5-axis automotive manufacturing addresses these two opposing challenges of light weighting and electrification at a very vital junction. More complex and integrated components can, therefore, be made in one machine efficiently to surmount the challenges thrown up by conventional methods. This holds the key to improvement in range for EVs and mileage in automotive.

Whereby the key benefit of sacrificing the inefficiencies of traditional 3-axis machining means a high degree of precision with complex geometry can be achieved in one pass, there is little to no accumulation error, or material wastage of previous multi-fixturing. This is the technology that really lies at the root of being able to produce the necessary complex, high-performance parts for next-gen electric and gas-powered vehicles.

5-Axis Automotive Manufacturing Full Text Quick Reference Table

| Aspect | Details |

| Core Advantages | Either complex machining—this is accomplished in single machine setting. Capable of doing high precision and complex surface creation. The tool angle is optimal. The cutting condition is optimal. Processes and fixturing are greatly reduced. |

| Addressing Pain Points | Shortcomings of Conventional Processes (3-Axis): Multiple setups and the resultant cumulative error are most probable; low material use; low processing efficiency for a complex shape. |

| Lightweighting Applications | Structural parts included in combined chassis and body parts; Lightweight alloy structural parts: aluminum, magnesium; Manufacturing of topology-optimized parts; Thin-wall, geometrically complex reinforced parts. |

| Electrification Applications | Battery box/tray processing, Motor cases/controllers, Components of an electric drive train, Complex channels of fluid flow in a cooling system. |

| Key Benefits | More productive: shorter cycle times; Lighter: increased milage or reduced operating costs; Materials reduced – same cost savings. |

| Success Metrics | More than 70% reduction in processes; Ability to improve machining tolerance to micron order of precision. Material use reduced to index of not less than 30%: Generates parts not producible from existing designs. |

LS Manufacturing with its strengths in 5-axis machining, offers a key solution for the manufacturing challenges that our customers face in their transformation lightweighting and electrification. The company offers solutions for the manufacturing challenges in an effective and precise way by providing solutions in the field of integrated parts manufacturing.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Our knowledge is based upon practical experience rather than theoretical knowledge. In the case study, the task or mission of the LS Manufacturing is not easy each day. For example, they are confronted with the task of machining the high strength alloys used in car parts such as the body and storage batteries. According to the National Association for Surface Finishing (NASF) guidelines concerning the requirements of the surface integrity of the machined part, the specifications are quite demanding.

Specifically in the company we have some level of expertise that has been tested in particular applications. This is because the company is engaged in manufacturing parts that will be used in applications where the strength of the parts is not something that can be negotiated. The parts include those for the use of electric drives. The precision is measured on the scale of the standard of quality set by the International Aerospace Quality Group (IAQG).

Each of tips has sprung from the realities of the current state of production. Whether it is the optimization of the tool motion for cast parts in aluminum or machining of titanium materials, the knowledge acquired has been painfully acquired in the process of the provision of the functional parts. The antecedents are the benefits of our daily struggles to resist the difficulties of quality and quality of efficiency for the realization of the 5-axis automotive manufacturing as realidad.

