In project development and manufacturing, cost control is often an organization's biggest concern, and part cost definitely figures most prominently in determining overall cost. There are numerous manufacturing methods to select from, so employing a cost-effective process to produce complex, mid-sized aluminum pieces directly affects profitability of the project. Sand casting is an example. While a less thrilling technology, it typically is a "hidden champion" in providing the optimal cost-performance ratio.

For LS Manufacturing, it is decades of sand casting experience and deep knowledge of sand casting field. We not only provide high-quality aluminum castings to customers, but we utilize our know-how and technical expertise to help you maximize the inherent cost advantages of sand casting for return on investment, reducing total project cost in various aspects, including molds, materials, and finishing. To save you time, here’s a quick overview of the core conclusions.

Sand Casting Aluminum Cost Advantages Quick Reference

| Advantage Category | Core Content Description |

| Low Mold Cost | Molds may be of resin or wood material and suitable for rapid design and manufacturing cycles and significantly lower costs than metal molds (e.g., die casting). They particularly fit new product development and low- to medium-volume production. |

| Excellent design flexibility | It enables large size parts with complex structure and random internal cavities to be produced, and different parts can be reasonably combined into a single part reducing subsequent assembly and joining costs. |

| No size limitations | Economical production is possible from one prototype to tens of thousands in batches with a range of cost-effective batch sizes, no minimum order quantity, and little project start-up capital investment. |

| Excellent material utilization | 100% of aluminum scrap from gating system (risers, sprues), etc., can be recycled and re-melted, hence effectively no material loss, hence lowering the cost of material per unit product to zero. |

| Low cost of late-stage costs | Product design cycle changes involve only mold changes regardless of how much better these are than changing high-strength metal molds or fixturing since the latter is much more expensive and time-consuming, thus enabling rapid response. |

Sand casting has a good foundation for saving the total cost of the project with its very low initial mold cost, unequalled design capability, and enormous and flexible batch production sizes. It is particularly well-suited for complex aluminum parts in the prototype or mid-volume application.

Choosing sand casting enables you to start your project with a smaller start-up point and adapt to changes more easily and agilely and thereby realize significant cost savings on your project investment without compromising on quality.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

LS Manufacturing boasts decades of experience on hundreds of successful projects. We understand sand casting's "low cost" does not translate to unrefined processing, but instead is a byproduct of the high level of control of material properties, mold design, and process flow.

For example, LS Manufacturing helped a heavy equipment customer redesign a critical aluminum housing's gating system. There was no strength loss with the improved design but the product yield improved by 15% and the machining time reduced by over 20%, significantly lowering unit cost. This valuable experience with designing with complex structures and addressing mid-volume production issues is the foundation of our expertise.

We're not just providing what we perfect and practice every day in our workshops. With LS Manufacturing, you're not just acquiring a supplier; you're acquiring a partner that completely understands how to create authentic value for you through sand casting.

Why Are Sand Casting Tooling Costs Significantly Lower Than Other Casting Processes?

Comparison with other casting processes reveals that tooling cost is among the primary motivations for initial cost. Clients looking to get the cheapest price in sand casting must understand what tooling cost includes. Compared to investment casting and die casting, with significantly higher tooling costs, sand casting tooling costs are significantly lower and ideal for low- to mid-range production and R&D. Below is an extensive comparison:

| Process Type | Typical Tooling Material | Tooling Cost | Production Cycle |

| Sand Casting | Wood, Resin, or Low-Cost Metal | Low | Short (Days to Weeks) |

| Die Casting | High-strength mold steel | Very High | Long (Months) |

| Investment Casting | Fusible Mold + Ceramic Shell | Medium (Tooling Charge + Cost Per Shell) | Medium |

And this phenomenal sand casting cost benefit is largely due to three factors:

- Low Cost of Tooling Material: Sand casting molds (patterns) are usually made of wood, resin, or aluminum alloy. The cost of cutting and buying these materials is much less than that for specially heat-treated, high-strength tooling steel used in die casting.

- Short production cycle and reduced labor hours: Less time is required to produce a wood or resin mold compared to carving and heat-treating enormous blocks of steel. This translates to shorter lead time and labor expense, having your project underway sooner.

- No high "spreading" pressure: The enormous die casting mold expenses need to be spread across hundreds of thousands of products to be economical. Sand casting custom shatters this. Its low-cost molds enable it to be excellent per unit economically even for quantities in the hundreds or thousands.

