guarantee on-time delivery CNC machining.

- Rigid production scheduling: Manual experience has shown that it is impossible for the planning model to quantify precisely the capacity of equipment and man-hours orders. In the event of any kind of emergency insertion and process delay of orders, chain reactions would certainly result in the total collapse of the order, without flexible data-supported planning.

- Reactive Equipment Maintenance: Because real-time monitoring of spindle precision and tool wear was unavailable, there have often been abrupt failures under full-load conditions. This directly used up buffer time and made the delivery commitment impossible.

- Fluctuating Supply Chain and Quality: Poor delivery of raw materials can make a production line short of raw materials; frequent dimensional deviation and surface defect also require repeated adjustment and rework, thus creating a vicious circle of "delay → rush work → quality control failure → further delays."

With a deep understanding of these painful points in the industry, our company has focused on building a digital production hub system that integrates equipment data with supply chain dynamics and quality indicators. This will help to facilitate a shift from "firefighting" to proactive management, making on-time CNC machining quantifiable and traceable as a technical standard.

Key Message: How Does LS Manufacturing Eliminate Delivery Delays Using Four Systems?

At LS Manufacturing CNC turning, we understand that saying "on-time delivery" is the easy part; it's the robust, unbreakable system behind the promise that really makes it a guarantee. To make every batch of precision parts on time with consistency, we have built our on-time delivery CNC machining service on the following four core pillars. The essential differences from the traditional model are given in the table below.

| Guarantee System | Traditional Model Pain Points | LS Manufacturing Core Guarantee |

| Intelligent Dynamic Scheduling | Rigid planning, ambiguous schedules | Real-time system tracking of order progress, updated to the hour. |

| Preventive Maintenance of Equipment | Sudden failure and passive downtime can be prevented |

Rest assured of overall equipment efficiency above 85% with data-driven predictive maintenance by means of OEE. |

| Strategic Raw Material Inventory | Temporary procurement, waiting time |

"Material shortage" from its very source and establish safety stock for usually used key materials. |

| Integrated Production Quality | Quality inspection after production/batch risks | Real-time quality control during processing, first-pass yield over 99%. |

Our "zero-delay" guarantee is itself an integral, sophisticated and interconnected system: from intelligent scheduling that offers optimal and controllable overall planning to strategic inventory and preventative maintenance for continuous and stable production, to integrated quality - all these assure the elimination of risks of rework and scrap right at their source. These four systems taken together make the LS Manufacturing CNC turning measurable, traceable, and a guaranteed deterministic service.

"Compensation for delay" is not an empty slogan. What does the law say?

As a CNC turning supplier that dares to make commitments, we believe that sincerity must be reflected in concrete terms, and the responsibility must be borne with real money. Our policy compensation for delayed delivery is not some marketing oratory but a legally binding clause clearly written into the commercial contract. Its core content is much different from the vague promises of traditional suppliers:

| Comparison Dimensions | Vague Promises of Traditional Suppliers | Hardcore Terms of LS Manufacturing |

| Compensation Conditions | Not well defined, hence difficult to define responsibility. | Clearly defined due date of delivery - as contractually agreed upon - the trigger to our responsibility. |

| Compensation Calculation Method | Verbal apology or difficult negotiation. | For each day of the delay, there will be a certain fixed percentage return against the total amount of the order, such as 0.2%. |

| Most compensation Caps and Procedures | Either undefined or set very high. | Our policy clearly defines the terms, puts a reasonable cap, and has simplified application and payment procedures. |

By nature, this policy is designed to put ourselves proactively into the shoes of customers and thus share the risk of supply chain disruption by directly linking "on-time delivery" with our financial cost. We'll be your trustworthy partner, not just a CNC turning supplier, and make "guaranteed delivery and risk control" the solid foundation that our cooperation shall be based on.

