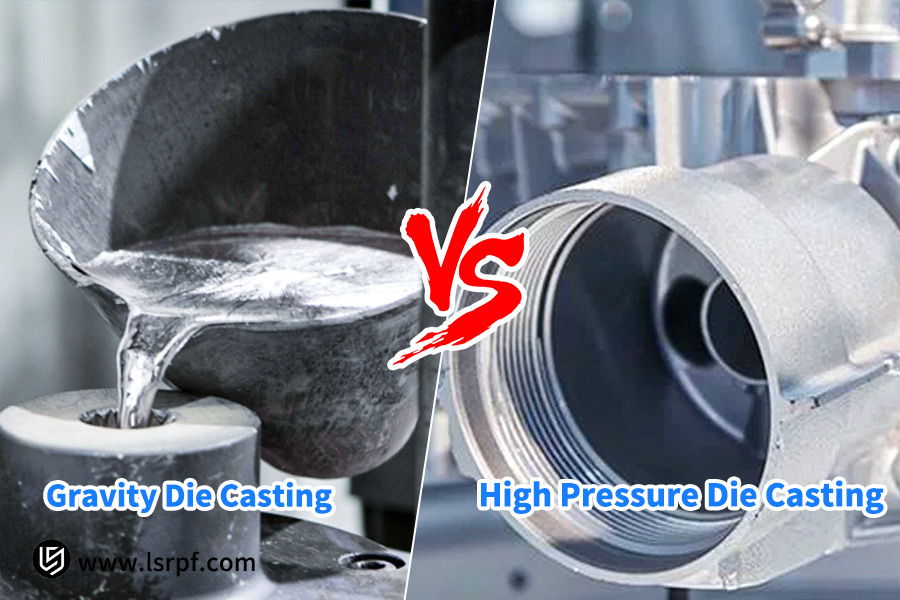

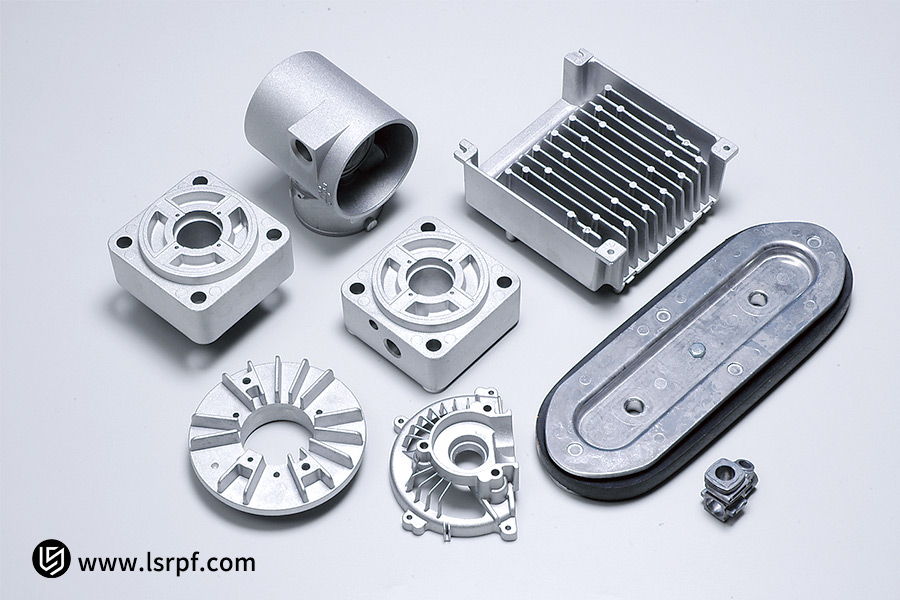

With lightweighting trends dominating the manufacturing landscape, die-casting aluminum alloy is a fundamental process to produce precise, complex parts. High-pressure die-casting and gravity die-casting are two dominant players, although both rate cost and performance equally high, such that compromise becomes decision-makers' choices. High-pressure die-casting offers unparalleled efficiency and is best suited for mass-producing thin-walled components, while gravity die-casting excels with higher density and better heat treatability.

In this situation, choosing an experienced partner is necessary. LS Precision, immersed in its tradition of die-casting know-how, not only boasts strong production power for cutting-edge procedures but also has experience in performing professional examination and specialized solutions. We are committed to helping you achieve the optimum cost-performance with meticulous process matching, where every product is delivered to the superior quality specifications, guaranteeing success in your project and actual cost savings and efficiency gain. To save you time, here is a brief summary of our observations.