By chosing custom sand casting, you're not only paying for the final product, but also reducing the initial investment and capital risk of the project at a lesser cost. Such an advantage cannot be matched, especially in the initial stages when there are several iterations of designs.

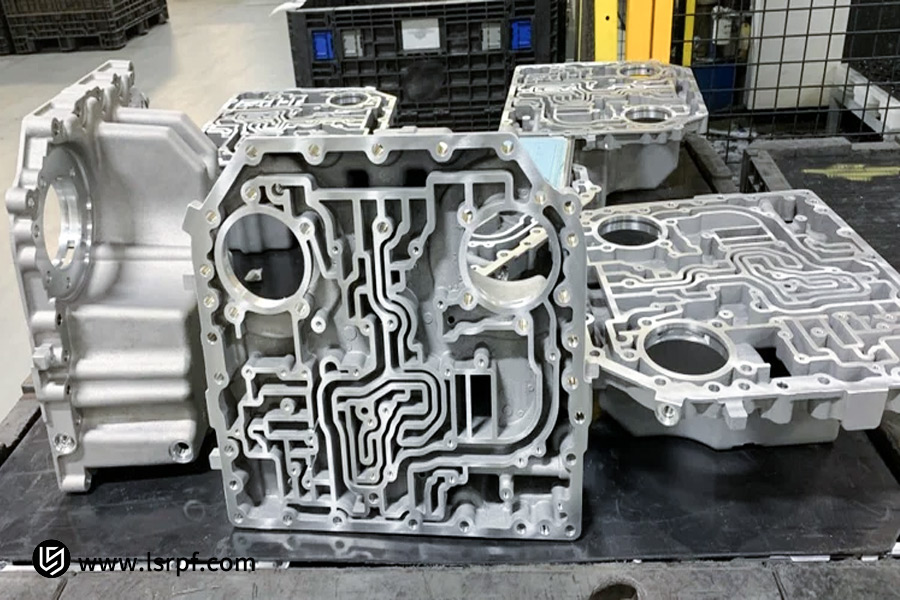

How Does Sand Casting Reduce Processing Costs Through Design Freedom?

Sand casting is appealing not only because of its low-cost molding effectiveness but also because it provides designers immense design freedom, which can significantly reduce or even eliminate unnecessary secondary processing costs. The advantage of a properly designed cast sand component is that it can be "cast, not machined." Without exception, the cost benefit is achieved primarily by the following processes:

1. Molding complex structures in one go, reducing machining steps:

Sand casting has no problem at all fitting in complex internal flow passages, cooling structures, or undercuts in the part design. Conventionally, machining such details from bar stock involves removal of way too much material, taking enormous quantities of time and material. Custom sand casting enables such details to be cast in one process with minimal finishing, saving enormous machine time and tool life.

2. Consolidating multiple parts, eliminating assembly costs:

This is one of the strongest cost advantages. As an example, a structural element originally made up of several steel plates welded or bolted together can be redesigned and cast as a complete single sand-cast piece. This eliminates the labor, time, and material of welding and assembly and the reinforcement of the part's integrity and structure toughness.

3. Near-Net-Shape Casting, Minimizing Material Waste:

With thoughtful mold design, sand casting can produce parts nearly their final size—so-called "near-net-shape" parts. That is, further machining requires small allowances and aluminum scrap and future processing time are minimized.

4. LS Manufacturing Case Study:

LS Manufacturing helped a customer redesign an aluminum bracket consisting of three separate machined components into a single sand-cast component. Not only did this eliminate the process of assembly, but it reduced the overall cost to produce the part by approximately 30%.

The choice of custom sand casting is not necessarily choosing a casting process; it's an upfront investment decision for the aim of achieving maximum product design optimization and cost reduction and efficiency gains.

Which Aluminum Alloy Options Are Most Cost-Effective?

When selecting the optimum sand casting aluminum alloy for a given application, one's objective is not to get the best grade but to attain the optimum cost-to-performance ratio and meet the design specifications. The acoustic filling characteristics of the sand casting process render its fluidity demands reasonably forgiving, with plenty of scope for optimization. Some of the most common and economical aluminum alloys applied to sand casting are the following:

1. A356 Alloy:

A356 is the most common and utilized sand casting material. It has high castability as well as mechanical properties, particularly if it is heat treated to T6. This greatly enhances its strength, toughness, and corrosion resistance. For components that will have high structural integrity and reliability, such as chassis components and brackets, A356 has excellent properties at a reasonable price.

