Do you worry about machining distortion, asymmetrical tool wear, and unpredictable surface finish when cutting bronze components? The nature of bronze poses advantages along with serious difficulties in CNC cutting. LS Precision Manufacturing, as a hard-to-machine machining leader worldwide, has made bronze CNC machining one of our specialties. Let's dispense with theoretical conjecture and present five key strategies that we've learned from decades of in-shop experience in order to make high-precision bronze machining a success.

Read this article for the hands-on approach you can experiment with. Even better, LS Precision is happy to share the worthwhile experience with you. Send your bronze part drawings now, and our skilled team will provide you with free, special evaluation reporting on a tailored machining plan and cost-saving advice. To save you time, here’s a quick overview of the core conclusions.

Bronze CNC Machining Core Skills Quick Reference

| Key Steps | Core Strategies | Key Points |

| Material Preparation | Source Control | Use low-stress materials like phosphor bronze; stress relieve anneal prior to machining. |

| Tooling Technology | Sharp Cutting | Utilize sharp, positive carbide cutting tools; diamond tools are suitable for good finishes. |

| Cutting Parameters | High speed and moderate amount | Utilize high linear speeds (150-300 m/min) with moderate feed rates to manage cutting heat. |

| Machining Strategies | Sequential stability | Use distinct roughing and finishing operations, and maintain a consistent cutting load direction (e.g., climb milling) to prevent impact. |

| Cooling and Chip Evacuation | Evacuate chips successfully | Low air cooling or lubrication is recommended; ensure adequate chip evacuation with high-pressure air gun to prevent thermal deformation. |

The key to effective bronze part machining is ‘controlling heat and preventing deformation through sharp, light cutting." By systematically applying the above five strategies, cutting forces and heat can be reasonably controlled, fundamentally settling issues of deformation, wear, and surface quality, achieving stable and efficient precision machining.

LS Precision's technical professionals will provide custom process solutions and cost optimization recommendations based on your specific part.

Why Trust This Guide? Practical Experience From LS Experts

With over a decade of experience, LS Precision Manufacturing has conducted numerous tests, optimizations, and mass production confirmations on various bronze materials (ranging from common tin bronze and phosphor bronze to high-strength aluminum bronze). We understand that the challenge of bronze machining typically lies in the details—a small parameter fluctuation or deliberate failure can lead to a total loss of precision for a batch of workpieces.

Overcoming these real challenges, we have developed bronze CNC machining as a fundamental technological pillar, with deep process database covering tool selection, cutting parameters, and deformation control. What we have in common is the underlying reasoning we employ daily on our manufacturing floor to ensure accurate delivery of parts to customers.

For example, the "high line speed" philosophy was the primary solution we used to restore surface microcracks for a high-precision hydraulic component customer; and the "sequential machining" philosophy conveniently enabled an aerospace customer to increase the yield rate of enormous, thin-walled bronze parts from 65% to over 98%. LS Precision believes that the true worth of experience is that it can be duplicated.

Let LS Precision Manufacturing turn experience into value for you. Chances are, we already have the right solution for your problem in machining. Call us today with your drawings and technical specs to experience the difference quality manufacturing makes.

Understanding The "Nature" Of Bronze: Why Is It Both A Promising Mterial And A Challenge?

The art of bronze CNC machining is initially possessing knowledge of the inherent properties of the material. Bronze is not a material but an alloy family. So-called tin bronzes (e.g., QSn6.5-0.1) are used and provide good toughness, while aluminum bronzes (e.g., QAl9-4) provide even higher strength.

Their concurrent high toughness, good thermal conductivity, and medium hardness and strength make them the best materials to be employed to produce wear-resistant components, pressure-bearing components, and intricate parts. The same features directly contribute to some of the issues in bronze machining:

1. High toughness leads to tool sticking, making surface quality difficult to maintain:

Bronze's increased toughness minimizes the tendency for breakage on cutting, but produces smooth, unbreakable chips. Adhering firmly to the tool rake face, a "built-up edge" is developed. In addition to scratching the machined surface, reducing the level of finish, it alters the effective cutting angle of the tool, which renders it worse to cope with vibration and tool wear.