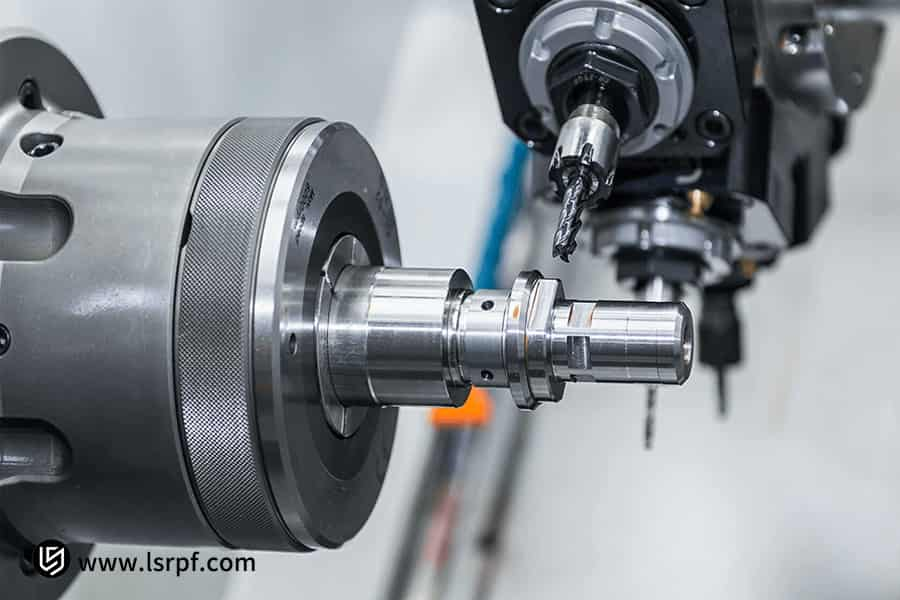

Figure 2: Powering precision CNC turning with the ROMI C620 by LS Manufacturing

Ultimate Precision: How Can Ultra-Precision Turning Be Achieved With On-Time Delivery?

The core value of the precision CNC turning service provided by LS Manufacturing is "certainty": certain delivery time and, more importantly, the microscopic precision of every dimension. How to reach both targets simultaneously is the question. The answer lies in the comprehensive technical system:

1. High machining capability based on high-class equipment

Equipped with the imported German and Japanese milling and turning centers, the thermal compensation system and mechanical precision of the whole line can be constantly kept within the range of ±0.005mm. This high-precision foundation not only enables complex custom CNC turning projects—such as integrated turning, milling, and drilling in a single fixture setup but also guarantees the consistency of batch production parts from the first piece to tens of thousands of pieces.

2. Deep process database on materials science based

We have established a database of comprehensive cutting parameters for tens of materials involving stainless steel, aluminum alloy, titanium alloy, and special engineering plastics. That is to say, at the very beginning of an order, we are able to predict the tool life, cutting force, and thermal deformation trend accurately. The optimization of the machining strategy can control dimension fluctuation within a micrometer while pursuing efficiency; thus, an excellent surface finish with a Ra less than 0.4 can be acquired.

3. Quality Control Moved Ahead Throughout the Manufacturing Cycle

Instead of relying on the final inspection, we integrate quality control into the machining cycle. The online measurement system allows for real-time data feedback and automatically compensates for any deviation in the trend. This avoids batch deviation risks, ensuring "correct from first try" and guaranteeing ultra-high precision, thus eliminating rework obstacles for on-time delivery.

This core capability-to streamline, standardize, and digitize our precision manufacturing processes-gives us the unwavering confidence to promise you more than just precision CNC turning. We guarantee dual certainty: absolute reliability in delivery time and uncompromising consistency in quality standards. It is precisely this ability to deliver certainty that defines the unique, foundational value of LS Manufacturing as your core supplier.

From Drawing To Part: How Do We Provide Flexible Solutions For Your Unique Needs?

