The mastery of each company begins with precise texture.

You're holding an expensive flashlight,Cold metal surfaceCovered with a unified diamond pattern, conveying silent reliability; you turn the focus ring onto the camera lens, with subtle and solid resistance under your fingertips making every focus accurate. You tighten the knobs of precision instruments, your fingertips feel strong, non-slip and controllable touch – this critical control experience is a silent masterpieceWork hard on craftsmanship.

But the value of swaying is more than just providing comfortable grip. It's onePrecision Engineering ArtThat "carved" or "pressed" metal surface creates permanent texture. These seemingly simple cross particles, rhombus convex or parallel lines are a combination of function and aesthetics. They can enhance friction, prevent slips, improve operational accuracy, and even become a unique identifier for product identification.

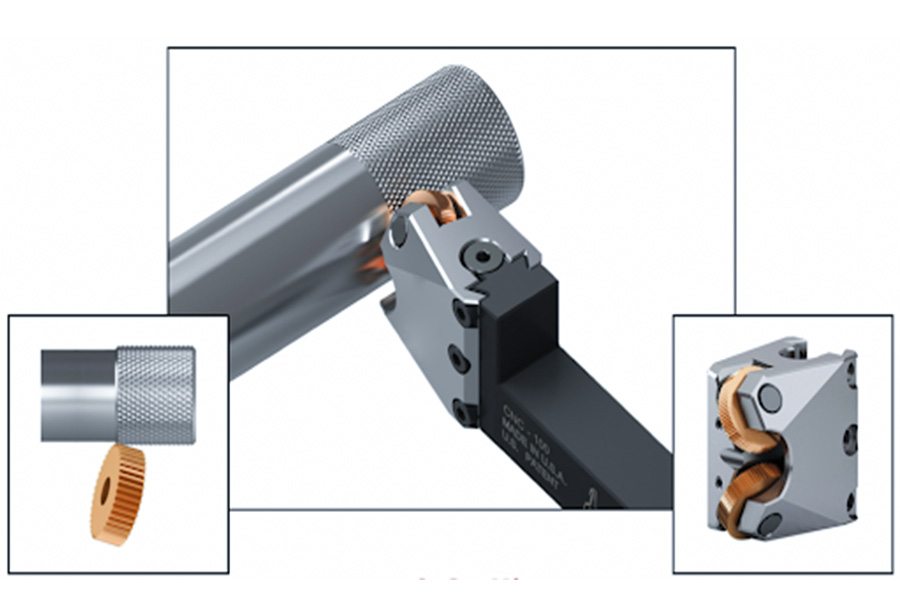

But how does this "tactile assurance" come about? The core secret is that it seems inconspicuousKey ingredients of lathe- Indent tool.This special tool, such as an accurate engraver, imprints the designed texture deeply on the surface of the workpiece when the metal workpiece rotates on the lathe spindle. How does it do it? What is it composed of? More importantly, facing a wide range of application requirements - from slender knobs for medical devices to solid heavy-duty mechanical handles -What unpredictable consequences will be produced by choosing the wrong knurling type or tool??

First, let’s uncover the mystery and focus on the starting point of this “touch revolution”:What exactly is the kurning tool on the lathe?Understanding this is the first step to mastering the art of this engineering.

Three main purposes for knurling , description and typical application

| Purpose | describe | Typical applications |

|---|---|---|

| Functional mastery | Creates a rough surface that increases friction and prevents hand or object from sliding when grasping. | Tool handles, knobs, fasteners |

| Aesthetic Appearance | Provides a unique industrial decorative texture to metal surfaces, thereby enhancing the appearance texture and value of the product. | High-end audio knobs, watch crowns, pens |

| Press FIT | The effective diameter of the surface of the axial part is increased by plastic deformation and is used to press the shaft into the hole to form a tight fit. | Secure the bearing or pin into the hole |

This guide will be detailedHow the Indentation Tool WorksFor lathes, show different types of rock, explanationThe process of knurling step by step, and use real situations to prove how perfect knurling enhances the value of the product. Finally, we will answer the key differences between knees and turns.

This is what you're going to learn

- Analysis of key mechanisms:How is it possibleKnurling tool rotates smooth surfaceTurn into a strong grip texture without "cutting" but "pressure"?

- Anatomy of the three core components of the indentation tool:Understand the design and functional differences of the tool body, the knurled wheel (soul component) and the three basic knurled types (line, diamond, twill).