High-Pressure Die Casting vs. Gravity Die Casting Process Comparison Quick Reference

| Comparison Items | High-Pressure Die Casting | Gravity Die Casting |

| Core Process Principle | Liquid metal is shot into a steel mold at high speed with extremely high pressure (tens to hundreds of MPa). | Liquid metal fills the mold under gravity. |

| Pressure Source | Injection Mechanism | Gravity |

| Filling Speed | Very rapid (completed within tens of milliseconds) | Relatively slow |

| Production Efficiency | Extremely high, applicable for large-scale automatic manufacturing | Relatively low |

| Product Wall Thickness | Thin-walled, intricate part can be produced. | Relatively thick walls |

| Internal Quality | Prone to porosity, low density, and generally not heat-treatable | Heat-treatable denser structure, for performance improvement |

| Surface Quality | High surface finish, high dimensional accuracy | Good surface quality |

| Cost of Mold | High (the mold has to withstand high pressure and have complicated structures) | Relatively low |

| Cost per Unit | Low (mass production) | Relatively high |

The main difference between gravity die casting and high-pressure die casting is in the formation pressure:

- High-pressure die casting is more efficient and economical and best suited to the mass production of thin-walled components having complex shapes and high surface requirements.

- Gravity die casting is superior in performance and weight characteristics and most suited for the manufacture of thick-walled components with stringent requirements for air-tightness, toughness, and heat treatability.

The advantage of LS Precision is that we have expertise in both processes. We are also able to provide you with expert process selection advice and tailored manufacturing solutions according to your product needs (e.g., output volume, performance specifications, and budget for cost), so you receive the optimal solution without having to make difficult choices between cost and performance.

Why Trust This Guide? Practical Experience From LS Experts

Conclusions made here are not textbook-driven, but by the experience acquired by the LS Precision team on hundreds of real projects. We understand textbook comparisons have a tendency to introduce more problematic trade-offs in actual production. For example, we assisted an auto parts customer whose product must meet extremely stringent requirements for structural strength and cost savings.

After thorough testing, LS Precision not only recommended gravity die casting for optimal performance. Instead, it employed an optimized high-pressure die casting process, combined with proprietary mold design and post-process technology. This not only achieved a 20% reduction in unit cost without compromising mechanical properties at the critical areas but enabled customized capabilities with deep process know-how. This means we can give you advice that is actually actionable.

Every problem we deal with at LS Precision is an individual issue. Not only do we give procedures, but proven solutions too, so every suggestion in this guide can be tested and assured to function.

What Is High-Pressure Die Casting? What Are Its Operating Principles And Characteristics?

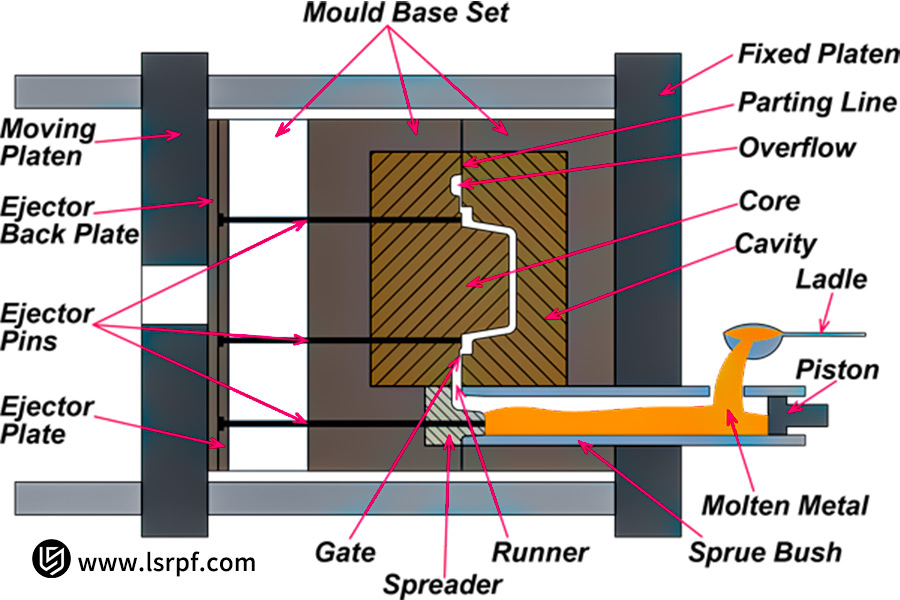

Die casting (or high-pressure die casting) is an advanced technique of metal forming, excellently suited for bulk production of small and precise aluminum alloy parts. In essence, molten metal is supplied in precise mould cavity with high pressure and high speed and rapidly quenched to transfer the shape to the part.