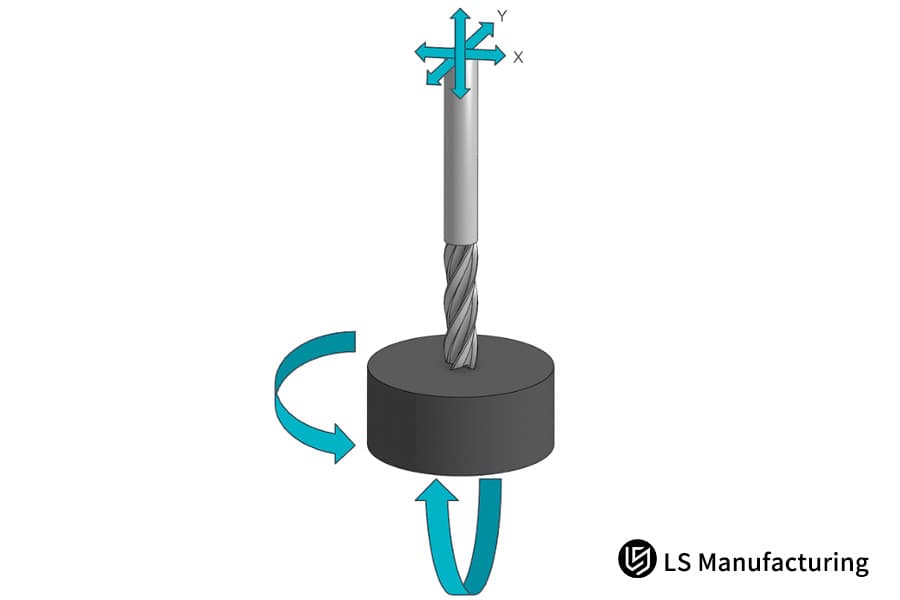

Figure 1: Advanced fabrication of intricate automotive components via 5-axis milling by LS Manufacturing

How Does 5-Axis Machining Enable Complete Automotive Part Production In One Setup?

This document details the implementation of 5-axis automotive manufacturing to solve the core challenge of machining intricate, high-tolerance 5-axis complex parts machining in a single setup. The solution eliminates cumulative errors from multiple fixturing, achieving unprecedented precision and efficiency improvement. The technical approach is as follows:

- Unified Datum Establishment & Process Consolidation: The biggest issue was to combine several machining steps. The answer was to generate one common coordinate system for further machining on the casting. Thus, every other machining path could be calculated in relation to one single, workpiece coordinate system, which allowed accessing every significant surface in one machining step on the 5-axis automotive manufacturing center without reclamping and with prevention of misalignments.

- Dynamic Tool Orientation & Collision Avoidance: While machining deep and angled ports, Agozar had to machine in 5 axes precisely. In our project, CAM software programming was employed to take optimal positions for machining, and due to this, it was possible to rotate the tool during machining to remain in the optimal cutting location. Agozar performed an entire collision check in the virtual environment so that there are no chances of collision during the machining process to shape any form.

- Adaptive Machining & In-Process Verification: To ensure the quality of the processed parts, on-machine probing routines have been integrated. This ensures that the system is able to interrogate key points on the datum and compensate for any variation in stock size post-roughing machining. This ensures key points on bores can be checked in the middle of the process such that modification can be made prior to the end process, and, therefore, the final positional tolerance of ±0.025mm can be achieved.

- Integrated Tool Management & High-Efficiency Milling: We also introduced high pressure coolant and tool sequence strategy in the machine's magazine. This was achievable for stability in deep cavities and carrying out high-efficiency milling strategies with uniform chip loads, thus achieving a 40% reduction in cycle time and an immense improvement in tool life.

This case offers completeness regarding the implementation of technology well beyond the ownership of machines. It also exhibits high skills in process transformation, enhanced CAM programming, along with in-process quality, in overcoming practical restrictions during the time of production. The document serves as a competitive benchmark for achieving holistic efficiency improvement and supreme accuracy in complex parts machining through engineered 5-axis solutions.

What Technical Challenges Does Automotive CNC Machining Face In The Era Of New Energy Vehicles?

The transition to new energy vehicles introduces unprecedented technical challenges in automotive CNC machining. For instance, large components such as large-sized battery trays and deep-cavity motors demand extreme precision on a macro scale. The following report introduces the solution to these unique difficulties in the manufacturing process:

Overcoming Large-Format Distortion for Macro-Precision

Machining of 2000x1500mm battery tray flatness of 0.1mm or better to be achieved in spite of thermal and clamping distortion considerations. The proposed machining approach would include a fixturing system that enables defined equal force distribution in clamping. Most significance would be given to proper sequence of machining in roughing followed by thermal equalization hold in finishing machining stages.

