Sheet metal fabrication is a critical process that transforms raw sheets of metal into functional and aesthetically pleasing components. At the forefront of this field is LS Hardware Tech Co., Ltd, a company renowned for its expertise and cutting-edge technology in metal fabrication services. Founded by Mr. Nick Zhang and a team of seasoned engineers, LS Hardware Tech boasts over two decades of experience in manufacturing high-quality hardware and plastic parts that cater to diverse industries worldwide.

For those unfamiliar with sheet metal fabrication, it encompasses various techniques that manipulate metal sheets into predetermined shapes and sizes, serving as the foundation for countless products across industries. From custom sheet metal fabrication and prototyping to precision bending services, this process involves a range of methods such as cutting, bending, and assembling that demand precision and skill. With a commitment to quality, LS Hardware Tech employs state-of-the-art machinery and adheres to ISO 9001:2015 standards, ensuring consistency and excellence in every project they undertake.

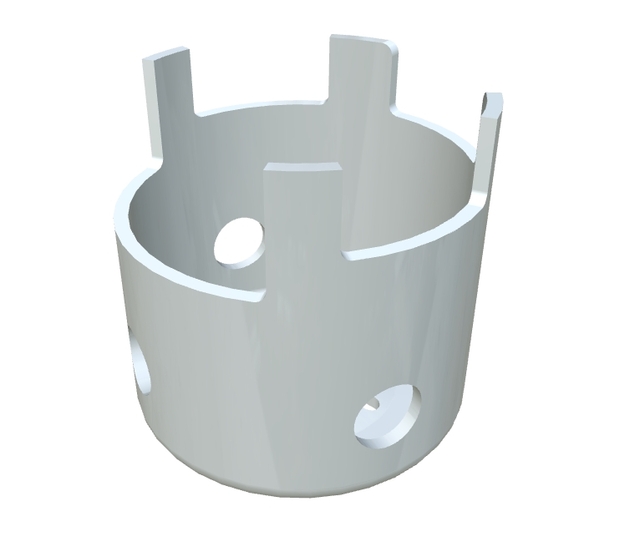

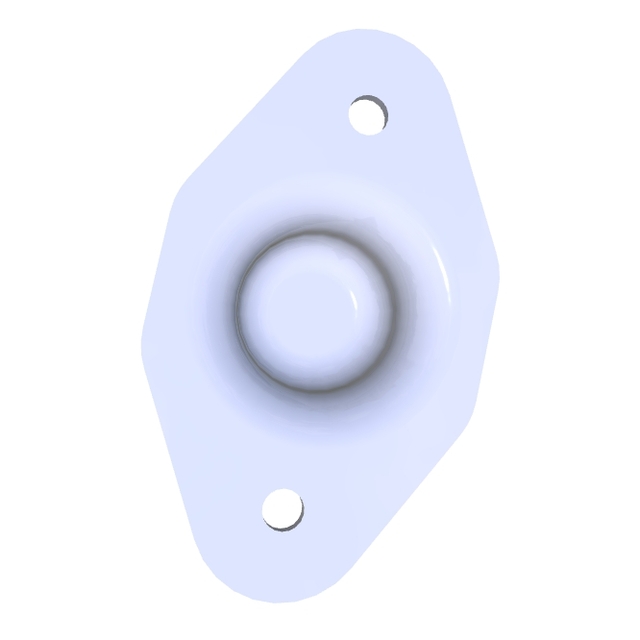

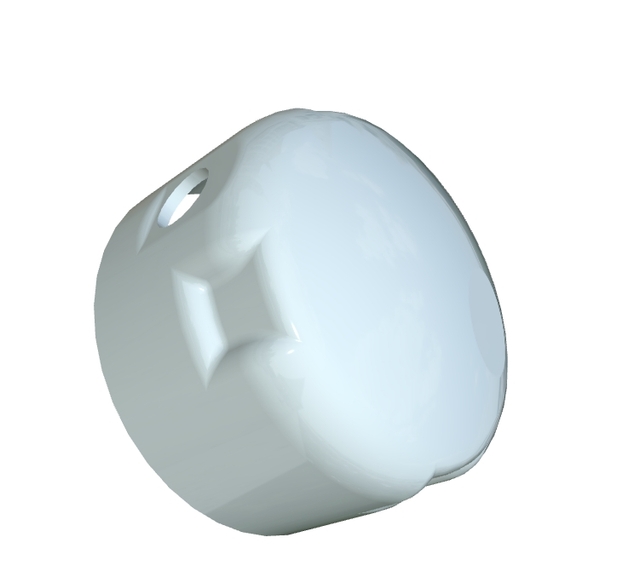

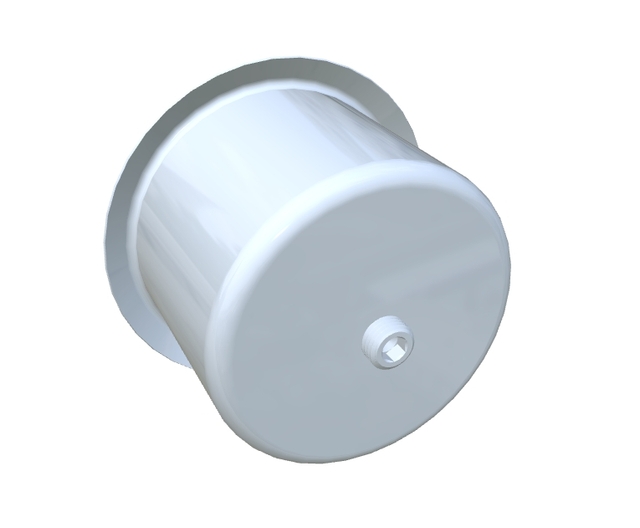

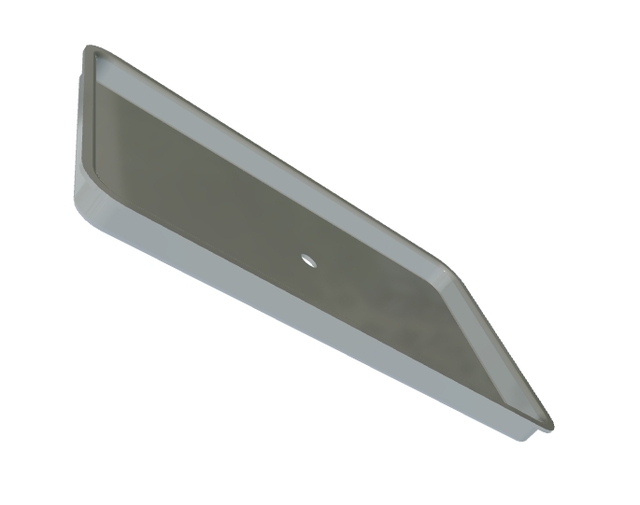

The new metal bracket offered by LS Hardware Tech epitomizes the marriage of style with functionality, taking advantage of advanced CNC sheet metal fabrication techniques. Crafted from high-grade stainless steel, this piece is designed to provide exceptional durability and corrosion resistance, ideal for both industrial applications and domestic use. Its sleek design features precision-cut circular cutouts to enhance mounting versatility and structural integrity, while the polished finish adds a touch of contemporary elegance suitable for modern environments.

Whether integrating the metal bracket into cabinetry, shelving, or bespoke projects, it guarantees ease of installation and robust support. Its adaptability and aesthetic appeal cater to consumers who value both performance and elegance in their hardware components. LS Hardware Tech's mission is to empower clients by transforming ideas into tangible innovations, keeping pace with technological advancements to enhance their manufacturing solutions.

