CNC machining vs 3D printing is a choice conundrum for development team members, hence resulting in expensive decision mistakes. The traditional flow of direction is linked to a lack of data, hence leading to projects exceeding their budget and project time delays. The forthcoming report will expound how the bar of experience will be surmounted for well-informed decision-making.

The solution to this dilemma is to use data analytics in identifying the true cost drivers. The relevance of our approach in identifying the Total Cost of Ownership and not the cost per unit in establishing decision guides for the choice between CNC machines and 3D printing can hence be viewed as a positive contribution to realizing cost savings.

CNC Machining VS 3D Printing: Quick-Reference Guide

| Aspect | CNC Machining | 3D Printing (Additive Manufacturing) |

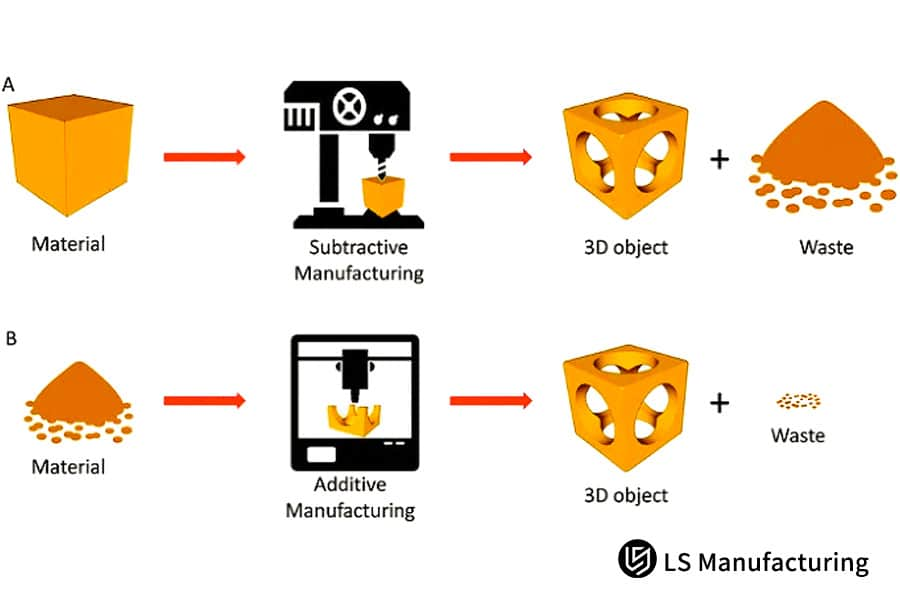

| Core Principle | Subtractive: Cuts material from a solid block. | Additive: Builds parts by adding material layer by layer. |

| Ideal Volume | High to medium-volume production; best suited to batch production. | Low-volume production; prototype; custom parts. |

| Material Range | Metal, Plastic/Resin/Polymers/Composites. Properties of materials excellent. | Increasingly: Consultants work with plastics, resins/metal predominantly. Properties of material can be anisotropic. |

| Geometric Complexity | Good, but limited by tool access. Internal features challenging. | Excellent. Unlocks complex, organic shapes (lattices, internal channels). |

| Set-up & Lead Time | Longer set-up & programming. Faster per-part cycle time at volume. | Minimal set-up. Lead time is independent of part count; ideal for rapid turnaround. |

| Cost Drivers | Highcost of equipment. Material wastage in subtraction. Setup is labor-oriented. | Tied to volume of material and time to print. Less Waste. Higher material cost per piece. |

| Precision & Finish | Excellent: High accuracy, excellent surface finish. | Good: Dimensional accuracy is technology dependent. May require post-production processing for good finish. |

| Key Strength | Enhanced accuracy, strength, and scalability capabilities for proven designs. | Wide design freedom capabilities to iterate through designs or customized geometries. |

| When to Choose | Final production parts, high-performance applications, tight tolerances, Larger batch sizes. | Prototypes, complex/lightweight designs, custom/low-volume parts, integrated assemblies. |

The costly decision dilemma of process selection has been resolved by moving beyond the unit cost of the process by exploring the total cost of ownership. Thus, the framework facilitates the calculation of trade-offs for both the CNC process as well as the 3D printing process and hence will assist in maximizing the reduction of the total cost of ownership to the tune of 25-40% in development costs.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

There are many articles available on the theory that relates to the CNC machining as well as the 3D printing on the internet. The thing that makes the article worth reading is that it is written from the experience of a practitioner named LS Manufacturing. It has been more than 15 long years that LS Manufacturing is fighting the battle that is associated with the machining process that affects the cost that relates to a piece.