- Five Steps Golden Rules to Ensure Perfect Rock:From precise center to decisive urgency, take a look at the key steps to perform oneSuccessful shrinkage surgery on latheAvoid blurred texture or damage to the workpiece.

- In-depth analysis of the actual situation:See how we upgrade the “frequently missed” diving flashlight grip to the industry benchmark for “tactical reliability” by optimizing effort parameters (such as TPI selection) and technology.

- Answering the core questions about the knee process:Clarify the fundamental differences between shrinkage and turn, core application solutions, and key limitations of material suitability (FAQ).

Now let's explore the mystery of the knurling tool and unlock the dual powerMetal surface functions and aesthetics.

Why believe this guide? LS CNC's "Science of Stress"

existLS-CNC, we think of the abbreviation as "pressure science" - the core is the plastic deformation of metal under high pressure, rather than simple cutting. This requires that the spindle speed, feed speed and indentation pressure must be coordinated like a precision instrument. If the pressure is insufficient, the texture will be blurred; if the pressure is too high,It will at least damage expensive workpieces,And damage the lathe spindle in the worst case. The birth of the perfect knee flower is based on precise control between millimeters.

Our experience is to ensure:

Knurling is optimized for medical device knobs. Surgeons report that wearing slippery gloves can easily slide. Instead of making it recklessly, we made precise adjustments:

Teeth pitch (TPI):Find the balance point of density and sparsity to ensure an effective "bite" under slippery gloves.

Depth of effort:Precisely adjust the pressure for perfect friction and comfortable touch.

Ultimately, we provide not only textured parts, but also deeply optimized "human computer interaction interface" that solves the point of use of core pain.

This guide comes from our myriad conversations with metals under high pressure and is the culmination of our deep understanding of precise knurling technology and its functional value.At LS, we use scientific “pressure” to portray reliable touches on trust.

Anatomy of Knurling Tools: How does it go from smooth to rough?

"The knurled tool itself is a smart mechanical deviceThis works by not "cutting" but by "pressing". ”

1. Tool body: the foundation of power

BodyThe swaying tool is powerful, heavy steel handle. Its core role is to provide rigidity and stability.

It is securely clamped to the tool holder of the lathe (similar to normalturning toolInstalled), make sure there is nobendingWhen subjected to huge radial pressure, or vibrate.

The human body usually contains precise adjustment mechanisms (such as Manders, eccentricity, slider or screw) to accurately control position, the spacing of the knee wheels, and pressure on the workpiece. This rigid frame is the basis for transmitting extrusion pressure.

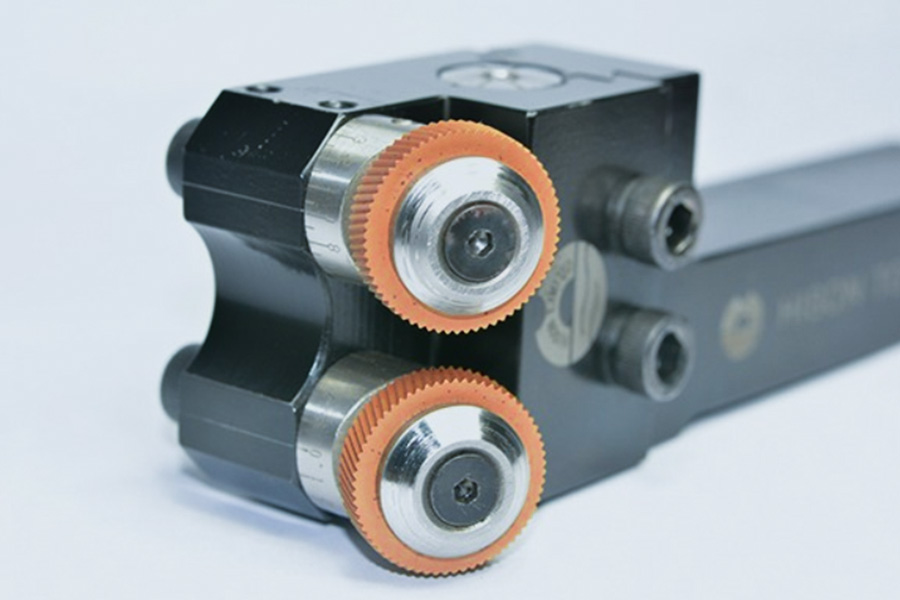

2. Wheels/Knife: Textured Engraver

Knee urls are the core component of the effort toolThat's really magical. They are fromAccurate measurementand hardened tool steel.