2. Good thermal conductivity but prone to thermal deformation:

Although bronze is a good heat conductor and can quickly draw off heat from the cutting area, inefficient cooling methods due to machining (e.g., providing excessive quantities of coolant for localized high-speed cooling) may create significant temperature gradients in different zones of the workpiece and result in non-homogeneous thermal contraction and expansion.

In thin-walled or complex precision articles, this thermally induced distortion can be adequate enough to generate size variation and redistribute internal stresses within the material after the machining operation is completed, leading to distortion.

3. Moderate strength but prone to work hardening:

It specifically happens in the process of turning aluminum bronze, especially with cutting parameters that are inappropriate, for example, low feeds or worn-out tools. The material surface ends up being over-compressed and plastically deformed, a layer of hardening. This makes it really tough to cut in the subsequent step; the tool suffers a tremendous increase in hardness when it reverses and gets to the same position hence wearing promptly and, in some instances, chipping off.

Successful bronze CNC machining is not a coincidence. It is founded on a deep understanding of the material science. All the following techniques and methods are harmonized to leverage the positives of the material and optimize the negatives, translating the material strengths into quality finished goods.

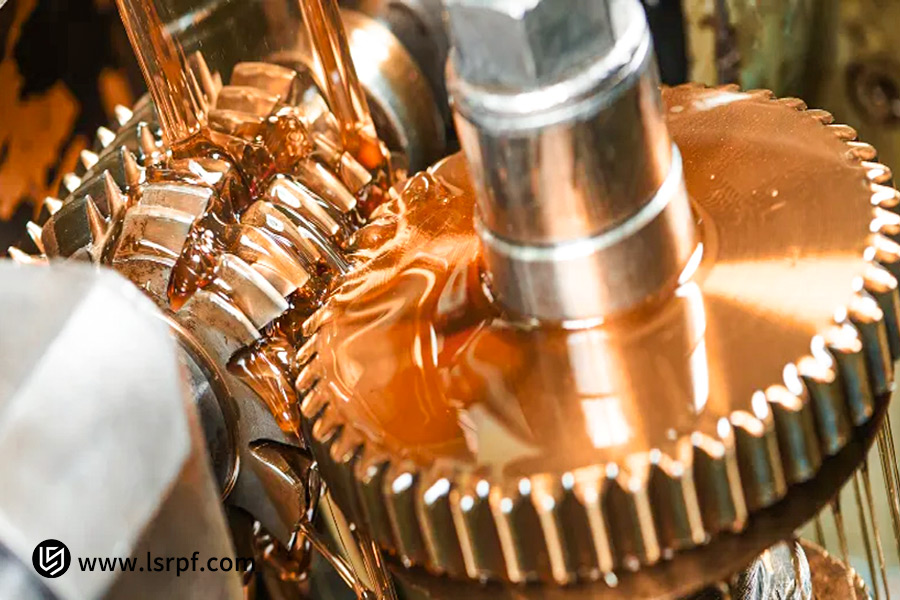

Figure 1: CNC machining precision bronze gears with coolant for marine engineering and industrial applications.

Strategy 1: "Customizing Tools For The Material" To Eliminate Tool Adhesion Wear

In bronze machining, abnormally worn and adhered tools (built-up edge) are the main causes of surface quality deterioration and dimensional loss. LS experience indicates that merely taking "general-purpose" tools is not enough to solve the particular problems of bronze. Success depends on "customizing tools for the material" by exactly matching the tool material and coating with the particular bronze grade and machining behavior.

1. Precise Matching of Tool Material and Coating:

Key Selection: We emphasize fine-grained/ultra-fine-grained carbide substrates that have higher wear resistance and toughness.

Key Coating: Owing to bronze's tendency to adhere, a low-friction, smooth coating is needed. The application of special diamond coatings or smooth TiB2-coated cutting tools prevents successful "cold welding" of chips onto the tool face, promoting smooth gliding away of chips and eliminating almost all built-up edge formation. On highly abrasive materials such as high-silicon aluminum bronze, uncoated sharp diamond tools are at times the only means of producing the finest surface finish.