Does "high cost and long lead time" always happen when sourcing customized CNC turning services? Not necessarily. True professional CNC turning services should respond flexibly to each unique requirement, rather than forcing your design to compromise with standardized processes. Our flexible manufacturing solutions are specifically designed to break this stereotype by offering both competitive pricing and accelerated production cycles while maintaining uncompromised quality for your custom parts.

- Deep Collaborative DFM Analysis: Our engineers with deep knowledge of materials science and processing proactively intervene before production. We perform manufacturability analysis on your drawings, give optimization suggestions for better processing efficiency and yield while ensuring functionality, and control costs from the source.

- Modular Rapid Process Configuration: For complex geometries, special industry standards, or post-processing requirements, we do not start from scratch. We have a mature process module library, which can quickly retrieve the corresponding matching mill-turn composite, heat treatment, and surface finishing solutions to ensure that "customization" does not mean "inefficiency."

- Transparent Project Management Throughout the Process: You will have your own communication channel from order confirmation to the final delivery. We synchronize the progress and data through the digital system, making sure changes in requirements and potential risks are taken care of on time. You will also enjoy flexibility in customization with full control of schedule and quality.

In other words, our core flexibility enables the translation of deep engineering knowledge into efficient collaborative processes. With this in place, even small-batch, very complex custom CNC turning projects become possible to attain deterministic, high-quality results within controlled costs and timelines. This way, "customization" really becomes an accelerator for innovation, not a burden.

No Long Waits: How To Get A Clear Quotation With No Hidden Costs?

Most important of all, in searching for manufacturing partnerships, a delayed or vague quotation very often means that communication costs and issues of trust have already been built up right from the very start of a project. We firmly believe that an excellent CNC turning quote should be more than just the starting point of protracted negotiation but rather the cornerstone in terms of a transparent and efficient partnership. Toward that end, we reorganized our quotation process to make sure your experience will be significantly different right from the very first minute:

- Standardized and precise calculation system: We have built a comprehensive database of time, material, and process costs. Only clear drawings and technical specifications will be required, whereas the system itself will quickly and more accurately calculate processing time, usage of materials, and all forms of processing costs-in essence, avoiding arbitrariness and bias in human estimation.

- 4-Hour Rapid Response Commitment: We fully understand the importance of efficiency in decision-making. We can, with full confidence that the inquiry is complete, give a clear and detailed quotation in 4 business hours that will not only include the total price but also the breakdown of the main cost components, together with a reliable delivery cycle confirmed by our production plan.

- Transparent List with Zero Hidden Costs: Quotation is commitment. Relevant costs of material, processing, heat treatment, surface finishing, and standard packing and shipment are clearly indicated. We eliminate any "unexpected" additional costs later to let you make budgeting and decision-making decisions based on full information.

A quotation efficiency-based mature internal management, with strong data capability, forms the basis for successful partnerships. A transparent, responsible CNC turning quote will therefore immediately gain trust right at the beginning and form a solid base for a seamless, predictable project journey through to final delivery from quote to reality.

Figure 3: Guaranteeing on-time delivery through precision CNC turning by LS Manufacturing

Case Study: How We Help Clients Resolve Supply Chain Disruption Crises?

In today's time-sensitive manufacturing environment, a surprise supply-chain break causes production delays and quality compromise that translate to financial loss. The following case study will show how LS Manufacturing CNC turning takes what some would call a simple delivery "commitment" and makes it integral operational insurance for our customers. With our sound system, we help turn supply chain uncertainty into dependable protection. Here are the details:

Customer Problem

The sudden, environmentally-related stop of production for a core brake component supplier to a well-known automotive Tier 1 supplier would mean that without 5,000 replacement parts within the stringent standard requirements of OEMs within 7 days, the client's downstream vehicle assembly lines go directly to shutdown, with massive claims of thousands of yuan per minute, amounting to millions.