1. High-Pressure Die Casting Principle and Process:

- Mold Closing and Injection: Molten metal is forced into the injection chamber and then injected into the mold cavity under high pressure (tens to hundreds of MPa) in the well-designed mold cavity by the punch.

- Rapid Cooling and Forming: The metal rapidly cools down and solidifies immediately in the mold. Due to the uniform high pressure, the casting is made up of tight structure and sharp boundaries.

- Mold Opening and Ejection: The mold is opened and the ejector mechanism forces out the casting molded, and the cycle is done. The process is highly automated, with very fast cycle times ranging from a few seconds to one minute, to give it a huge advantage in speed of production.

2. Key Features of High-Pressure Die Casting:

- High Precision and High Efficiency: The extremely high rate of production and the level of automation make it highly suitable for bulk production; castings are dimensionally good and have high surface finish, enabling near-net-net shape and reducing further processing.

- Complex and Thin-Wall Ability: High pressure ensures complex, thin-walled cavities are filled with the molten metal to satisfaction, an ability shared by very few other die-casting techniques.

LS Precision has a high-pressure die-casting cell with full automation and real-time monitoring system to ensure stability of every shot and product consistency. This ensures optimal high-pressure die-casting efficiency and precision to satisfy customers' demands for quality solutions in economy.

What Is Gravity Die-Casting? How Does It Work, And What Are Its Applications?

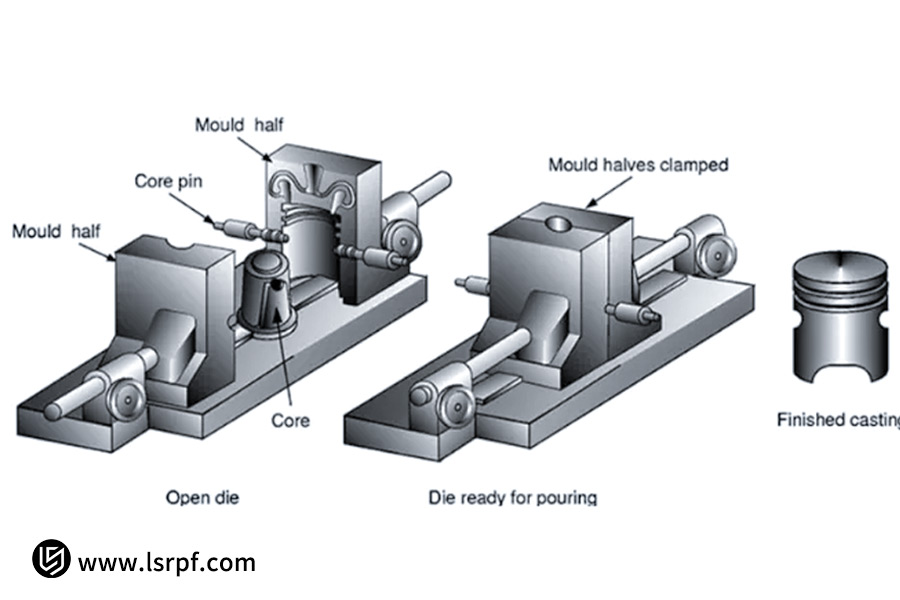

Gravity die casting is a fundamental and metal forming process. In nomenclature, it employs the force of gravity to facilitate the pouring of the molten metal and the filling of mold cavities. As one of the traditional aluminum die-casting processes, it cannot be substituted in certain industries due to its own special capabilities.

1. Gravity Die-Casting Process:

- A precisely measured quantity of molten aluminum alloy is poured into a pouring cup above the mold cavity.

- Gravity allows the molten metal to flow freely and naturally into the mold.

- After the casting has cooled and solidified, the mold is opened and the part is removed. The entire process eliminates the necessity for additional high-pressure shock, thereby keeping the mold structure comparatively simple and reducing the initial investment cost significantly.

2. Compared with high-pressure die casting, the advantages of gravity die casting are:

- Low-cost molds and equipment: It is not a complex process, and equipment and mold material are not highly demanded, thus a more appropriate die casting method for large pieces or small quantities.

- Good internal quality: The metal flows smoothly into the mold cavity and also is gas- and oxide-inclusion-free. The interior of the casting is solid and of low porosity, resulting in good airtightness and mechanical properties. Even heat treatment may be applied to further enhance strength.