2. Refined Geometric Design:

- Large Rake Angle (γo > 10°): A steep rake positive rake angle allows the cutting resistance to be minimized considerably, facilitating the easy removal of material instead of compressing it, thus minimizing the cutting heat and work hardening. It plays an important role in obtaining steady cutting parameters of bronze.

- High Relief Angle (αo > 12°): Greater relief angle is sufficient enough to lower the tool flank and machined surface friction to a point where frictional heat generation, which impacts surface quality and promotes excessive wear of the tool, is avoided.

3. Targeted Geometry Optimization:

Optimally designed geometry effectively breaks the ribbon chips into short spiral or C-shaped chips. By utilizing inserts having sharp cutting edges and best chip evacuation, we make sure that chips are curled and shattered rapidly to enable simple discharge from the machining zone. This avoids the long chips curling around the tool or workpiece and getting destroyed, as well as scratching the surface and even resulting in equipment downtime, thereby achieving uninterrupted and safe precision bronze machining.

Optimizing the three factors in harmony, LS Precision transforms cutting tools from "consumables" to stable and reliable "solutions" and offers a sound foundation for optimizing subsequent cutting parameters and achieving efficient high-quality machining.

Figure 2: CNC machining precision bronze components for marine engineering and corrosion-resistant industrial applications.

Strategy 2: Optimizing Cutting Parameters And Paths, Balancing Efficiency And Precision

With the success of the concept of "applying cutting tools to the material," a proven set of bronze cutting parameters and judicious machining paths becomes the most important ingredient in realizing the potential of the tool and producing high-quality output. We at LS Precision avoid traditional parameter settings and adopt instead a dynamic strategy with the focal point of "thermal management" and "force control." This is the nature of our bronze CNC machining services and ensuring the consistent delivery of high-quality outcomes.

1. Adopting a "High Speed, Moderate Feed" Strategy to Achieve "Cold Cutting":

- High linear velocity (Vc = 150-300 m/min): Take advantage of bronze's satisfactory thermal conductivity, with high cutting rates fully utilizing chip travel and allowing increased heat dissipation by the rapid-moving chips instead of jamming in the workpiece or the tool. This readily regulates temperature rise of the workpiece as well as warms distortion. This is the secret of so-called "cold cutting."

- Moderate feed rate (fz = 0.05-0.15 mm/tooth): Too low a feed rate will make the tool rub against the work-hardened layer rather than cut it, and this will lead to undue wear. Our suggested moderate feed rate causes the tool edge to "bite" into the work, giving a satisfactory shearing action, providing efficiency and good surface finish.

2. Utilize a "small depth of cut" for finishing to ensure final dimensions and surface quality:

In finishing, LS Precision uses a small depth of cut (for example, 0.1-0.3 mm), yet makes it greater than the hardened layer thickness formed as a result of previous machining. It decreases cutting forces, eliminates deflection and tool chatter, and thus provides uniform final dimensional accuracy and mirror finish.

3. Advanced CAM programming strategies for intelligently controlling cutting loads:

At the time of programming, LS Precision uses most efficient methods such as trochoidal milling and dynamic milling. These toolpaths maintain uniform low radial contact without generating sudden force spikes and heat generation due to full engagement. This not only protects the tool and prolongs tooling life, but also makes cutting forces more stable, making it feasible to process thin-walled complex and easily deformed parts, and delivers a common improvement in the reliability and quality of bronze CNC processing services.

By synchronized path and parameter optimization, LS Precision makes bronze machining an optimal and predictable process, opening the door to stable, high-precision, and efficient production.

Strategy 3: Systematically Overcoming Machining Deformation: From Clamping To Cooling

In the LS precision bronze machining deformation control system, optimizing one step alone is not always enough. Deformation is the cumulative effect of force, material, and heat. It is for this reason that LS Precision has architected an end-to-end prevention and control system, from clamping to programming to cooling, to meet this fundamental challenge in a comprehensive manner.