Enabling Stable Deep-Cavity Machining with High D:R Tools

This is because the motor housing having a depth of diameter ratio of 5:1 poses enormous difficulties in tool deflection and chip evacuation. In this regard, we are employing an advanced reach tool featuring an evacuation path for coolant. Regarding machining, we are employing well-balanced trochoidal machining patterns coupled with appropriate depth cuts that ensure favorable radial force factors for both cutter holding and high pressure force for evacuation.

Integrating Volumetric Compensation for Single-Setup Accuracy

In the production process of such huge and complex parts on a single fixture on the 5-axis machine with a 1.5m rotary table, it is necessary to perform compensation for geometric errors on the CNC machine itself. This process is accomplished by volumetic accuracy calibration with a laser tracker, in which all the working area is recorded. This function will be used to perform compensation for geometric errors on the CNC machine.

This methodology demonstrates that advanced automotive CNC machining for new energy vehicles requires engineered process solutions beyond standard capabilities. It provides a competitive technical blueprint focused on distortion control, dynamic tool management, and system-level accuracy compensation to solve the concrete technical challenges of scale, complexity, and precision.

How Can Lightweight Automotive Components Achieve Breakthroughs Through 5-Axis Machining?

The problem in manufacturing advanced and lightweight automotive parts like topologically optimized battery cases consists of machining critical features without distortion, which in turn affects the quality of the manufactured components. The answer to this problem is based on the implementation of technologies that combine:

- Mitigating Thin-Wall Distortion via Predictive Machining Simulation: Deformation is quite probable in walls that are 1.2mm thick. To overcome this problem, we opted to conduct a simulation of machining through finite element analysis. Through simulation, we could predict force values and, therefore, deformation that aided us in modifying machining simulation to ensure that we maintained the tolerance level of ±0.1mm.

- Translating Topology Optimization into Stable Machining Sequences: The resulting shape, having formed via topology optimization, has an organic structure, which is hard to fixture and hard to machine. In our solution, we split the overall process into stages. Firstly, there is a semi-finished part with equal excess material, playing a role in determining the stability of the part. The last step of contouring involves radial engagement milling and climb milling simultaneously to create equal force cuts to secure the walls.

- Integrating Adaptive Toolpaths for Dimensional Compensation: Though simulated, some variation can be introduced by stresses. We, in our process, have an adaptive machine with a closed loop. After semi-finishing, our critical dimensions would be checked by on-machine probing. Therefore, we would be able to produce a final finishing tool path as a means to correct spring-back and drift, so as to ensure no distortion beyond 0.05mm.

Unlike conventional 5-axis machining processes, it can be seen that there is an interface between prediction FEA, process sequencing, and compensation techniques in the current approach. There exists established technological groundwork that makes possible the efficient production of lightweight automotive parts with a complex nature in terms of controlling the manufactured process variables, which will realize the optimal weight reduction and optimal stiffness release potential through topology optimization.

Figure 2: High-accuracy production of detailed electric vehicle components by LS Manufacturing

What 5-Axis Processes Are Needed For Key EV Components?

The EV component manufacturing requires high tolerance levels and thermal stability. The following are the methods that would eliminate the challenges involved in the critical special processes with 5-axis machines and quality control: Available for use in the process of ensuring the seal tightness of the motor and the dimension correctness of the reducer housing:

Guaranteeing Motor Housing Coolant Seal Integrity

The most difficult part was to ensure the leak-tight nature of the seals, particularly with a large number of water jacket areas internally. In order to address the problem, we decided to perform the critical sealing area in one piece with one 5-axis machine move without any joints. Additionally, an in-process inspection was employed that checks the flatness of ≤0.01mm in one shot before unclamping the work pieces.

Maintaining Ultra-Precise Bore Geometry for Reducers

When dealing with reducer housing bearing bores, requiring cylindricity of less than 0.008mm, the significant causes were thermal deflections. A reduction machining operation was conducted in a temperature-controlled environment whose temperatures are set at 20°C ±1°C. This is followed by the thermal stabilization phase after the machining operation. The bore can only be fully finished after the temperature stabilization of the workpiece has been achieved.