The circumferential surface of the wheel is engraved with carefully designed patterned teeth. The shape, angle and arrangement of these teeth directly determine the type of pattern that ends up forming on the workpiece (line, diamond, twill).

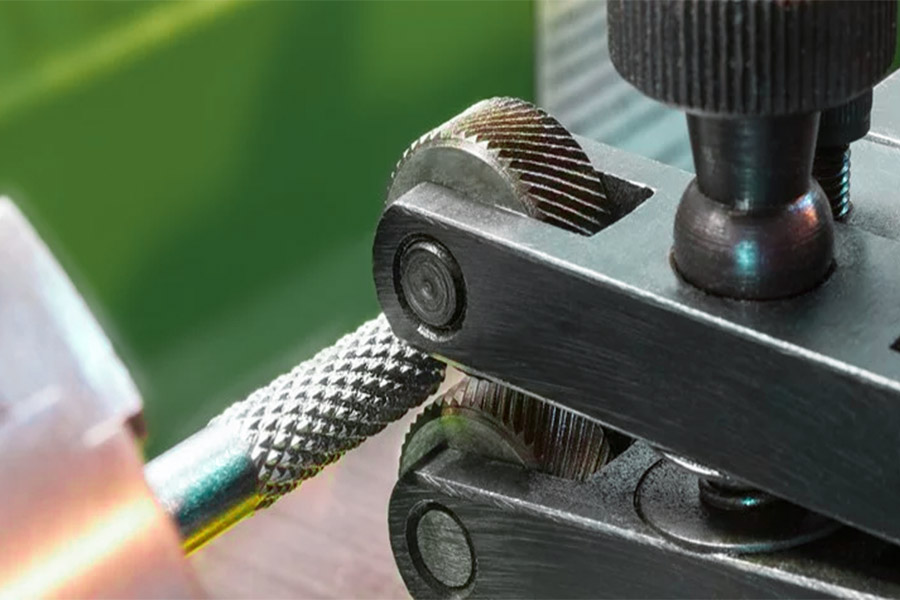

The wheels of the knee are not fixed, but bearings or mandels mounted on the bearingsAnd can rotate freely. When the tool presses the rotary workpiece,The rock wheel is driven to the workpiece rotate.

3. Different types of rock: Choice between features and aesthetics

Efforts are not a single form. Based on design and combinationKnee teethThere are three basic types to meet different needs:

- Linear Type:Use two gears that are completely parallel to the teethaxle(No hand direction). When they are pressed against the rotating workpiece, continuous straight grooves (and ridges) parallel to the axis are formed on the surface of the cylinder. This texture provides a strong one-way grip and is often used in handlesRequires strong anti-slip characteristics (such as screwdriver handles)Or as the fitted parts need to withstand large axial forces.

- diamond:This is the most commonly used and widely used type. As mentioned earlier, use left-handed and right-handed rollers in combination. The teeth of the two wheels pedal at specific angles (usually 30° or 45°), forming a conventional interlaced, convex and concave diamond grid. This texture provides a full range of grip (regardless of which direction it holds), and the visuals are classic and beautiful, with excellent practicality and decorativeness.It is widely used in tool handles, knobs, adjusting rings, etc..

- Twill:Use only one knee wheel (can be left or right). When pressed against the rotating workpiece, it forms parallel grooves (and ridges) in a single direction and is continuously inclined on the surface of the cylinder. The texture has some grip but is more like a decorative effect, often used to beautify the surface of the part or as a lightweight sliding mode. The direction of the texture depends on the rotation of the selected roller wheel.

The money-rolling tool transmits strong mass pressure through its solid body, and drives steel head gears with specific teethCold thornRotate the workpiece surface. The material flows under pressure, forming grooves and ridges, thus "replicating" the teeth pattern of the knee wheel - straight lines, diamonds or diagonal lines. This "pressure" rather than "cutting" process effectively converts the surface of smooth metal (or other plastic material) into a rough texture with specific functions (mainly grip, slip, fit) and aesthetic effects, and perfectly explains the "smart mechanical equipment" in the introduction. Which oneThe type of knee selected depends on the specific needs of function(grip, fit for strength) and appearance (decorative).

Knurling surgery on lathes: step by step

Knees require patience and precision, not brute force. It's a process of working hard for the first time right and right - hesitation and mistakes often lead to irreparable flaws.

Target:A clear, uniform, wear-resistant diamond or straight texture is imprinted on the cylindrical surface of the workpiece to increase friction or improve appearance.

