CNC milling represents a transformative approach for manufacturers grappling with production inefficiencies, inconsistent part quality, and complex order requirements. Onventional milling relies heavily on CNC technology, which enables digital precision and repeatability.

This systematic analysis explores seven critical distinctions between these methodologies, supported by LS Manufacturing's implementation case studies. The evidence demonstrates CNC's capacity to convert artisan-dependent processes into predictable, automated production lines capable of meeting modern industry's demanding standards for precision, complex geometries, and throughput.

This overview condenses key insights to facilitate informed decision-making regarding milling methodology selection. To save you time, here is a brief overview of the key findings.

Figure 1: Comparison of CNC milling and conventional milling by LS Manufacturing

CNC Milling VS. Conventional Milling: A Quick Reference Table Of 7 Key Differences

| Comparison Dimensions | CNC milling |

Conventional milling |

| Automation level | Program control of automated manufacturing processes | Fully manual operation |

| Machining accuracy | Stable and consistent | The operator's skill level can significantly affect accuracy. |

| Machining of complex parts | Precision machining of complex three-dimensional surfaces is possible. | It is primarily suitable for simple geometric shapes. |

| Production efficiency | Suitable for large-volume continuous automated production | Low production efficiency, relying on individual operation |

| Personnel skill requirements | Requires programming and process planning skills | Depends on operator experience and manual skills |

| Production flexibility | This allows for the fastest possible production switchover through program replacement. | Product transition requires a considerable amount of preparation time. |

| Cost structure | The initial investment is high, but the long-term returns are considerable. | Initial costs are low, but labor costs are high. |

This tutorial will guide you through every important detail. We offer not only an introductory overview of concepts, but also a practical decision-making framework, professional operating guidelines, and real-world case studies from machining workshops. Through systematic comparison, you can make informed choices based on your needs, thereby improving both productivity and processing quality.

Why Trust This Guide? It Comes From The Practical Experience Of Our Experts.

In this age of information overload, articles comparing CNC milling and conventional milling are everywhere. However, the unique value of this guide lies in the fact that all practical experience stems from 15 years of accumulation in our workshop. Our experts are not only theoretically proficient but also experienced practitioners who deal with various materials, tolerances, and complex drawings every day. Here, the success or failure of a part depends on the selection of every machining parameter ; every process optimization embodies the wisdom of actual production.

We understand that choosing the right milling method is crucial. In machining critical components for the aerospace industry , the stability of CNC milling ensures micron-level precision ; in manufacturing complex implants for medical devices , its machining consistency directly impacts product reliability.

To date, we have delivered over 50,000 precision parts and accumulated a rich process database. The conclusions in this guide regarding the seven key differences between the two technologies have been fully validated through thousands of practical operations. This article not only compares technical parameters but also shares the valuable experience we have gained in overcoming various material processing challenges and optimizing production processes.

This article covers topics such as selecting machining methods based on order batches and techniques for setting machining parameters for complex curved surface parts. All content is derived from real-world case studies . The lessons learned and coping strategies we summarize will help you make more informed decisions.

What Are The Fundamental Differences Between CNC Milling And Conventional Milling?

The main difference between CNC milling and conventional milling control lies in the core principle: conventional milling relies on real-time operation using both human brain and hand, while CNC technology is driven by digital programs. This is not merely an innovation in technological approach, but a profound transformation in production thinking. In fact, to deeply understand this, a systematic comparison is needed from the following key dimensions:

| Comparison Dimensions | Conventional milling | CNC milling |

| Control Core | Operator experience and manual skills | Computer programs control the specific implementation process. |

| Accurate guarantee | It is heavily reliant on personnel and has poor stability. | Program-controlled, ensuring stable and reliable accuracy. |

| Automation level | Manual operation, high labor intensity | Highly automated, reducing human intervention |

| Machining of complex parts | Limited to simple geometric shapes | Capable of processing complex surfaces and precision structures |

| Production efficiency | Efficiency varies considerably depending on individual skills. | Standardized production ensures consistently high efficiency. |

| Adaptability | It can handle small batches of simple parts. | For more complex components, different batches are used for processing. |

| Skill Requirements | Requires long-term experience accumulation | Requires programming and process design skills |

Through the above comparative analysis, we can conclude that the essential difference between CNC milling and conventional milling lies in the profound shift in manufacturing from "experience-driven" to "technology-driven." Its advantages are reflected not only in the remarkable improvement of machining accuracy and production efficiency but, more importantly, in the standardization and controllability of the production process. Just by this very difference, CNC technology can better meet the stringent requirements of modern manufacturing for high-quality, high-efficiency, and flexible production.