Our workshop operates under ISO 9001 uncompromising quality management systems and the International Aerospace Quality Group (IAQG). It is in the actual work process that our true expertise was laboriously acquired. We are well aware of the discrepancies between the two, but it is because of this awareness that puts us in a place to decide whether it is an aircraft part processed to the ideal surface quality in CNC machines or the authenticity of 3D-printed prototypes.

All the suggestions below were hard-won knowledge. We have learned what the parameters of 3D printing are, the values of which give the highest strength for end-use parts; and how to modify the CNC method to effectively process high-temperature alloys. Below is a summary of all our knowledge pertaining to more than 50,000 custom parts and helps you avoid costly mistakes in deciding whether to use CNC machining or 3D printing.

Figure 1: Comparison and cost evaluation of different production methods by LS Manufacturing

What Are The Cost Structure Differences Between CNC And 3D Printing?

The correct choice of the process cannot, hence, be done without a certain deconstruction of the cost drivers. The deconstruction of the CNC machining cost process as well as the 3D printing cost can thus be achieved by the use of the document. The document facilitates an unbiased manufacturing cost analysis process.

| Cost Component | CNC Machining | 3D Printing |

| Primary Driver | Weight of raw material billet is the most weighing factor, which translates to 40-60% in the entirety of costs. | Specialized feedstock material is the major cost, accounting for 50-70%. Specialized feedstock material is the major cost, accounting for 50-70%. |

| Secondary Driver | Machine time and labor are an important cost component contributing to 25%-35%. |

Equipment and systems amortization are costs of 20%-30%. |

| Key Variable Factor | Tool wear and consumables contribute a notable 10-15% to the overall expense. | Post-processing labor for support removal and surface finishing adds variable cost. |

| Economical Batch Size | Becomes favorable for generic aluminum pieces for orders over 500 pieces. | It remains favorable for prototyping and complex pieces as well as for orders less than 500 pieces. |

| Volume Cost Differential | When it involves 1000+ pieces, it can provide about 35% of a qualified geometry costing less per part. | The costing of the part will be more or less the same, meaning there will be no economy of scale in this case. |

In reference to CNC machining cost, it is ideal that there be volume production. However, 3D printing cost would be most optimal for low volume complexity. For actionable manufacturing cost analysis, first calculate costs at your specific batch size. In case your volume is over 500 units, you must do a competitive TCO analysis, and in this case, CNC would be most optimal.

How To Scientifically Select The Optimal Manufacturing Process Based On Batch Size?

For making a well-informed decision on which production process will prove to be the most effective in the current business situation, there is a requirement for the use of data-driven strategies and not rule of thumb. The data given to make a systematic decision on the high volume production choice is as follows:

Establishing the Multi-Factor Evaluation Framework

We will examine the simplification of choice by looking at three variables simultaneously, which are the batch size, part complexity, and the required lead time. Take, for example, the same volume scenario, whereby the simple bracket and engine mount based on topology will have different economic points in comparison. A matrix will provide weighted values of the variables, thus eliminating opinions and instead using a manufacturing cost analysis.

Quantifying the Primary Batch-Size Threshold

More than 125 projects have been used for the development of the first rule of thumb. The crossover point for cost expectation for 3D printing service and CNC machining service for simple geometric components is estimated to have values between 80 and 100 pieces. This is because the high upfront programming and setup cost of CNC is quickly amortized, while additive costs remain largely linear with part count, making it the less efficient high volume production choice.

Adjusting for Complexity: The Secondary Critical Point

The geometrically complex parts containing internal passages and biological lattices become relevant at this stage. In such cases, though historical cost competitiveness based on CNC production would decrease because the problems associated with machining increase the processing time, such effects become less influencing due to the geometrical freedom provided to 3D printing, thereby obstructing expensive multi-axis CNC machining and transition to the CNC machining service in case studies-leading to crossover values between 200 to 300 units.