Ensuring Process Stability for Volume Production

In order to achieve an average first-pass yield of 99.5%, we implemented a closed-loop, real-time compensation system on each machine. This has resulted in the CMM data, after the process, being used to provide feedback to the machine tool, such that the machine tool parameter was varied based on tool wear/temperature difference.

This is the level of sophistication seen in the integration of processes when precision 5-axis machining, environmental chambers, and metrology have seen a trend wherein they function as part of an integrated systems viewpoint as opposed to being viewed as part of an orchestrated flow related to different processes taken one after another. This is the data-driven way with which we specialize in addressing the specific and tighttolerance levels being asked for by high volume quality EV component manufacturing.

How Can Efficient Automotive Manufacturing Optimize Production Cycles Through 5-Axis Technology?

In the pursuit of high-efficiency automotive manufacturing, optimizing the production cycle is essential. This technical report outlines the impact that the incorporation of modern 5-axis machines has brought about in the production of complex components like the bodies of gearboxes. This technical paper is meant for technical personnel only.

| Aspect | Before Optimization | After 5-Axis Implementation |

| Processing Steps | 28 oil channels machined separately | 28 oil channels completed in one setup |

| Production Cycle Time | 45 minutes |

28 minutes (37.8% reduction) |

| Tool Life Improvement | Baseline | Increased by 30% |

| Spindle Load | Frequently exceeded 90% | Consistently below 80% |

| Operational Stability | Intermittent stops | Enables 24/7 continuous production |

The data has thus proven the fact that the integral process of the 5-axis machining process procedure with the precision process optimization has a deciding impact on the compression of the production cycle. The application of the strategy would consist of the combination of the multi-angle properties in one setting, along with the parameter optimization utilization to ensure that the fact of the spindle loading does not exceed 80%, which would clearly affect the increase of the tools/machine life. The completion of the report offers authentic technical information.

How Does Precision Automotive Machining Ensure Micron-Level Accuracy And Stability?

A micron-level accuracy is required for precision automotive machining. This report explores a way of stability assurance, and delves into methodologies and conditions. It provides technical information that can be used for accomplishing stability and making decisions.

| Control Category | Methodology / Equipment | Target Performance Metric |

| Machine Calibration | Periodic Laser Interferometer | Positioning Accuracy: ±0.003 mm |

| Dynamic Accuracy | Regular Ballbar Testing | Circular Contouring Error: ≤0.008 mm |

| Environmental Control | Climate-Controlled Workshop | Constant Temperature: 20°C ±1°C |

It requires an integrated system to guarantee a certain level of micron-level accuracy. On a stability of results guarantee level, periodic specified laser & ballbar calibrations based on the above-mentioned criteria have to be maintained, together with the specified input data requirement of environmental factors. This technical report provides a technical solution for high-value precision automotive machining processes.

Figure 3: Sophisticated vehicle part fabrication using multi-axis computer-controlled machining by LS Manufacturing

What Special Techniques Are Required For 5-Axis Machining Of Complex Automotive Parts?

Successful 5-axis machining for complex parts must actively engage in handling tool interference, stability, and geometrical accessibility. These are some of the important technical requirements not addressed by the current standard programming approach:

Eliminating Collision Risks Through Digital Twin Verification

The tool holder, spindle, and work part are the critical problem areas in collisions. VERICUT software provides a digital twin of the machine, fixture, and work piece. It runs a simulation of the entire CNC program, and interference detection happens automatically in software, allowing changes to be made offline to program paths and tool holders.

Enabling Access with Optimized Tool Axis Control

For the situation involving complex shapes, a requirement emerges for the dynamic change in the orientation of the cutting tool. For the present case, the emergence and discussion present the idea related to the utilization of the axis vector control for the cutting tool in the context of the CAM system. This would include the dynamic positioning change of the cutting tool, with the cutting angle at the optimal position, without the option for a possible collision, with the cutting tool avoiding all features of the workpiece.