Gravity die casting is particularly well suited to those parts with extremely stringent requirements for pressure-bearing strength and mechanical properties and small batch production, i.e., auto structural parts, wheels, or heavy equipment enclosures.

We scientifically select die casting processes based on our customers' parts' basic needs at LS Precision. Where performance requires more focus than maximum efficiency, gravity die casting is our reliable option.

What Are The Core Differences Between High Pressure Die Casting And Gravity Die Casting?

To illustrate the basic differences between gravity die casting and high pressure die casting in terms of a metaphor, high pressure die casting is like a syringe, which employs very high pressure to push the molten metal into the mold with high speed. Gravity die casting is more akin to pouring water from a teapot and relies on the own gravity of the molten metal to flow and naturally fill up into the mold. This simple difference determines their fundamentally opposite technical properties and conditions of use.

Specifically, this fundamental difference is expressed in the following points:

- Pressure and Speed: The key to high-pressure die casting is "high pressure" and "high speed," which creates an instantaneous filling operation and extremely high production efficiency. Gravity die casting is much less stressful with low filling velocities and longer cycle times.

- Product Performance: High-speed filling can trap air inside the part, which, although the surface of the casting is smooth, it is difficult to heat-treat and harden. Gravity die castings have a heavier internal structure, less porosity, and better mechanical properties and heat-treatability.

- Cost Structure: High-pressure die casting requires a high initial investment in molds and equipment but its rapid production rate reduces the cost per part to make it suitable for mass production. Gravity die casting requires lower initial investment but labor cost per part is higher, thus it is best suited for small to medium size runs or large-sized parts.

The entire purpose of comparing this die casting process is a trade-off between performance and efficiency.

As experts in both processes, LS Precision Manufacturing can provide the most impartial die casting method selection based on your product requirements (such as production volume, performance indicators, and budget), ensuring the optimal technical and economic benefits for your project.

Why Is Production Speed The Absolute Advantage Of High-Pressure Die Casting?

Production rate is unquestionably the biggest advantage provided by high-pressure die casting as opposed to other molding technology, having a direct role in its pivotal application in bulk mass production. Such speed advantage is no accident; it is mandated by its own process rules. The secret to its high-speed production is:

1. Extremely short cycle time:

The entire high-pressure die casting process, from mold closing, high-pressure injection (typically completed within tens of milliseconds), rapid cooling, to mold opening and ejection, is highly automatic and smooth. An entire production cycle might only take 30 seconds to 1 minute, so one machine can produce one to two molds per minute or more. In contrast with this, gravity die casting relies on natural flow and solidification of the molten metal and has a very much longer cycle time, typically many minutes or more than ten minutes.

2. High degree of automation and integration:

Modern high-pressure die casters have automated processes such as molten metal charging, mold release spraying, ejecting the part, and cleaning, which provide constant uninterrupted production. Gravity die-casting still employs manual labor in some operations and limits overall cycle time.

LS Precision has a number of high-end, large-capacity high-pressure die-casting machines and is available with efficient automatic production lines. This facilitates speedy response and assured delivery, even for massive orders in the millions, with quality manufacturing support for your business growth.

When choosing a die-casting process, if your product is looking for maximum efficiency and economy of scale, then high-pressure die-casting offers a significant advantage in the speed of production. High efficiency directly translates to lower unit costs and strong market supply.

Performance Showdown: Which Offers Greater Strength And Sealing?

In a contrast between a high-pressure and gravity die-casting performance, each process has its own advantage in mechanical properties and inner quality. These differences stem from the fundamental variations in pressure and speed during casting. The adopted process immediately affects the strength, density, and application level of the end product. The table below is a visual contrast between the two measures of performance at their core:

| Performance Index | High-Pressure Die Casting | Gravity Die Casting |

| Strength and Density | Moderate. May contain minor internal porosity; heat treatment may lead to non-uniformity and limited strengthening. | Excellent. Low surface roughness, high density, and heat treatable, with significant strengthening of strength, hardness, and toughness. |

| Sealing | Good but susceptible to leakage due to internal pores. | Excellent. High density renders it suitable for use in applications demanding high airtightness. |

| Surface Quality and Machinability | High-Pressure Die Casting, due to being pressurized, can replicate highly smooth surfaces of molds to high dimensional tolerances. | Surface finishing of Gravity Die Casting is also good, but its main advantage is its suitability for welding and heat treatment, thus secondary strengthening. |

LS Precision utilizes the latest inspection technology including industrial CT and in-process real-time X-ray imaging technology that allows precise internal density and flaw assessment in castings. This ensures that core product functionality is flawless regardless of the process employed, providing sound data support and quality assurance to your design.