1. Source Control: Utilizing Specialized Low-Stress Tooling

For annular, thin-walled, and deformation-critical components, we dispense with general-purpose fixtures and substitute custom flexible tooling (i.e., resin fixtures and liquid plastic mandrels) with a corresponding part shape. This concept converts localized clamping force into a high, spread-out clamping force that reduces localized clamping stress to a minimum and eliminates deformation at the source.

2. Process Management: Programming Strategies to Balance Internal Stress

Symmetrical Machining: In the programming step, on symmetrical structure members, we set tool paths either in a symmetrical or alternate pattern. It enables symmetrical release and re-redistribution of internal residual stresses in the removal of material, thus cancelling one another and preventing stress imbalances causing part warpage.

3. Temperature Control Guarantee: Selecting an Appropriate Cooling Method

Cooling method selection determines workpiece thermal deformation directly. The comparison of two commonly applied methods that are decision points to control deformation in machining bronzes effectively is as follows.

| Cooling Method | Core Principle | Applicable Scenarios and Advantages |

| Minimum Quantity Lubrication (MQL) | It provides an incredibly small but precise quantity of oil mist, used primarily for lubrication, to reduce friction heat, and to provide assistance in chip evacuation. | It is used in nearly all uses of bronze machining deformation control. It does not have the inhomogeneous distributed cooling property of liquid cooling and the chips are dry and less difficult to deal with. |

| High-Pressure Air Cooling | It involves room-temperature compressed air applied directly in the cutting area, with cooling and aggressive chip evacuation provided. | Tin bronze, with its high thermal conductivity, is especially suited to this. Near-isothermal machining is likely the easiest and most elegant way of keeping temperature deformation under control. |

Successful bronze machining deformation control is a discipline with integration of low-stress tooling, equilibrium machining path, and adequate temperature control practices to create stable and precise parts under various complicated working conditions.

Strategy 4: Decisive Details--Critical Inter-Process Treatments

In LS Precision, we are firmly convinced that final success or failure in precision bronze machining very much relies on meticulous attention to detail, beyond and above the basic processes. These time-consuming processes in each step of the process are the key to the superior performance and long-lasting reliability of LS Precision parts.

1. Critical Stress Relief Annealing: Proactively Releasing Intrinsic Stress

For geometries that are complicated and have large machining allowances, we do not blindly execute continuous machining. Rather, we specifically do a stress relief annealing operation after rough machining. This low-temperature heat treating efficiently and uniformly relieves most of the residual stress induced by rough machining.

Although this process might appear to be an unnecessary process, it's actually trading time for quality, giving a dimensionally stable, "neutral" blank to downstream finish. It is an essential solution to the recurring issue of deformation upon natural storage when machining.

2. Predictive Edge Treatment: Eliminate Cracks and Stress Concentrations at the Source

When we program at programming time, we pre-negotiate all the sharp edges of an object (internal cavities, external surface) and play by some edge chamfering or rounding conventions. It's not just a drawing but also a formerly required process requirement.

A mild chamfer reduces the stress concentration very effectively, hence avoiding cracks or deformation at acute corners at the time of loading or during the subsequent handling, thus improving the structural integrity and fatigue life of the product.

3. Strict Cleaning and Isolation Processes: Protecting Material Purity

Within LS Precision plants, we conduct cleaning and isolation procedures stringently. Bronze parts, particularly high-conductivity copper, must be isolated from metal shavings such as steel and aluminum alloys during turning and turnover.

LS Precision work in separate workstations and equipment, and after critical processes, dry clean meticulously with a high-pressure air gun and specific cleaning agents in an attempt to prevent surface electrochemical corrosion (galvanic corrosion) from contamination by dissimilar metals and part cleanliness and finish surface quality.

These seemingly additional steps all add up to LS Precision's quality moat that sets it apart from other precision bronze machining manufacturers, the end result of which is that each part shipped has inherent stability and higher quality.

Figure 3: Displaying precision bronze components for custom bronze CNC machining and industrial applications.