Figure 2: Metal parts precision machined using CNC technology by LS Manufacturing

Why Can CNC Milling Achieve Such Amazing Precision And Consistency?

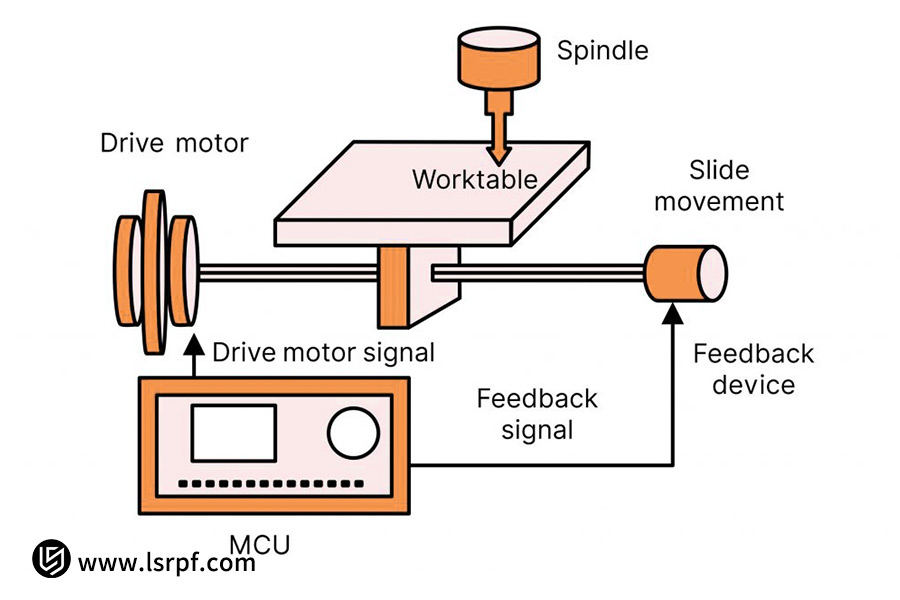

CNC milling achieves a level of precision and consistency unattainable by conventional machining processes. In other words, it's a systemic technological innovation that completely eliminates the uncertainties caused by human factors. This technological advantage is not only reflected in the improved performance of individual machines but also in the construction of integrated precision machining systems . This superior machining performance is particularly based on the following technological foundations:

- Closed-loop control system: It ensures that the tool movement trajectory control reaches the micron level of accuracy, thereby achieving system-level machining accuracy through real-time position feedback and automatic compensation mechanisms during operation .

- Servo drive technology: The combination of high-performance servo motors and precision ball screw drives provides highly accurate and stable motion control during the cutting process , while completely avoiding the uncertainties caused by manual operation.

- Optical grating ruler positioning system: High-resolution optical grating rulers can monitor the processing status in real time and correct micron-level deviations in a timely manner, providing a reliable guarantee for processing accuracy.

- Digital programming control: Scientific machining parameters and optimized toolpaths further ensure dimensional accuracy and significantly improve the surface finish of CNC milling. The combination of these technical elements constitutes the highly advantageous CNC milling system.

Compared to conventional milling, which relies on the individual skills of operators, the standardized process flow and automated precision control under CNC technology can significantly improve machining quality. More importantly, CNC equipment can maintain stable machining accuracy during long-term batch processing, which is the fundamental reason why the surface finish and dimensional consistency of CNC milling are far superior to those of conventional machining.

What Advantages Does CNC Milling Have Over Conventional Methods In Machining Complex Parts?

The significant differences in operation between the two machining methods are particularly evident when processing workpieces with complex geometries. CNC technology, with its unique digital programming capabilities, has completely broken through the technical barriers of conventional machining methods, bringing unprecedented freedom to product design. The following comparison will demonstrate the application of the two machining methods in the processing of complex parts :

| Comparison Dimensions | CNC milling | Conventional milling |

| 3D surface machining | Precisely realize complex curved surface shapes | Simple planar machining only |

| Micro-feature processing | Machining millimeter-scale fine structures | Due to the precision requirements of the operation, it is difficult to achieve. |

| Contour complexity | Supports any complex geometry | It can only process basic outlines. |

| Processing consistency | Products from the same batch exhibit a high degree of consistency. | Each product is different. |

| Design Implementation | It can turn perfect design drawings into reality. | Only a portion of the design intent has been achieved. |

The advantages of CNC milling are evident when dealing with complex three-dimensional surfaces, intricate microstructures, or irregular contours. CNC milling technology overcomes many limitations imposed by conventional machining processes, enabling companies to create more innovative and creative product designs and stand out in market competition.