LS Manufacturing's Emergency Response Mechanism

The moment the call for help came, we sprang into high gear with our highest level "firefighting project" plan: within 2 hours, a dedicated team drew and reviewed the process; opened the "emergency production capacity" window reserved for key clients and adjusted the whole production line for uninterruptive operation 24/7. Meanwhile, with a daily progress report mechanism set up by a project manager, all the key data was transparently shared to enable the real-time tracking of each stage's progress by the client.

Results and Value

We completed the whole process-from designing the process to delivering 5,000 qualified products-in only 5 days with highly effective collaboration, two days ahead of the customer's deadline at 100% product yield. On-time delivery of the aforementioned CNC machining services has not only helped customers avoid huge financial losses and reputational risk but also allowed us, with outstanding crisis response capability, to change from "firefighter" to a long-term and trusted strategic backup supplier.

In one word, this case fully demonstrates that real supply chain resilience is reflected not only in the stability of daily output but also in the absolute capability to tackle sudden crises. Results show that LS Manufacturing CNC Turning had integrated on-time delivery CNC machining into its operational DNA: rapid response processes, flexible capacity reserves, and absolutely reliable quality control altogether form a solid and reliable safety line in the customer's supply chain.

Figure 4: Delivering precision CNC solutions for intricate metal parts by LS Manufacturing

Three Steps To Start Cooperation: Your Exclusive Delivery Guarantee Plan Is Ready

Choosing a reliable CNC turning supplier should not mean complicated processes and uncertain results. We have integrated an efficient and reliable experience of cooperation into these three streamlined steps, which let you seamlessly take advantage of our CNC turning services:

- Submit your requirements and get a guaranteed quote: Just send us your sketches and specification list, and our team will supply a well-structured quotation within 4 hours based on our standard cost database, specifying exact pricing and delivery timelines. This quote is a commitment; there are no hidden fees.

- Sign a contract with a "delay compensation" clause: Upon confirmation of the quotation, a formal legally binding contract will be signed by both parties. This contract has in writing a "delay compensation" clause, where substantial implementation of our responsibility for on-time delivery is in place. Our interests are deeply linked with your project risks.

- Arrange for production and enjoy full progress visibility and delivery on time: We will immediately put your order into our intelligent production scheduling system as soon as the contract is in effect. A window allows you to monitor the whole production process in real time from material preparation to the final quality inspection. All you need to do is to wait for us to deliver qualified parts on time.

Underpinning this three-step process, which is in fact extremely simple, are a mature standardized system, an intelligent management platform, and a strong commitment to responsibility. That means we work on changing complex manufacturing and delivery into simple, predictable collaboration, so you may focus on your core business with full confidence, leaving the supply of precision parts in the hands of a reliable CNC turning supplier.

The Ultimate Consideration For Supplier Selection: Beyond Price, What Is The Real "Total Cost Of Ownership"?

When choosing a CNC turning supplier, the unit price for parts is of importance, but what really matters in determining the long-term value of a partnership is the hidden "Total Cost of Ownership." It's often the cascading losses from a single delivery delay or quality incident that far exceed the unit price savings at the time of procurement. As a partner specializing in precision CNC turning, we recommend you focus on the following three core dimensions:

Delivery Certainty Avoids Downtime Losses:

What seemed to be a low price will turn right away into the leading factor for the stoppage of your production line and default of orders if it is delayed. Our "Delay Compensation" commitment and intelligent scheduling system are designed to eliminate this biggest risk and guarantee the continuity and stability in your production schedule.

Quality stability eliminates the following risks:

Since customers require perfect consistency both in dimensions and in batches, any inconsistency in dimension or batch can lead to customer returns, after-sales claims, and even damage to the reputation of your brand. With our integrated production quality with a high first-pass yield, we ensure the reliability of each batch of parts. This serves to reduce your quality control costs at the source.

Engineering Collaboration Value: Optimizes Source Costs

An excellent supplier should provide proactive suggestions for process optimization. Our DFM analysis service can optimize the structure and material of parts during the design stage to reduce machining difficulties at its root and lower the total manufacturing cost.