The company’s success in the realm of metal fabrication is anchored by a production facility outfitted with over 100 high-end machining centers, providing high-efficiency production to meet the needs of over 5,000 clients. They serve as a trusted partner not only to major factories in China but also to clients spread across more than 150 countries and regions globally. This expansive reach is supported by their ability to handle everything from prototypes to mass production with ease, particularly in high-precision sectors such as the automotive, aerospace, medical devices, industrial equipment, and consumer electronics industries.

With a strategy focused on continual process improvement and innovation, LS Hardware Tech strives to remain at the cutting edge of sheet metal fabrication. Their comprehensive services and ability to adapt to the evolving needs of their clients illustrate why they stand out as leaders in the field. By selecting LS Hardware Tech for your metal fabrication needs, you're entrusting your projects to an expert team that prioritizes quality, precision, and customer satisfaction, ensuring that the final product not only meets but exceeds expectations. With products like their new metal bracket, LS Hardware Tech not only delivers on its commitment to quality and design but also solidifies its reputation as a premier player in the industry.

Expert Sheet Metal Fabrication: Cutting-Edge Services & Techniques

Obtenha o preço mais recente >

| Label | Value |

|---|---|

| Marca | LS Fabricantes de peças personalizadas |

| Serviço de Personalização | Fabricação de chapas metálicas, Corte a laser, Dobrar, Estampagem, Soldagem |

| Formato de desenho | 2D/(PDF/CAD) 、 3D (IGES/Etapa/Glb) |

| Recursos de material | Alumínio 、 latão 、 bronze 、 cobre 、 metais endurecidos 、 metais preciosos 、 aço inoxidável 、 ligas 、 tpr |

| Amostra | Livre |

| Capacidade de fornecimento | 100000 peças por dia |

| Acabamento superficial | Acabamento personalizado |

| Grossura | Espessura personalizada |

| Tipo | Braching/perfuração/gravura/usinagem química/usinagem a laser/moagem/giro/arame EDM/prototipagem rápida/outros serviços de usinagem |

| Serviços | Usinagem CNC, fundição de metal, moldagem por injeção, fabricação de chapas metálicas, prototipagem rápida, impressão 3D |

Contato

Pronto para iniciar seu próximo projeto com a LS Manufacturing?

Entre em contato conosco hoje mesmo para saber mais sobre nossos serviços e como podemos ajudá-lo a alcançar seus objetivos.

LS Manufacturing

LS ManufacturingPrazos de entrega rápidos, a partir de apenas 1 dia útil.

Certificações ISO 9001, ISO 14001, IATF 16949 e AS9100D.

Mais de 100 materiais disponíveis, com mais de 50 opções de acabamento de superfície.

Produção em massa com boa relação custo-benefício.

Faça seu pedido a partir de 1 unidade.