Why Does CNC Milling Achieve A Better Surface Finishes?

Compared to conventional milling, CNC technology offers precise control over every step of the machining process, ensuring the uniformity and smoothness of the final product surface—a fact that has been thoroughly proven. Its technological advantages are primarily reflected in the following four key aspects:

- Constant spindle speed control: The CNC system maintains the stability of the spindle speed, effectively avoiding changes in cutting force caused by speed fluctuations, and obtaining uniform cutting texture.

- Intelligent feed rate optimization: The program provides a precise feed rate to ensure optimal cutting parameters at different machining stages and avoid overcutting or undercutting.

- Smoother toolpaths: CNC programming reduces sharp turns and pauses; it provides optimal toolpath planning, resulting in smoother and more fluid tool movement.

- High-efficiency cooling system: The intelligent cooling system can adjust in real time according to the processing status, effectively control the cutting temperature, and reduce the impact of thermal deformation on surface quality.

The combination of these technological advantages ensures that CNC milling achieves surface finishes that are difficult to attain using conventional methods. This superior surface quality not only improves appearance and performance but also reduces subsequent machining steps such as polishing, thereby lowering production costs and increasing efficiency.

Figure 3: Fine surface finish achieved by LS Manufacturing through CNC machining

Which Milling Method Can Meet The Needs Of Urgent Orders More Quickly?

When evaluating the efficiency of urgent order delivery, the comparison between conventional milling and CNC milling should not be based on superficial impressions, but rather on a systematic consideration of the "overall production cycle," abandoning the narrow-minded view of "single-piece processing time." In fact, CNC milling has a more significant advantage in mass production . Specifically, the efficiency differences between the two machining methods are mainly reflected in the following aspects:

1. Production preparation stage:

Conventional milling offers the advantage of quick setup, but its manual operation mode becomes an efficiency bottleneck in mass production. While CNC milling requires initial programming and verification, fully automated production can be achieved once the program is confirmed. Furthermore, the so-called "one-time investment" yields substantial returns in mass production, significantly improving productivity.

2. Continuous operation capability:

CNC equipment supports continuous production around the clock, completely unaffected by the operator's physical strength or skill level. This is especially suitable for large-volume orders with tight delivery deadlines, minimizing the production cycle of parts and components.

3. Quality stability:

Thanks to its digital control capabilities, CNC machining can obviously guarantee a higher single-pass yield rate than conventional methods. From another perspective, its quality stability also ensures timely delivery, as it directly avoids the time wasted on rework and repairs.

Through systematic comparison, the results of conventional milling and CNC milling show that CNC milling has a significant advantage in overall production efficiency. For urgent orders, CNC machining can ensure shorter delivery cycles while maintaining quality. With such comprehensive efficiency advantages, choosing CNC milling is a wise move for modern manufacturing enterprises when handling urgent orders.

What Is The Cost Of CNC Milling? Is It Always More Expensive?

Although the investment and programming costs of CNC equipment are higher than those of conventional equipment, in the long run, the significant cost advantages of CNC machining more than compensate for this gap. This is just one example of the economic advantages. The cost advantages of CNC milling are mainly reflected in the following two key aspects:

1. Quality Control:

For example, CNC machining using digital program control can keep the scrap rate below 20%, far lower than conventional machining methods. For companies with an annual output of tens of thousands of pieces, this can avoid hundreds of scraps each year, significantly saving on raw material costs and rework time. More importantly, consistently high product quality will earn customer trust and enhance brand value. These benefits, though intangible and difficult to quantify, are highly beneficial to the long-term development of a company.

2. Human Resource Allocation:

Conventional machining methods heavily rely on the experience of skilled workers in individual processes, leading to high labor costs and a severe shortage of skilled workers. However, CNC milling embeds this knowledge into the programming. In this scenario, a single programmer can control multiple machines, significantly increasing output per worker. This transformation not only saves on labor costs, but more importantly, it frees businesses from dependence on the mobility of skilled workers and ensures the smooth implementation of production plans.

The actual cost of CNC milling should be considered over its entire lifecycle. While the initial investment may be large, unit costs will be more competitive through excellent quality control, optimized human resource allocation, and consistently high production efficiency.

For manufacturing companies pursuing sustainable development, choosing CNC milling is not only a technological advancement but also a strategic investment to enhance core competitiveness, and its return on investment will be reflected in long-term operation.

How Does LS Manufacturing Tailor CNC Milling Solutions For Each Customer?

The following case study demonstrates how LS Manufacturing translates technological advantages into customer value, showcasing its superior performance in custom CNC milling solutions for a wide range of complex manufacturing challenges.