In using such an approach, the first process involves assigning levels of complexity in your component while designing your component based on the targeted batch. The units of assignment for applying such an approach in the less complex include units of 80-100, while the units of the 200-300 scale are for the complex designs.

How Can The Cost-Effectiveness Of Different Materials In The Two Processes Be Quantitatively Compared?

Cost of material is an important factor in deciding the manufacturing process selection; raw numbers are very misleading when taken out of context. The economic comparison in numbers of the 3D printing cost of specialized powders versus CNC machining cost of bulk materials is quantified in this work and provides information necessary to develop a realistic comparison.

| Factor | CNC Machining | 3D Printing |

| Raw Material Cost | Bulk material bar and plate cost less: for example, ~$8/kg for 316L. | Specialized feedstock powder and resin are much more costly: for example, ~$120/kg for 316L. |

| Effective Utilization | Traditionally, material utilization is 40-60%, with large amounts of material wasted by subtractive process. | Virtually 100% utilization of the fed material, as well as minimized wastage of the support structure. |

| Key Optimization Lever | Strategic nesting and highly optimized CAM programming could increase the utilization level to as high as 85%, and the CNC machining cost process could decrease by an order of magnitude. | Cost Optimization primarily focuses on maximizing the utilization of the build chamber volume and lowering the amount of support structures. |

| Economic Batch Threshold | When analyzing the case of an article made of 316L material, the optimal CNC machining is more economical than 3D printing when the production volume is above 150 units. | Retains advantage for very low volumes (<50) and highly complex geometries where CNC waste is prohibitive. |

| Total Cost Impact | Post-optimization, CNC machining cost for batches >150 units can be up to 42% lower than the additive alternative. | There is not much difference with respect to cost per piece, and for simple shapes, scalability is not possible. |

While seeking the optimum manufacturing process selection, one should define the value for the effective material cost per part, which, for CNC, would be (Blank Cost/Utilization Rate) in contrast to (Powder Weight * Powder Cost) for 3D printing. Volumes over 150 units must focus on the use of CNC to produce the parts, together with advanced nesting to maximize utilization rate.

Figure 2: Cost assessment for precision parts produced via CNC machining by LS Manufacturing

How Does Part Complexity Affect The Economics Of Process Selection?

The reasons for the pivot are the complexity of parts, and its effect reverses the typical breakdown seen in the cost models for CNC machining vs 3D printing. The incorporation of inner channels, lattices, or organic shapes to the geometric parts leads to the typical analyses carried out by the portion or volume to be a correct match for sub-optimal manufacturing process selection. This is how an economic value for complexity may be applied to denote

Defining and Quantifying Complexity in Cost Models

- How we quantify it: Instead of using a subjective metric, we gauge the complexity of a CNC operation based on access to equipment, secondary processing, and special fixturing of a CNC machine.

- Practical application: In the case of the conformal cooled mold, the impact was that CNC machining had to be done in 5 setups, while the 3D printing took one setup, thus validating the assumption that there would be a 60% reduction in cost and the time reduced from 3 weeks to 5 days.

Leveraging Design for Additive Manufacturing (DfAM) Principles

- How we integrate DfAM: Topology optimisation isn't considered an intermediate step; it is merged with manufacturability analysis so as to consolidate the assemblies.

- Outcome achieved: In a medical device scenario, this technique enabled the creation of an optimized part that was 40% lighter and 35% less expensive to produce than the original complex assembly realized with a CNC machine.

Calculating the Complexity-Adjusted Breakeven Point

- How we model the shift: We modify the breakeven calculation based on volume to account for complexity by adding a complexity factor that increases costs for CNC.

- Data-driven decision: It means that as parts get increasingly complex internally, there may be another economic crossover point that could be greater than 300 units for when to switch from 3D printing to machining rather than 100 units. This is a radical shift in the manufacturing process selection.

For this specific goal, you have to determine your complexity penalty with regard to your part. Assuming that you have complexity penalties for your part, your new goal will be to give your preference for 3D printing service for prototyping or for the First Article. When you move along with your final manufacturing process selection, you will utilize your new method of break-even analysis, not using the conventional method of break-even for volume. This will give you the required precision for purchasing your valuable parts.