The value of a great precision CNC turning partner is in sharply decreasing the huge hidden costs associated with the latter two by providing delivery certainty, quality stability, and engineering collaboration. LS Manufacturing is committed to being that kind of partner who stands beside and supports you in reaching the best balance between cost and efficiency.

Figure 5: Commitment to on-time custom CNC turning delivery by LS Manufacturing

FAQs

1. Does the commitment to deferring compensation apply in all kinds of orders?

This applies to an overwhelming majority of the standard mass production orders. In cases involving very complicated structures or special materials which need to be imported, active evaluation and discussion will be made at the quotation stage with all related clauses clearly defined in the contract so as to ensure clear rights and responsibilities, hence legally protecting your fundamental rights at all times.

2. What is a "delivery delay"?

'Delivery delay' is objective and clearly defined, matching a due date of delivery clearly agreed upon within the formal contract signed by both parties. If we are responsible for the failure to deliver the goods and to notify you of receipt before that date, then the automatically triggered Delay Compensation Clause applies.

3. Is it possible to deliver small batch orders on time?

Absolutely, the flexible production system and intelligent scheduling module can deal with batches in small sizes efficiently. Whatever the size, every order will fall into the same guarantee system for timely delivery.

4. Will changes to my design impact the delivery due date?

Where a customer wants to change a design, we will immediately assess the impact that such a design change will have on the production cycle, and we will clearly show that impact to you within 2 hours while triggering our internal resource rapid allocation mechanism in order to minimize the time impact of the change.

5. In which formats and drawing standards do you support?

We support all common formats such as STEP, IGES, SLDPRT, DWG, and PDF, and can meet multiple industry standards such as ISO, AS9100, and IATF 16949.

6. Will my product data be kept confidential?

Your IP protection is our lifeline. An internal encrypted data management system will be applied throughout the process. Legally binding agreements of confidentiality with you can also be signed to secure your technical data.

7. How is payment arranged?

In general, we can offer a "prepayment + final payment before shipment" model. This can balance both sides' interests for an order of mass production. We are flexible; thus, we are able to negotiate more convenient ways of paying according to the amount of orders and cooperation history.

8. How will I be able to check on my order in real time during production?

You will be assigned a project manager who acts as a single point of contact. He/She will proactively report to you about the key milestones in material warehousing, first-piece inspection, and shipment completion. You can also contact him/her at any time for the most accurate and real-time progress.

Summary

The competitiveness of your supply chain directly depends on its reliability in today's competitive environment. Choose LS Manufacturing, and you're choosing more than a processing service; it is about choosing supply chain insurance with strong system capabilities and legal terms in support.

Now, let us turn "delivery anxiety" into a "supply chain advantage." Just upload your drawing for a tailor-made "Quotation and Delivery Guarantee Plan" or directly contact us. Enjoy transparent processes from the very first collaboration, precise delivery, and anxiety-free manufacturing cooperation that makes LS Manufacturing your most reliable strategic partner.

📞Phone: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website: https://lsrpf.com/

Disclaimer

The content on this page is for informational purposes only. LS Manufacturing makes no representations or warranties, express or implied, regarding the accuracy, completeness, or validity of the information. It should not be inferred that third-party suppliers or manufacturers will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type, or processes through the LS Manufacturing network. The buyer is solely responsible for this information. For parts quotations, please specify the exact requirements for these parts. Please contact us for more information .

LS Manufacturing Team

LS Manufacturing is an industry-leading company specializing in customized manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precision CNC machining , sheet metal fabrication , 3D printing , injection molding , metal stamping , and other one-stop manufacturing services.

Our factory boasts over 100 state-of-the-art five-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries and regions worldwide. Whether it's small-batch production or mass customization, we can meet your needs within 24 hours. Choosing LS Manufacturing means choosing efficiency, quality, and professionalism.

For more information, please visit our website: www.lsrpf.com .