1. Customer Challenges:

The core components have complex spatial curved surface structures, requiring extremely high biocompatibility. The dimensional tolerances of some key components are difficult to control within ±0.01mm, and the surface roughness Ra < 0.4μm. Using conventional milling machines, the supplier's yield rate has historically been below 70% , and the dimensional stability cannot meet medical-grade quality requirements, severely limiting the product's launch.

2. Customized solutions provided by LS Manufacturing:

For this medical device , the engineering team developed a comprehensive high-precision machining solution .

- First, five-axis CNC milling is used; then, a customized vacuum clamping system is used to ensure clamping accuracy and prevent any deformation of the parts.

- Secondly, a dedicated toolpath strategy was developed, employing a smaller depth of cut and rapid feed parameters, followed by the introduction of micro-lubrication technology to effectively control machining stress.

- Finally, an online measurement system was established for real-time quality monitoring during the production process.

3. Results and Value Realization:

After the solution was implemented, product yield increased from less than 70% initially to an industry-leading 98.5%. Production efficiency was significantly improved: the processing cycle for a single product was shortened by 40%. In addition, it helped the client complete clinical validation three months ahead of schedule.

More importantly, consistent product quality ensured that our clients successfully obtained FDA certification and seized market opportunities as quickly as possible. Furthermore, this not only solved our clients' current delivery challenges but also established a long-term technical partnership.

The key value of our CNC milling solutions fully demonstrates that the reason we create such significant value lies in our consistent focus on practical needs and our deep integration of technological advantages with industry experience. It is precisely this customer-value-oriented service philosophy that has made us a trusted partner for numerous high-end manufacturing enterprises.

Figure 4: LS Manufacturing's optimized manufacturing process using CNC milling

Which Milling Method Is More Suitable For My Product? What Are The Key Decision Factors?

When choosing the most suitable milling method , the comparison between conventional milling and CNC milling should be conducted from multiple perspectives. To determine when CNC milling can maximize its value, companies must consider the following three key factors:

1. Production batch size and part complexity:

For simple parts requiring single-piece or small-batch production, conventional milling still holds an advantage due to its rapid setup capabilities. However, when producing medium to large batches of 20 or more parts, or machining parts with complex surfaces, conventional milling becomes less suitable. For precision holes, the automation advantages of CNC milling become significant.

Its digital programming capabilities ensure consistent machining accuracy, while optimizing toolpaths significantly improves machining efficiency , thus ensuring excellent cost-effectiveness in mass production.

2. Accuracy requirements and quality stability:

If product tolerances are extremely stringent, such as within ±0.05mm , or if batch consistency is critical, then CNC milling is the obvious choice. Its program control effectively eliminates human error, ensuring that every part meets design standards. Especially in industries with extremely high quality requirements, such as medical and aerospace, conventional machining can hardly achieve the quality assurance level of CNC milling.

3. Return on Investment and Strategic Development:

Although the initial investment in equipment is high, the higher quality stability, greater production efficiency, and optimized labor cost structure can typically bring a return on investment within 1-2 years . From this perspective, for companies seeking long-term development, choosing CNC milling is both a technological upgrade and a strategic decision to enhance core competitiveness.

A systematic evaluation can determine the timing for implementing CNC milling, and this timing should be based on a comprehensive assessment of the company's current situation and future development needs. It is recommended that companies adopt a scientific decision-making process.

- First, conduct a technical feasibility assessment.

- Then, an economic benefit analysis is conducted .

- Finally, formulate a development strategy.

By conducting a comprehensive comparison of conventional milling and CNC milling, the company can find the optimal balance between technology investment and business value, and lay a solid foundation for sustainable development.

What Features Should Be Considered When Selecting A CNC Milling Machine Supplier?

When selecting a CNC milling supplier, companies must invest significant effort in evaluating the supplier's overall capabilities. This evaluation should encompass three core aspects: technological equipment level, quality control system, and engineering service capabilities. LS Manufacturing is a leading company in the precision manufacturing industry in all three areas.

1. Technical equipment:

LS Manufacturing's production base is equipped with all five-axis machining centers and high-speed milling equipment . The base possesses and is equipped with advanced equipment such as German-imported DMG MORI five-axis machining centers and Japanese Mazak high-speed milling machines . All multi-axis programming software and machining simulation platforms work together to form complex curved surface parts in a single operation, with tolerance control accuracy down to ±0.01mm .

2. Quality Control System:

We have established a comprehensive quality traceability system and are equipped with advanced testing equipment, such as coordinate measuring machines and surface roughness testers. Our laboratory is CNAS accredited. From raw material warehousing to finished product delivery, we implement end-to-end quality control to ensure consistency and stability during mass production.