2. A380/383 Alloy:

When you need to cast complex, thin-section parts, A380 and its variant A383 are extremely cost-effective options. The alloys have excellent fluidity, hot cracking resistance, and low shrinkage, which significantly increase casting success and reduce scrap rates. While its mechanical strength and ductility are even slightly lower than A356, its lower unit cost and higher yield offer better overall economics for many non-load-carrying or general structure components.

3. LS Manufacturing's Cost Savings Recommendations:

Our specialty is leveraging our extensive materials science knowledge to facilitate you in making wise choices. For example, to have a housing subjected to only very small impact loads, specing A380 aluminum alloys can be more than 15% less costly in materials than specing A356, with further smoother production.

LS Manufacturing is dedicated to bringing about a full knowledge of your application to suggest the sand casting aluminum that optimizes your project's overall cost the best.

Why Is Sand Casting Particularly Suitable For Large-Scale Production Of Medium To Large-Sized Parts?

When it comes to large and medium-sized aluminum parts in projects and need to be manufactured in hundreds or thousands of pieces, sand casting is unsurpassable from an economic point of view. In sand casting use cases such as large frames, gear houses, or equipment bases, sand casting provides an extremely effective means of achieving cost savings on an economical scale. Such economies of scale are primarily due to the following:

1. Nearly unlimited molding capacity:

Compared to all other casting processes, sand casting has tremendous flexibility when it comes to size of the part. It might be from a large structural piece weighing several hundred kilograms to a complex part occupying more than a meter of floor space; special sand casting can easily accommodate these requirements by creating the respective sand box and mold. This natural facility is a highly desirable feature when undertaking large jobs.

2. Molding costs are quickly amortized:

While molds are required for manufacture, initial investment in sand casting is far lower than for processes like die casting. Magnified, this initial cost of the permanent mold gets distributed among hundreds or thousands of parts cast in sand. At higher volume, the cost of the mold per piece becomes irrelevant, far reducing overall cost per piece.

3. Efficient replication with a stable process:

Once the mold has been created and the parameters of its casting process (e.g., pouring temperature and cooling time) optimized and established, sand casting enters the domain of stable and efficient replication. This is maintaining a very stable production rhythm and volume from the initial part to the 1,000th. Such reliability is needed for control of total cost and lead times in high-volume manufacturing.

Choosing custom sand casting for large parts allows access to volume production with low up-front investment. With increasing batch sizes, cost-per-part efficiency benefits become increasingly important, making it an assured method of achieving project size and maximizing cost-effectiveness.

How Can We Further Unlock The Cost-Saving Potential Of Sand Casting Through Design Optimization (DFM)?

Excellent custom sand casting production is not just accurate duplicate drawing-production; it's also about preventing unnecessary costs at the outset by design optimization first. Well-thought-out DFM (design for manufacturing) can minimize potential defects and waste and optimize the end cost of sand casting directly. Some of the most critical, actionable DFM techniques are:

1. Properly setting draft angles to save post-processing time:

Correct draft angles on planes perpendicular to the parting plane are absolutely vital for easy demolding of the casting. A perfect draft angle reduces the frictional contact between the mold and the casting significantly, reducing by far the level of subsequent grinding and finishing work, saving directly labor expenses

2. Maintaining uniform wall thickness fundamentally improves yield:

Non-uniform wall thickness creates non-uniform cooling rates, which will easily lead to casting defects such as hot cracking and shrinkage cavities. With uniform wall thickness design and utilization of ribs rather than merely thickening for the sake of strength requirements, scrap can be reduced significantly. Every sand-cast part brought out to quality in one pass is a significant cost reduction in material as well as time.

3. Collaboratively optimize the gating and riser system to maximize material utilization:

Gating system configuration and risers directly affect the filling order and effectiveness of shrinkage-feeding of the molten metal. Simulation analysis of your 3D part model, which our engineers use, is applied to optimize its configuration to attain a solid, dense casting with less metal usage, thereby reducing material utilization and unit material cost.

At LS Manufacturing, we believe this is a key aspect of our relationship. We provide a free Design for Material Function (DFM) analysis with every customer, applying our knowledge to your design procedure.

Not only does this help you to prevent potential production hazards, but it also allows us to scrutinize every single detail, collaborating to tap the full potential of sand casting pricing and achieving absolute cost optimization.

Can "Online Quote" Accurately Assess The True Cost Of A Sand Casting Project?