Step 1 - Preparation

- Workpiece clamping:Secure the workpiece firmly in the lathe Chuck (three or four chins) or in the fixture. Make sure the clamp is rigid and vibration-free.

- Diameter completed:The surface to be retracted must be poured into the final precisely designed diameter.

Why?Knurling causes plastic flow of the material, resulting in a slight increase in diameter (the increase is about 0.5-1 times the knee energy pitch). The completed diameter should take into account this extension. If the exact diameter is required behind the knee, it is necessary to leave a zero-point allowance before completion (but the texture will be weakened).

Surface condition:The surface to shrink should be clean and smooth (after completion), free of oil, fries or burrs.

Step 2 - Tool Center - The most critical step!

Install the knurling tool:Mount the knurled tool holder securely on the tool holder (usually a small slide or a square tool holder). Tighten all locking bolts.

Accurate consistency:

- Use the end face that carries the tail of the disk or the finished workpiece.

- Core Requirements:Adjust the height of the tool bracket (through the height adjustment mechanism of the gasket or tool holder) to ensure that the centerline of the knurled wheel must be exactly the same as the centerline of the lathe spindle (workpiece).

- Inspection method:Gently move the knurled direction wheel to the end of the workpiece or the surface of the cylinder to see if the contact point is at the exact center of the roller width. You can also use the center gauge to assist.

Consequences of misalignment: misalignment of the center line is the main reasonKnurling failed (fuzzy texture, unevenness, single-sided depth/shallow, workpiece bent), no one else!

Step 3 - Initial Contact and Engagement - Need to be sure!

Manual mode:With the lathe stationary, manually move the large and medium slides, moving the knee wheel into the light contact at the starting position to be retracted into the workpiece surface.

Determined to participate:

Using a medium-sized sliding handle (or small slider, regardless of feeding direction), firmly and continuously moving the knee sheath perpendicular to the surface of the workpiece.

In-depth of participation:The initial depth of participation is about 1/4 to 1/2 of the depth of the nose teeth (depending on pitch). The exact depth must be varied based on material hardness, roller type (straight/crossed particles) and thread pitch. Soft materials or large pitches may be deeper.

Avoid hesitation:Do not hesitate or repeat progress and retreat during the process of participation. Hesitation can cause the knee wheel to slide off the surface of the workpiece, creating a "double knee" mark (fuzzy, overlapping texture), disfigure the surface and potentially damage the rolling wheel.

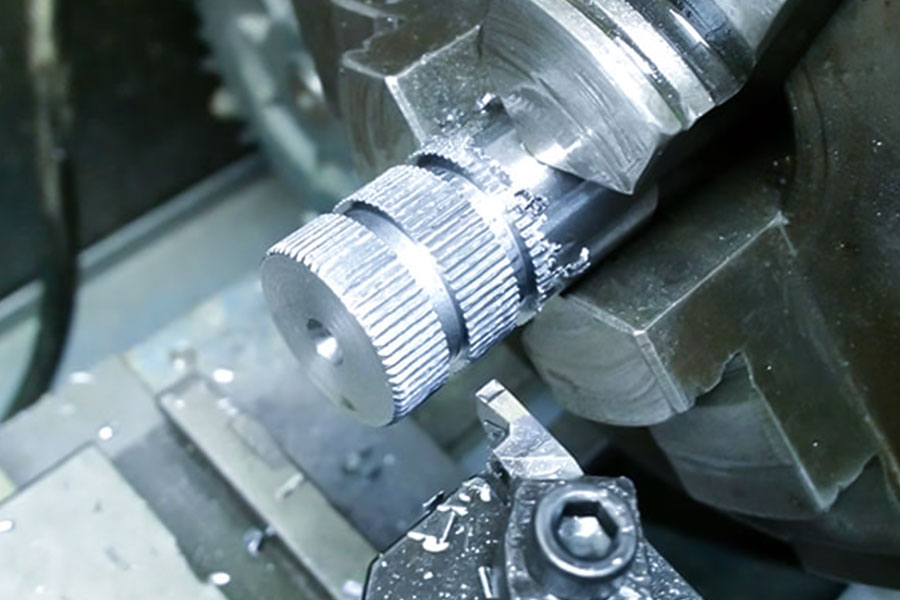

Step 4 - Make the knurled through - Slow, lubricated, constant speed

Set speed:Participate in the lathe spindle and choose a very low speed. It usually does not exceed about 1/3 of the speed of normal turning workpieces of the same diameter.