3. Engineering Services Team:

Our senior process engineers possess years of industry experience, averaging over ten years, and have extensive expertise in fields such as medical devices and aerospace applications . We provide comprehensive process technology services, covering every aspect from design optimization and process planning to mass production support.

In other words, LS Manufacturing is a leader in technology, equipment, quality control, and engineering services . We sincerely invite potential clients to visit our factory and witness firsthand how we support their precision manufacturing projects through on-site tours and equipment demonstrations. Choosing LS Manufacturing means choosing a trustworthy long-term partner.

Figure 5: Continuous monitoring of the CNC milling process by LS Manufacturing

FAQS

1. What materials can a CNC milling machine process?

CNC milling boasts excellent material adaptability, enabling the machining of metallic materials such as steel , aluminum alloys , and titanium alloys, as well as non-metallic materials like engineering plastics and composite materials . Leveraging a vast material database and extensive machining experience, we can customize optimal machining solutions for different materials to ensure the best machining results.

2. Is CNC milling cost-effective for small-batch production (e.g., 100 pieces)?

CNC milling offers numerous advantages for high-precision, small-batch orders or machining complex structures. Consistent quality guarantees avoid rework costs. We can professionally evaluate and optimize small-batch orders to help clients achieve the best cost-effectiveness.

3. Is CNC milling programming too time-consuming?

Modern CAM software has greatly improved programming efficiency. With a professional programming team and advanced software, we can complete programming in the shortest possible time while ensuring quality. Programs can be archived for future reuse, which, in the long run, actually improves overall efficiency.

4. Are the maintenance costs of CNC milling equipment very high?

Maintenance of CNC equipment must be performed by qualified professionals. Regular maintenance ensures long-term stable operation. We have established a comprehensive preventative maintenance system to minimize failure rates and ensure that maintenance work is controllable, cost-effective, and efficient.

5. What is the optimal precision that machining can achieve?

Our five-axis CNC equipment has a standard accuracy of ±0.01mm, and can reach ±0.005mm under special conditions. Actual accuracy is affected by a variety of factors, such as material properties and part structure. We will provide professional advice based on your specific needs.

6. Is the conventional grinding process completely outdated?

Conventional milling remains valuable as long as the machining process involves single-piece machining or repair. However, CNC milling offers numerous advantages in high-volume production requiring higher precision. We are always able to recommend the most suitable machining solution based on each customer's needs.

7. How long does it usually take from design drawings to receiving samples?

Processing time for simple samples is approximately 1-3 days, while complex structures require 5-7 days . We have a rapid prototyping channel that can significantly accelerate processing speed and ensure on-time delivery to meet our clients' R&D plans.

8. What would you do if an unexpected problem occurred during the processing?

Quality monitoring for all processes has been completed. In the event of an issue, we will activate the contingency response plan. The engineering team will analyze the cause of the problem and immediately adjust the process parameters to ensure that the problem is resolved promptly and accurately, while maintaining the original high quality and not affecting the final delivery or schedule.

Summary

Compared to conventional milling, CNC milling technology offers numerous advantages in machining accuracy , production efficiency, complex parts processing, and long-term cost-effectiveness. Therefore, adopting CNC milling technology is a strategic decision for enhancing the core competitiveness of modern manufacturing enterprises. With years of industry and project experience, LS Manufacturing has helped numerous companies upgrade their manufacturing processes, achieving a qualitative leap.

Your innovative project deserves a higher level of support in the manufacturing sector. For a free expert-level processing solution evaluation and accurate quote, please contact us today. Let us become your most trusted manufacturing partner, working together to create more competitive, high-quality products and set new industry benchmarks.

📞Phone: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website: https://lsrpf.com/

Disclaimer

The content on this page is for informational purposes only. LS Manufacturing makes no representations or warranties, express or implied, regarding the accuracy, completeness, or validity of the information. It should not be inferred that third-party suppliers or manufacturers will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type, or processes through the LS Manufacturing network. The buyer is solely responsible for this information. For parts quotations, please specify the exact requirements for these parts. Please contact us for more information .

LS Manufacturing Team

LS Manufacturing is an industry-leading company specializing in customized manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precision CNC machining , sheet metal fabrication , 3D printing , injection molding , metal stamping , and other one-stop manufacturing services.

Our factory boasts over 100 state-of-the-art five-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries and regions worldwide. Whether it's small-batch production or mass customization, we can meet your needs within 24 hours. Choosing LS Manufacturing means choosing efficiency, quality, and professionalism.

For more information, please visit our website: www.lsrpf.com .