If maximum strength and maximum sealing are the requirement, heat-treatable gravity die casting is the option; if extremely fine detail shapes and an extremely high surface finish smoothness are the requirement, high-Pressure Die Casting is the option.

LS Manufacturing Case Study: How We Optimized Battery Tray Manufacturing For A New Energy Vehicle Client

In manufacturing core parts of new energy vehicles, process selection will have a direct impact on product performance, cost, and market competitiveness. We have also utilized our consulting advantage with the leading new energy vehicle company to create a monumental aluminum alloy battery tray for its next-generation platform. This case study actually reflects LS Precision's advantage in customer-driven solutions.

1. Customer Pain Points:

The most basic need for the client was a structurally completed, over 1.5 meters long battery tray that required extremely tight sealing to prevent moisture and sufficient strength to ensure battery safety. Moreover, with demand in tens of thousands of units every year, cost control and delivery performance were priorities. The client originally favored high-pressure die casting due to its high efficiency.

2. LS Precision's Solution:

Upon thorough scrutiny, the LS engineering staff identified the potential disadvantages of the high-pressure die-casting alternative:

- The enormous anticipated area of the part required gargantuan die-casting equipment, with economically devastating mold investment expense;

- High-rate and high-pressure mold filling easily trapped gas within the product, a challenge to achieve hermeticity required.

LS Precision strongly objected to the proposed solution and proposed another one: gravity casting (metal mold) with T6 heat treatment. We created a sophisticated pouring and venting system to ensure smooth filling of the liquid aluminum and achieve high-density microstructure. The T6 heat treatment significantly enhanced the product's total strength and stiffness.

3. Results:

This solution not only ensured the product met the stringent airtightness and strength test with 100% consistency, but also reduced the total mold and production cost by approximately 30% compared to the initial high-pressure die-casting solution. LS Precision not only successfully saved the customer enormous investment, but also gained the trust of the customer by its consistent quality, having established a long-term strategic partnership.

This example indicates that LS Precision's true value is to provide customers with customized solutions with maximum overall cost and achievable performance, according to its rich experience gained over years. It is a reliable manufacturing partner.

Which Die-Casting Method Should I Choose For My Project?

Don't get bogged down with the question of choosing a die-casting process. You may make an initial judgment upon the following key parameters. This quick guide will help you make an informed decision.

- Yearly Production: In the event your part has gigantic amounts (hundreds of thousands of units, for example) and you wish to have the lowest cost per piece, high-pressure die casting is the way to go. Gravity die casting offers the lower mold cost and greater flexibility in low-volume or high-variety production.

- Part Size and Performance: Thick-wall parts, large parts, or parts with highly demanding requirements for strength, elongation, and tightness (and heat treatment requirements) are better ensured of inherent quality by gravity die casting. High-pressure die casting is best suited for those with thin walls, intricate structure, and high surface finish requirement.

Choose gravity if performance and structural integrity are the top priorities. If the aforementioned concerns still hinder you from making a decision, this is where the worth of LS Precision comes in.

LS Precision not only provides process technology, but even die-casting method selection and expert analysis services. Send us your drawings and product specifications today and we will provide the most price-effective, performance-improved made-to-measure solution.