What Are The Key Impacts Of Accuracy Requirements On Process Selection?

When making a comparison between the CNC machining service and the 3D printing service, there are tolerance requirements which could conflict with the cost aspects. It can easily reach a stage where it will no longer be cost-effective to just machine to a high tolerance level as far as the non-delivery of functionality specs according to the additive process within the following document:

Mapping Critical Tolerances to Process Capability

We evaluate these criteria in a feasibility matrix. The criteria are also process-specific. The criteria are derived from the blueprint requirements. The criteria may include ±0.025mm tolerance, which is an indicator criterion in the CNC machining service but is irrelevant in the 3D printing service (±0.2mm). This could be done in terms of critical versus noncritical dimensions.

Quantifying the True Cost of Post-Processing for Accuracy

Our approach models the ancillary processes required for 3D printing parts to provide CNC-quality surface finishes, thus addressing the hidden cost issue. For Ra 0.8μm surface finishes, we provide calculations on the additional time and costs for machining a 3D printing near-net-shape part over machining from solid stock and incorporate it into the overall manufacturing cost analysis.

Implementing Hybrid Manufacturing as a Strategic Solution

As needed, we employ the use of 3D printing in the creation of complex material-saving near net shapes that can then be precisely finished using CNC machining service as needed. This technique also helped our client save 25% on the total cost while minimizing material waste in CNC machining and post-processing of the additively manufactured part.

For this purpose, it is required that you perform an audit of the component's drawing in order to identify universal as well as critical local tolerances. For products that exhibit universal as well as critical tolerances, you can create a hybrid manufacturing plan for prototype production with the 3D printing service for the complex component as well as the functional components done through CNC machining. The methodology used in the RFA has its focus on precision that has technology depth for cost and precision for critical performance.

How Should Process Selection Be Optimized When Delivery Deadlines Are Tight?

Deadlines by their urgent nature undercut all conventional criteria for process choice whereby the weight of costs is emphasized over the factor of speed. There exists a tactical manner in which one can approach those projects involving tight timing in order to ensure the best results for working under time constraint deadlines:

Strategic Process Selection Based on Project Milestones

We itemize the time span for aligning each stage with its optimal process flow. For creating prototypes for validation in 1-3 days, for the process of creating prototypes, we will make use of the 3D printing service. For functional prototypes and faster time-to-market, but without being locked into one process too soon, we will make use of CNC machining service after freezing the design.

Implementing Parallel Processing to Compress Lead Times

To mitigate the difficulty created by the need for sequence bottlenecks, we perform critical path activities concurrently. Where one CNC machining service is programming the last pass, another task may include building the bridge tool and assembling fixtures for the 3D printing service. This method allowed for at-least 30% reduction in delivery time for the 50-piece emergency order.

Leveraging Digital Inventory for Critical Components

As these are urgent and repeat orders, we preroute and keep stock of the standard raw materials/components that are frequently used. A CNC machining service, therefore, need not wait for 2-3 days for material procurement and can thus become a decent option even in high volume production choice, as all that is left is feature machining.

To act, the timeline is to be aligned with the level of completion: apply 3D printing before 72 hours for the first products, then CNC once over 20 products. The interaction with suppliers has to be carried out as soon as possible in order to plan parallel execution. This enables agility in competitive execution.

Figure 3: 3D printing process in action for manufacturing selection by LS Manufacturing

How To Balance Cost And Performance Via Hybrid Manufacturing?

The strategic question of whether to use CNC machining vs 3D printing is one of the false binary dilemmas. Hybrid manufacturing solves this because it involves the strategic integration of both processes into a single component to produce something of value that neither could generate on its own. The document presents the rationale behind integrated manufacturing process selection:

Deconstructing the Component for Strategic Process Allocation

- How we analyze the part: Geometric and functional decomposition is done to determine the regions of applicability for each of the types of technologies.

- Practical application: Conformal cooling channels assigned in an elite mold for 3D printing, while critical sealing/mounting surfaces are taken into account for precision CNC. This hybrid technique allowed for the wynndlad cost, which was 40% lower.