Strategy 5: Establishing A Full-Process Quality Monitoring System

The first four methods guarantee process correctness. But to convert high-quality CNC-machined bronze parts from "samples" to a consistent stream of "products," there needs to be a rigorous, traceable, and end-to-end quality monitoring system. LS has data-driven closed-loop control, which guarantees high consistency in each batch of shipped parts.

1. Online Measurement and Real-Time Feedback:

LS Precision uses touch-trigger probes and laser tool setters extensively on its machining centers. Workpiece datum features or critical dimensions are automatically measured online after critical processes are completed by the probes. Secondary clamping error is removed along with real-time feedback to the CNC system. In case of dimensional drift, the system will automatically compute tool compensation or provide an alarm so that the machining process can be corrected in real time.

2. First-article Inspection and Intelligent Comparison:

LS Precision employ a coordinate measuring machine (CMM) for thorough first-article inspection and obtain full geometric profile information. With intelligent comparison with the digital 3D model, we can confirm machining process integrity and process plans in early mass production without batch-specific quality risks.

3. SPC Statistical Process Control:

To enable mass production, LS Precision Manufacturing uses SPC statistical process control. This technique of gathering measurement data systematically on critical dimensions and establishing control charts. This enables our quality engineers to detect with ease normal and abnormal trends during production and thus move from "post-inspection" to "pre-emptive prevention" and ensure long-term stable and reliable production.

This comprehensive monitoring program transforms our manual experience in bronze CNC machining into a system- and data-based guarantee. It is not a tool for inspection; it is the foundation guarantee for our ongoing process improvement and zero-defect objective.

Case Study: LS Solves The Problem Of Aluminum-Bronze Internal Threads On High-Pressure Hydraulic Valve Manifolds

This LS precision bronze machining example case study is the best example of how, when faced with challenging machining problems, we create winning value for our customers with methodical assessment and professional bronze CNC machining solutions.

1. Customer Pain Point:

A customer's high-pressure hydraulic valve manifold was made from high-strength aluminum-bronze (QAl9-4). Machining deep-hole internal M36x2 threads, they faced a monolithic problem: thread surface roughness consistently fell short of design specifications, and taps often chipped and wore unevenly. This had a 30% first-article scrap rate, massive backlogs in the production line, and massive pressure on project delivery schedules.

2. LS Precision's Solution:

Faced with this problem, the LS team didn't just try and hit harder. We recognized the problem as a system cause of material stickiness, poor chip evacuation, and poor heat management. From that, we provided a complete custom bronze CNC machining solution:

- Tool Innovation: The conventional taps were replaced by single-task thread milling cutters. We re-designed the micro-geometry of the tool and coated it with extremely slippery diamond, effectively reducing material adhesion by a considerable amount. We also improved the chip flute area to ensure longer chip evacuation smoothness.

- Parameter and Cooling Optimization: Focusing on aluminum-bronze characteristics, we established a higher cutting speed and stepped milling depth strategy. We also tightly raised the internal cooling pressure and flow through the toolholder center to provide sufficient cooling and cleaning in the cutting zone.

- Process Strategy Enhancement: We enhanced from one-shot to layered milling strategy. This minimizes cutting load per cutting edge, optimizes the cutting forces and heat, and leaves more room for chip evacuation.

3. Results and Value:

With the implementation of this solution, the output was instantaneous:

- Quality Improvement: Thread surface roughness well surpassed customer drawing specifications, with the attainment of a mirror finish of Ra < 0.8μm.

- Efficiency and Cost: The tool life in the current process was more than five times the life of the previous process; thus, tool change downtime and tool use were minimized immensely.

- Basic Solution: The product qualification rates have consistently risen from 70% to over 99.8%, suggesting that the client was able to deliver the project within time and with minimum chances of major default.

The success of this LS Precision bronze machined project not only prevented the client from having to suffer huge losses, but also, through its exceptional reliability, had us appointed as a long-term strategic bronze parts supplier of their main hydraulic components.

Figure 4: Showcasing precision bronze components for advanced machining techniques and deformation control applications.