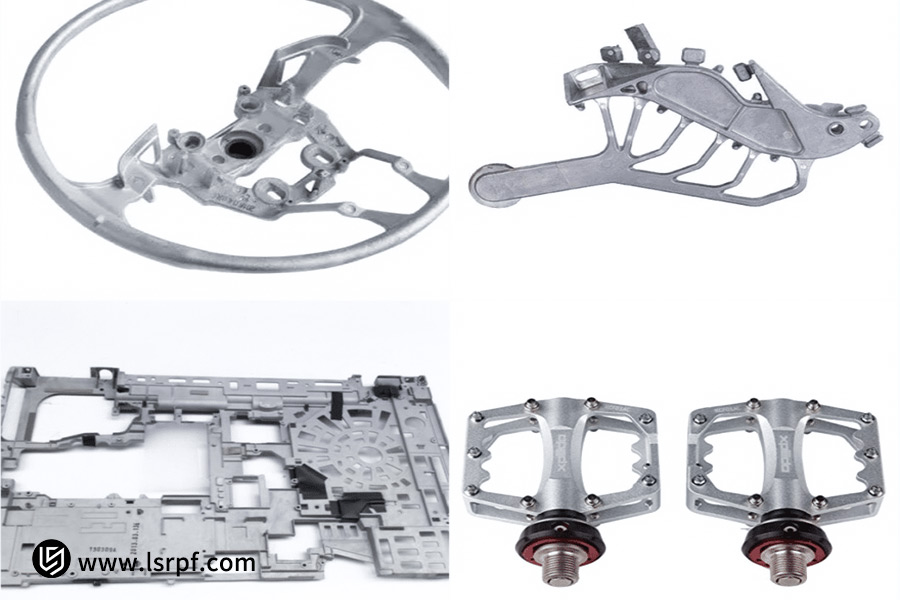

Beyond Process: What Else Can You Receive When You Choose LS Precision Manufacturing?

Choosing LS Precision Manufacturing offers much more than a gravity or high-pressure die casting process solution. Instead, you are given a one-stop solution and genuine partnership for the life of the product. Our value begins the moment you have your drawings. Our principal value-added services are:

1. Proactive Design for Manufacturing (DFM) Analysis:

Before production, our engineering team actively conducts a complete DFM analysis (Design for Manufacturability) and generates optimization recommendations on your product design in advance, eliminating manufacturing risks at their source and reducing costs and increasing efficiency.

2. Comprehensive Back-end Capabilities:

As a precision LS Manufacturing system specialist, we integrate efficient mold manufacturing, precision machining, various surface treatment, and rigorous quality inspection. This means your products get efficiently supplied under the same quality system, with consistent and reliable delivery and overall lead time elimination.

LS Precision Manufacturing is not just a supplier, but a reliable manufacturing partner. We are committed to bringing your concepts to competitive, high-performance products through close interaction so that we both solve future challenges together.

FAQs

1. Why are mold costs higher for high-pressure die casting?

The primary reason why the mold cost is more for high-pressure die casting is the severe working environment. Molds must be constructed from high-strength, high-quality hot-working die steel (e.g., H13 steel) to be able to take thousands of tons of clamping load and thermal cycling without premature cracking. Further, their internal geometry is extremely complex, including high-pressure runner systems, venting grooves, and cooling channels that must be precision machined. This results in an extremely long product development process and extremely high precision demands. All these result in very much higher initial investment than gravity die casting molds.

2. Can gravity die casting produce highly complex parts?

Gravity die casting cannot be utilized for the manufacture of highly complicated parts. Because it capitalizes on natural flow of molten metal through gravity, fluidity and filling capacity are poor, and thus perfect parts with thin walls, deep holes, or complicated inner details are difficult to achieve. Under-run and cold shuts are normal flaws. High-pressure die casting is used where such a need is needed. Its high-speed, high-pressure injection enables immediate filling of complex cavities and precise replication of mold detail.

3. Which process is more suitable for subsequent CNC machining?

Both are suitable, but gravity die casting provides a stronger foundation to CNC machining. Its single-step solidification process creates an even, dense internal structure with very little porosity. This allows uniform application of tool forces during machining, increased tool life, and improved dimension tolerance and surface finish. High-pressure die castings offer a hard surface but can contain very tiny pores beneath the surface. If exposed during machining, it is very easy to ruin the tool or create the workpiece scrap.

4. Can LS Precision provide a complete service package from mold to finished product?

In fact, LS Precision is its core competency in vertically integrated, one-stop shop facility. From the first DFM (Design for Manufacturability) study and mold construction and design, to mid-process die casting manufacturing, to end-stage precision CNC machining, different surface treatments (e.g., anodizing and painting), and comprehensive full-scale inspection, all are performed in-house. Not only does this guarantee controlled quality and shorten delivery lead times, but it also lowers your supply chain management costs significantly.

Summary

The choice between gravity and high-pressure die casting involves a strategic trade-off between cost and quality, as well as between performance and efficiency. High-pressure die casting dominates the high-volume sector due to its high production capacity, yet gravity die casting takes the lead in improved part integrity and mechanical properties. Because it is an expert in both processes, the advantage of LS Precision is that it can break free from the confines of one process and provide you with the most unbiased, custom-fit solutions that suit your project needs best.

Contact LS Precision today and provide your part drawings or 3D files, along with your expected annual production volume and material requirements. Our sales engineers will reply with a full report including a sample process plan and quotation back to you within 24 hours.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com