Designing for Hybrid Manufacturing from the Onset

- How we implement DfAM and DFM concurrently: The near net shape is designed with DfAM for 3D printing, with datums and excess material in critical interface areas.

- Outcome achieved: It will provide the geometry needed for further CNC machining to achieve the tolerances of ±0.025mm for a hermetic seal, besides material properties for surface finish value Ra 0.8μm.

Validating Performance and Cost Gains Quantitatively

- How we model the total value: The Total value will be calculated based on the value of Weight Reduction, Performance Improvement and Total costs.

- Data-driven result: Regarding automotive part manufacturing, this methodology made it possible to achieve a weight reduction of up to 25% using organic lattices (3D printed) and strengthened machine points by 20% compared to machine or printed parts at a reduced cost.

Beginning with your hybrid process of manufacuring your part, you will have to analyze your component breakdown based on features, complex features delegated to 3D printing, while functional surfaces will be delegated to CNC machining. The hybrid part will be designed with fixturing features integrated into your part design. This strategic synthesis transcends the standard CNC machining vs 3D printing decision, delivering a superior manufacturing process selection for high-value applications.

How To Control Costs Through Process Optimization In Small-Batch Production?

The small production batch faces some technical cost issues in which scale economy is necessary to ignore. Here, the normal remedy might not be efficient; therefore, process optimization is a great aid in reducing the cost. The discussion below outlines the possibilities to minimize the cost involved in the CNC machining cost and 3D printing cost when the production is below 100 units:

Standardizing Machining Sequences to Slash Setup

To such high costs of initialization, we suggest a library of common machining procedures and tool paths. This allows us to save up to 50% of programming and fixturing time for similar parts, hence lowering the per-batch CNC machining cost and allowing faster turnaround times of 40%.

Implementing Modular Fixturing Systems

Instead of designing fixtures for new work, we are now using a modular grid system incorporating adjustable clamps and locators to allow the same fixtures to be used on a whole series of different projects. Effectively removing the need for fixture design work that is one of the biggest cost drivers for small-batch CNC machining cost.

Leveraging Batch Optimization in Additive Manufacturing

In our efforts to cut down 3D printing cost, we managed to accommodate multiple customer parts in one piece that maximizes the volume of the chamber. The nesting software we use allows us to effectively utilize the volume by compensating for the cost of the machine using the high volume of the parts. Therefore, the customer parts experienced a cost savings of 30% for a job volume ranging from 5-10 pieces.

Regarding cost containment, analyze your processes for CNC setup standardization. Regarding 3D printing, it is absolutely necessary to combine all orders for build volume density. Strategically, this process-driven optimization enables small batch production to be feasible for other strategic alternatives before making a strategic high volume production choice.

Figure 4: Comparing the cost and services of CNC machining and 3D printing by LS Manufacturing

LS Manufacturing: Optimizing Surgical Navigation Stent Production

This case study demonstrates how the critical crossroads presented in LS Manufacturing was overcome by combining both the additive world and the subtractive world to provide a viable solution for the production of medical devices, exemplifying what we do best at a critical crossroads between complex CNC machining and 3D printing:

Client Challenge

The company that developed medical devices required surgical navigation brackets with 200 pieces of Ti-6Al-4V ELI Grade 23 material and ±0.05mm bore tolerances. The price quotation related to the whole process of the 5-axis CNC machining service exceeded the budget margin by 45% but could be provided in just 4 weeks. Meanwhile, on the other side, the whole process of the 3D printing service could not provide sufficient tensile strength and critical surface accuracy as needed.

LS Manufacturing Solution

lattice structure of the component since it will enable optimal support structure design and hence less post-processing. The key locating surfaces and bores will then undergo processing by the 5-axis CNC machine in order to attain the required tolerance of ±0.05mm and Ra of 0.8 μm.

Results and Value

The total cost decreased by 38%, and the lead time was cut from 4 weeks to 12 days. The final weight of the part was reduced by 30%. The time-to-market enlarged by two weeks; however, the margin was enhanced by 22%. This was accomplished while maintaining the surgical precision.