Ensuring Stability with Engineered Tooling Strategies

When we consider the cutting tools of large and thin sizes, we realize that the problems of deflection and chatter marks could pose challenges regarding both the quality and accuracy of the cutting. However, the use of long-reach cutting tools and proper machining paths is essential in this regard. For the purpose of analysis, we provide the use of cutting tools with high L/D ratios and trochoidal machining along with efficient machining.

This approach demonstrates that reliable 5-axis machining for complex parts hinges on a preemptive, digital-first workflow. The core competency is integrating kinematic simulation for collision avoidance, precise tool axis programming, and application-specific toolpath strategies to de-risk the machining of high-value, intricate components, transforming complex technical requirements into predictable outcomes.

How Can Advanced Automotive Manufacturing Achieve Intelligent Upgrades?

The changeover to the advanced automotive manufacturing requires a shift from the reactive to the predictive regime. As a concept, the use of machine data in a predictive manner to optimize operations is really the point of the challenge at hand. It involves the following steps during the data-driven intelligent upgrade process:

Establishing a Comprehensive Data Acquisition Infrastructure

The foundation is implementing an IoT sensors mesh around critical machine tools. The sensors are calibrated to measure operating parameters linked to machine tools. The operating parameters from machines are channeled to a fast network to the central industrial IoT-IIoT platform, creating an unbroken digital fingerprint.

Developing Predictive Models for Critical Consumables

The failure of the tools causes downtime. We start building a history based on sensor data related to actual wear data of the tool. By doing so, we formulate an algorithm based on machine learning techniques based on certain patterns, such as some levels of vibration, which will give us the prediction of the remaining life with ≥85% accuracy, and the preventive changeover of the tool has become the tradition without any shut-downs.

Optimizing Overall Equipment Effectiveness Through Analytics

In order for the OEE to have its greatest worth, we implement the machine information, running time, cycle time, and down time causes in the manufacturing execution system. This enables the analytical part of the system to be informed of the reasons for the loss of efficiencies, and the typical reasons for the loss of efficiencies are long setup times and down times with small loss values. This section maximizes the predictive maintenance activities and improvements for the OEE at an 85% level of efficiency.

This vision outlines the future of the technology that is needed to effectuate the intelligent upgrade. This encompasses building layers of data utilizing sensors, predictive analytics to identify major modes of failure, as well as taking advantage of an analysis of overall equipment effectiveness. It provides a blueprint for achieving a predictive, data-driven manufacturing state, moving beyond basic connectivity to solve tangible availability and performance challenges in advanced automotive manufacturing.

Figure 4: Rapid production of vehicle components using 5-axis computerized machining by LS Manufacturing

What Core Capabilities Are Required For Precision Automotive Parts Manufacturers?

A precision automotive component manufacturer would require the ability to achieve precision measurement at the micrometric level. This itself involves the integration of planning and traceability on the shop floor. The following outlines the essential core capabilities and their implementation:

Front-Loading Quality and Process Development

In order to reduce the risk of downstream activities, we adopt the principle of Advanced Product Quality Planning (APQP), aiming at 30% early launch in the project. This is achieved through the principle of concurrent engineering workshops, critical part characteristics, failure analysis, and control plan development.

Implementing Real-Time In-Process Verification

A brief verification of the finish products is not enough. We close the technology cycle when we check the work in progress on the machining line itself using touch-probe sensors in conjunction with laser systems. This forms a closed-loop process where any variation beyond the specified control limits necessitates a machine adjustment/shutdown because production of non-conforming items is not permitted.

Enabling Full-Lot Traceability for Root Cause Analysis

Rapid isolation means that there is a detection of non-conformance. Rapid isolation or containment has been achieved by the use of an electronic traceability system that assigns an ID to every component, thus making the entire set of manufacturing-related information, for instance, material batch, machine parameter, inspection, operator, among others, be tied to that particular ID for quick isolation of the lot as well as carrying out a root cause analysis.

These activities are interwoven in order to form the modern set of quality tools that the precision automotive component manufacturer should follow. The ability is demonstrated not by the equipment for the machine shop, but by utilizing quality assurance in APQP, by real-time controls in SPC, and by digital traceability.