Choosing LS Precision: Beyond The Part's Value

When you choose the bronze CNC machining services of LS Precision, you receive so much more than a precision bronze parts. We are committed to being your manufacturing partner by offering a full range of value-added services to ensure your project’s success in cost, efficiency, and risk management.

1. Design for Manufacturability (DFM) Support:

Before ordering, our engineering team at LS Precision will offer a professional review of custom bronze CNC machining designs. We can help guide you to optimize the usage of material efficiently, streamline manufacturing process, and eliminate potential quality risks right from the start in pursuit of the lowest overall cost.

2. Stable Supply Chain and Committed On-Time Delivery:

We know how essential on-time delivery is for your projects. LS Precision has an extensive material management system and lean production planning system, strategically holding inventory of key raw materials so that your bronze CNC machining service orders are not delayed by lack of materials. Our estimated delivery date is our firm commitment.

3. Comprehensive Quality Documentation Package:

Every lot of products produced at LS Precision is accompanied by a full quality documentation package, which can be included in such things as first article inspection reports, full-dimensional inspection reports, material certification, and so on. Apart from reflecting our faith in the products, it offers full documentary evidence of product certification, traceability, and quality assurance with an underlying tone that shows faith in your market competition.

Let's Start a Partnership: Contact LS Precision today and enjoy a genuine worry-free, reliable, and value-added custom bronze CNC machining relationship.

FAQs

1. When machining different bronze grades (e.g., tin bronze vs. aluminum bronze), do parameters require significant adjustments?

Yes, some of them must change. Aluminum bronze, for instance, possesses much greater strength and hardness than tin bronze and has a greater tendency to work harden. Therefore, machining requires more wear-resistant tool coatings (such as diamond coatings) and high-precision line speed and feed rate reductions to respond to cutting forces and heat. LS Precision has created a large parameter library for all significant grades, and so we can provide you with the optimal machining solution for your specific material.

2. Can you guarantee stringent tolerances (such as IT7)?

Yes, we are provided with foreign-imported precision five-axis machining centers and perform high-precision machining in a cleanroom with temperature control and humidity control. With complete-process temperature control and online testing and compensation technology, LS Precision can mass-produce uniform extreme tolerances of IT7 and above in precision bronze machining, and provide full dimensional inspection reports for confirmation.

3. What are the differences in pricing strategies for small-batch prototypes and large-scale production?

LS Precision's cost model is flexible and highly customer-focused. For prototypes, we acknowledge the proof requirements and offer competitive unit prices so that your innovation is possible. Process efficiency and bulk manufacturing will significantly reduce unit costs through mass production. LS Precision is committed to offering you the optimal combined cost solution for the full product lifecycle with tailored bronze CNC machining services.

4. How long does it take from inquiry to quote?

LS Precision Manufacturing can respond promptly. For standard bronze parts with defined structures, we promise to return a clear quote in under 4 hours after we receive the drawings. For complex structures or special orders, our process engineers would aggressively work with you on details in under 8 hours to clearly understand what you want before setting up a clear quote and preliminary manufacturability design recommendations, saving you time.

Let LS Precision's Bronze Machining Experts Safeguard Your Project

For the bronze machining industry, choosing a partner is in reality choosing risk management. A seasoned bronze machining expert who knows the business from the inside out, LS Precision not only has the capability to supply competent parts but also end-to-end solutions for hard-to-machine materials, such as process design, production execution, and quality control.

Let LS Precision Manufacturing translate its knowledge into assurance of production, allowing you to properly manage the risks of your projects and ensuring a successful first-time machining process.

Summary

Unveiling the mystery of bronze CNC machining is a material properties understanding combined with a process formalization. The five basic strategies laid out here unveil a recipe for success in machining. Contact LS Precision and submit your drawings today. LS Precision bronze machining specialists will give you tailored process recommendation and cost optimization analysis so that your project turns successful right from day one.

Upload your design drawings now and get an instant CNC machining quote ( CNC machining price), let LS be your strong backing in pursuit of ultimate CNC machining precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.