This is reflected in this particular situation where it is clear that in the selection of the manufacture process itself, there is no single way of doing it because it is evident that in looking at the component functional requirement in terms of the integrated hybrid approach of manufacture itself, benefits have been realized in terms of technical market advantages in the medical industry.

Click below to get professional analysis of CNC and 3D printing processes and solve your project problems.

How To Establish A Scientific Manufacturing Process Decision-Making Process?

The elimination of guesswork in the manufacturing process selection is further guaranteed by a systematic way of data analysis. This can be remedied by turning complex terms of part specification into a data scoring system which facilitates the comparison and contrasts of the trade-offs between a CNC machining service and a 3D printing service in terms of:

Deconstructing Requirements into Weighted Parameters

For generic filtering requirements, the project is divided into 12 parametric dimensions, starting with batch size, geometric complexity, tolerance, material, right up to critical tolerance, all of which will be assigned dynamic weights for parameters such as surface finish, for which the importance will be different for, say, a bearing housing compared with a ducting component.

Executing Algorithmic Scenario Analysis

Rather, in our system, comparison is accompanied by simulation processes. The algorithm analyzes hundreds of scenarios related to the production process, calculating the cost required as well as the processing time in terms of mere CNC machining service, mere 3D printing solution, and accordingly, even mixed services between those two production solutions. The algorithm identifies exactly where in between the cost function is intersected, indicating shapes in which there is a cost advantage of between 20% to 40% through this mixed production methodology.

Generating an Actionable Implementation Roadmap

The result will be a complete, detailed protocol, not a guideline. The protocol will determine the order, determine which functions will be done through which method for a hybrid protocol, and establish a phase-gated timeline. The complex procedure of manufacturing process selection will then become a function that is easily actionable, taking much of the overhead out of the project for the customer.

To do this, you have to systematically determine the 12 key attributes for your part, focusing on the aspects of batch size, complexity, and materials, and do a comparison for project time and quality risks using the data. By doing so, you will be able to develop the technical sophistication to make process selection a key differentiator rather than a constraint.

FAQs

1. Where is the cost inflection point between CNC machining and 3D printing typically?

The inflection point in cost for simple components in a structure is attained when they are between 80-150, while in complex structures, this is achieved when they are between 200-300. The structure of costs is based on material complexity and precision estimates.

2. Is 3D printing truly more economical for small-batch production?

Regarding complex components with up to 50 pieces and having a part number, the conclusion is that 3D printing will offer savings as compared to the cost of the mold and will also be 30-50% cheaper compared to CNC machining.

3. How to evaluate the performance differences between the two processes?

The density and isotropy coefficients for the members produced by the CNC process are 100%, while for 3DP, they possess the properties of isotropy, and in reality, the strength coefficients are just 80-95% of forged components.

4. Can 3D printing reduce costs for mass production?

If the batch size goes beyond 5000 units, CNC production experiences economies of scale and the costs will be 40-60% less than 3D printing. 3D printing can be used for small-scale production.

5. How does hybrid manufacturing achieve cost optimization?

3D printing is concerned with complex features, while CNC machining is concerned with critical components. The combination of the preceding two will help reduce the cost by 30-40% as well as improve performance above 20%.

6. How to quickly obtain accurate quotes for two processes?

Materials data, 3D files, batch size, and the level of accuracy required are required. The comparative estimate will be sent to the customer by the LS Manufacturing team in both instances within 2 hours of receiving the details.

7. How does new material development affect process selection?

High-performance composites are suitable for 3D printing, while high conductivity materials will find application in CNC machining. Having appropriate processes for materials requires knowledge of material properties.

8. How to reduce small-batch CNC machining costs?

Through the utilization of standardized processes, modular equipment, and material management, LS Manufacturing is able to reduce small-batch CNC costs by 25-30% and lead times by 35%.

Summary

By scientific process selection value engineering, manufacturing companies can maximize cost, as well as accelerate time-to-market. The decision-making process, developed by LS Manufacturing, with actual values, will be helpful for many customers to achieve cost savings ranging between 25% and 40%.

For customized process solution comparison and proper quotes, you are requested to contact the technical group of LS Manufacturing immediately to avail cost analysis and optimization advice on both options.

Get professional CNC machining and 3D printing process analysis now to accurately solve your project selection problems!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.