LS Manufacturing New Energy Vehicle Sector: Integrated Processing Project For Battery Trays

One of the greatest difficulties when machining the new energy vehicles sector, where multi-stage machining methods have remained the convention, is the aim to ensure the leak-tight integrity with accuracy of the large-sized aluminum battery enclosures. Following is the description regarding how machine builder LS Manufacturing overcame the production bottleneck by creating an -axis machining solution:

Client Challenge

The sealing surface of the client battery tray, constructed out of series 6000 aluminum, was required to be: ≤0.1mm flatness. Additionally, as indicated above, there was an accumulated total error of 0.3mm in the previous six steps of the process setup, and this indicated the system leaked by 5%. Furthermore, the cycle time of 8 hours indicated that the production process was in the bottleneck stage, and as such, the production of 50,000 units yearly was jeopardized.

LS Manufacturing Solution

In our case, the overall production system was created on the basis of an integrated manufacturing principle that employed a 5-axis gantry machining center and an individually developed single-setup fixture to facilitate the machining of the entire sealing surfaces, threaded holes, and cooling channels in one clamping operation. High-speed machining methods with spindle speeds of 12,000 rpm and feeds of 15 m/min were adopted.

Results and Value

It thus ensured that the flatness of the sealing surface was 0.08mm, thus reducing the rate of leaks by 0.1%. The production cycle time was reduced to 4.5 hours; thus, it allowed the production target of 50,000 units per annum. It thus ensured that the removal of 100% offline leak testing and rework was done, thus ensuring that the production ramp-up for the customer was done in satisfaction with the precision manufacturing output.

This example proves the capability and competence of LS Manufacturing that can deliver the 5-axis machining solution addressing particular high-value manufacturing challenges. The pace-setting standard addressing the production of large format EV components has been set by the transformation from the inefficient process to the single-setup machining solution.

If you are looking to achieve high-precision machining of automotive components in a single setup, contact us today for a professional assessment of your needs.

FAQs

1. What advantages does 5-axis machining have over three-axis machining in the production of cars?

The machining process of the 5-axis machine can facilitate the processing of the complex curved surface at the same time, and the effects of shortening the clamping time and improving accuracy can be achieved. This can be used for the machining process of the lightweight parts of new energy cars.

2. How can consistency be ensured in the mass production of automotive parts?

By the application of the SPC technology, with critical parameters above CPK = 1.67, the quality of the lots is assured through the calibration of the equipment.

3. What is new energy vehicle component processing?

They must be able to seal well and must be designed to be lightweight and optimal for heat removal to fulfill the requirement of high precision for machining.

4. How long is the Return on Investment for 5-axis machines?

In mass production, the overall production time for automotive parts would generally be 12 to 18 months. This may vary depending on the automotive parts being produced.

5. How to control deformation during the machining of thin-walled parts?

By applying symmetrical machining procedures, optimizing cutting parameters, and making control on the cutting force and thermal deformation, it keeps the value of deformation at 0.1mm constantly.

6. What do I have to do to get certified in the automotive industry?

Certification of the system, according to IATF 16949, and performance testing with regard to the concerned products, is mandatory.

7. What special techniques should be used in 5-axis programming?

It requires optimization of tool axis vectors, collision detection, and machining strategy optimization, and specialized CAM software is needed.

8. How to evaluate a supplier's 5-axis machining capabilities?

Besides, any new source must consider the accuracy of equipment, process experience, and quality systems; the only method that would be able to test capabilities would be trial machining.

Summary

All this is because the 5-axis machining technology has, in fact, ushered in a radical innovation in the automotive industry, specifically in those relating to light weight and electric automobiles. All this has been achieved by technological innovations.

Please contact our technical engineering expert for the development or our free pre-processing analysis necessary for 5-axis automotive parts machining at LS Manufacturing. In return, our experts will analyze your challenges with the specific car part and provide their own solutions.

5-axis technology helps you achieve high-precision manufacturing of automotive components. Contact our experts for a customized solution!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.