Why?Knurling is a squeezing operation that creates huge pressure and frictional heat. Slowly reduce heat buildup, reduce vibration, prevent slipping and retain tools and workpieces.

refer to:For medium-sized carbon steel, the diameter is about 30mm and the speed can be as low as 30-50 rpm.

Completely cooled and lubricated:

Turn on the cutting fluid!Use a lot of cutting fluid (lotion or special shrinkage oil) and pour it continuously into the contact area between the roller and the work.

Function:Lubricate (reduce friction and prevent chip from sticking), cooling (carrying heat, prevent workpiece annealing, overheating and damage to the indentation wheel), rinse debris (knurling will produce fine extruded chips).

Start summary:

- Turn off the automatic longitudinal feed of the lathe.

- Choose a very slow feed rate (usually much slower than completing the feed).

- Slowly, stably, evenly feed the knurled surgical tools along the working surface and press into the surgery throughout the length.

Keep pressure:During the cutting process, keep the central bracket fixed (i.e., keep the penetration depth stable).Knurling requires constant pressure.

Step 5 - Disconnect and Inspection

Quick disengagement:When the knurled tool goes through the necessary distance:

- Stop automatic feeding immediately.

- Rotate the central carriage smoothly (or lift the carriage) and quickly remove it completely from the surface of the workpiece from the knurled wheel. Stay stable and avoid dragging the knee surface during disengagement.

Stop the spindle.

Check carefully:

- Check for definition, integrity and continuity of shrink texture.

- Is the texture consistent in the length and circumference of the nose? Is there any in-depth change?

Check for defects such as "double knee joints", blur, tear, material accumulation, etc.

Manually determine the depth and uniformity of the texture.

Subsequent processing:

- Cleaning: A small metal chip that completely removes shrinkage from the workpiece (can be placed in the texture).

- Burrs: Burrs usually form at the edges of the knee area at both ends and require careful removal of them with a document, oilstone or wire brush.

- Dimension Check: Check the shortened actual diameter to verify that it is required (considering the amount of expansion).

Important safety points:

- Wear safety glasses! Knurled will form hot fries.

- Avoid gloves! Never lean against rotating workpieces and knurled surgical tools to prevent entrainment while wearing gloves.

- Secure clamping: Secure the workpiece and tool without a doubt.

- Slow operation: Always strictly abide by low speed requirements.

- Beware of chips: The fries produced by shrink sheets are small, sharp and hot, so be careful when cleaning.

- Note the exception: If you hear abnormal noise, strange vibration or signs of overheating (smoke), stop immediately and check.

Following these procedures, with particular attention to the accuracy and firmness of the core and initial press-in, as well as low speed and good lubricity, can greatly improve the success of knurling surgery and produce high-quality rock surfaces.

Case Study: Developing an "absolutely reliable" tactical knee grip for professional diving flashlights

1. Customer Challenge: Functional malfunction of high-end equipment in harsh environments

Our company is retained by a professional diving equipment manufacturer, whose flagship diving flashlights are experiencing extreme usability issues. This product utilizes high precisionCNC-treated anodized aluminum alloy box. Despite its high resistance to corrosion and a very attractive industrial appearance, it shows serious flaws in real life: Operators (especially with heavy-duty diving gloves) report that the surface friction coefficient of the handle and switch knob sections is too low and there are a lot of misses when operating with one hand. What's more serious is that in suspended sediment water, its high TPI, shallow knee decorative surface is easily blocked by sediment particles to form a smooth "mud film" and eliminate all its anti-sliding functions. This will directly lead to doubts about its "high-end" position among Pro divers and the potential for brand crisis. The basic requirement of the customer is that under extreme working conditions (naked hands/insulated gloves/working environments filled with sediment), shell materials and minimal structures can be used to achieve complete safe control.

2. LS Solutions: From failure analysis to tactical level knee design and manufacturing

After approaching the failure mode and effect analysis (FMEA), we determined that the root cause is that the original knee energy design does not meet the tribological requirements of high load, self-cleaning and large fit:

Inadequate texture depth: Cannot penetrate the glove material or dig into the soil layer to provide a good bite.

Too dense texture (TPI too high): tiny grooves have a low pollution resistance and are likely to be clogged.

Geometric design: chip removal and insufficient pressure concentration.

Our analytical solutions:

Revise abbreviation parameters and settings: Abandon traditional aesthetic rock ideas and choose low TPI (approximately 20-30), deep grooves andOpen geometric diamond knee energy (diamond nose). Functions of this setting:

- Deep and razor cone prediction:High positive bite force to cut gloves or mud layers.