If you use our web-hosted sand casting service to request a quote, you will typically receive a preliminary estimate based on weight and basic parameters. While this can be helpful as an initial budgeting tool, its limitations must be realized. A real sand casting cost is far more than "price per kilogram"; it is strongly influenced by design and process details. The deficiencies of online resources are primarily in these ways:

1. Design optimization potential is not accounted for:

The post-processing time (i.e., material used and yield) and expenditures of an unoptimized design and an optimized design that has undergone DFM analysis can differ dramatically. No web-based system can analyze the manufacturability of your design, the largest unknown affecting the final cost.

2. Special post-processing requirements are easily overlooked:

Does it require a T6 heat treatment for strength? Does it require a specific paint or anodizing process? Such critical post-process operations are high-ticket items, but they are often omitted or as an add-on option in bare-bones online RFQs, resulting in the discrepancy between the final quote and the initial quote.

3. Lack of accurate assessment of batch size benefits:

While batch size does impact unit cost, there exists a bandwidth in which it is the most economical. Digital tools struggle with intelligently allocating mold expense and optimizing production processes based on your own distinct batch size and therefore will not hit that optimum.

LS Manufacturing engineers will personally review your drawings and look at the entire process, from mold design and surface finishing to large volume production, to provide a better, more open-ended final quote with accurate cost-saving suggestions.

How Does LS Manufacturing Help Automation Equipment Manufacturers Reduce The Total Cost Of Base Components?

In industrial automation, traditional manufacturing processes for equipment bases are normally a cost and efficiency bottleneck. We show through an example customer case study how we solved this root problem for a customer with custom sand casting.

1. Customer's Dilemma:

A leading industrial automation equipment manufacturer previously used a number of steel plates cut, welded, and machined for the heavy base of its product lead. The labor-intensive process translated to weeks-long production cycles and significant material and labor expenses. Furthermore, the heavy base greatly impacted the mobility and deployment flexibility of the equipment, jeopardizing its market competitiveness.

2. LS Manufacturing's Solution:

Following thorough scrutiny, we proposed the client utilize a sand-cast aluminum high-performance solution. Specifically, we proposed using A356 alloy, which was heat-treated in a T6 to make it stiff and strong. Our engineering department redid the base entirely, combining it from hundreds of welded components into a single continuous fully sand-cast component. This combined cable management system and sensor mounts are biomimetic rib designed, reducing weight while sustaining structure.

3. Value and Results:

The final results were even more superior to what was expected: Relative to the original welded component, the new sand-cast aluminum base saw an incredible 40% weight reduction, significantly improving the device's mobility. From a cost perspective, by process consolidation and improved efficiency, total production costs were reduced by 25%. Furthermore, the production lead time was drastically cut from weeks to a regular 10 working days.

This case significantly enhanced the end-user competitiveness of the customer's product and led to a long-term strategic partnership with LS Manufacturing.

Beyond Price, What Other Long-Term Benefits Does Sand Casting Offer?

In production alternative analysis, merely looking at the initial unit price is short-sighted. Decisive managers should first consider total cost of ownership. The long-term value of sand castings in dependability, adaptability, and supply chain robustness well outweighs their seemingly low cost.

1. Superior reliability significantly reduces after-sales risks:

Sand casting produces dense grain structure and good internal soundness, and sand cast parts have higher impact resistance and fatigue strength. This means core components manufactured using sand casting are less prone to crack or depreciate in the future, reducing after-sales repair rates directly, warranty costs, and customer brand image risks, achieving the goal of "cast once, lasting peace of mind."

2. Inherent flexibility for rapid response to market trends and design iterations:

Product design modification and product improvement are a standard practice in manufacturing. Timeliness and low cost of mold changes in sand casting allow you to refine your products with minimal effort and cycle time. This inherent flexibility allows you to bring improved products to market faster, seizing opportunities – an advantage of strategy far beyond the high-cost, fixed-mold approach.

3. Quality stability ensures a smooth and predictable supply chain:

The basis of supply chain management is production stability. With our state-of-the-art process control and rigorous quality system, we ensure highly consistent performance and dimensions of every batch of sand-cast parts. Reliable quality output prevents production line downtime or assembly hold-ups resulting from component quality, thereby ensuring smooth production flow and timely deliveries.

Choosing sand casting is more than choosing a process; it's choosing a reliable manufacturing partner that can develop your products and evolve to meet future challenges together. Its long-term robustness and flexibility are the bases of cost optimization in a sustainable manner.