- Great open valley floor:Allows rapid passage through silt, water and air, to get rid of silt from silt and to have the ability to clean yourself.

- Multi-directional texture:Diamond mesh provides stable friction regardless of the direction of grip.

- Optimization of manufacturing processes with high precision and high stability:Deep Knurling poses a huge challenge to processing technology:

- Material control at high forming pressure:For 6061-T6 aluminum alloy workpieces,CNC turn conditionsOptimization: Significantly reduced spindle speed and precisely controlled constant feed rate are used to reduce cutting heat and impact loads and to avoid microscopic formation or surface tearing of the workpiece.

- Special high pressure lubrication and cooling:Use special cutting fluids with high permeability and extremely high pressure (EP) characteristics and sprayed accurately in high pressure mode to the contact area of the knurled tool table, effectively reducing the formation force, controlling temperature rise, improving surface quality (RA values), and ensuring substrate integrity before consumption.

- Tool selection and wear status monitoring:High-strength wear-resistant carbide roller wheels were selected and a strict online wear condition monitoring and replacement system was implemented to ensure uniformity of texture geometry.

- Quick iterative verification based on user solutions:We did not provide a solution, butQuickly processed CNCThree diamond rock prototype samples have different TPIs (22, 26, 30). These are tests conducted by professional divers organized by clients in real underwater conditions, from bare hands, diving gloves of varying thickness/materials to water-controlled sediment levels. Ultimately, the TPI 26 solution won the best haptic feedback by landslides, glove compatibility and sediment drainage capabilities.

3. Project Results: Rebuilding Professional Reliability and Market Confidence

User Experience and Word of Mouth Reversal: Divers praised the new handle as “tactical grip” and its reliable grip has been widely praised under harsh underwater conditions, completely reversing the initial negative image of the product. User recommendations clearly show that the new design significantly improves operational confidence and security.

Quantitative business benefits:

- Product yields attributed to grip failures fell by more than 90%.

- In the customer satisfaction survey, the grip reliability level jumped to the first item.

- With the “professional reliability” of the tested core sales point, sales of this flashlight model have increased significantly by 40% in the subsequent quarter.

Spillover technology and brand promotion:Based on the successful experience and technical results of the project, we have developed a unique knurled design standard for our clients and applied it to their entire line of handheld tools, which comprehensively enhances the technological reliability image of their brand in the industry.

Core engineering inspiration

This case clearly shows that the knee is much more than an aesthetic finishing process, but the crucial manufacturing technology is directly related to basic human-machine interaction performance and the functional integrity of the component. As a provider of technical precision manufacturing solutions, valueLS is not only about graphics-based processing, but also lies in fully understanding the rigorous needs of end application environments, with expertise in materials science, tribology and precision machining techniques to be able to predict and provide innovative manufacturing solutions that can rule out functional failures. In applications where safety is critical, such as diving equipment, the engineering discipline of details (such as the knurled model) directly means the manufacturing or destruction of the product and brand reputation. The "tactical-grade" knee developed for diving flashlights this time is a successful implementation of this engineering philosophy.

FAQ - Answers to more questions about shrinking

1. What is the difference between hard work and turning?

Knurling is a plastic deformation process that uses gears to deconcave and convex patterns on the surface of the workpiece without removing the material. Turning is a cutting process that uses a turning tool to cut and rotate the workpiece to change its shape and size, thereby eliminating the material.

2. What is the main purpose of the knurling?

Knurling is mainly used to increase friction on the surface of the part to clamp the part (e.g. tool handles, knobs), provide decorative textures or enhance bond strength between parts interfering with fits (e.g. shaft sleeve fittings).

3. Can I work hard?

Knurled is suitable for materials with good plasticity (such as mild steel, copper, aluminum, brass and certain engineering plastics), but brittle materials (such as cast iron, hardened steel and unmodified brittle plastics) are prone to cracking and difficult to form a complete pattern and are generally not suitable for exercise.

Summary

Knurling looks simple, but it embodies the essence of materials science.Mechanics and ergonomics. Perfect rock is a fusion of practicality and aesthetics, and it is also a key detail that moves ordinary parts toward a professional level – it proves the decisive power of detail in precise manufacturing.

Your product requires:

- Absolutely reliable grip at critical contact points?

- Unique metal texture enhances texture and value?

Don't let efforts become a drawback of your design!

Contact LS’ expert team now!We not onlyProvides high-precision CNC machining, but also provides you with professional solutions to optimize these key functional features. Upload your designs and get detailed quotes and free productive analysis now!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com