What Additional Services Will You Receive By Partnering With LS Manufacturing?

By choosing LS Manufacturing, you are not only getting a casting supplier but so much more. We commit to becoming your extra manufacturing engineering personnel, dedicating ourselves to ensuring your custom sand casting project achieves highest cost, quality, and efficiency through a set of meticulous value-added services.

1. In-depth Design and Engineering Collaboration:

LS Manufacturing offers a complimentary Design for Manufacturability (DFM) review, better than a cursory examination of your plans. Our engineers, who have spent countless hours working in the trenches, actively provide you with solutions to design thinner walls, structure simplification, and better draft. Errors are caught at their beginning, cost is kept to an absolute minimum, and value is added to your project.

2. Professional Material and Process Consultants:

With such a wide variety of aluminum alloy grades and post-processing options at your disposal, you don't have to decide alone. LS Manufacturing is your technical consultant, recommending the best-balanced custom sand casting solution on performance, cost, and delivery schedule basis, depending upon the specified application environment of the component, such that your budget penny is utilized to value value.

3. Integrated Post-Processing and Quality Assurance:

LS Manufacturing provides one-stop shop capabilities from casting to end product. From the necessary T6 heat treatment, precision machining, or surface finishing, we can do them all in-house. Not only do we save the headache of coordinating with multiple parties, but we also cut down on delivery time with our integrated processes. Our stringent end-to-end quality control system ensures that each part shipped meets expectations.

When you order a quote through our web-based sand casting facility, you're becoming part of an all-inclusive partnership. LS Manufacturing is committed to providing transparent pricing, prompt delivery, and superior technical support, giving you peace of mind and cost-effective access to quality castings. We're your reliable, long-term manufacturing ally.

FAQs

1. Can sand-cast aluminum parts meet the strength requirements of structural components?

Yes. Under the conditions of employing high-strength aluminum alloys (e.g., A356 and A357) and a T6 heat treatment (solution treatment + artificial aging), it is feasible to significantly enhance the mechanical properties of sand-cast aluminum parts, including tensile strength over 250 MPa and yield strength over 180 MPa. Their dense inner structure, satisfactory fatigue strength, and toughness meet the high strength and stiffness requirements of industrial machinery structures, load-bearing brackets, and car components.

2. What is the minimum order quantity for sand casting?

LS Manufacturing sand casting offers maximum flexibility, having a minimum order quantity as small as 20-50 pieces, ideal for product development, pilot runs, and medium-volume production. We manage initial investment by maximizing mold solutions (e.g., removable mold cores and resin molds), making the cost even for low-volume orders. In large-volume production (over 1,000 pieces), per-unit cost is further diluted, allowing customers to achieve maximum end-of-life costs.

3. What is the surface finish of sand casting?

Sand-cast aluminum parts have typically an as-cast surface finish of Ra 12.5-25μm with a uniform roughness that is completely acceptable for use and assembly of general industrial parts. If even superior finishes are required, we offer a variety of post-processing techniques: sandblasting can achieve a uniform surface finish of Ra 6.3-12.5μm, polishing can be employed for locally enhanced finishes, and painting, electrophoresis, or powder coating can achieve both appearances and corrosion protection, responding to the range of end product requirements.

4. How long does the entire process take, from inquiry to delivery?

The average project lead time is around 4-6 weeks: 1-2 weeks for mold production and design, one week for first-piece casting and inspection, and 2-3 weeks for mass production and finishing. Expedited delivery within three weeks is available in the event of high priority. Real lead times are precisely scheduled based on part complexity, batch size, and process requirements, and an open production schedule is provided in the quote so that timely and controllable delivery is ensured throughout the manufacturing process.

Summary

Sand cast aluminum offers a unique cost advantage in metal forming by its minimal tooling investment, high design integration capability, versatile and inexpensive material selection, and high economies of scale in medium- to large-batch production. This not only impacts the cost of each part, but highly optimizes the total cost of ownership for your project. Applying this proven and versatile process is a wise move to attaining the optimal solution for your project budget without compromising on quality.

Send your rough sketches or rough drawings to LS Manufacturing today. With a single simple step, our experienced personnel will create a customized Sand Casting Cost Optimization Analysis Report, highlighting the five key areas of potential savings: tooling, material, post-processing, assembly, and overall lead time. Contact LS Manufacturing and let us leverage our on-the-shop-floor expertise to provide you with a foretaste of the actual value proposition!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.